Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Mitigate Thermal Mismatch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

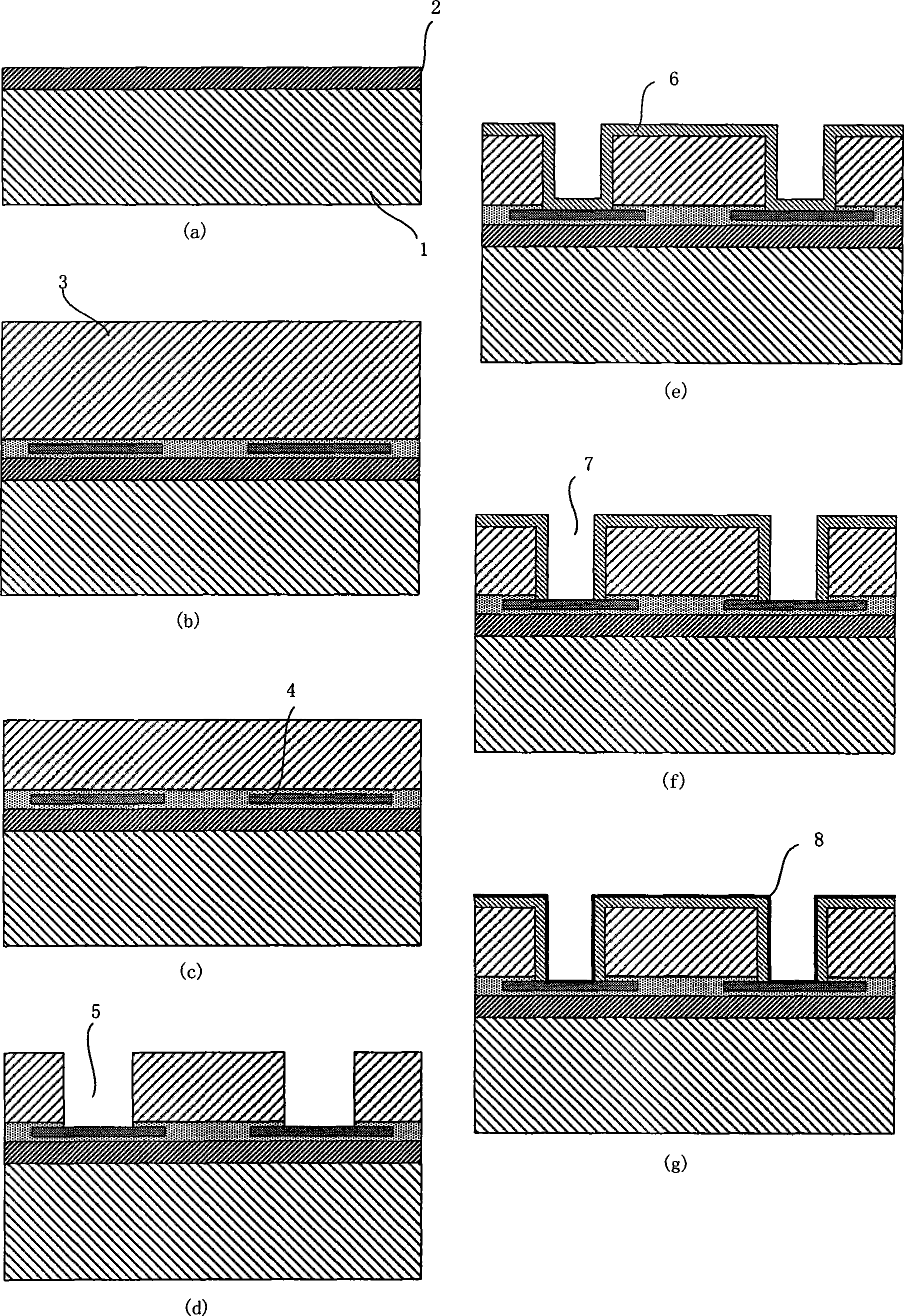

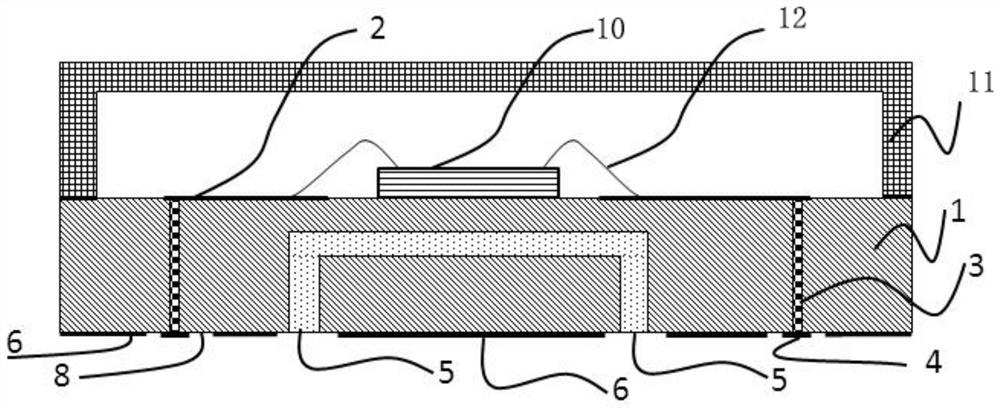

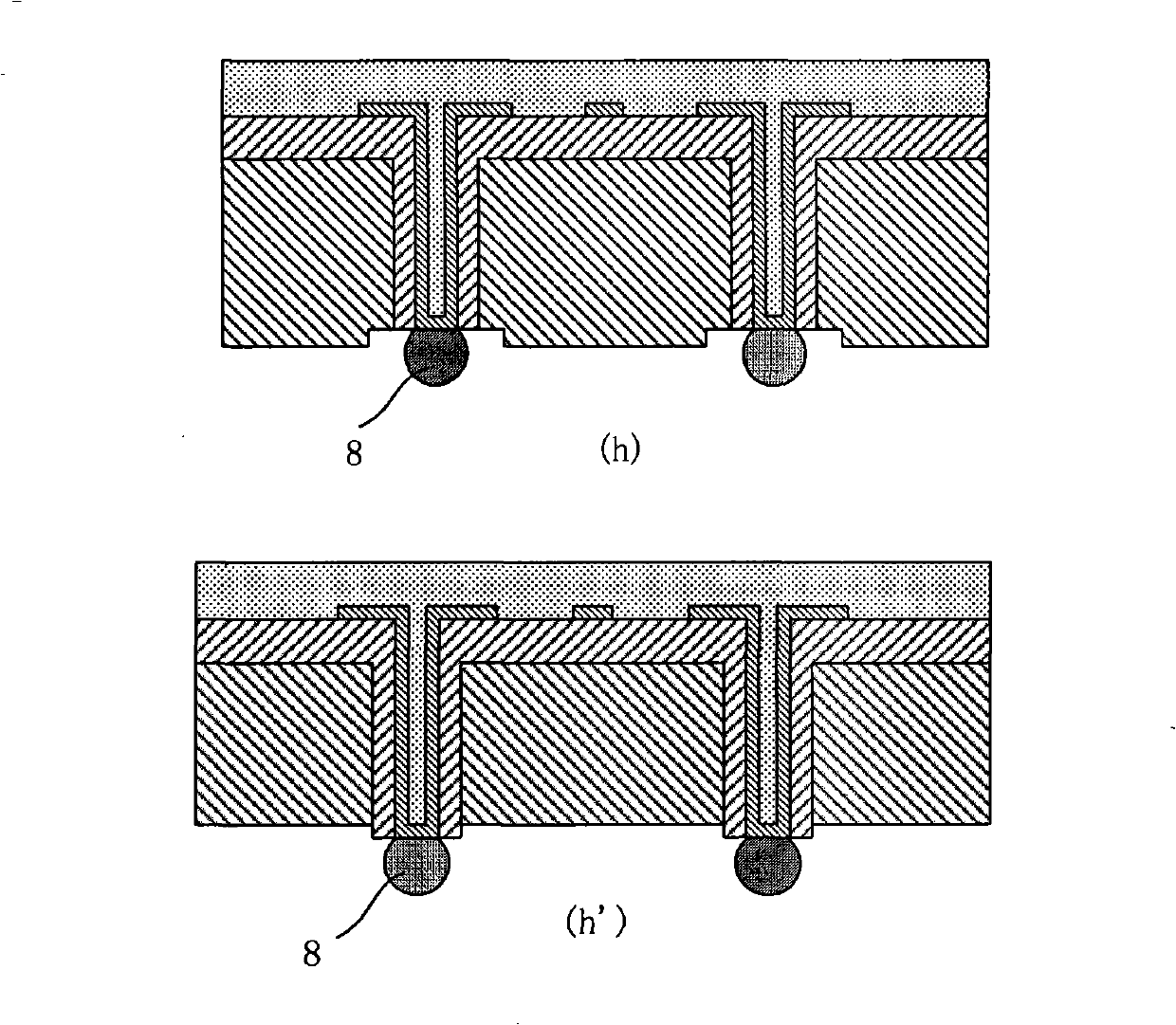

Production method for through wafer interconnection construction

ActiveCN101483149AMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParyleneParasitic capacitance

The invention discloses a through wafer interconnect structure preparation method comprising: 1. bonding a bonding silicon device wafer on a silicon wafer substrate; 2. thinning the silicon device wafer, etching the silicon device and forming a blind hole; 3. coating a layer of pattern dielectric material (such as poly-p-xylene) on the silicon device wafer; 4. etching the pattern dielectric substance layer, etching the dielectric material at the bottom of the blind hole, keeping a blind hole side wall; forming a dielectric substance hole on the substrate and enabling the dielectric substance hole and the blind hole coaxial; 5. depositing a layer of conductive material on the dielectric substance hole as a conductive layer and forming a conductive hole; 6. re-depositing a layer of pattern dielectric substance on the conductive layer; 7. forming a solder micro-convex point on the conductive layer. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance, improves a interconnect electrical behavior, suits for the RF three-dimensional interconnection structure; releases the thermal mismatch between the conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

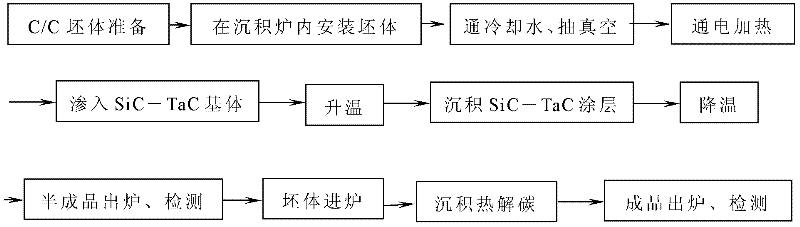

Graphite base with protective coating layer and preparation method thereof

InactiveCN101775590ANo porosityMitigate Thermal MismatchChemical vapor deposition coatingReaction chamberGraphite

The invention provides a graphite base with a protective coating layer and a preparation method thereof. The invention prepares a silicon carbide coating layer on the surface of the porous graphite base through combining the in-situ chemical gas-phase reaction permeation and the chemical gas-phase deposition two-step method. The preparation method is carried out according to the following steps: placing the a base body of the graphite base in a reaction chamber, introducing SiCl4 gas and H2 gas into the reaction chamber according to the volume ratio that SiCl4 / H2 equals to 1 / 5 to 50 under the condition of the reaction chamber temperature between 1300 and 1600 DEG C and the vacuum between 200 and 500 Pa, wherein the hydrogen flow rate is between 200 and 1000 ml / min, the gas introduction time is between 0.5 and 2 hours, and a primary SiC coating layer is permeated on the base body of the graphite base through the in-situ gas-phase reaction; and then b, introducing CH3SiCl3 gas and H2 gas into the reaction chamber according to the volume ratio that CH3SiCl3 / H2 equals to 1 / 5 to 100, controlling the hydrogen flow rate to be in a range between 200 and 1000 ml / m and the gas introduction time between 1 and 50 hours, and depositing a secondary SiC coating layer outside the surface of the primary SiC coating layer after schizolysis.

