Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Improve interface binding state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of enhanced polyacrylonitrile hollow fiber membrane

InactiveCN102580577AImprove mechanical propertiesExtended service lifeSemi-permeable membranesMembranesHollow fibre membranePolymer science

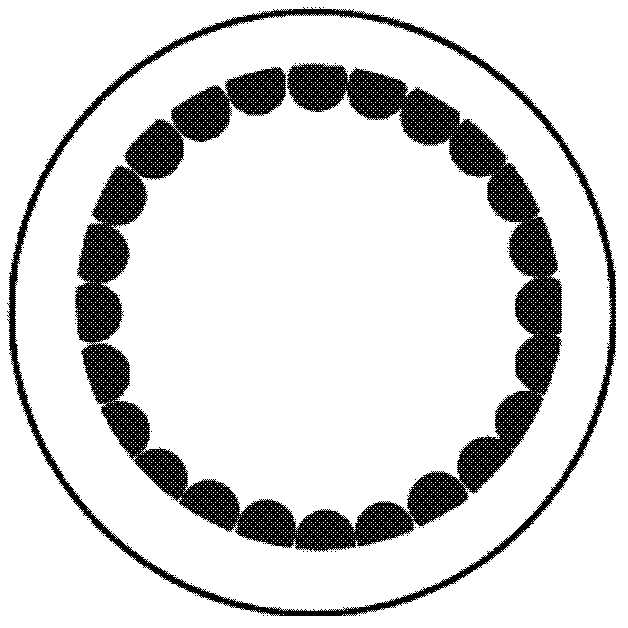

The invention discloses a preparation method of an enhanced polyacrylonitrile hollow fiber membrane. The preparation method comprises the following steps of: (1) knitting a polyacrylonitrile fiber reinforcement body: knitting a polyacrylonitrile fiber hollow knitted tube by a two-dimensional knitting technology, wherein the polyacrylonitrile fiber hollow knitted tube is used as a reinforcement body of the hollow fiber membrane; (2) preparing polyacrylonitrile membrane casting liquid, wherein the polyacrylonitrile membrane casting liquid consists of the following components in percentage by mass: 3-25% of polyacrylonitrile resin, 50-95% of solvent and 2-30% of additive; (3) performing surface pretreatment of the reinforcement body: wetting the hollow knitted tube with low-polarity organic liquid for 1-60 seconds, wherein the low-polarity organic liquid is ethanol, glycerol, isopropyl alcohol or polyethylene glycol-600; and (4) preparing a hollow fiber membrane: co-extruding the hollow knitted tube and the membrane casting liquid through an annular spinning nozzle, and performing sufficient solidification in a coagulating bath to obtain the enhanced polyacrylonitrile hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

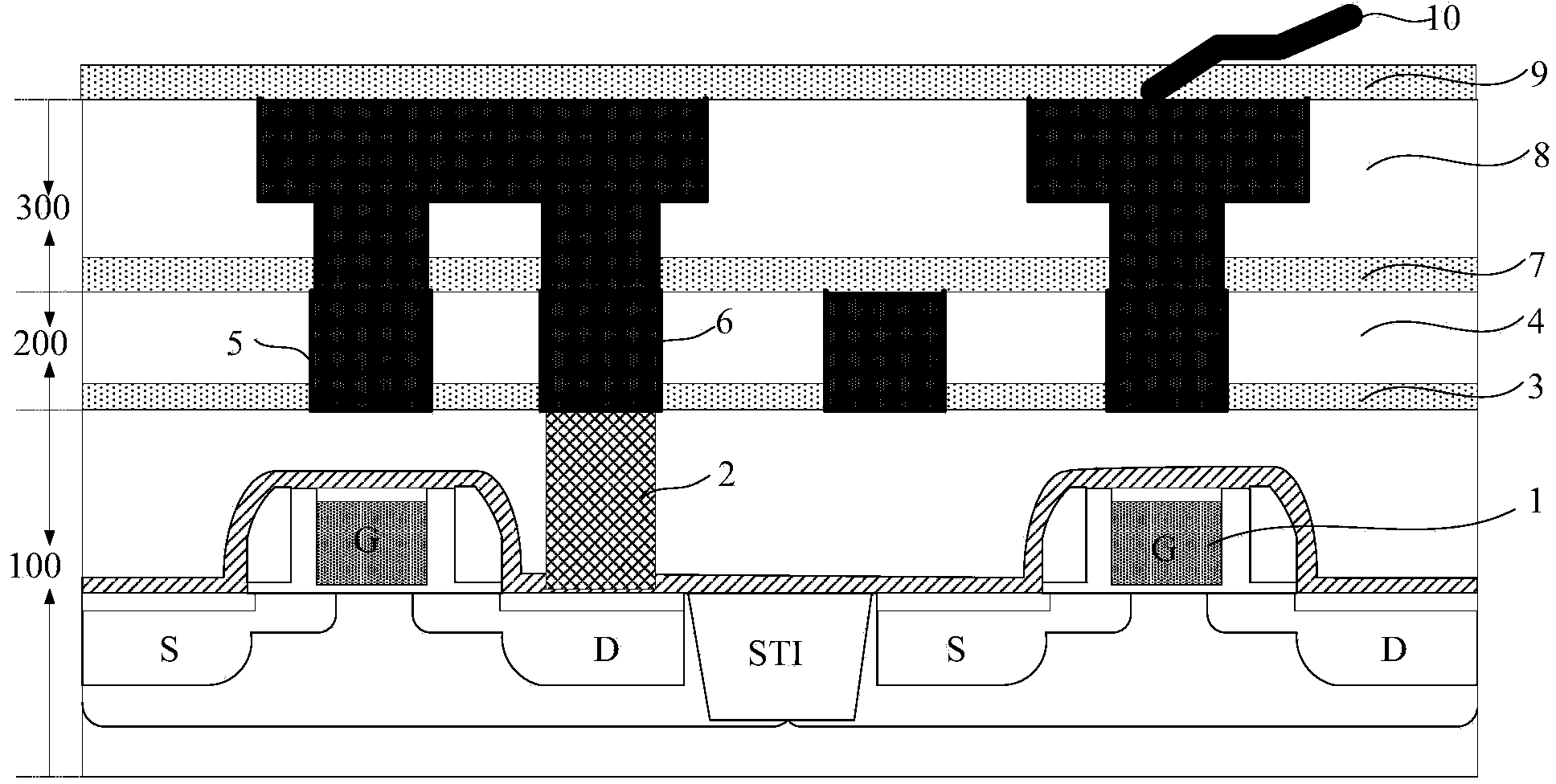

Process for preparing silumin electronic package materials

InactiveCN1877821AImprove featuresImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSiluminMaterials processing

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) proceeding ball grinding disposal for Al-Si alloy powder at 5-15:1 percentage for 8-32 h; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

