Preparation method of enhanced polyacrylonitrile hollow fiber membrane

A technology of polyacrylonitrile fibers and polyacrylonitrile, which is applied in the field of preparation of reinforced polyacrylonitrile hollow fiber membranes, which can solve the problem of unsatisfactory improvement of the bonding strength between the separation layer and the transition layer, the limitation of the interface bonding strength, and the impact on the use of the membrane Life and other issues, achieve good interface bonding state, improve service life, and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method (abbreviation preparation method) of the enhanced polyacrylonitrile hollow fiber membrane (abbreviation hollow membrane) of the present invention's design, adopts following processing steps:

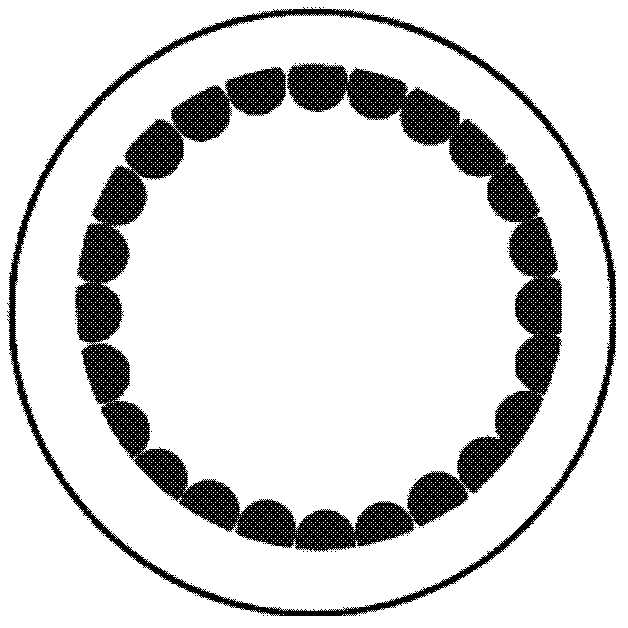

[0023] (1). Braided polyacrylonitrile fiber reinforcement; use two-dimensional weaving technology to weave polyacrylonitrile fiber into polyacrylonitrile fiber hollow braided tube (referred to as hollow braided tube), and use the hollow braided tube as the reinforcement of hollow fiber membrane Body; Described polyacrylonitrile fiber is conventional polyacrylonitrile continuous fiber (filament) or polyacrylonitrile staple fiber yarn;

[0024] (2). Prepare polyacrylonitrile casting solution; said polyacrylonitrile casting solution (casting solution for short) is prepared by mixing and dissolving polyacrylonitrile resin and additives in a solvent, and its mass fraction consists of:

[0025] Polyacrylonitrile resin 3-25%;

[0026] Solvent 50-95%;

[0027] Add...

Embodiment 1

[0042] (1) The polyacrylonitrile fiber filaments are braided into a polyacrylonitrile fiber hollow braided tube by two-dimensional weaving technology, and the breaking strength is 540.4N.

[0043] (2) polyacrylonitrile resin accounting for 11% of the total mass of the system, dimethyl sulfoxide accounting for 80% of the total mass of the system, polyvinylpyrrolidone accounting for 7% of the total mass of the system and Tween- 80 blended, dissolved evenly, and defoamed to obtain polyacrylonitrile casting solution.

[0044] (3) The hollow braided tube obtained in step (1) is infiltrated with ethanol, and the infiltration time is 1 s.