Owner:刘锡潜 +1

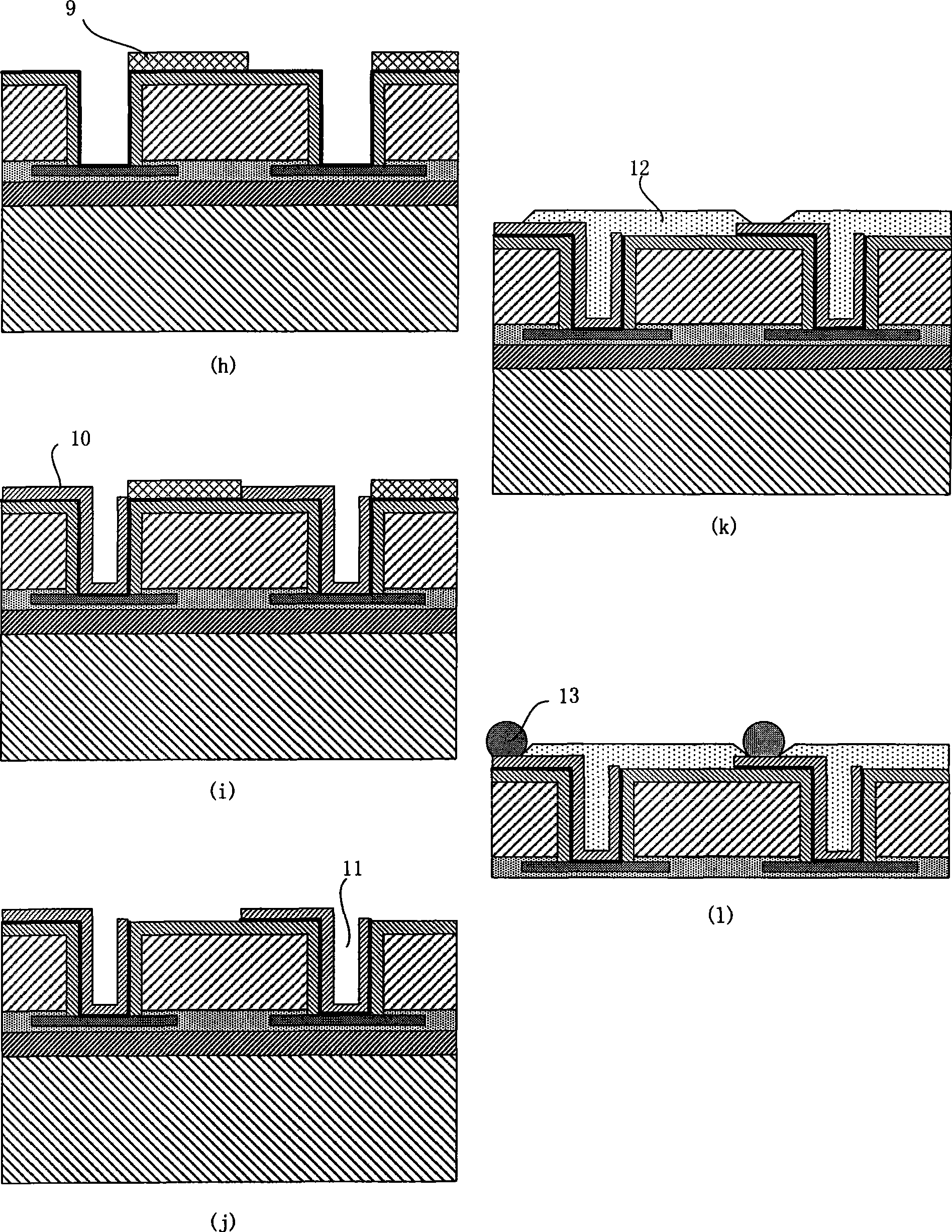

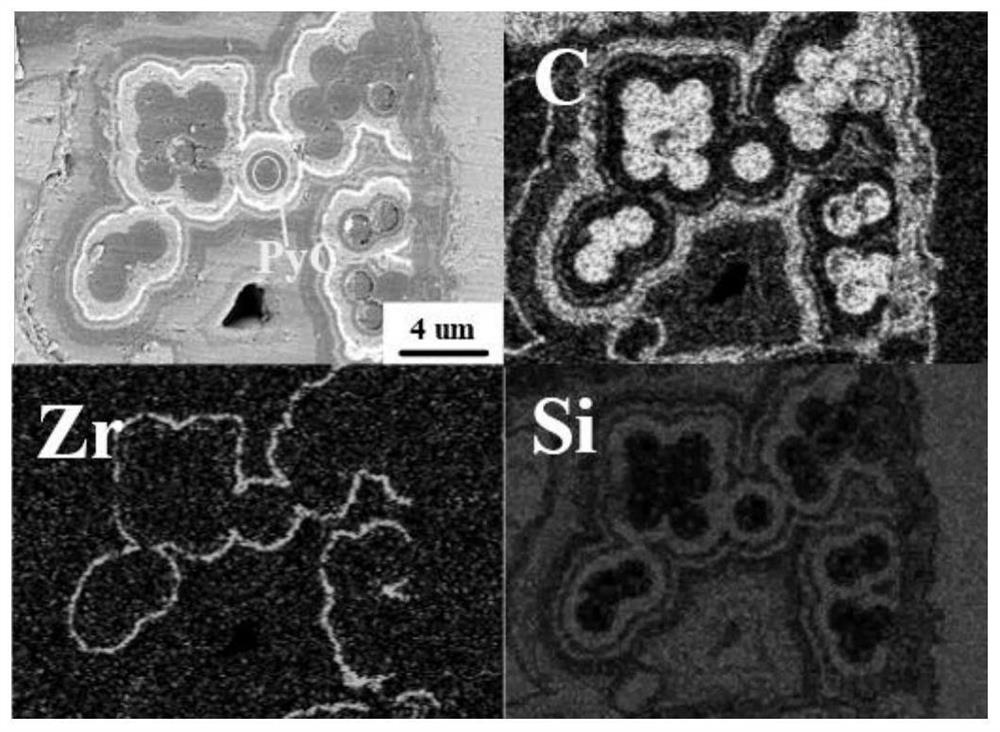

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

Method for epitaxial growth of crack-free high-crystal-quality LED epitaxial layer on metal gallium nitride composite substrate

ActiveCN106328771AAvoid decompositionMitigate Thermal MismatchSemiconductor devicesDecompositionCrack free

The invention discloses a method for epitaxial growth of a crack-free high-crystal-quality LED epitaxial layer on a metal gallium nitride composite substrate. The method comprises the steps of performing annealing treatment on the metal GaN (gallium nitride) composite substrate firstly in an N<2> atmosphere at a temperature of 750-850 DEG C at reaction chamber pressure of less than 300torr, and enabling a low-temperature GaN stress release layer with a thickness of 100-300 nanometers to be grown at a low speed of 0.2-1.0 micron / h; then enabling a high-temperature non-doped GaN buffer layer with a thickness of 1-2 microns to be grown at a variable speed linearly changed from 1 micron / h to 3 micron / h in an H<2> atmosphere at a temperature of 950-1,050 DEG C; next, enabling an n type GaN layer with a thickness of 1-2 microns to be grown at a constant growth speed; then enabling a multi-period InGaN / GaN multi-quantum-well active region to be grown in the N<2> atmosphere at a temperature of 750-850 DEG C; and next, enabling a p type AlGaN / GaN superlattice electron barrier layer and a p type GaN layer to be grown in the H<2> atmosphere at a temperature of 950-1,000 DEG C. According to the method, by optimizing parameters of carrier gas, growth temperature, growth speed and the like in the initial growth period of the metal substrate, thermal mismatch between the GaN epitaxial layer and the metal substrate can be effectively relieved to prevent decomposition of the GaN; and the high-quality GaN-based LED epitaxial layer is prepared on the metal substrate.