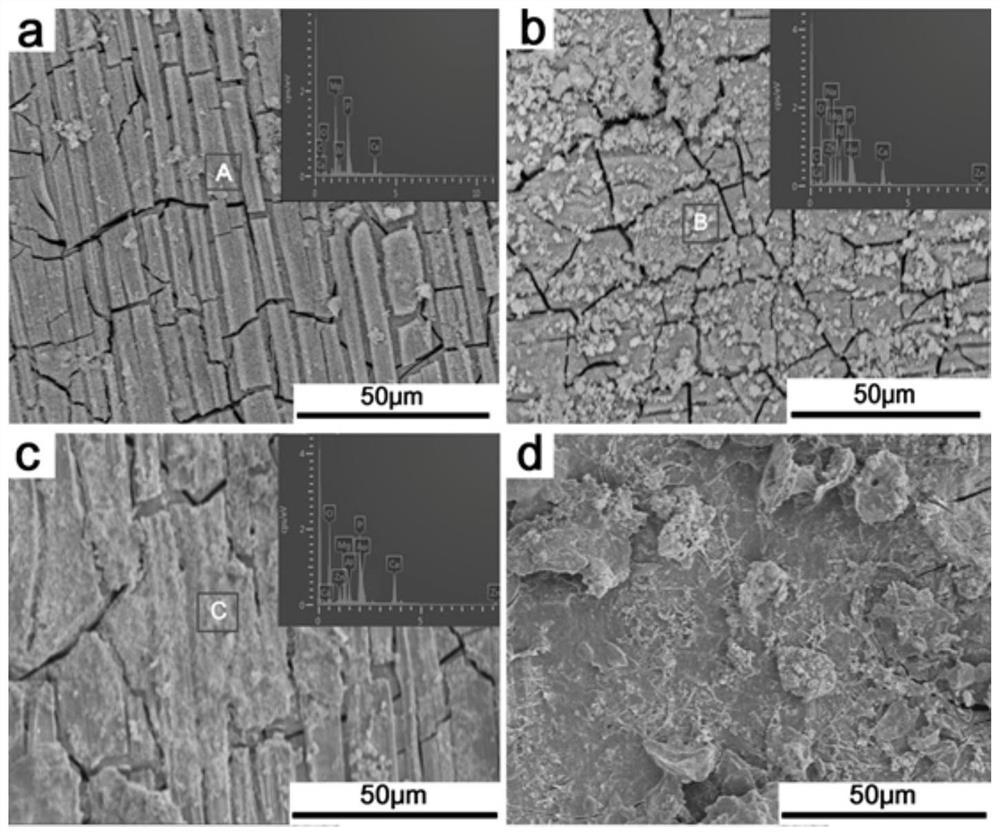

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

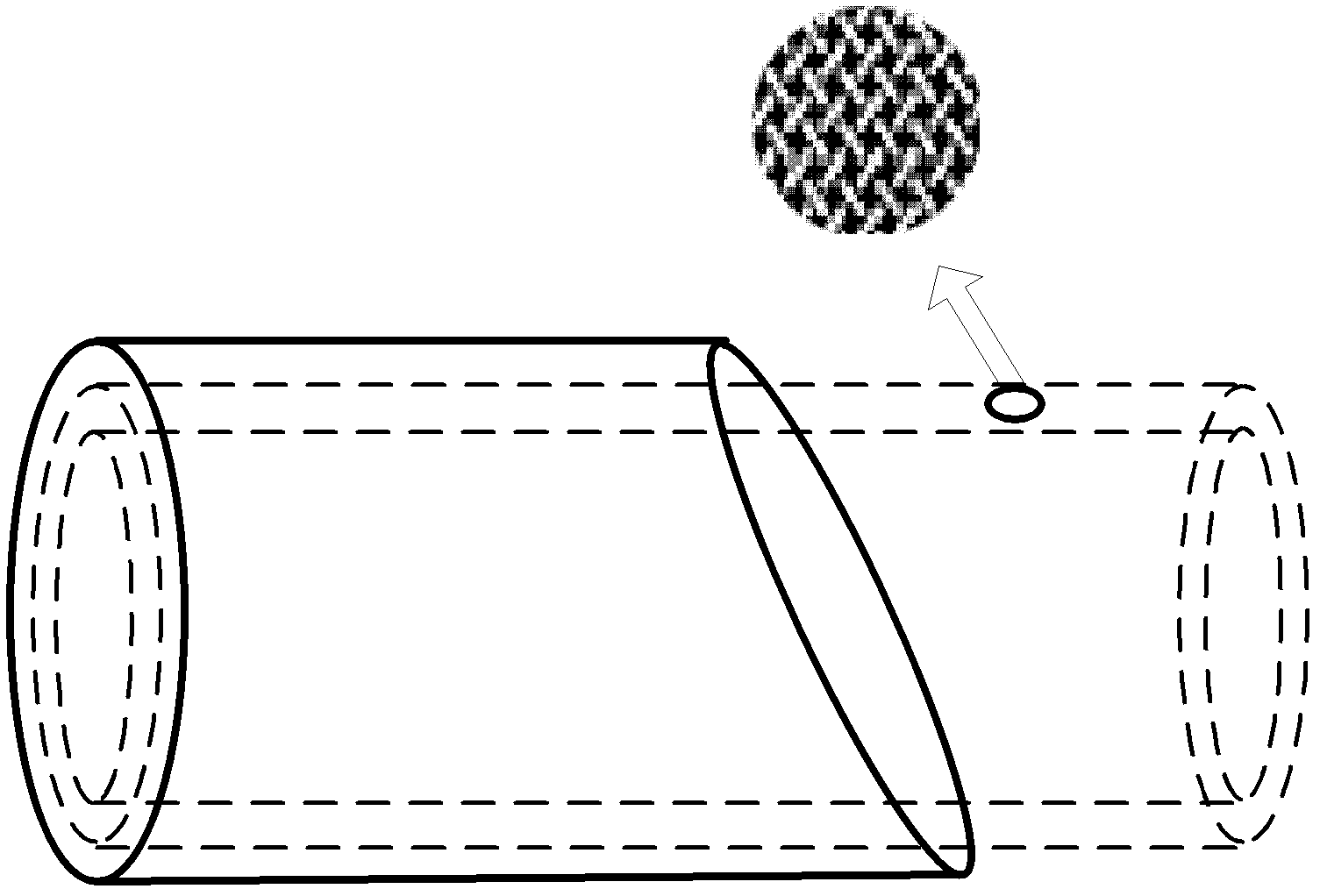

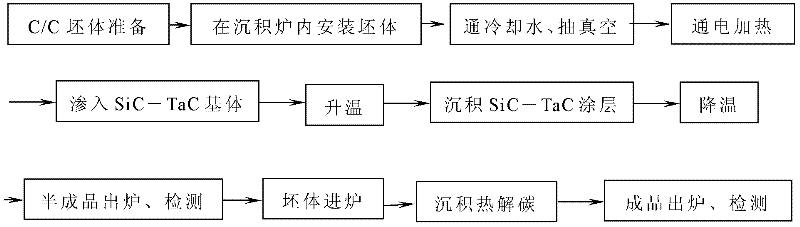

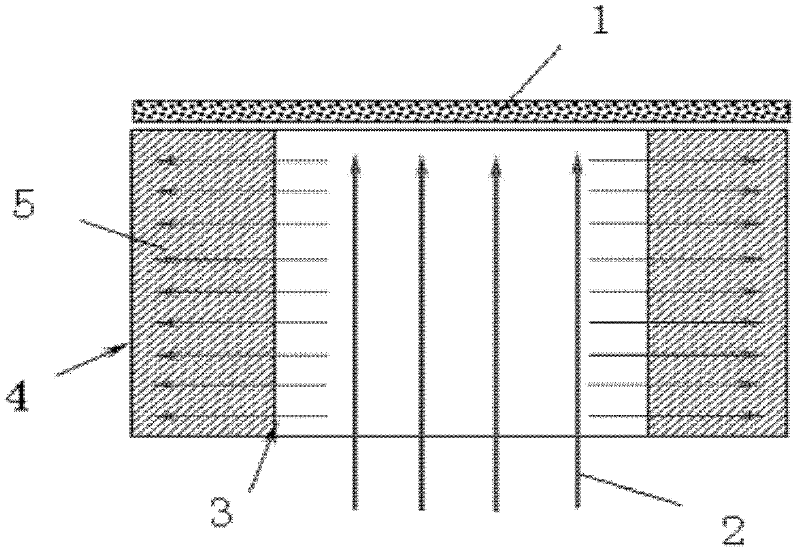

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

Preparation method for alumina coat on quartz fibre surface

The invention relates to a preparation method for an alumina coat on quartz fibre surfaces, and belongs to the technical field of special functional ceramics. The preparation method comprises the following steps: respectively adding aluminum ion, nitric acid and chelating agent in solvent according to the molar ratio of 1: (0.03-0.28): (0.5-1) till all the materials are hydrolyzed to generate sediments; then, adding peptizator to carry out peptization; carrying out reflux heating and stirring for 8 to 24h at a temperature of between 50 and 100 DEG C to obtain transparent and stable Al2O3 sol; putting quartz fibre into a steeping vat of Al2O3 sol for steeping and then heating up and gradually drying the quartz fibre at a temperature of between room temperature and 80 DEG C; and finally, carrying out heat treatment at a temperature of between 450 and 850 DEG C to obtain the quartz fibre coated with the alumina coat. The preparation method is scientific, reasonable and easy to implement; moreover, the Al2O3 coat coated on the surface of the quartz fibre increases material mechanical property and reduces material brittle fracture.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

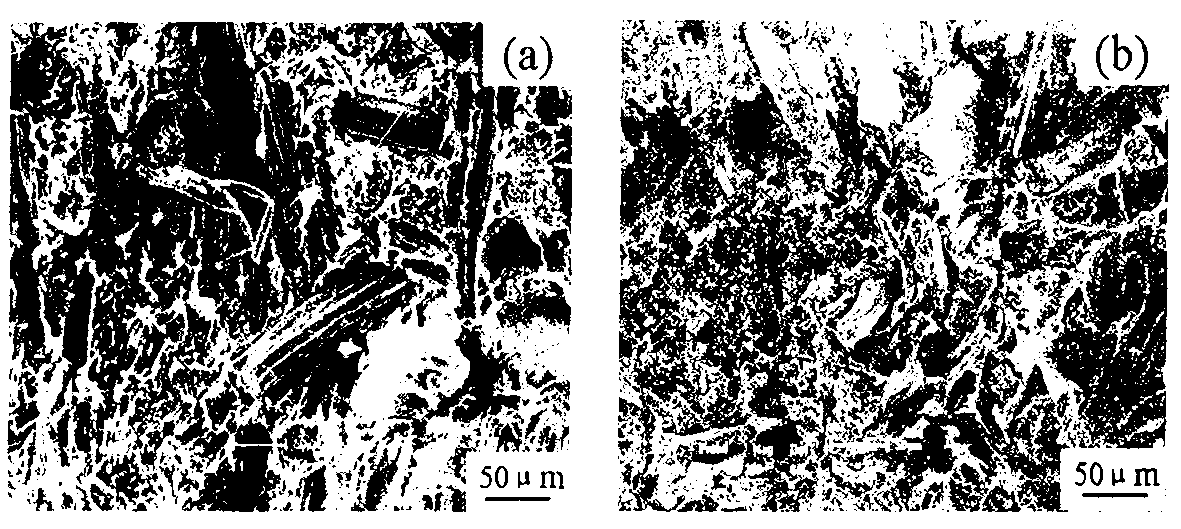

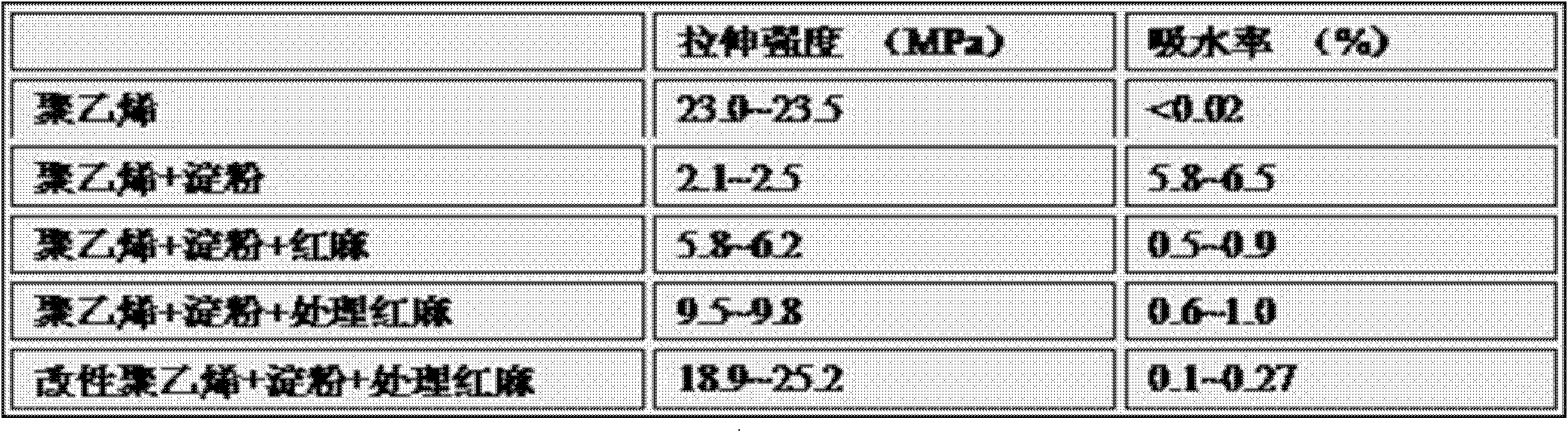

Degradable resin-starch-kenaf extruded plastic master batch

The invention belongs to the field of high polymer materials and in particular relates to a degradable resin-starch-kenaf extruded plastic master batch. The degradable resin-starch-kenaf extruded plastic master batch comprises the following components by volume percent: 30%-60% of polyethylene, 0-50% of starch and 5-40% of kenaf, wherein the polyethylene is composed of low-density polyethylene and maleic anhydride modified polyethylene in the volume ratio of (0.2-5):1. The extruded composite resin (master batch) material with higher tensile strength and good processing performance is prepared by virtue of a molecular design method; the biodegradation rate is 40%-70% in the presence of aerobiont; the using performance and the processing performance of the composite material are similar to those of the polyethylene, so that the material is green and environment-friendly, and therefore, the purposes of protecting the environment, efficiently utilizing the resources and lowering the cost are achieved.