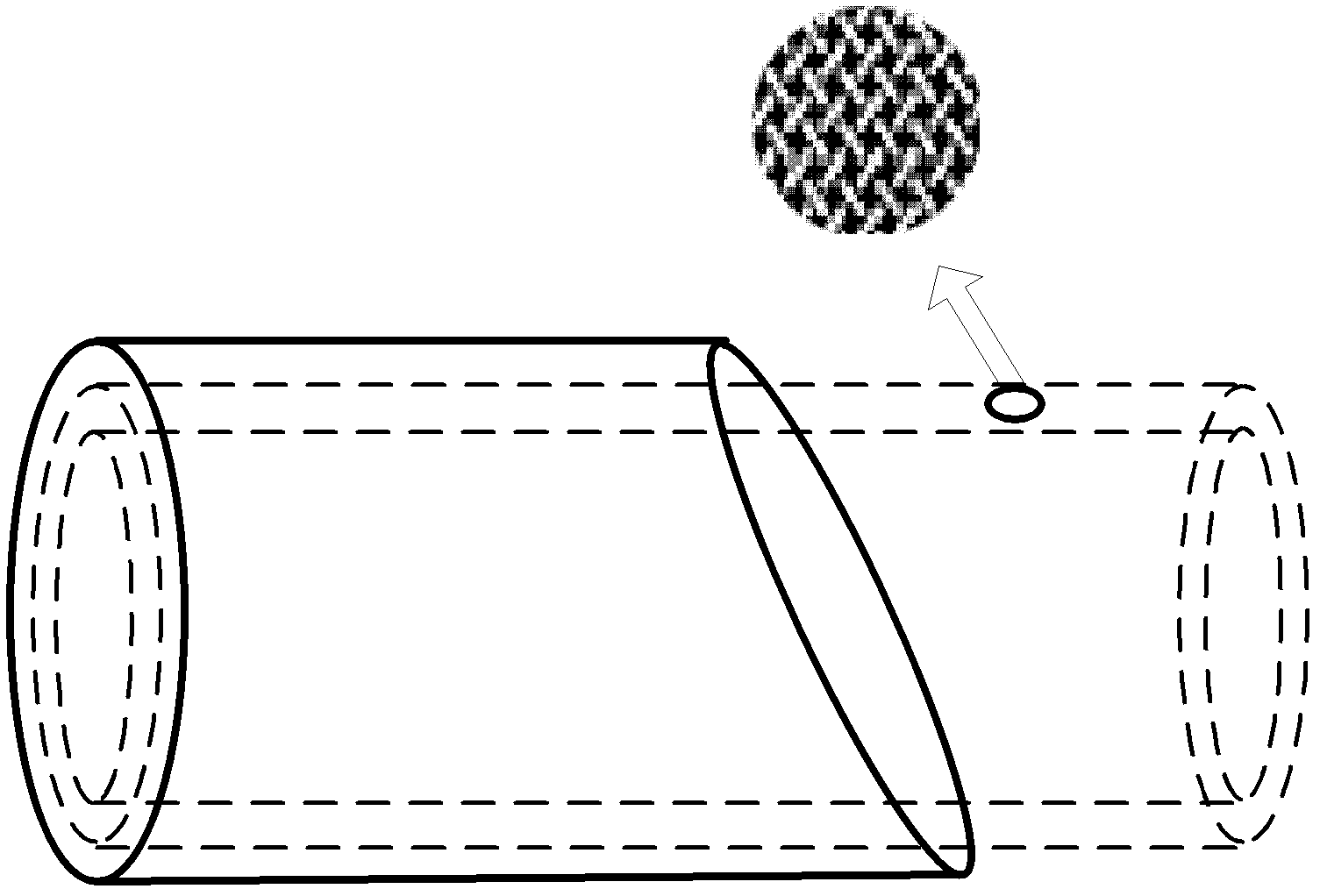

[0045] (4) According to the skin / core composite spinning process, the polyacrylonitrile fiber hollow braided tube obtained in step (3) is used as a reinforcement, and co-extruded with the polyacrylonitrile casting solution obtained in step (2) through an annular spinneret The casting liquid is evenly coated on the surface of the polyacrylonitrile...

Embodiment 2

[0048] (1) The polyacrylonitrile fiber filaments are braided into a polyacrylonitrile fiber hollow braided tube by two-dimensional weaving technology, and the breaking strength is 540.4N.

[0049] (2) polyacrylonitrile resin accounting for 12% of the total mass of the system, N,N-dimethylformamide accounting for 79% of the total mass of the system, polyvinylpyrrolidone accounting for 8% of the total mass of the system and 1% of the total mass of the system Tween-80 is blended, dissolved evenly, and defoamed to obtain polyacrylonitrile casting solution.

[0050] (3) The hollow braided tube obtained in step (1) is infiltrated with ethanol, and the infiltration time is 60 s.

[0051] (4) According to the skin / core composite spinning process, the polyacrylonitrile fiber hollow braided tube obtained in step (3) is used as a reinforcement, and co-extruded with the polyacrylonitrile casting solution obtained in step (2) through an annular spinneret The casting solution is evenly coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com