Owner:SINO NITRIDE SEMICON

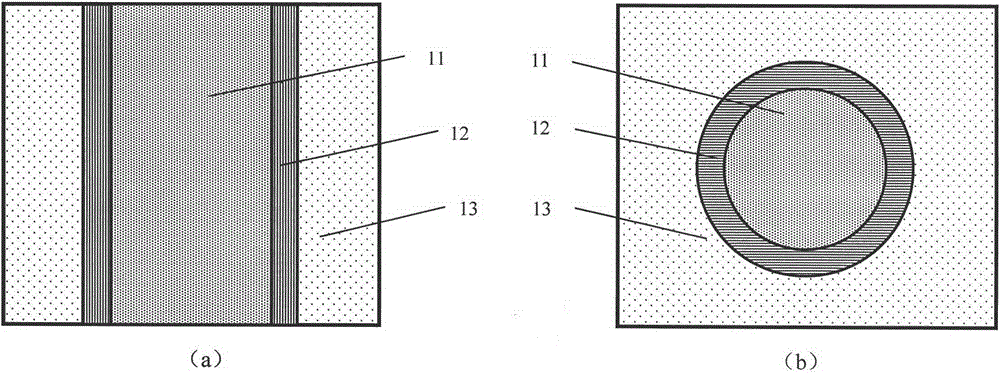

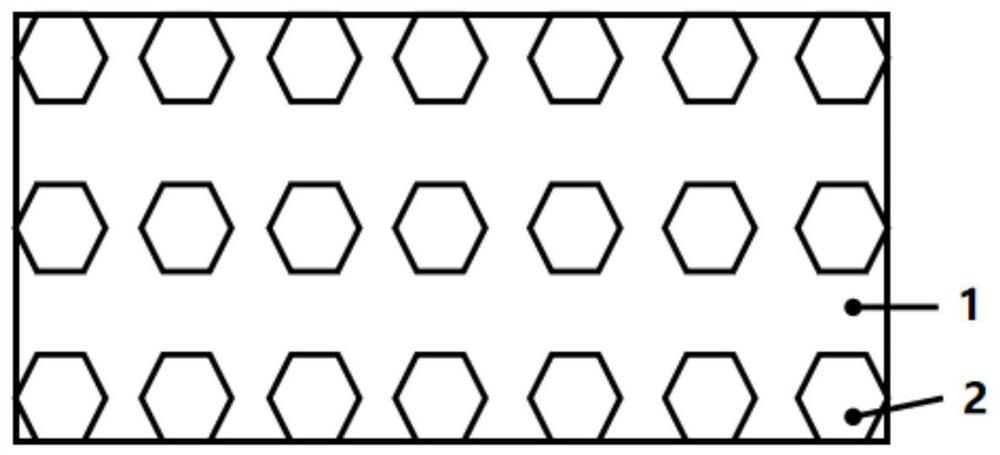

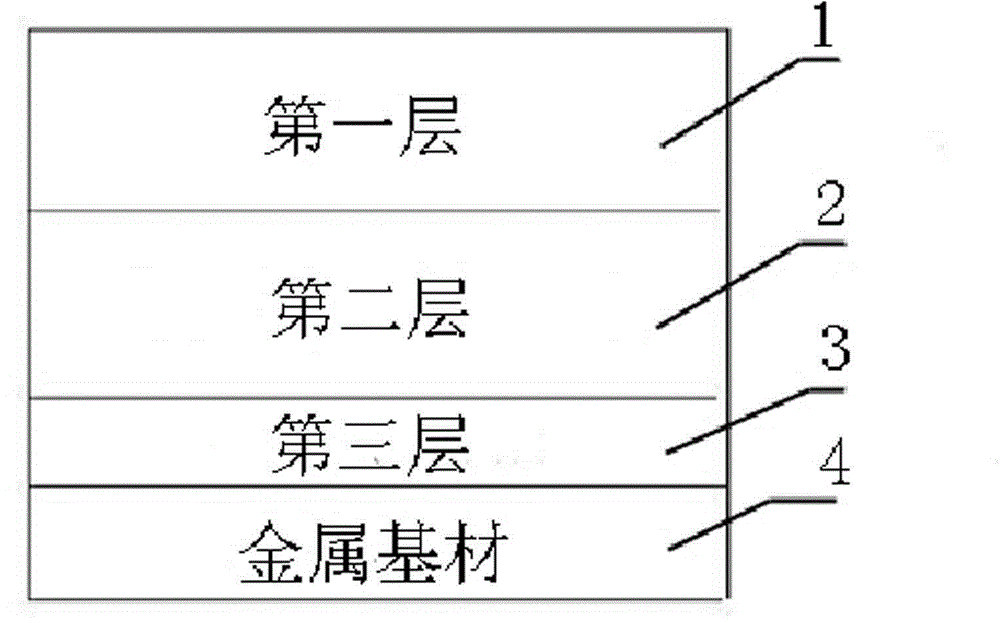

Three-layer alumina-magnesium aluminate spinel insulation coat and coating method thereof

InactiveCN103225054AEnhanced ability to withstand instantaneous high voltageMitigate Thermal MismatchMolten spray coatingMetallic oxidesPlasma sprayedHigh voltage

The invention discloses a three-layer alumina-magnesium aluminate spinel insulation coat and a coating method thereof. The composite insulation coat has a three-layer structure, the first layer is a high-purity alumina coat (1), the second layer is an alumina-magnesium aluminate spinel mixed powder coat (2), the third layer is a metallic nickel tack coat (3), and the metallic nickel tack coat (3) is sprayed on the surface of a metal substrate (4) which is a sample piece through a plasma spraying device. The three-layer alumina-magnesium aluminate spinel insulation coat is obtained through granulating and coating through plasma spraying by treating high-purity alumina having an average particle size of 45mum and magnesium aluminate spinel powder having an average particle size of 40mum (and a purity of 99) as spray powder. The three-layer alumina-magnesium aluminate spinel insulation coat has the advantages of manure preparation technology, easily available spray powder, easy adjustment of the alumina and magnesium aluminate spinel components in the medium mixed layer, large thickness, good combination performances with the substrate, and the like, and can tolerate the instant 10kV high-voltage impact.

Owner:YANSHAN UNIV

Metal ceramic matrix composite used at temperature of below 2000 DEG C for long term

The invention discloses a metal ceramic matrix composite used at the temperature of below 2000 DEG C for a long term. The metal ceramic matrix composite is characterized by being composed of inorganic fibers, an alloy wire and a ceramic matrix. The inorganic fibers are carbon fibers, boron fibers, silicon carbide fibers or mixed fibers thereof, and the diameter of the inorganic fiber is 4-8mu m. The alloy wire is a high-temperature alloy wire such as a niobium-tungsten alloy wire, a tungsten-molybdenum alloy wire or a tungsten-rhenium alloy wire and the like and mainly contains elements such as Nb, W, Mo, Re, Ni and the like, and the diameter of the alloy wire is 0.01-0.5mm. The ceramic matrix is a mixed matrix of silicon carbide, silicon carbide and carbon or a mixed matrix of zirconium carbide and carbon, wherein a preform is formed by knitting continuous carbon fibers and one or more of a chopped niobium-zirconium alloy wire, the niobium-tungsten alloy wire, the tungsten-molybdenum alloy wire, the tungsten-rhenium alloy wire and any other high-temperature alloy wires in a staggered lapping way. The modified high-temperature alloy wire is mixed with knitted carbon fibers to serve as a strengthening and toughening phase of the metal ceramic matrix composite, so that the high-performance oxidation property of a fiber material and the integral toughness of the composite are improved.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

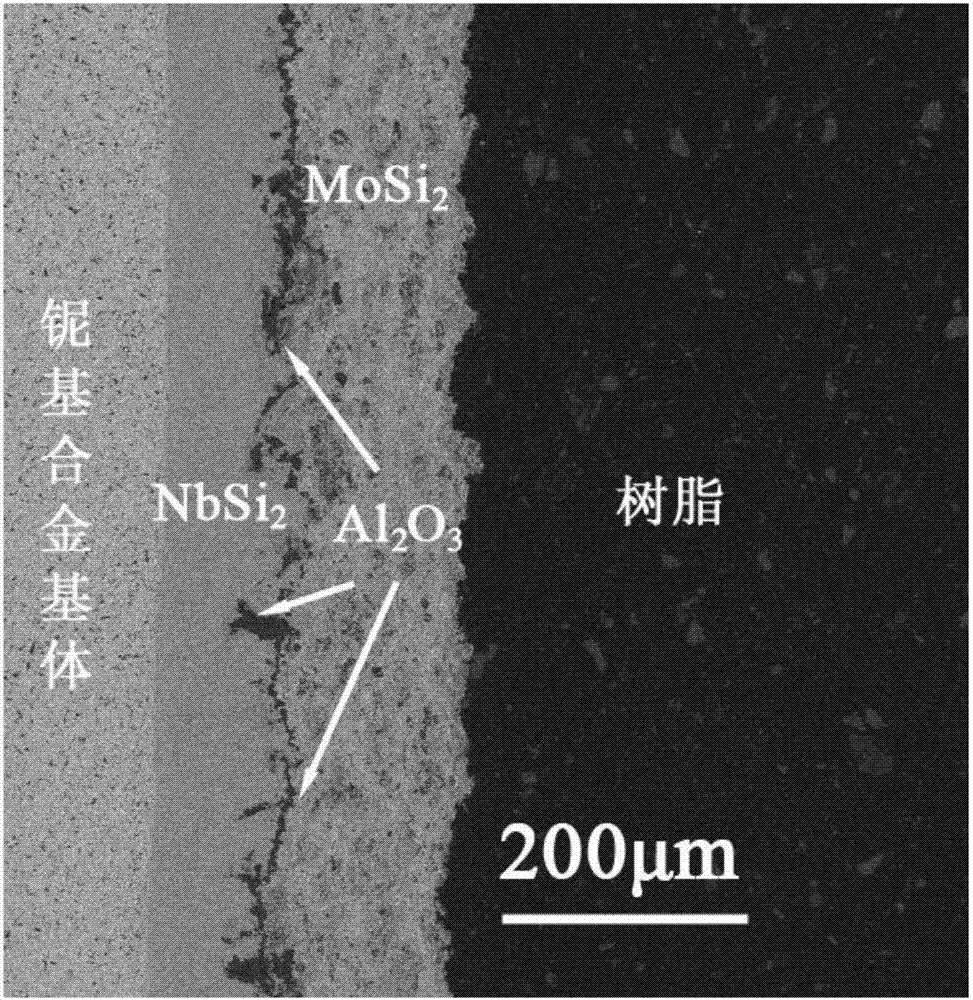

High-temperature anti-oxidization niobium alloy surface composite silicide coating and preparing method

ActiveCN107190261AImprove controllabilityEasy to prepareMolten spray coatingSolid state diffusion coatingGas phaseSand blasting

The invention relates to a high-temperature anti-oxidization niobium alloy surface composite silicide coating and a preparing method. An Nb521 alloy is subjected to acid pickling, sand blasting, ultrasonic cleaning and drying to be used later. A halide gas phase pack seepage method is used for preparing an NbSi2 inner coating containing Al2O3 adsorption particles. An atmosphere inner powder sending supersonic speed plasma spraying method is used for preparing a MoSi2 outer coating. The high-temperature anti-oxidization niobium alloy surface composite silicide coating and the preparing method have the beneficial effects that compared with the heat oxidation performance of the publicly reported niobium alloy surface protection coating, the anti-oxidization performance of the niobium base alloy at the temperature of 1,500 DEG C is obviously improved through a composite coating system prepared through roughing siliconing and heat spraying, and the service life is longer than or equal to 128 h. According to a designed Al2O3 intermediate layer, an element barrier layer can be formed at the high temperature, and the phenomenon of coating erosion due to mutual diffusion of the coating elements can be effectively prevented.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