Owner:赵振峰

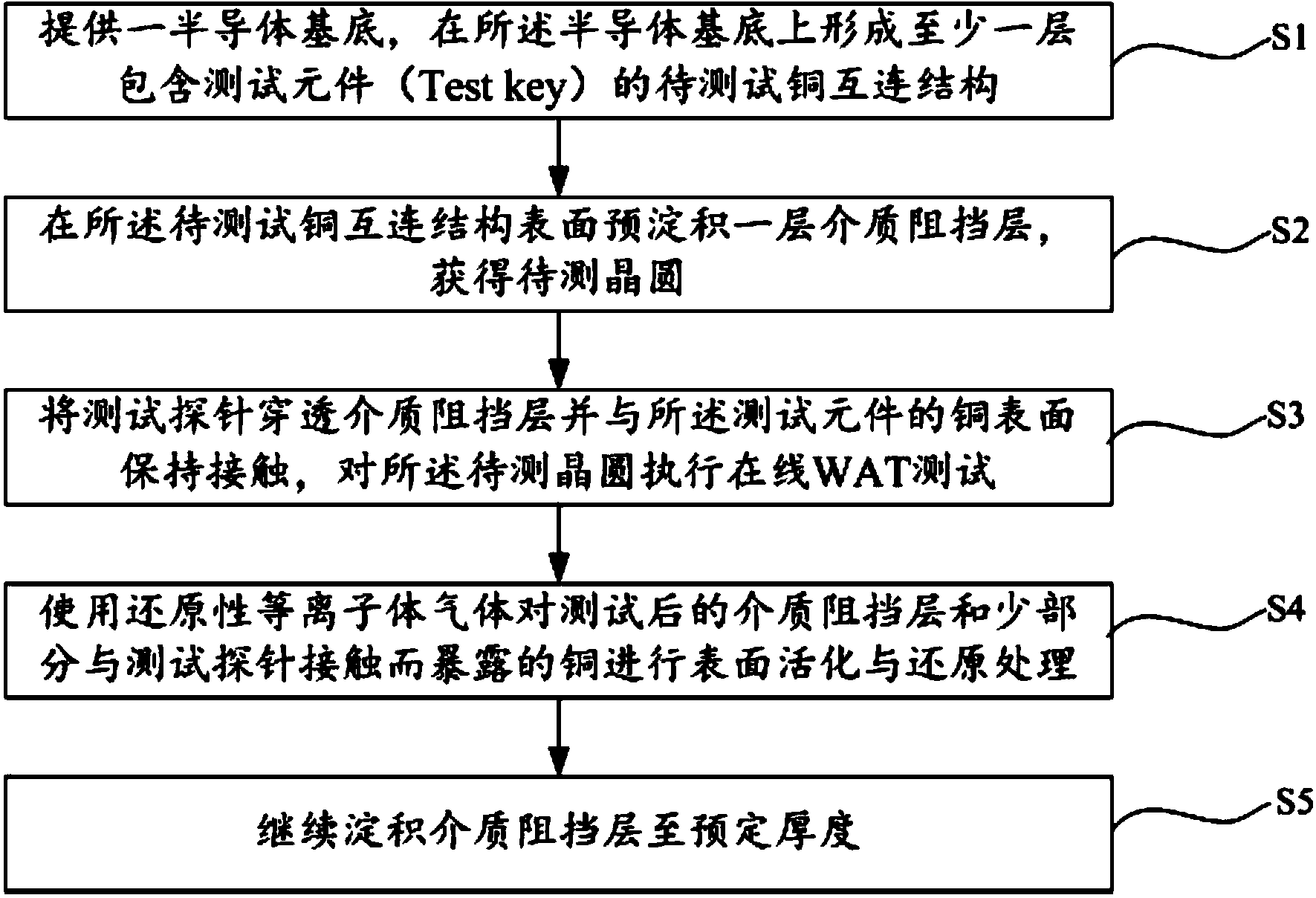

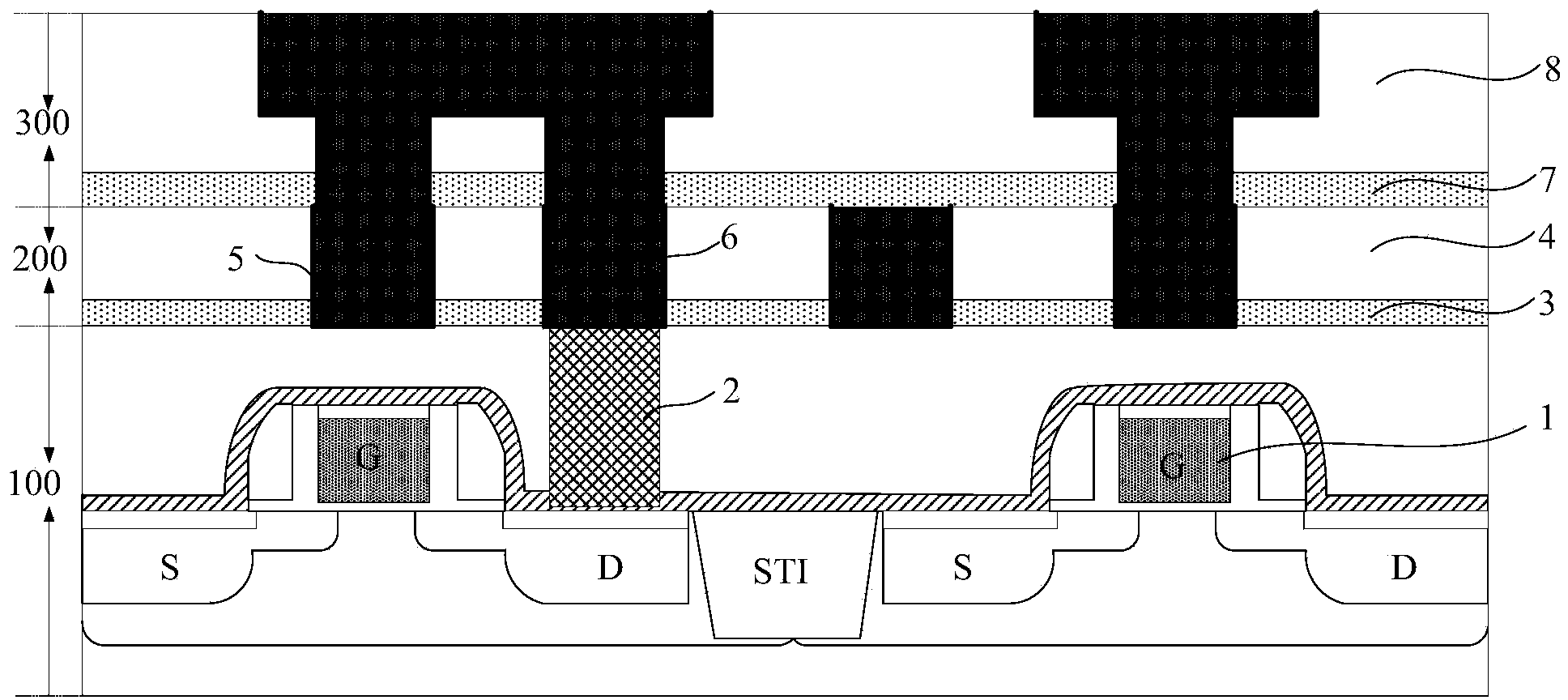

Method for lowering influence on copper interconnection reliability from online WAT testing

ActiveCN103972160AConvenient thermal protectionEfficient removalSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingReduction treatmentSurface plasmon

The invention provides a method for lowering the influence on the copper interconnection reliability from the online WAT testing. The method comprises the steps that at least one layer of to-be-tested copper interconnection structure comprising a testing component is formed on a semiconductor substrate; a dielectric barrier layer is deposited on the surface of the to-be-tested copper interconnection structure in advance, and a wafer to be tested is obtained; a testing probe penetrates through the dielectric barrier layer and keeps contact with the copper surface of the testing component, and online WAT testing is carried out on the wafer to be tested; surface activation and reduction treatment are carried out on the tested dielectric barrier layer and a small part of copper exposed after making contact with the testing probe through reducing plasma gas; the dielectric barrier layer continues to be deposited to be at the preset thickness. Through the method for combining the pre-deposited dielectric barrier layer serving as an isolation protection layer before the testing with the surface plasma activation and reduction treatment after the testing, defects in copper and dielectric materials are effectively restrained from being generated in the online WAT testing process, and the influence on the copper interconnection reliability from the online WAT testing is lowered significantly.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

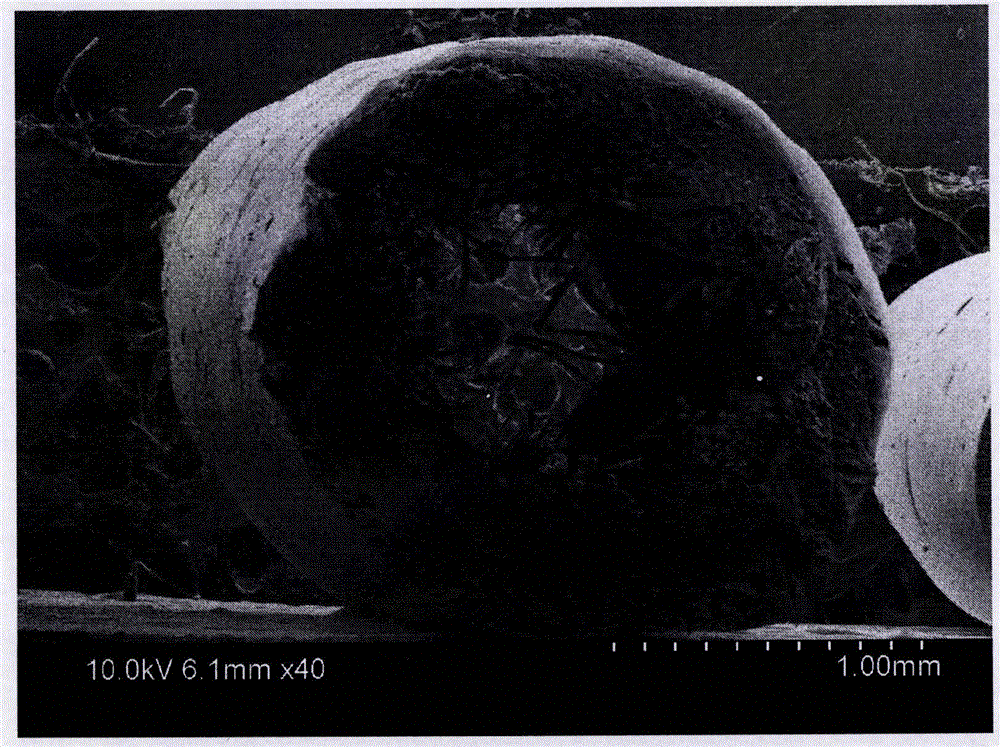

Preparation method and functionalization process for fiber-reinforced hollow nanofiber membrane

InactiveCN108772106AHigh mechanical strengthImprove interface binding stateOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsNanofiberNanofibrous membrane

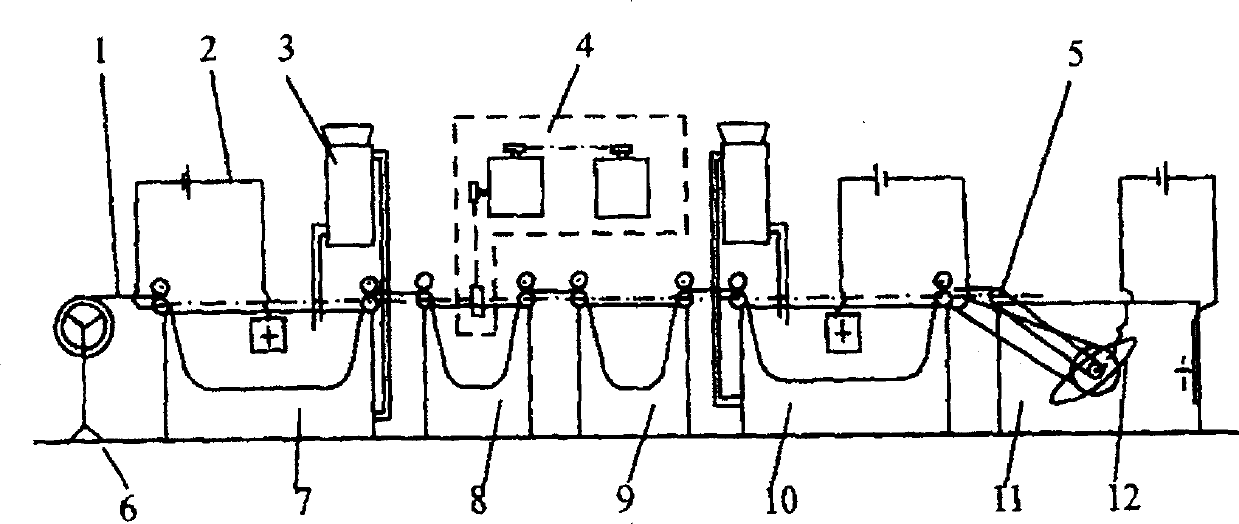

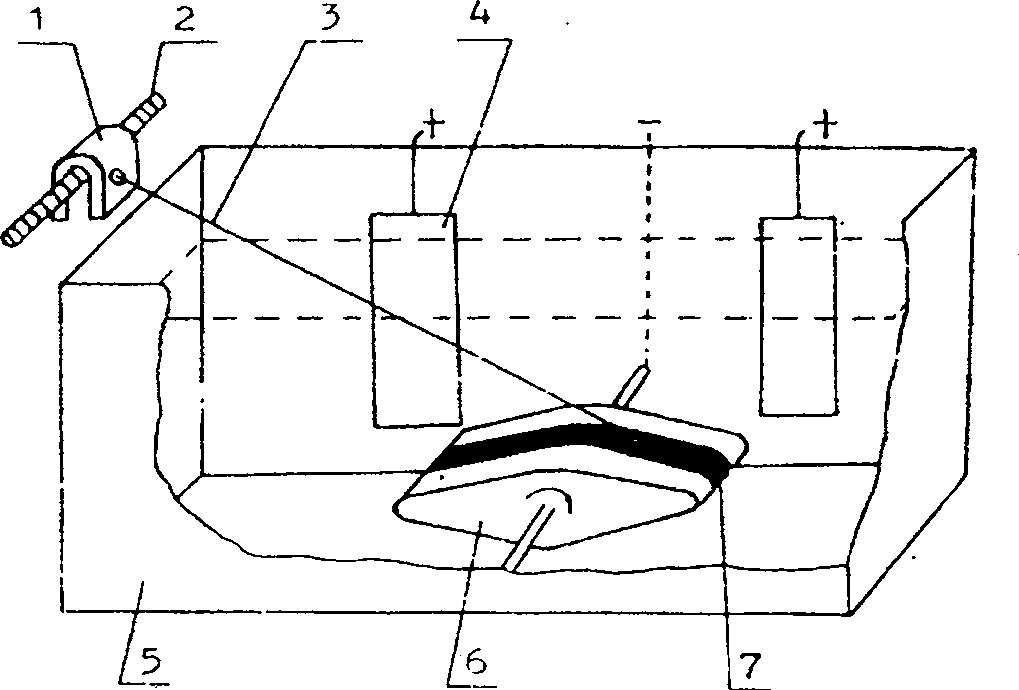

The invention discloses a preparation method and functionalization process for a fiber-reinforced hollow nanofiber membrane. The preparation method comprises the following steps: 1) braiding a tubularbraid as a reinforcement by using a two-dimensional braiding technique; and 2) preparing an electrospinning solution, subjecting the prepared electrospinning solution to defoaming, putting the electrospinning solution in an electrospinning device, installing the reinforcement on the receiving unit of the electrospinning device, and carrying out electrospinning under condition of a temperature of15 to 50 DEG C, a relative humidity of 50 to 80%, a positive high voltage of 5 to 35 kV, a negative high voltage of 0 to 10 kV, a solution propulsion speed of 0.2-3 mL / h, a needle inner diameter of 0.16-2.0 mm and a rotating speed of 500-3000 r / min so as to obtain the product with improved mechanical properties. The preparation method is simple in process, low in cost and convenient for industrialimplementation. The functionalization process comprises the following steps: sequentially immersing the fiber-reinforced hollow nanofiber membrane in a modified solution and a metal ion salt solution, and carrying out washing and drying so as to obtain a product having catalytic properties.

Owner:TIANJIN POLYTECHNIC UNIV

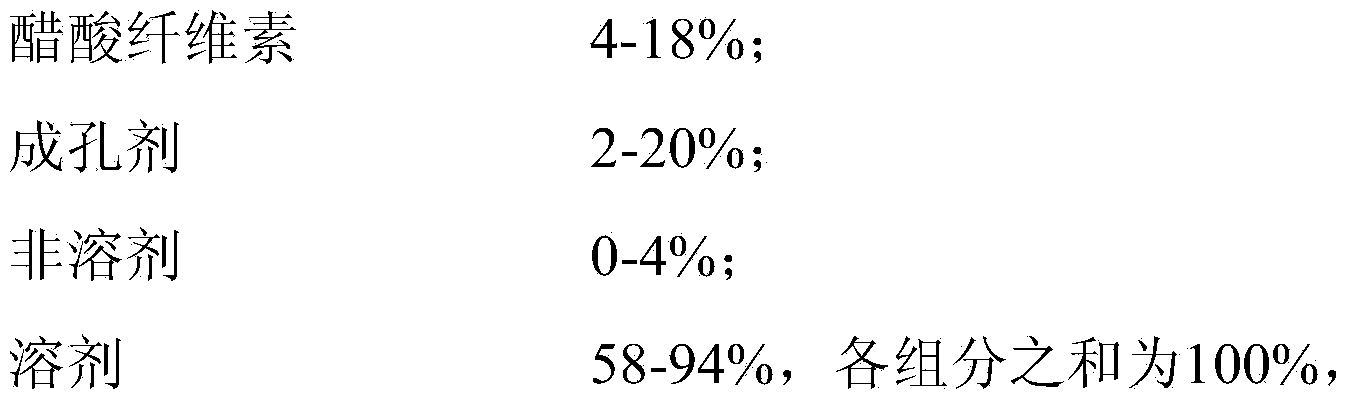

Preparation method of homogeneous enhanced cellulose acetate hollow fiber membrane

InactiveCN104001428AImprove mechanical propertiesExtended service lifeSemi-permeable membranesFiberNon solvent

The invention discloses a preparation method of a homogeneous enhanced cellulose acetate hollow fiber membrane, and the preparation method comprises the following process steps: 1, preparation of a hollow braided tube reinforced body, to be more specific, using a 2D woven technology to prepare a cellulose acetate filament into a hollow braided tube with the diameter of 1-2mm, and using the hollow braided tube as the reinforced body; 2, preparation of a cellulose acetate membrane casting solution comprising 4-18% by mass of cellulose acetate, 2-20% by mass of a pore forming agent, 0-4% by mass of a non solvent and 58-94% by mass of a solvent; 3, preparation of the hollow fiber membrane, to be more specific, homogeneously coating the surface of the hollow braided tube with the membrane casting solution by use of a co-extrusion spinneret, then using a silk guide roller for leading to pass through the air gap of 2-20cm to immerse into a solidification bath at 10-50 DEG C for forming to obtain the hollow fiber membrane; the hollow fiber membrane has good mechanical properties and interfacial bonding state, is easy to process after being abandoned, and has the advantages of simple preparation method.

Owner:TIANJIN POLYTECHNIC UNIV

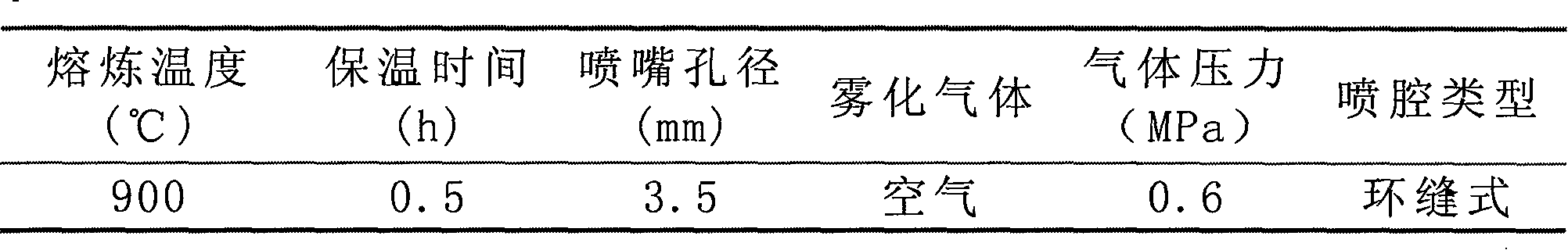

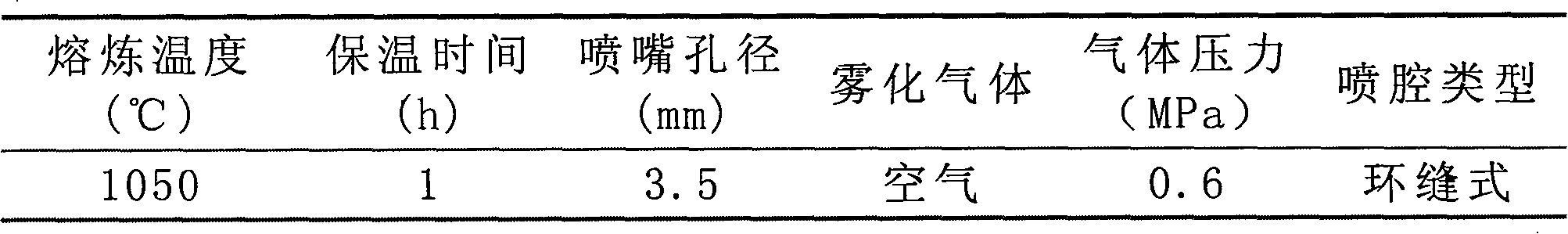

Method for preparing high-silicon aluminum alloy by peeling and thermal extruding through rapid-solidified powder metallurgy

InactiveCN106670467ASmall tissueImprove mechanical propertiesTransportation and packagingMetal-working apparatusRoom temperatureVolumetric Mass Density

The invention relates to a method for preparing high-silicon aluminum alloy by peeling and thermal extruding through rapid-solidified powder metallurgy. The method comprises the following steps: preparing high-silicon aluminum alloy powder through an atomizing powdering method; screening the powder; selecting the high-silicon aluminum alloy powder with average particle being not greater than -150 meshes; transferring into an aluminum covered sleeve; performing air removing and opening sealing; then carrying out peeling and thermal extruding to obtain a high-silicon aluminum alloy bar; machining to remove the aluminum covered sleeve in the periphery of the high-silicon aluminum alloy bar; and performing solid solution treatment and aging treatment to obtain the finished high-silicon aluminum alloy. The high-silicon aluminum alloy material prepared by the method is small and uniform in structure, high in density which can reach 100%, and high in powder deformation, so that the powder interface combination state can be improved; the mechanical property of the alloy can be improved; the strength of the high-silicon aluminum alloy material under room temperature is not less than 450MPa, and the plasticity is not less than 1%.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Diamond/copper high-thermal conductivity composite material and preparation method thereof

ActiveCN102108458AMeet needsImprove interface binding statePhotography auxillary processesProcess efficiency improvementCopper highThermal expansion

The invention provides a diamond / copper high-thermal conductivity composite material and a preparation method thereof. The composite material comprises a base material copper, and reinforced materials are diamond particles coated with chromium or molybdenum or tungsten or titanium, wherein the volume fraction of the reinforced materials in the composite material is 15-65%. The preparation method of the composite material comprises the following steps: firstly, mixing the diamond particles with pure chromium powder or molybdenum powder or tungsten powder or titanium powder in a mixer; carryingout high-temperature treatment; and then, preparing the high-thermal conductivity composite material by adopting an electroplating process. The invention solves the problem of poor diamond / copper interface combination, and avoids the problems of diamond graphitization and the like at high temperature. The prepared composite material has higher thermal conductivity and lower thermal expansion coefficient, thereby meeting the requirements of high-power integrated circuit packaging materials.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation process of modified magnesium borate crystal whisker reinforced magnesium-matrix composite material

InactiveCN101705458AImprove interface binding stateImprove plastic forming abilityMagnesium matrix compositeVacuum pressure

The invention belongs to the technical field of new materials, in particular to a preparation process for modifying and optimizing magnesium alloy matrix and reinforcing the interphase contact surface and interface aiming at the magnesium borate crystal whisker reinforced magnesium-matrix composite material. The study proves that no obvious interface reaction occurs at the interface of the magnesium borate crystal whisker and the magnesium matrix, and the bonding strength of the interface is not high. By adopting the invention, the interface of the crystal whisker reinforced magnesium-matrix composite material reaches a better bonding state, and the performance of the magnesium borate crystal whisker reinforced magnesium-matrix composite material is improved. The preparation process comprises steps of coating the magnesium borate crystal whisker, preparing the modified magnesium borate crystal whisker prefabricated block, preparing cast composite ingot blank by a vacuum pressure infiltration method; and thermally extruding the ingot blank. The composite material comprises components of aluminium isopropoxide Al(OC3H7)3, distilled water, muriatic acid, magnesium borate crystal whisker, magnesium and the balance of magnesium alloy.