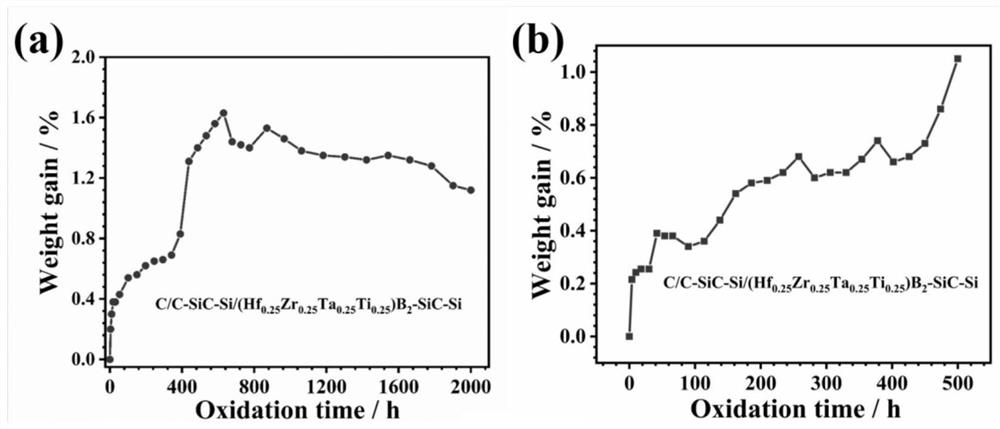

High-temperature-resistant long-service-life composite coating on surface of carbon/carbon composite material and preparation method

The invention relates to a high-temperature-resistant long-service-life composite coating on the surface of a carbon / carbon composite material and a preparation method. The (Hf0.25Ta0.25 Zr0.25Ti0.25) B2-SiC-Si / SiC-Si composite anti-oxidation coating is prepared by combining slurry dip-coating with a gas-phase siliconizing technology, a SiC-Si inner coating is used for relieving thermal mismatch between the coating and a base body, an outer layer is (Hf0.25Ta0.25Zr0.25Ti0.25) B2-SiC-Si, high-entropy ceramic is introduced into the outer coating, and a multi-element metal oxide is generated after oxidation, so that the stability of SiO2 at a high temperature is improved, and finally, long-time effective protection of the coating on the C / C composite material at the high temperature is realized. The weight of a (Hf0.25Ta0.25Zr0.25Ti0.25)B2-SiC-Si / SiC-Si composite anti-oxidation coating sample prepared by the preparation method disclosed by the invention is increased by 1.12% after the sample is oxidized for 2000h at the temperature of 1500 DEG C, and the weight of the coating sample is increased by 1.05% after the sample is oxidized for 500h at the temperature of 1700 DEG C.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

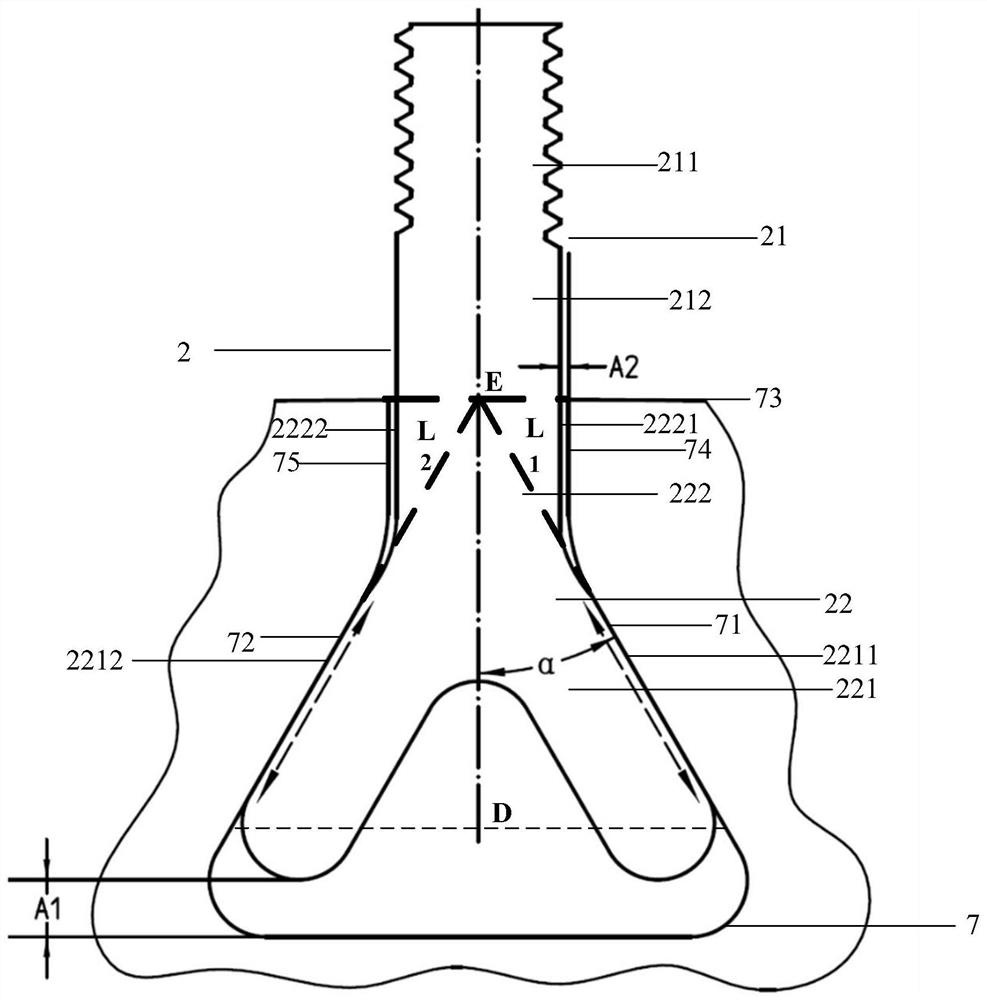

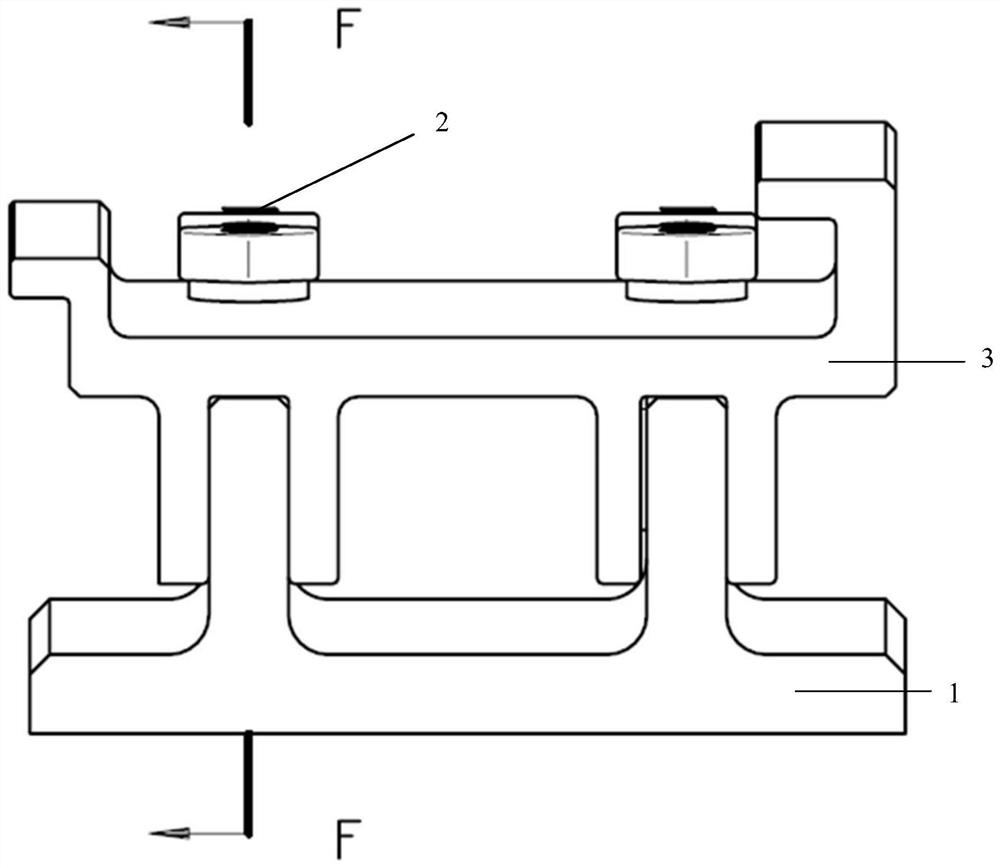

Connecting device, gas turbine engine, connecting piece and turbine outer ring

ActiveCN111622810AMitigate Thermal MismatchImprove connection strength and reliabilityEfficient propulsion technologiesStatorsPhysicsGas turbines

The invention relates to a connecting device, a gas turbine engine, a connecting piece and a turbine outer ring. The connecting device includes a first component, a second component and connecting pieces. The first component is equipped with annular ribs arranged on the outer circumference of the first component, and each annular rib is equipped with a plurality of first grooves in the circumferential direction; the second component is arranged around the outer circumference of the first component; each connecting piece includes a rod part and a block part; wherein a connecting piece is arranged corresponding to each first groove; and the block part of each connecting piece is placed in the first groove. The connecting device has the advantage of reliable connection, and the gas turbine engine has the advantage of good overall performance.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Preparation method of gallium nitride single crystal substrate

ActiveCN111769036ARelease stressMitigate Thermal MismatchFinal product manufactureSolid-state devicesWaferingLiquid state

The invention provides a preparation method of a gallium nitride single crystal substrate. The method comprises the following steps: 1) providing a sapphire substrate, and forming a gallium nitride template layer on the sapphire substrate; 2) providing a transfer substrate and a bonding layer, wherein the bonding layer can be converted between a liquid state and a solid state, and bonding the transfer substrate and the gallium nitride template layer by the bonding layer; 3) stripping the gallium nitride template layer from the sapphire substrate; and 4) converting the bonding layer into a liquid state, and carrying out epitaxial growth on the stripped gallium nitride template layer to obtain the thickened gallium nitride single crystal substrate. According to the invention, the transfer substrate and the gallium nitride template layer are bonded through the bonding layer; the bonding layer can be converted between the liquid state and the solid state, in the process of epitaxially generating a gallium nitride single crystal, the bonding layer is in the liquid state, so that the gallium nitride template layer is in a free state, stress can be effectively released, thermal mismatch can be effectively relieved, and the problems of stress accumulation and wafer warping caused in the production process are solved.