Owner:QINGHAI UNIVERSITY

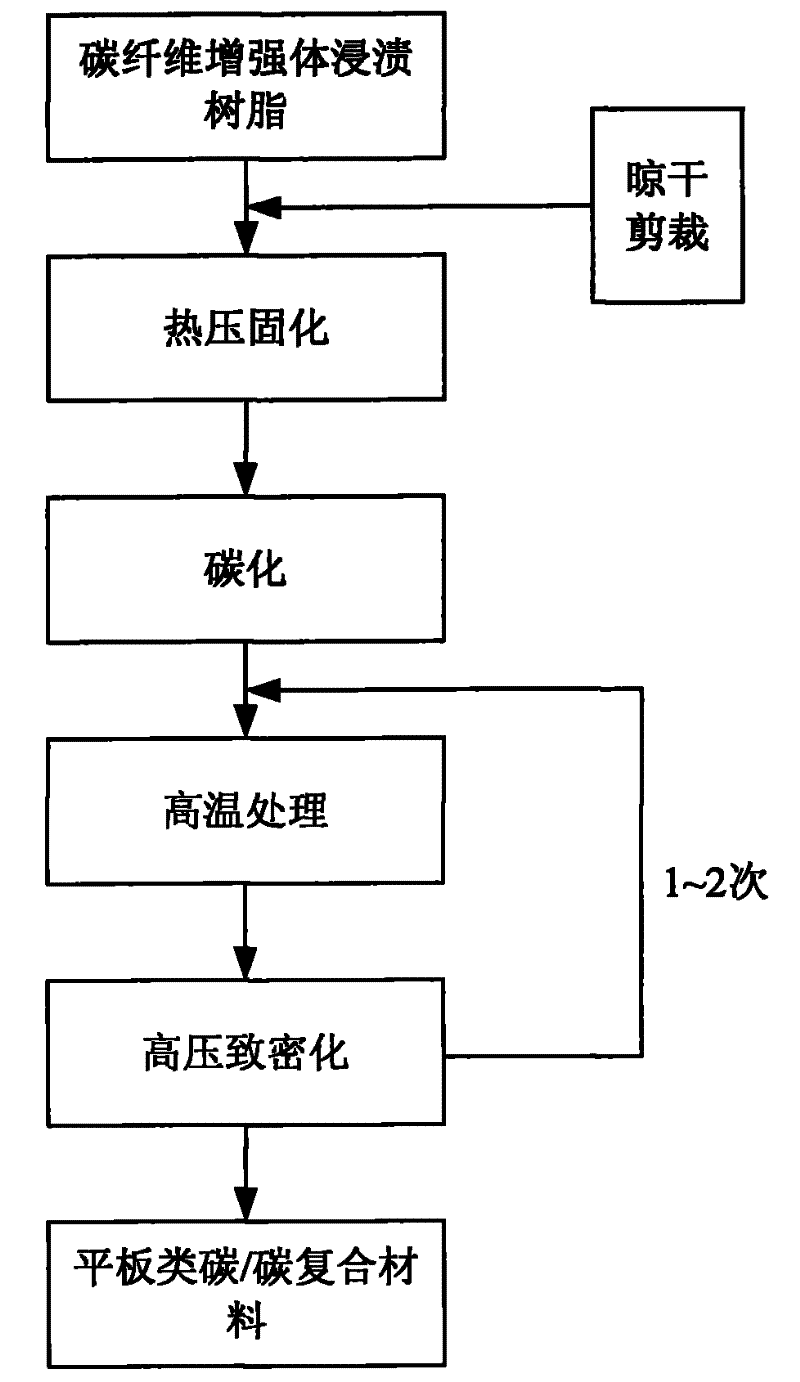

Method for rapidly forming flat plate carbon/carbon composite material

The invention aims at the problems of long preparation period, high cost and the like of a carbon / carbon composite material at present and provides a method for rapidly forming a flat plate carbon / carbon composite material. In the method, the thought of a resin-based composite material hot-pressing rapid forming process is adopted; and a carbon / carbon composite material carbonization process is combined with a high-pressure densification rapid densifying process. During preparation of the flat plate carbon / carbon composite material, the process is simple and is easy to control; the flat plate carbon / carbon composite material with large size and thick wall can be prepared; the flat plate carbon / carbon composite material has high density and high structural homogeneity; the preparation period can be greatly shortened; and cost of the material can be reduced.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Preparation method of electrostatic spinning hollow fiber membrane

ActiveCN107344075AHigh porosityHigh separation precisionSemi-permeable membranesPorosityPolymer science

The invention discloses a preparation method of an electrostatic spinning hollow fiber membrane. The method comprises the steps of (A) preparing a hollow braided tube: braiding fiber filaments into the hollow braided tube by adopting a two-dimensional braiding technology; (B) preparing a spinning liquid: dissolving 5-20w% of polymer resin and 0-10wt% of an additive into 70-95wt% of solvent to prepare a spinning liquid, wherein the sum of various components is 100wt%; and (C) preparing the electrostatic spinning hollow fiber membrane: sleeving a filament receiving device with the hollow braided tube obtained in the step (A), injecting the spinning liquid obtained in the step (B) into a spinning device, carrying out electrostatic spinning and air solidification, and then solidifying and forming in a coagulating bath to obtain the electrostatic spinning hollow fiber membrane. The hollow fiber membrane is prepared by adopting the method of combining the two-dimensional braiding technology and an electrostatic spinning method. The prepared electrostatic spinning hollow fiber membrane mainly comprises a reinforcement body and a separation layer, and meanwhile has the advantages of high porosity, high separation accuracy and high strength.

Owner:TIANJIN POLYTECHNIC UNIV

Enhanced TiNi layered composite material and preparation method thereof

ActiveCN110293717AEffective control generationGood mechanical propertiesLamination ancillary operationsLaminationTitaniumPre treatment

The invention discloses an enhanced TiNi layered composite material and a preparation method thereof, and belongs to the field of processing of special material composite technology. By aiming at theproblems of poor mechanical properties of the existing Ti / Ni layered composite material, pure titanium and pure nickel are used as raw materials; titanium plates and pure nickel plates are respectively subjected to surface pretreatment; then, the placement is performed in an alternate laminated sequence in a mode of Ti / Ni / Ti; through the subsequent rolling compounding and heat treatment processes,the Ti / Ni layered composite material with excellent mechanical property is prepared. The preparation process is simple; the cost is low; the mechanical property is excellent.

Owner:JINCHUAN GROUP LIMITED

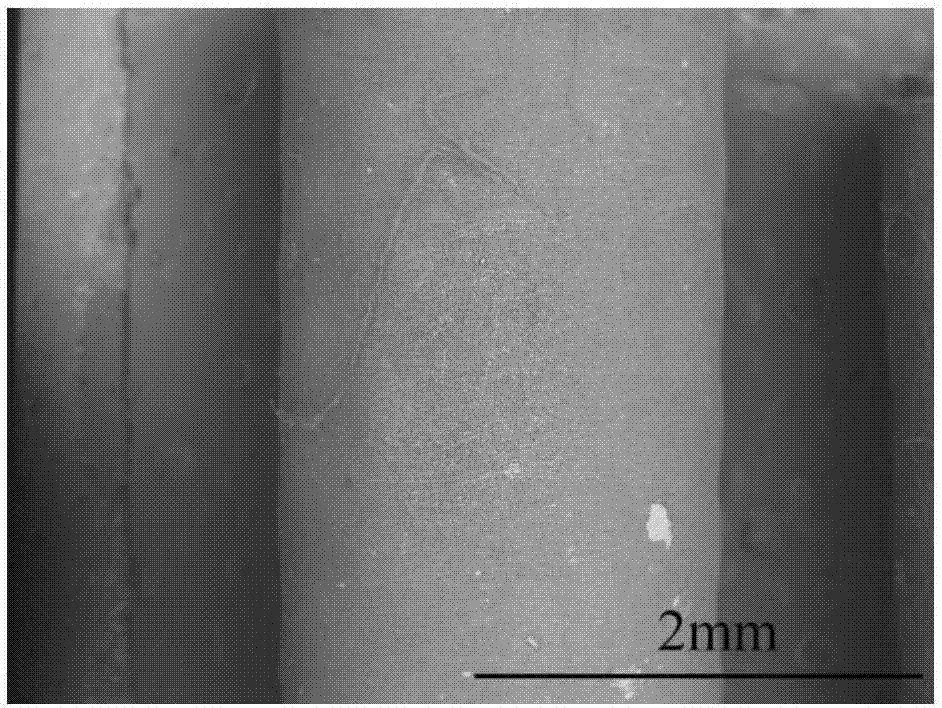

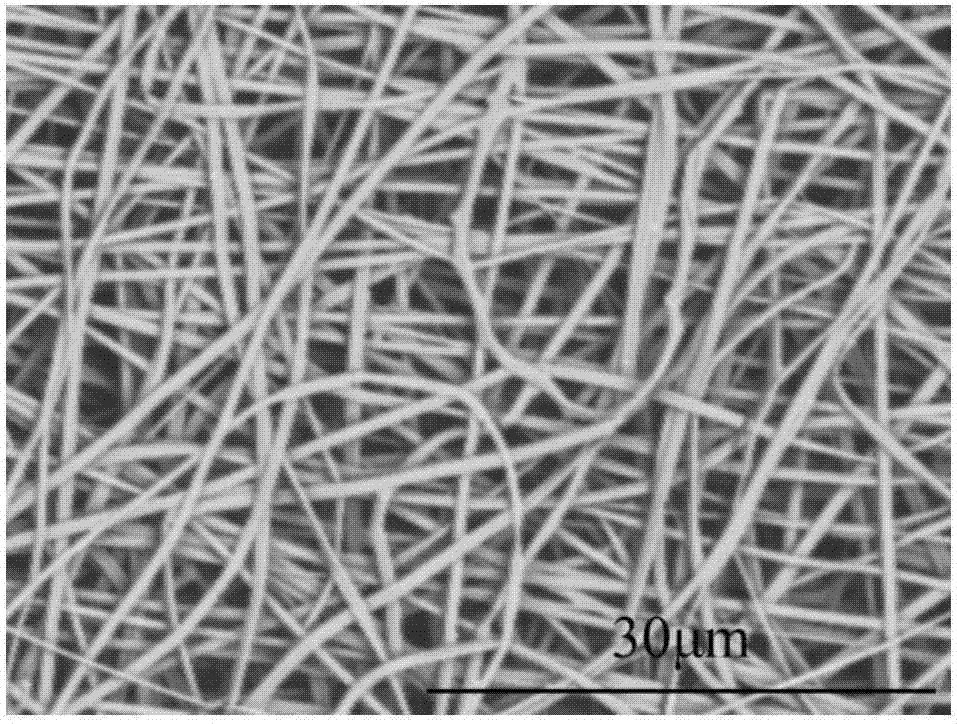

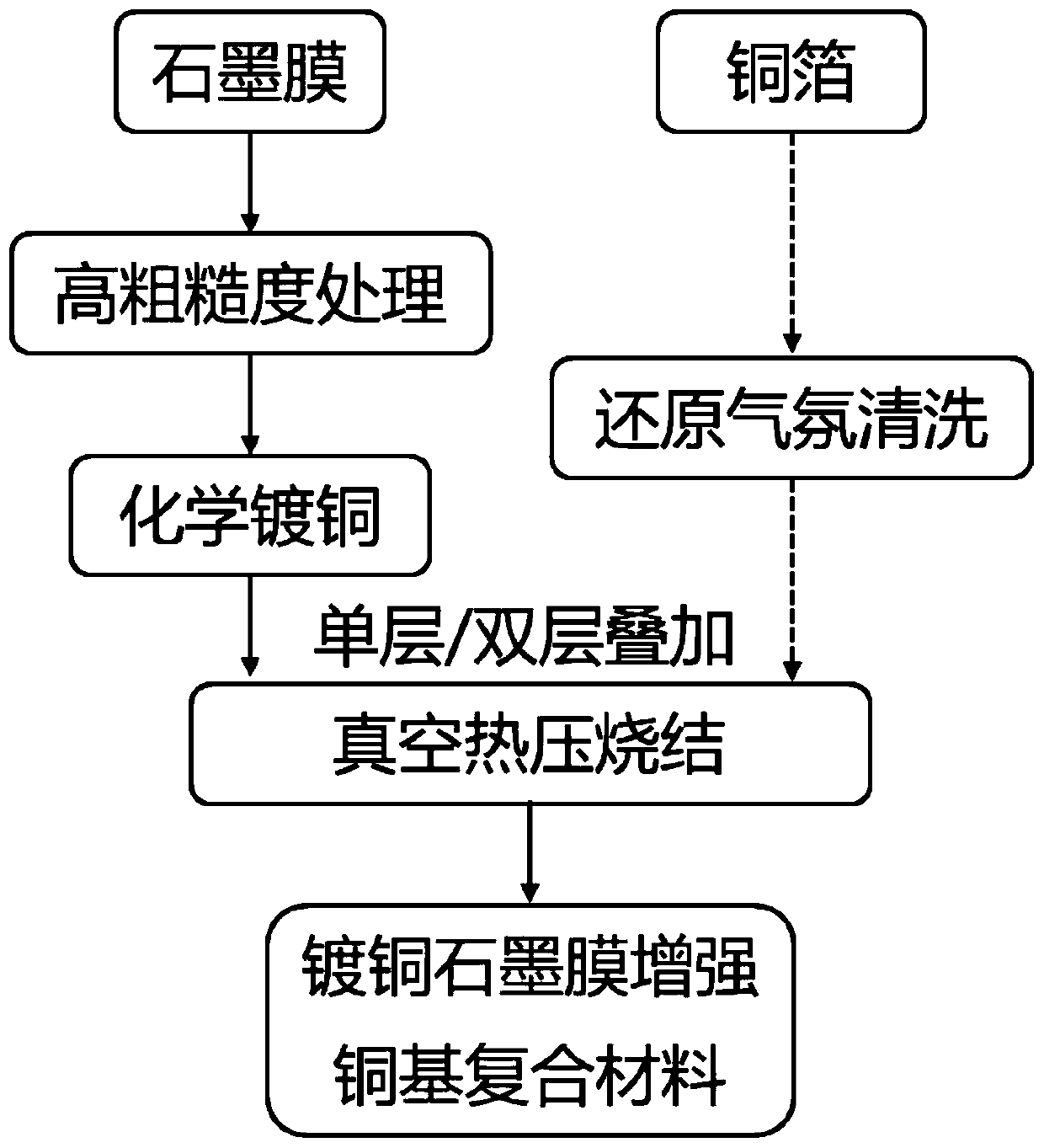

Copper-plated graphite film reinforced copper-based laminated block composite material and preparation method thereof

InactiveCN111349807AImprove thermal performanceSmall coefficient of thermal expansionLaminationLamination apparatusMetallic materialsCopper foil

The invention provides a copper-plated graphite film reinforced copper-based laminated block composite material and a preparation method thereof. The composite material is the laminated block composite material composed of a copper-plated graphite film and a copper foil. The preparation method of the copper-plated graphite film adopts improved electroless plating to obtain a coating with good bonding and being controllable and uniform and clean; and the preparation method of the composite material adopts vacuum hot pressing sintering, so that requirements on equipment are low, and the operation is simple. The thermal conductivity of the composite material prepared by the preparation method exceeds 1000 W / (m.K), a coefficient of thermal expansion can be lower than 10 ppm / K, and the composite material is a promising thermal management material with both bending strength and advantages of metal materials and graphite materials.

Owner:苏州优越新材料有限公司

Preparation method of enhanced chlorinated polyvinyl chloride hollow fiber membrane

InactiveCN106693725AImprove mechanical propertiesSolve the problem of high brittleness and easy wire breakageSemi-permeable membranesPolymer scienceFoaming agent

The invention discloses a preparation method of a chlorinated polyvinyl chloride (CPVC) hollow fiber membrane. The preparation method comprises the following process steps: (1) preparing fibers into a hollow braided tube by adopting a two-dimensional braiding technology, and taking the hollow braided tube as a hollow fiber membrane enhancement body; (2) preparing a CPVC casting solution from the following components in percentage by weight: 15 to 35 percent of CPVC, 5 to 20 percent of pore-foaming agent, 2 to 10 percent of processing aid and 40 to 70 percent of organic solvent, totaling 100 percent; (3) coextruding the hollow braided tube obtained in the step (1) and the CPVC casting solution obtained in the step (2) through an annular spinning nozzle by adopting a co-extrusion compound spinning process, uniformly coating the surface of the hollow braided tube with the casting solution, and fully curing to obtain the enhanced CPVC hollow fiber membrane. The enhanced CPVC hollow fiber membrane prepared by the method has high toughness, is low in production cost, and has a wide practical application prospect; the problem of insufficient mechanical strength of an elemental CPVC hollow fiber membrane can be solved effectively.

Owner:康泽源(天津)科技发展有限公司

Zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial property as well as preparation method and application thereof

ActiveCN113082290AHigh antibacterial activityImprove interface binding statePharmaceutical delivery mechanismMetallic material coating processesUltraviolet lightsOxide coating

The invention discloses a zinc oxide coating-hydroxyapatite coating with biological activity and antibacterial property as well as a preparation method and an application thereof. The zinc oxide coating-hydroxyapatite coating comprises an alkaline zinc oxide coating and a hydroxyapatite coating, the alkaline zinc oxide coating is excited by ultraviolet light to generate .OH on the surface to form a zinc oxide coating-hydroxyapatite coating with the hydroxyapatite coating; and the preparation method comprises the following steps: exciting the surface of the alkaline zinc oxide coating to generate. OH, and reacting with SBF simulated body fluid to form the zinc oxide coating-hydroxyapatite coating. The zinc oxide coating-hydroxyapatite coating is used for preparing an orthopedic implant. The method is low in cost, high in efficiency, simple and easy to implement and environmentally friendly, and the zinc oxide coating-hydroxyapatite coating prepared through the method has good biological activity and antibacterial performance and has high commercial popularization value.

Owner:北京科技大学天津学院

Preparation method of enhanced hollow polyvinylidene fluoride fiber membrane

ActiveCN103432916BImprove mechanical propertiesExtended service lifeSemi-permeable membranesEnhanceosomePolyvinylidene difluoride

The invention discloses a preparation method of an enhanced hollow polyvinylidene fluoride fiber membrane. The preparation method comprises the following steps: (1) preparation of an enhanceosome: braiding polyacrylonitrile fiber into a hollow braided pipe by adopting a two-dimensional braiding technology; (2) preparation of separation layer casting film liquor: respectively dissolving 5-25wt% polyvinylidene fluoride resin and 5-30wt% of additive into a solvent, stirring and dissolving under the condition of 70-90 DEG C, conducting vacuum defoaming to obtain the separation layer casting film liquor; (3) surface pretreatment of the enhanceosome: cleaning and drying the enhanceosome with a neutral detergent, and then infiltrating the enhanceosome with slight polar organic liquid; and (4) preparation of the enhanced hollow polyvinylidene fluoride fiber membrane: evenly coating the separation layer casting film liquor obtained from the step (2) on the surface of the enhanceosome treated in the step (3), and curing to obtain the enhanced hollow polyvinylidene fluoride fiber membrane. The binding strength of a separation layer on the surface of the enhanced hollow polyvinylidene fluoride fiber membrane prepared by adopting the method and the enhanceosome is high, and the separation layer and the enhanceosome are unlikely to strip, and high-pressure backflushing can be conducted.

Owner:TIANJIN POLYTECHNIC UNIV

CrAlN thermal insulation coating for aluminum alloy piston combustor surface and preparation method thereof

ActiveCN108728804AIncrease ionization rateHigh ion energyVacuum evaporation coatingSputtering coatingCombustion chamberThermal insulation

The invention discloses a CrAlN thermal insulation coating for an aluminum alloy piston combustor surface and a preparation method thereof. The CrAlN thermal insulation coating comprises a transitionlayer and a thermal insulation layer from the inside out in order, the transition layer is a CrAl coating, and the thermal insulation layer is a CrAlN coating. The method adopts filtered cathodic vacuum arc technique, takes a CrAl alloy target material (Cr, Al metal target) as the cathode, performs deposition of the CrAl coating on the aluminum alloy surface to form a transition layer, then uses nitrogen as the working gas, and coats the transition layer surface with the CrAlN coating evenly to form the thermal insulation layer. The CrAlN thermal insulation coating provided by the invention not only solves the problem of poor binding force and bearing ability caused by large difference of basic physical properties between the CrAlN coating and the aluminum alloy substrate material, also the coating is uniform and compact, has good film-substrate combination state and hardness up to 40GPa, and shows good high temperature thermal insulation properties and thermal shock resistance in piston thermal load test. The CrAlN thermal insulation coating provided by the invention significantly improves the performance reliability and service life of the aluminum alloy piston, and can meet thehigh power and low emission development requirements of modern engines.