Owner:SINO NITRIDE SEMICON

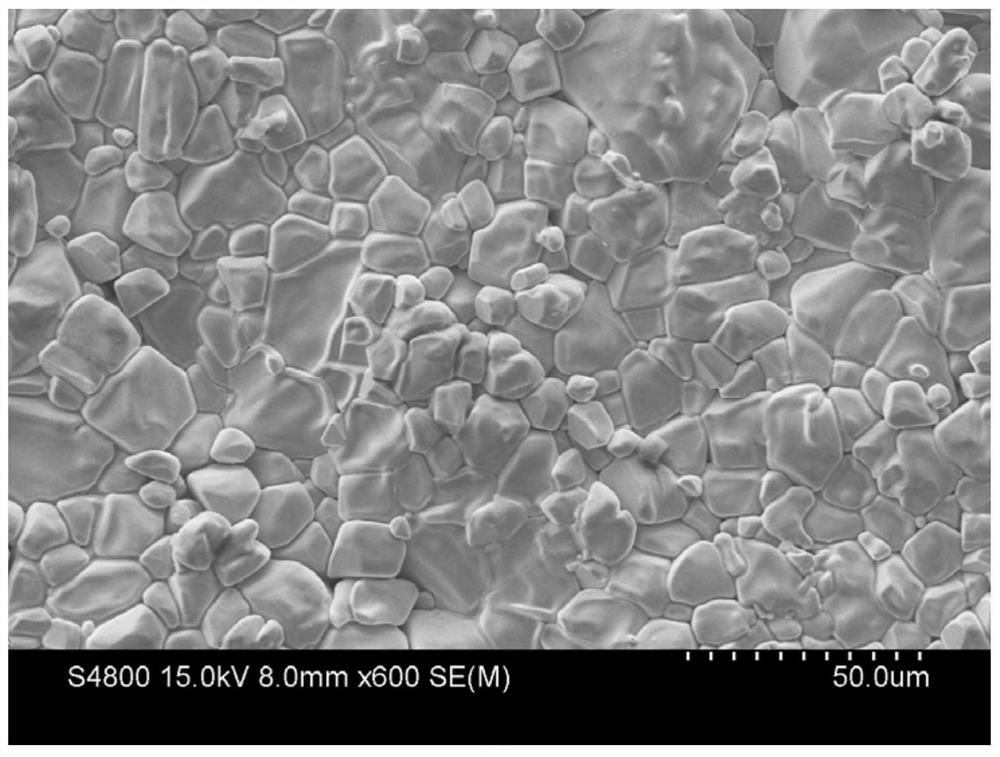

Method for carrying out spark plasma diffusion bonding on silicon carbide ceramics by adopting refractory high-entropy alloy interlayer

ActiveCN113828880AHigh strengthMitigate Thermal MismatchHeating appliancesWelding/cutting media/materialsCarbide siliconInter layer

The invention discloses a method for carrying out spark plasma diffusion bonding on silicon carbide ceramics by adopting a refractory high-entropy alloy interlayer. According to the method, a refractory high-entropy alloy TaxHfZrTi (wherein x is equal to 0.51, Ta (at.%) is equal to 14.225%, and three elements of Hf, Zr and Ti are equal in molar weight) is taken as an interlayer material, and solid-phase diffusion welding is carried out on two SiC ceramic base materials to be welded through an SPS technology, so as to obtain a SiC ceramic welding joint. According to the obtained SiC joint, a high-strength (Ta, Hf, Zr and Ti) C high-entropy ceramic phase is formed on an interface, and brittle silicide with a large thermal expansion coefficient is prevented from being generated by diffusion bonding of SiC ceramic through single refractory metal, so that thermal mismatch of the SiC joint is mitigated, the strength of the joint is improved, the maximum room-temperature shear strength of the joint is up to 326.2+ / -9.9 MPa, the hardness of the interlayer is up to 2552.1+ / -357.1 HV, and the engineering practical value in a high-temperature environment is high.

Owner:ZHEJIANG UNIV OF TECH

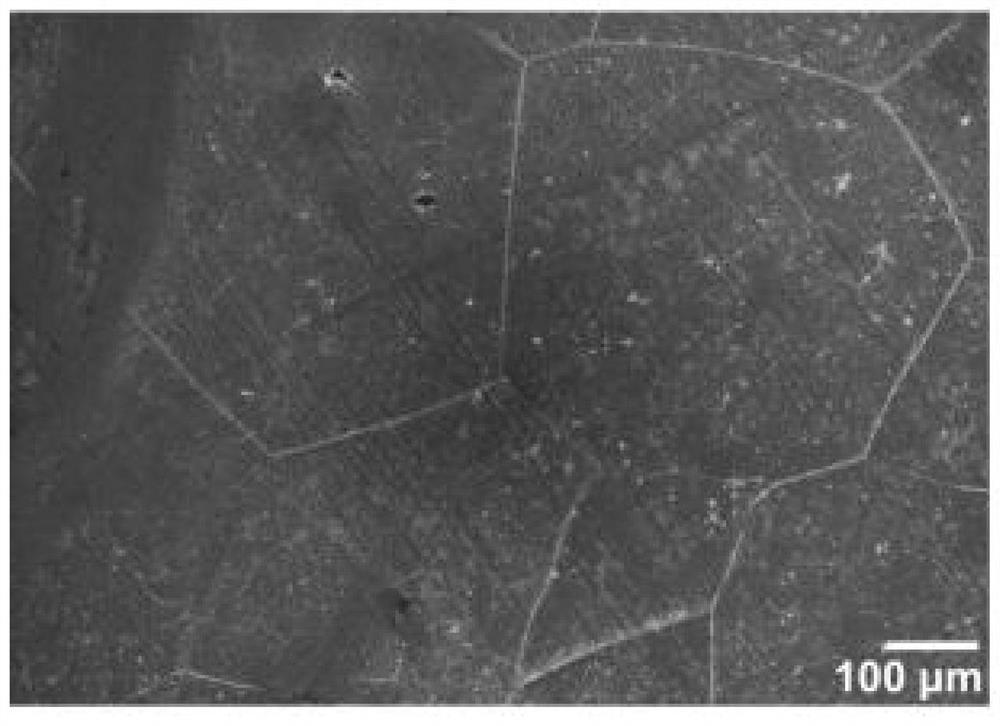

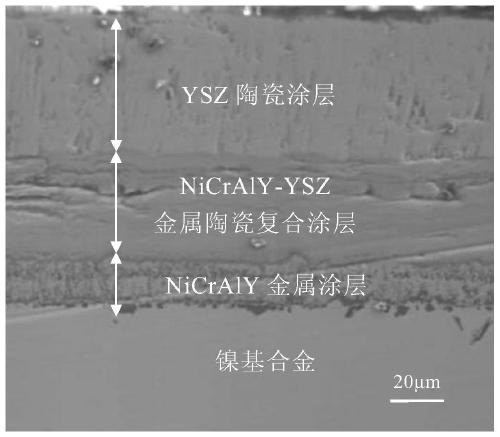

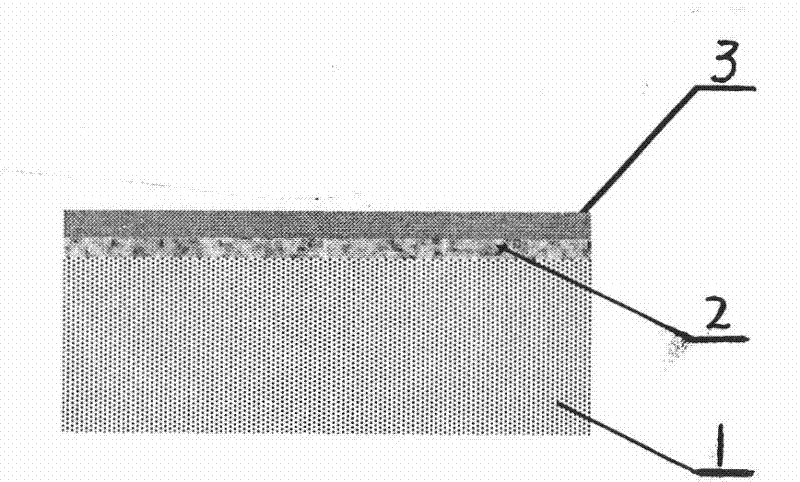

NiCrAlY/NiCrAlY-YSZ/YSZ thermal barrier coating on surface of nickel-based alloy and preparation method thereof

InactiveCN110129729AMitigate Thermal MismatchImprove thermal shock resistanceVacuum evaporation coatingSputtering coatingCeramic coatingCermet

The invention discloses a NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating on the surface of a nickel-based alloy. The NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating on the surface of the nickel-basedalloy comprises a NiCrAlY metal coating, a YSZ ceramic coating and a NiCrAlY-YSZ metal ceramic composite coating which are deposited on the surface of a nickel-based alloy in sequence, wherein the NiCrAlY-YSZ metal ceramic composite coating is located between the NiCrAlY metal coating and the YSZ ceramic coating. The invention further discloses a preparation method of the thermal barrier coating.The method comprises the steps of depositing the NiCrAlY coating, the NiCrAlY-YSZ coating and the YSZ coating on the surface of the nickel-based alloy through an electron beam physical vapor deposition method. According to the NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating on the surface of the nickel-based alloy, the thermal expansion coefficient of the NiCrAlY-YSZ metal ceramic composite coating is within the range from the thermal expansion coefficient of the NiCrAlY metal coating to the thermal expansion coefficient of the YSZ ceramic coating. The thermal mismatching performance betweenthe NiCrAlY metal coating and the YSZ ceramic coating is relieved. The thermal shock resistance of the thermal barrier coating is improved. The NiCrAlY / NiCrAlY-YSZ / YSZ thermal barrier coating providedby the invention is simple in process, good in repeatability and easy to operate.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