Owner:XIANGTAN UNIV

Preparation method of silver-based graphene electric contact material and electric contact material

The invention relates to a preparation method of a silver-based graphene electric contact material and the electric contact material prepared by the preparation method. The preparation method comprises the following steps that 1, nickel / graphene composite powder is prepared; 2, the nickel / graphene composite powder prepared in the step 1 and copper powder are mixed to prepare copper / nickel / graphenecomposite powder; 3, the copper / nickel / graphene composite powder prepared in the step 2 is prepared into a copper / nickel / graphene composite foam body; and 4, infiltration is carried out on the copper / nickel / graphene composite foam body prepared in the step 3 and a silver infiltration sheet to obtain the silver / copper / nickel / graphene composite electric contact material. The silver-based grapheneelectric contact material prepared by the method has an excellent mechanical property and an excellent electrical property.

Owner:WENZHOU JUXING ELECTRIC CONTACT TECH

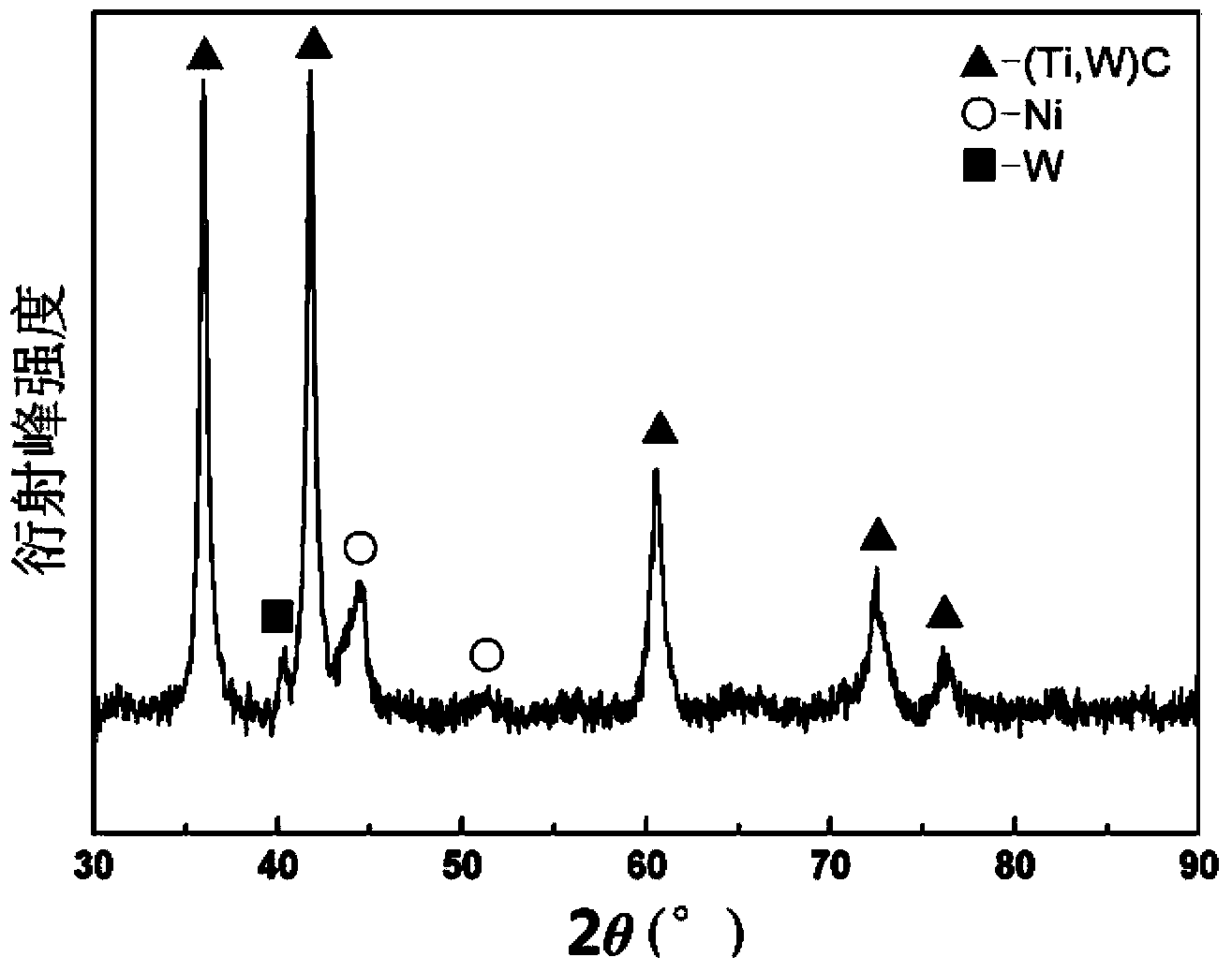

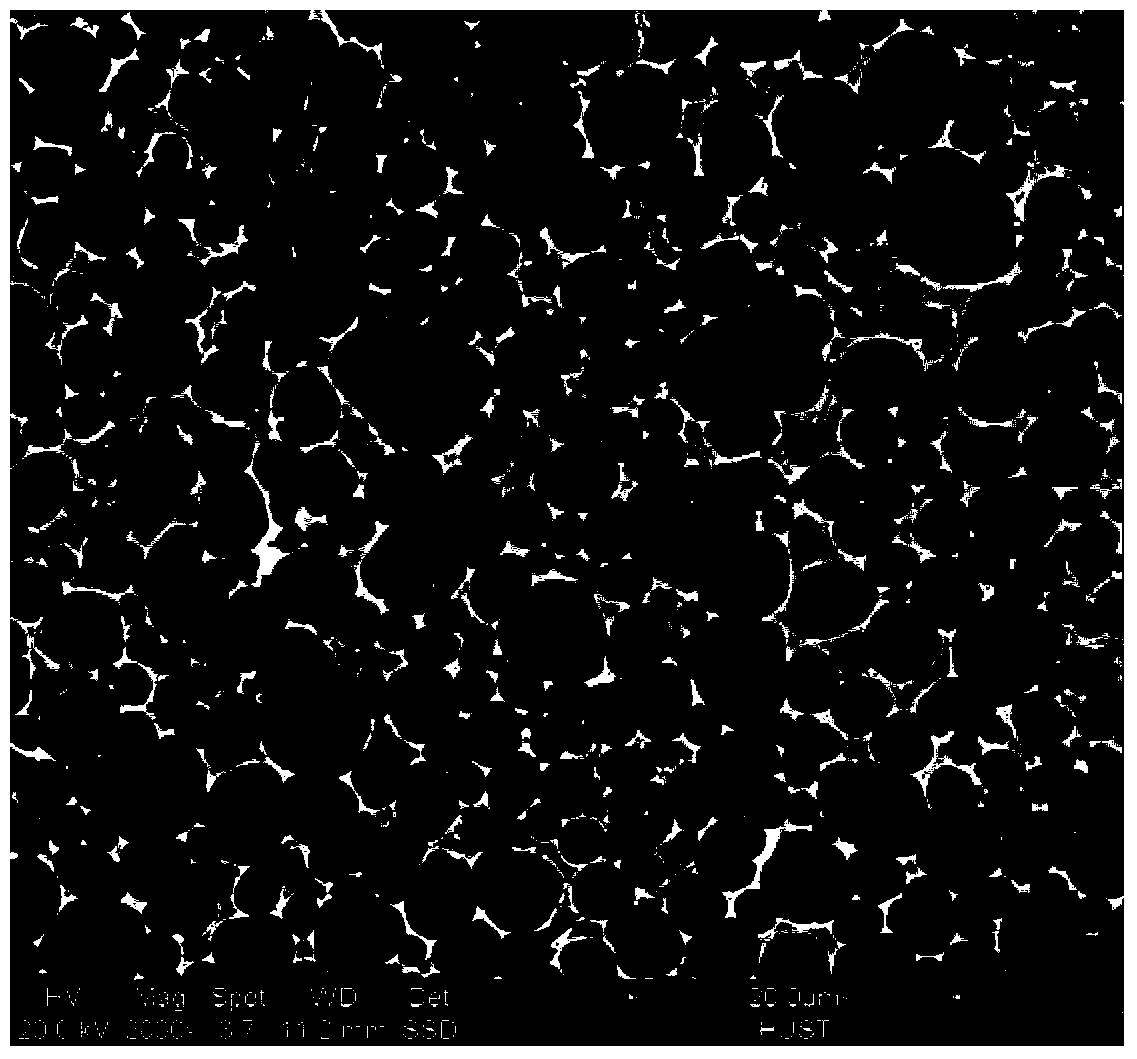

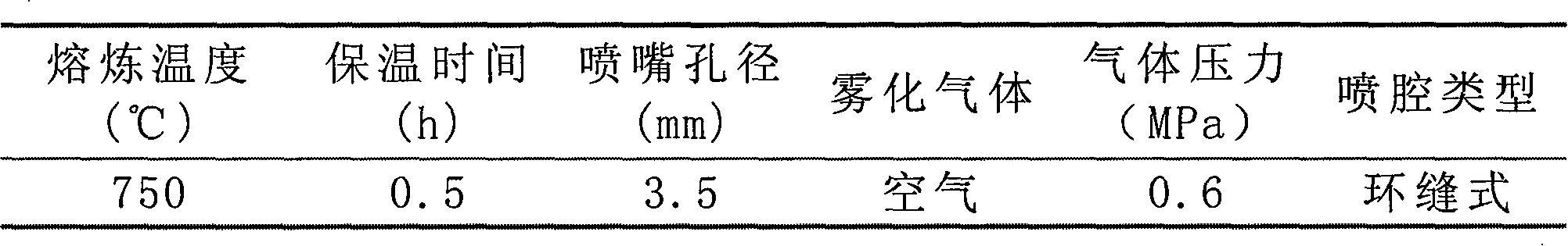

Titanium carbide-based solid solution metal ceramic and preparation method thereof

ActiveCN103361533BImprove the bonding strength of the interfaceSmall granularityWear resistantHigh energy

The invention discloses titanium carbide-based solid solution metal ceramic and a preparation method thereof. The titanium carbide-based solid solution metal ceramic is composed of a hard phase (Ti, W) C solid solution and an adhesive phase Ni, wherein the composite material powder is prepared by mold pressing forming, degreasing and vacuum sintering; the composite material is synthesized by utilizing Ti powder, W powder, Ni powder and graphite powder as raw materials and performing a high-energy ball milling induced self-propagating reaction under argon protection, and the raw materials comprise the following ingredient by mass percent: 40.60-58.02% of Ti powder, 11.02-29.18% of W powder, 15.00-20.00% of Ni powder and 11.94-15.27% of graphite powder. The preparation of solid solution powder is simple in process, short in cycle, low in energy consumption and easy to control the oxygen content, the hardness of the prepared titanium carbide-based solid solution metal ceramic is 89.0-91.8HRA, the bending strength is not smaller than 1680MPa, and the fracture toughness KIC is not smaller than 12.5MPa.m1 / 2, so that the titanium carbide-based solid solution metal ceramic is suitable for serving as high-speed and high-efficiency cutting tools, hot extrusion molds and heat-resistant, corrosion-resistant and wear-resistant parts and components.