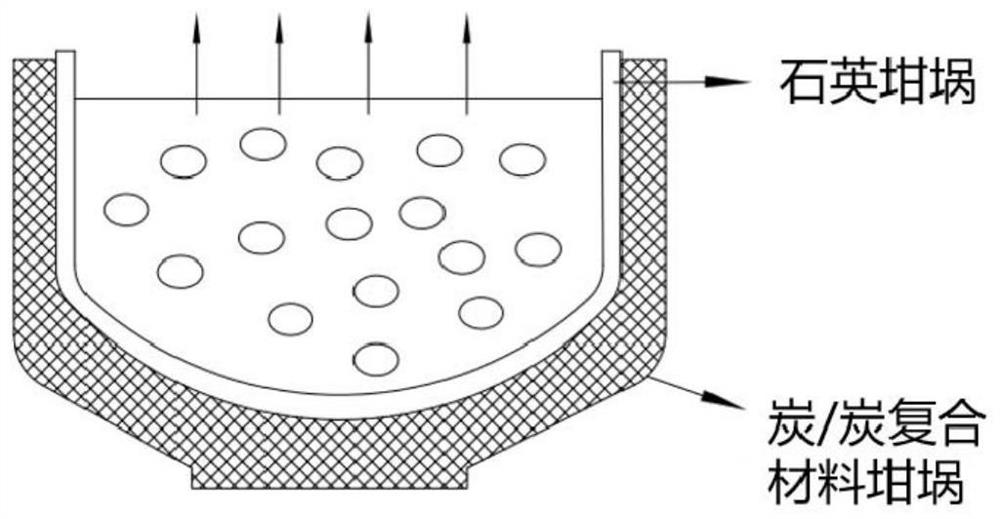

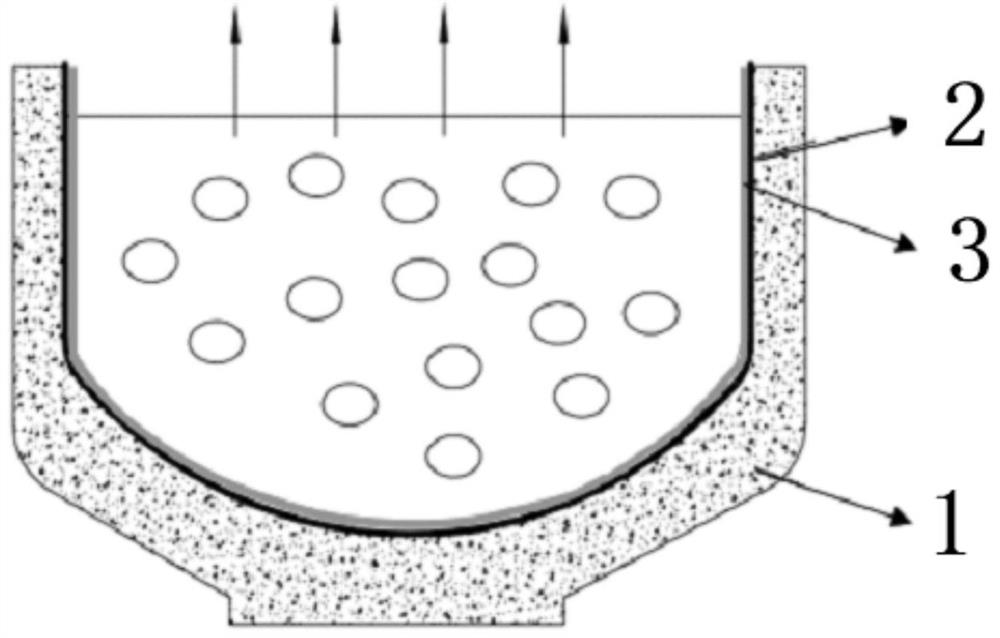

Carbon/carbon composite material crucible containing aluminum oxide coating and silicon carbide coating

ActiveCN114455982AAvoid heavy useAddress the lack ofPolycrystalline material growthBy pulling from meltCarbon compositesCarbide silicon

The invention relates to a carbon / carbon composite material crucible containing an aluminum oxide coating and a silicon carbide coating, and belongs to the technical field of thermal field parts for monocrystalline silicon drawing furnaces. The composite material crucible comprises a carbon / carbon composite material crucible body as well as a silicon carbide coating and an aluminum oxide coating which are sequentially coated on the inner surface of the crucible body, the silicon carbide coating effectively relieves thermal mismatch between the aluminum oxide coating and a matrix, impurities are not introduced into the aluminum oxide coating in a silicon melting process, the purity of a silicon material can be effectively ensured, and the service life of the composite material crucible is prolonged. The silicon carbide coating and the aluminum oxide coating are matched for use, so that excellent erosion resistance is achieved, erosion of silicon-containing steam to the composite material crucible body can be effectively avoided, the service life of the composite material crucible is further prolonged, and the requirement for pulling monocrystalline silicon is met.

Owner:XIAN CHAOMA SCI TECH

Integrated interconnection structure of self-airtight packaging function module and implementation method

ActiveCN111698824AImprove electromagnetic shielding performanceMitigate Thermal MismatchPrinted circuit assemblingElectrical connection printed elementsStructural engineeringMechanical engineering

The invention provides an integrated interconnection structure of a self-airtight packaging function module. The integrated interconnection structure comprises the self-airtight packaging function module, a structure switching layer and a system mother board, wherein the self-airtight packaging function module is welded on the system motherboard through the structure switching layer, a heat dissipation micro-channel port of the self-airtight packaging function module is connected to a micro-channel interface of the system motherboard through windowing of the structure switching layer, and theself-airtight packaging function module is in signal interconnection with the system motherboard through a BAG ball. Through the introduction of the metal structure switching layer, the BGA vertical interconnection of high / low-frequency electric signals of the self-airtight packaging function module and interface connection of a built-in micro-channel and a system heat dissipation channel are realized at the same time; high-frequency / low-frequency electrical interconnection and heat dissipation channel interface connection between the function module and an external system are integrally achieved; thermal mismatch between the function module and a system mother board is relieved through optimization of the material of the structure switching layer, the assembly strength is improved by increasing the welding area, and therefore the overall reliability of the system is improved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

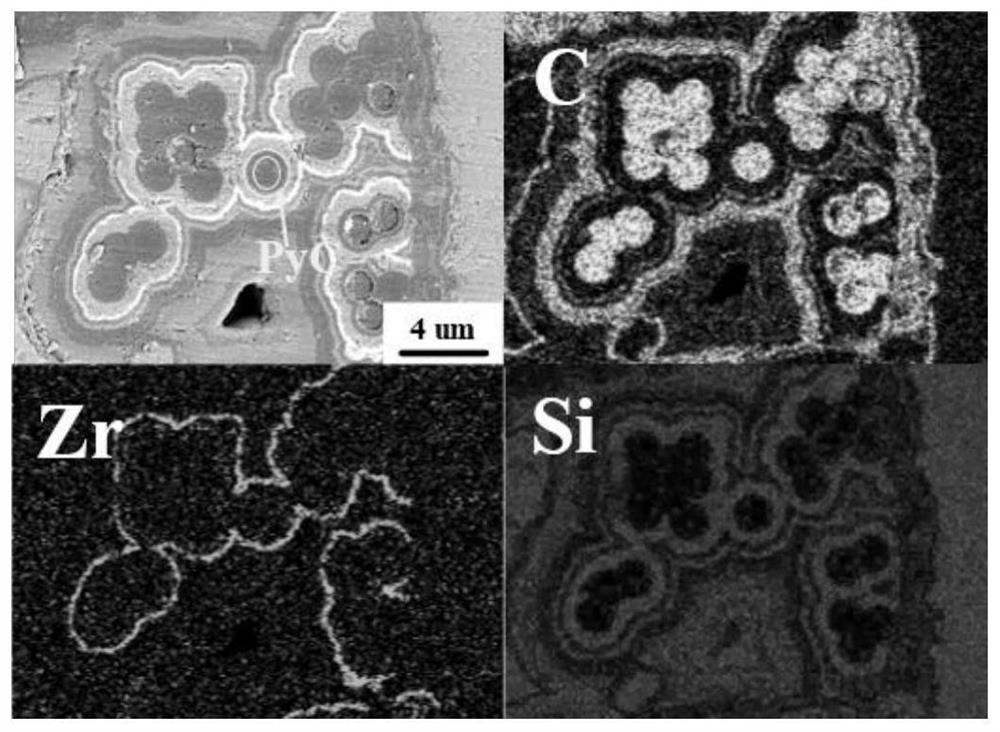

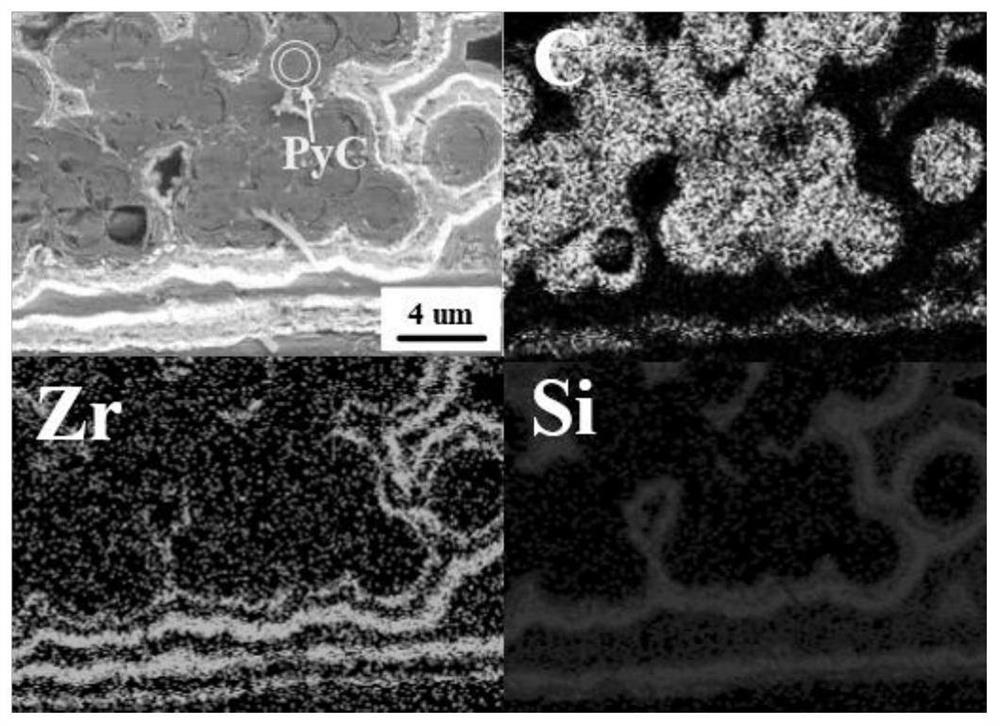

Carbon fiber reinforced ceramic matrix composite material and preparation method thereof

The invention discloses a carbon fiber reinforced ceramic matrix composite material and a preparation method thereof, and belongs to the technical field of ceramic matrix composite materials. The composite material comprises a carbon fiber layer containing a carbon interface phase, a SiC-ZrC matrix located on the carbon fiber layer and a SiC layer located on the surface of the SiC-ZrC matrix. The preparation method comprises the following steps: depositing pyrolytic carbon in carbon fiber cloth by adopting a chemical vapor deposition method to obtain a carbon fiber layer containing a carbon interface phase; alternately depositing a SiC layer and a ZrC layer on the obtained sample by adopting a chemical vapor deposition method to obtain a SiC-ZrC matrix, and then depositing a SiC layer on the surface of the matrix by adopting the chemical vapor deposition method to obtain the composite material. The carbon fiber reinforced ceramic matrix composite material provided by the invention is high in density, has good ablation resistance and mechanical properties in a low-temperature environment, and has a wide application prospect in the aspect of ceramic composite material components for high-thrust-ratio aero-engines.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Metal ceramic composite material used at temperature less than 1,200 DEG C

The invention discloses a metal ceramic composite material used at a temperature less than 1,200 DEG C. The material is characterized by comprising the following steps: firstly, weaving mixed metal wires and fibers into a preformed body, permeating a deposited interface layer on the fiber surface of the preformed body by using a CVI (Chemical Vapor Infiltration) method, and further preparing an Sic ceramic matrix by using a CVI technique so as to finally prepare the metal ceramic composite material. The preformed body is formed by weaving mixed carbon fibers with nickel-chromium-nickel-silicon alloy wires; the carbon fibers and the alloy wires can be independently woven, or can be also combined and kneaded into bundles and are subsequently woven; the interface layer consists of carbon or BN (Boron Nitride) adopting a layered structure; the thickness of the carbon interface layer is 0.1-0.3 [mu]m; the thickness of the BN interface layer is 0.3-0.5 [mu]m; the Sic ceramic matrix accounts for 30-50% of the total volume of the composite material. The layered interface layer can be used as a baffle layer, and has the functions of conducting load, deflecting crack and relieving thermal mismatch.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Novel thermal barrier coating structure and preparation method thereof

PendingCN113718188AImprove antioxidant capacityGrain refinementMolten spray coatingLaser beam welding apparatusPicosecond laserBond coat

The invention relates to the technical field of thermal barrier coatings, in particular to a novel thermal barrier coating structure and a preparation method thereof. According to the method, laser shock is conducted on a DD6 base body, then a microstructure is constructed on the surface of the DD6 base body through picosecond laser, finally, a Gd2Zr2O7 ceramic layer is sprayed on the surface through a PS-PVD technology, the technical problem that a metal bonding layer of a traditional thermal barrier coating is prone to failure can be effectively solved, and the technology is simplified.

Owner:苏州金航纳米技术研究有限公司

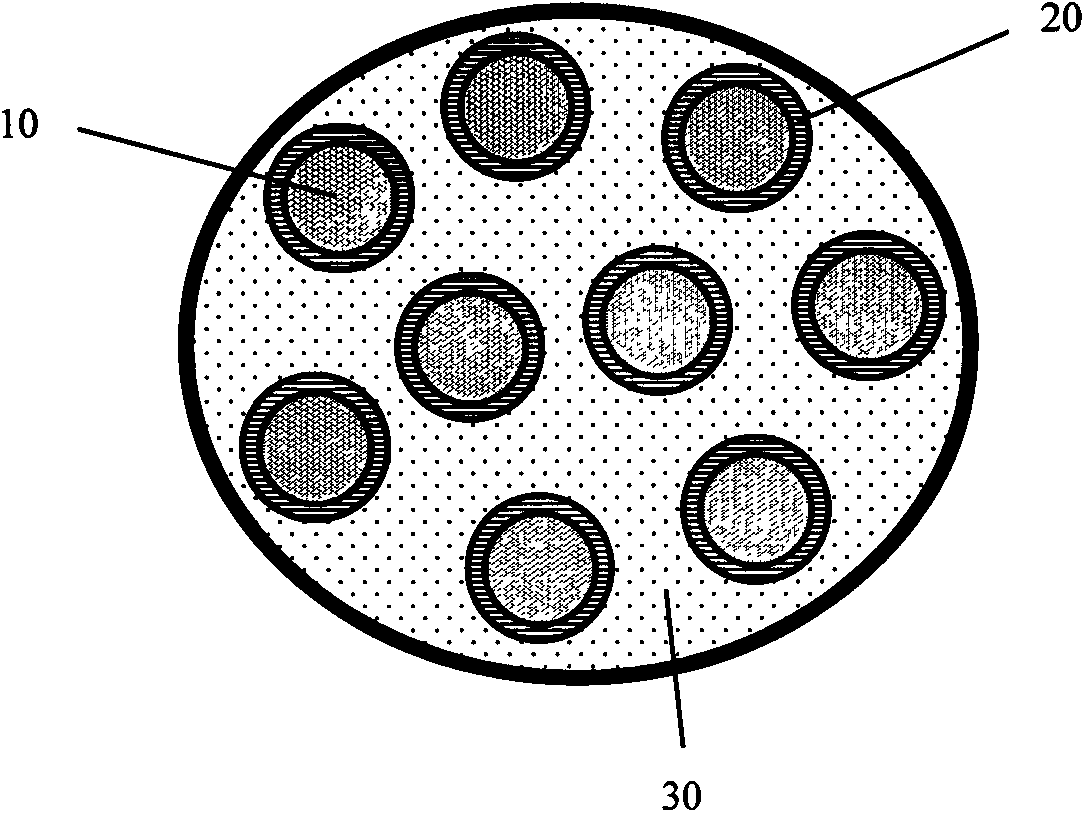

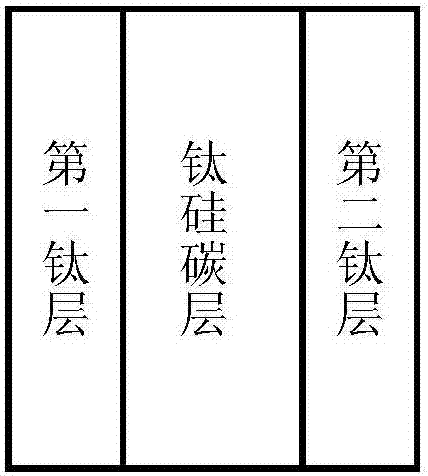

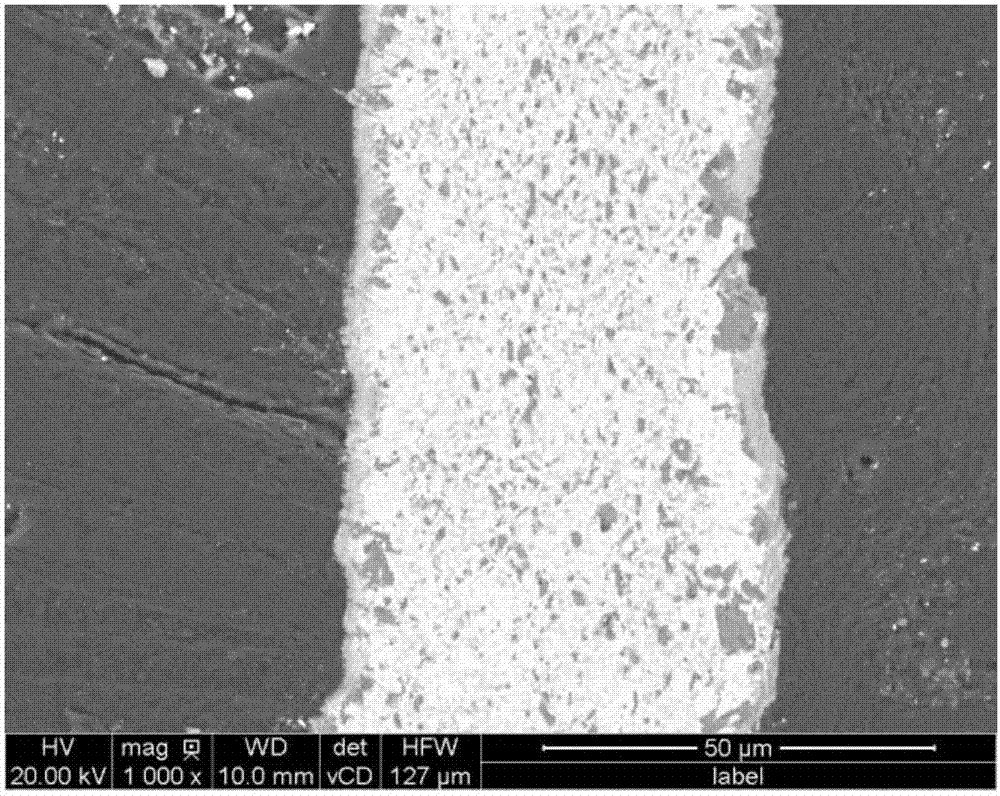

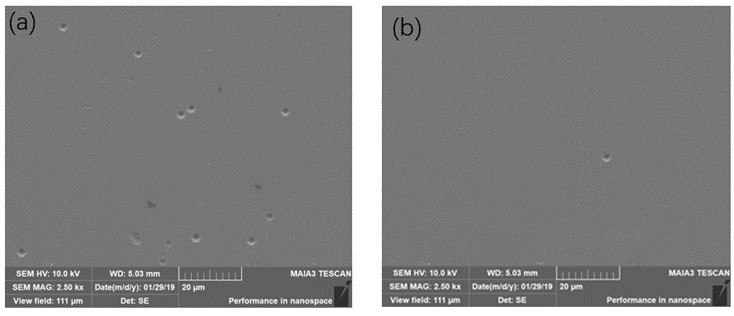

Multilayer composite film and preparation method thereof, and application of multilayer composite film as connecting material for carbon fiber-reinforced carbon composite materials

ActiveCN107487055AImprove compactnessReduce energy supplyLaminationLamination apparatusCarbon compositesCarbon fibers

The invention provides a multilayer composite film composed of nanometer titanium layers and a titanium silicon carbide layer. The multilayer composite film is applied as a connecting material for carbon fiber-reinforced carbon composite materials. The invention has the advantages that a strong interface transition layer titanium carbide is formed via a reaction of high-activity metallic titanium layers with carbon in carbon fiber-reinforced carbon composite materials, so thermal expansion mismatch between the carbon fiber-reinforced carbon composite materials and the titanium carbide layer can be effectively alleviated; the reaction is an exothermic reaction, so transient high temperature can be realized, which is beneficial for densification of a connection layer; and the titanium silicon carbide layer can alleviate the collapse failure of a connection interface at a high temperature, compensate for surface defects of the carbon fiber-reinforced carbon composite materials, reduce requirements on surface processing precision of the carbon fiber-reinforced carbon composite materials, improve production efficiency and lower production cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Composite structure AlN seed crystal for PVT and preparation and application thereof

PendingCN113957536ALow purityHigh purityPolycrystalline material growthVacuum evaporation coatingPhysical chemistryThin membrane

The invention provides a composite structure AlN seed crystal for PVT, the AlN seed crystal sequentially comprises an aluminum nitride seed wafer, a back sealing film and an AlN thick film from top to bottom, the two faces of the aluminum nitride seed wafer are polished faces, and the roughness of the back face of the aluminum nitride seed wafer is smaller than 2 nm; the back sealing film is a combination of one or more layers of any one of W, Mo, Ta, WC, TaC, BN and diamond, and is formed on the back surface of the aluminum nitride seed wafer through a coating method; and the AlN thick film covers the back sealing film through a film coating method, and the thickness of the AlN thick film is 0.5-5 mm. The invention provides a method for preparing the composite-structure AlN seed crystal and application of the composite-structure AlN seed crystal in PVT epitaxial growth of an AlN crystal. The density of various defects (cracks, dislocations and air holes) can be effectively reduced, and the crystal growth quality is improved.