Owner:HUAZHONG UNIV OF SCI & TECH

3D printing diamond/metal matrix composite material and preparation method and application thereof

ActiveCN113770381AEffective bezel settingFine grainAdditive manufacturing apparatusVacuum evaporation coating3d printMetal matrix composite

The invention discloses a 3D printing diamond / metal-based composite material and a preparation method and application thereof. The 3D printing diamond / metal-based composite material comprises core-shell structure doped diamond, a metal-based material and an additive, and the core-shell structure doped diamond comprises a core, a transition layer, a shell, a coating, a porous layer and a modification layer. The preparation method of the material comprises the following steps: uniformly mixing diamond, a metal matrix and the additive, and then carrying out 3D printing according to a three-dimensional CAD slicing model to finally obtain the composite material designed by the model. According to the 3D printing diamond / metal matrix composite material, the obtained metal matrix and the diamond surface are mainly subjected to metallurgical bonding, and the bonding strength of the diamond / metal matrix can be improved, so that the use performance of the composite material and a diamond tool is improved, the core-shell structure doped diamond is good in ablation resistance, and the problem of diamond thermal damage in the 3D printing forming process can be effectively avoided and reduced.

Owner:CENT SOUTH UNIV

Process for preparing silumin electronic package materials

InactiveCN100411157CImprove featuresImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSiluminMaterials processing

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) proceeding ball grinding disposal for Al-Si alloy powder at 5-15:1 percentage for 8-32 h; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

Preparation method of ceramic substrate high-frequency copper-clad plate

InactiveCN110053331AHigh bonding strengthImprove impact resistanceSynthetic resin layered productsLaminationMetal foilAlloy

The invention relates to a preparation method of a ceramic substrate high-frequency copper-clad plate. The preparation method includes the procedures of substrate preparation, plasma spraying of a ceramic material layer, metal foil lamination curing and the like. According to the method, plasma spraying is added in the preparation process of a traditional high-frequency copper-clad plate, the shortcomings of existing high-frequency plate preparation are overcome, a plasma spraying technology is high in efficiency, simple and unrestrained by sample piece shapes and sizes, the sprayed ceramic material layer can be effectively combined with a substrate and a metal foil, an alloy middle layer is thin and uniform, the thickness of the alloy middle layer can be adjusted, and the high-frequency copper-clad plate prepared by the preparation method is excellent in processability, high in impact resistance, good in heat resistance and mechanical property and excellent in electromagnetic shielding property.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

High heat-conductive diamond-copper composite encapsulating material and method for making same

InactiveCN101139515BImprove wettabilityEnhanced binding stateOther chemical processesMicrometerHeat transmission

The invention discloses a diamond-copper compound encapsulating material and producing methods for the material. The substrate is copper. The content of the diamond particles for improving heat transmission and increasing strength is 5-60% by weight, the grain size of the particles is 1 swung dash 150 micrometer. The additives are Cr, Ni, W, Ti, Fe, Ni, Mo, and Ta or Nb, the content is 0.1-10% byweight. Two methods are used to prepare the material: (1) Powder pre-treating, mixing, hot pressing and forming, parting and machining; (2) Powder pre-treating, mixing, pressing and forming, packing,cold equal static-pressure and hot equal static-pressure sintering, parting and machining. The material is of high heat conductivity and low heat expansion coefficient. The invention is a diamond-copper compound encapsulating material with high heat conductivity and low heat expansion coefficient.

Owner:CENT SOUTH UNIV

Preparation method of carbon fiber powder reinforced silicon nitride-based composite material

The invention belongs to the field of preparation of a silicon nitride-based composite material, and discloses a preparation method of a carbon fiber powder reinforced silicon nitride-based composite material. The liquid phenolic resin is dispersed in anhydrous ethanol; Si3N4 powder is added into an obtained solution and is stirred uniformly at 40-60 DEG C; carbon fiber powder is added into the obtained solution, and stirring is continued at 60-80 DEG C until the slurry is thick and cannot be stirred; the slurry is dried, granulated and sieved, the obtained particle powder is placed in a mold and pressed and formed to obtain a green body; the green body is covered by mixed powder of silica powder and titanium powder, and then is placed in a graphite crucible to react in vacuum of 1550 to 1650 DEG C for 1 to 3h, thus the carbon fiber reinforced silicon nitride-based composite material is obtained. The preparation method has the advantages of simple process, convenient operation and the like, the C / Si3N4 has the advantages of carbon fiber and silicon nitride at the same time, and the shortcomings of larger brittleness of Si3N4 and the like are overcome.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

A kind of graphene-copper composite material and preparation method thereof

The invention relates to a preparation method for a graphene-copper composite material. The method comprises the following steps: uniformly mixing graphene powder, MAX-phase ceramic powder and copper powder, and then performing hot-pressed sintering to obtain the graphene-copper composite material. The graphene-copper composite material prepared according to the method provided by the invention has the following advantages: (1) through the MAX-phase ceramic powder, the interface bonding state of graphene and copper matrix is improved and the problem in bonding graphene and copper is solved; (2) the prepared graphene-copper composite material has excellent mechanical properties and ductility; and (3) the method provided by the invention is simple in technical process, low in cost, convenient in design of material components and suitable for large-scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-strength modified polypropylene material and air-conditioner wind wheel made from high-strength modified polypropylene material

The invention relates to high-strength modified plastic, and discloses a high-strength modified polypropylene material. The problem that a modified polypropylene material is poor in strength and toughness is solved. The high-strength modified polypropylene material is prepared from, by mass, 90-100 parts of PP, 5-7 parts of maleic anhydride, 32-37 parts of glass fibers, 25-35 parts of zinc oxide and 15-22 parts of tetrafluoroethylene / perfluoroalkyl vinyl ether copolymer powder; the length of the glass fibers is 2 mm to 3 mm, the diameter of the glass fibers is 10 microns to 15 microns, the zinc oxide is tetrapod-like zinc oxide whiskers, the diameter of the tetrapod-like zinc oxide whiskers is 460+ / -5 nm, the length of the tetrapod-like zinc oxide whiskers is 6 microns to 8 microns, and the tensile strength and the bending strength of the tetrapod-like zinc oxide whiskers are large. The invention also discloses an air-conditioner wind wheel made from the high-strength modified polypropylene material, and the air-conditioner wind wheel is resistant to water and oil and large in tensile strength and bending strength, is not prone to deformation under high-speed rotating, and is longin service life.

Owner:宁波闻华电器有限公司

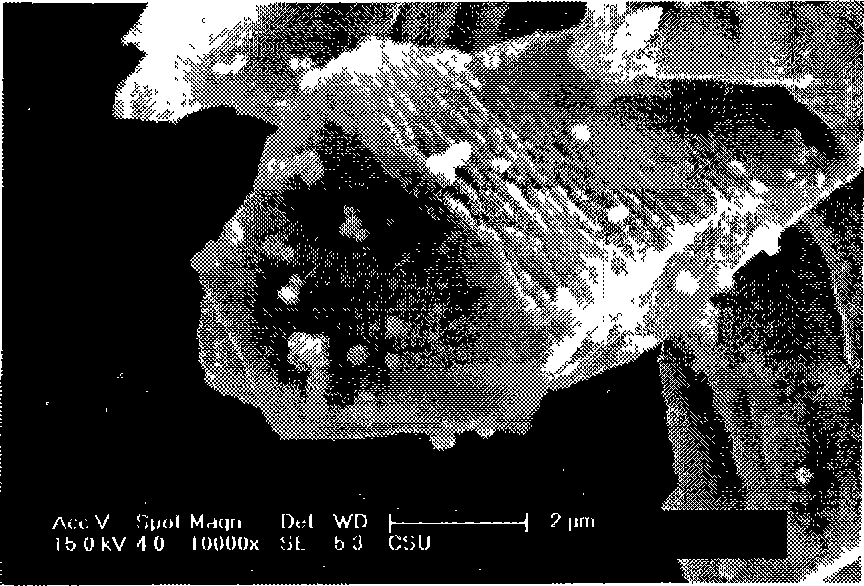

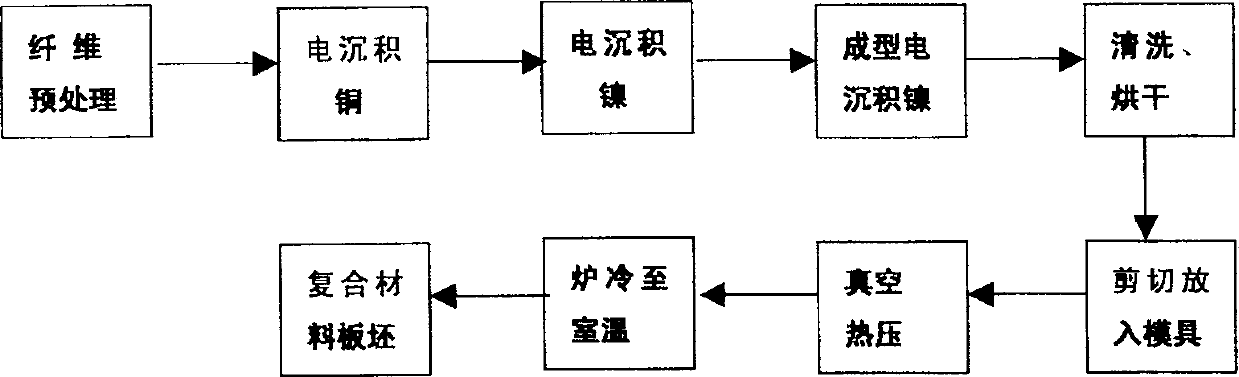

Carbon fiber reinforced nickel-based composite material and producing method thereof

The invention discloses a carbon fiber reinforced nickel-based composite material and a preparation method thereof, and relates to a metal-based composite material. The metal matrix composite materials prepared by the prior art are not suitable for parts such as steam turbines used at high temperatures. The composition and volume percentage of the composite material of the present invention are: carbon fiber: 30-35%, copper: 6-8%, nickel: 57-64%. The process steps are: carbon fiber pretreatment, copper electrodeposition, cleaning, neutralization, nickel electrodeposition, forming electrodeposited nickel, billet cleaning, drying, cutting billets into molds, vacuum hot pressing, and furnace cooling. The Cf / Ni composite material prepared by the three-step electrodeposition method in the present invention can not only meet the use requirements of gas turbine engine blades, but also has the advantages of good high temperature strength, high elastic modulus, low density, high melting point, and creep resistance. .

Owner:ZHONGBEI UNIV

High-thermal conductivity electronic packaging material and preparation method thereof

ActiveCN101615600BMeet needsImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectronChromium

The invention belongs to the technical field of electronic packaging materials, and provides a high-thermal conductivity electronic packaging material and a preparation method thereof. The packaging material comprises a reinforcement body comprising diamond grains, pure copper powder and a third component, namely chromium, molybdenum, silicon, titanium or tungsten, wherein the volume percentage of the reinforcement body is 25 to 80 percent and that of the third component is 0.01 to 10 percent. The preparation method comprises the following steps: mixing the reinforcement body, the pure copperpowder and the third component evenly in proportion, and reducing the mixture by hydrogen in a reducing furnace for 1 to 5 hours, at a temperature between 200 and 400 DEG C; feeding the mixed powder in a graphite die and treating the mixed powder by adopting a spark plasma sintering process; vacuumizing the graphite die, heating up the graphite die to between 700 and 1,100 DEG C at a rate of temperature increase of 50 to 200 DEG C / min and pressurizing the graphite die to between 20 and 50MPa; and carrying out heat preservation for 1 to 20 minutes when reaching a sintering temperature and thentaking the packaging material out for demoulding after furnace cooling.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com