Owner:ULTRATREND TECH INC

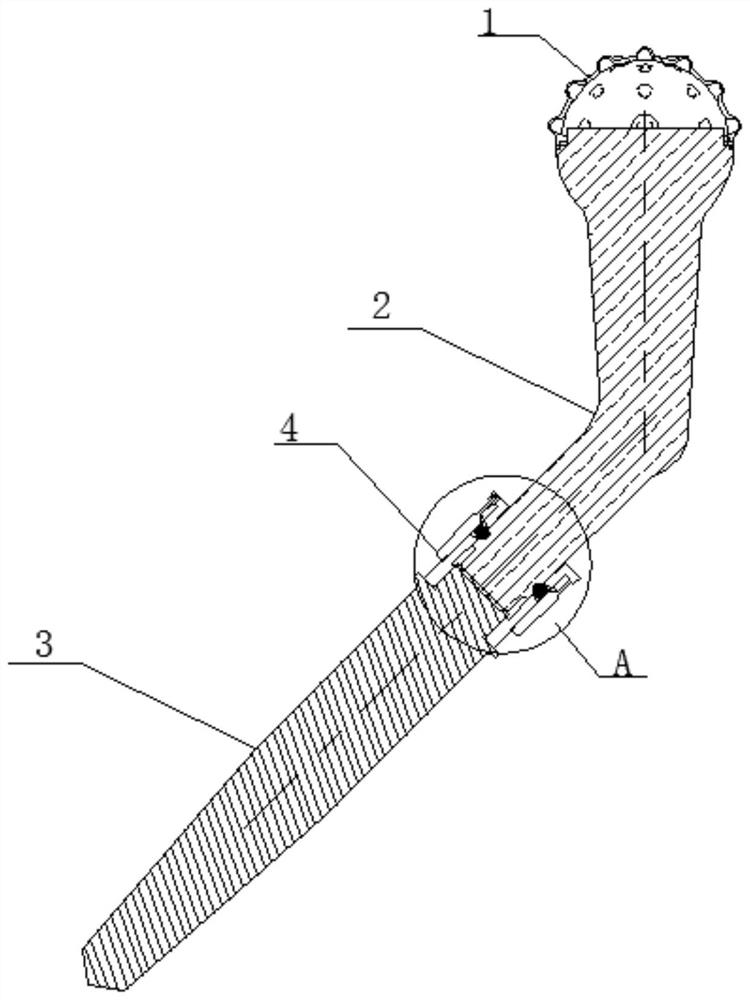

artificial hip joint

ActiveCN112998914BFirmly connectedEasy to replaceJoint implantsFemoral headsArtificial hip jointsPhysical medicine and rehabilitation

An artificial hip joint, which relates to the field of medical equipment, the present invention solves the problem that the femoral neck and the femoral stem in the existing hip joints are mostly integrated structures, and if the femoral neck breaks, it needs to be replaced as a whole; while the existing split structure , no fixed structure, the problem that the femoral neck is easily detached from the femoral stem; and the problem that the substrate coating of the current artificial hip joint has poor wear resistance. The inventive joint includes a ball, a femoral neck, an artificial femoral insert and a connecting joint. The coating is sprayed on the surface of the sphere, and the coating is composed of nano zirconia and nano hydroxyapatite. The invention is applied to the field of artificial joints.

Owner:JIAMUSI UNIVERSITY

Semiconductor HEMT device and manufacturing method thereof

ActiveCN113097163AReduces the possibility of crackingNot easy to fall offSemiconductor/solid-state device detailsSolid-state devicesCarbon filmEngineering

The invention provides a semiconductor HEMT device and a manufacturing method thereof. The semiconductor HEMT device comprises: a substrate; a heat conduction layer which is located on the surface of one side of the substrate, and comprises a plurality of supporting structures arranged at intervals and a heat conduction structure, wherein the supporting structures are located on the surface of one side of the substrate; the heat conduction structure is located on the surface, on the same side as the supporting structures, of the substrate, and gaps among the multiple supporting structures are filled with the heat conduction structure; and an insulating layer which covers the surface of the side, back to the substrate, of the heat conduction structure, and further covers the surfaces of the sides, back to the substrate, of the multiple supporting structures, wherein the heat conduction structure is a carbon film. According to the semiconductor HEMT device, through the arrangement of the heat conduction layer, stress concentration caused by thermal mismatch of the device can be reduced, and the possibility of cracking of the device is reduced.

Owner:深圳市红与蓝企业管理中心(有限合伙)

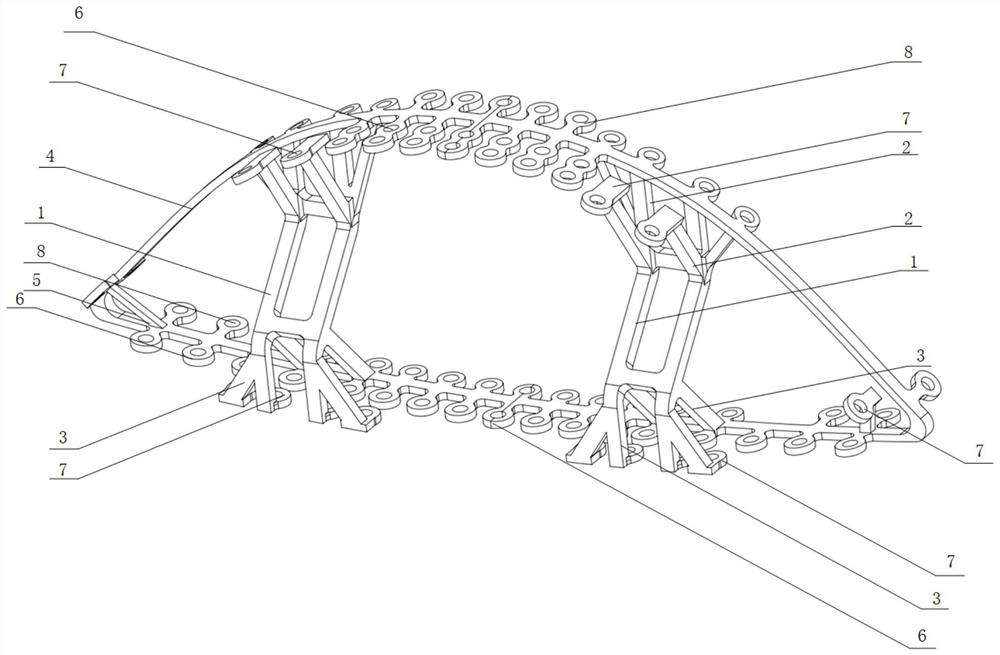

An independent arch with support for high and low temperature connection structure

ActiveCN112678148BHigh strengthImprove the ability to withstand external loadsClimate change adaptationFuselagesEngineeringBolt connection

An independent arched high-low temperature connection structure with support, which is a left-right symmetrical structure, and the left and right structures are the same, including the main supporting beams, the secondary arc supporting beams, the secondary bottom supporting beams, Arched connecting beams, end support beams, outrigger side bolt feet for support beams, outrigger side bolt tables for support beams, and outboard side bolt feet for unsupported beams. The bolt feet on the outrigger side of the supporting beam and the bolt platform on the outrigger side of the supporting beam are located at the high temperature end, and the bolt feet on the outreaching side of the unsupported beam are located at the low temperature end. Among them, the secondary supporting beam transmits the load to the primary supporting beam; the arched connecting beam is the main part of the connection, and also the main transition part of the high temperature end and the low temperature end. The present invention adopts wedge-shaped bolt connection and installation, which can effectively reduce the hot-end structure connected with the connecting piece, such as a ceramic cover, and effectively reduce the thermal mismatch phenomenon between the structures. At the same time, the support structure of the secondary beam can be added to improve the ability of the connector to withstand external force loads, and the overall strength of the high and low temperature connection structure can be enhanced.

Owner:DALIAN UNIV OF TECH +1

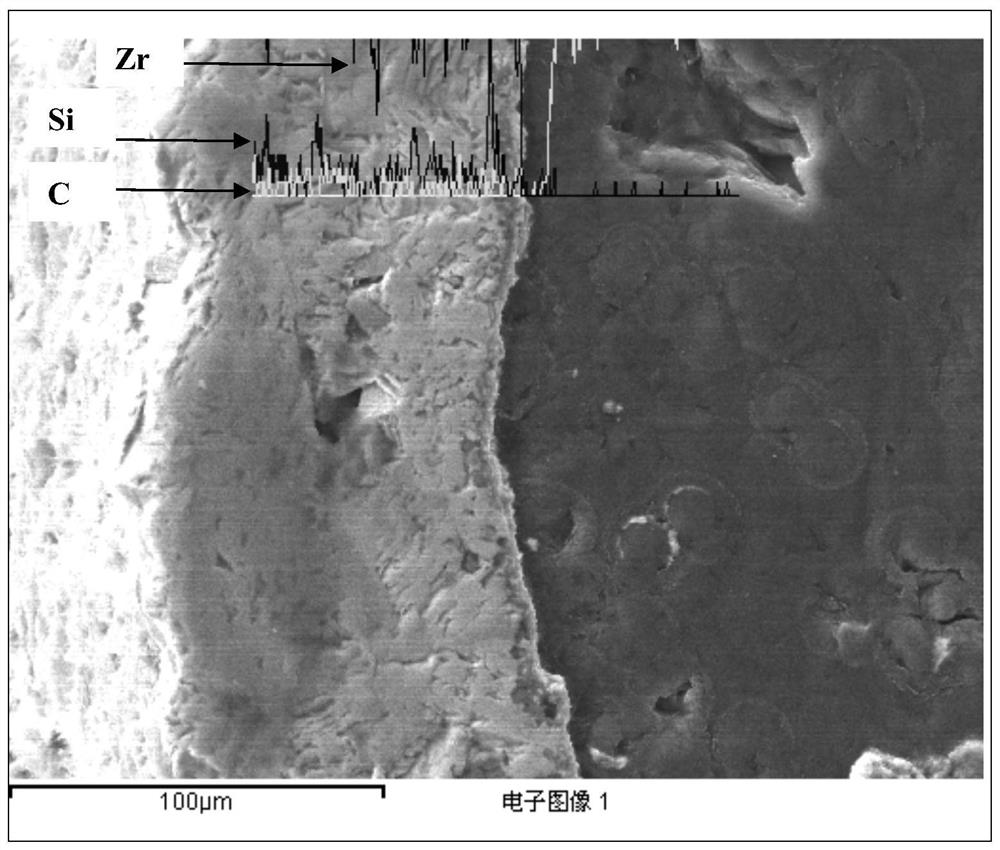

A kind of preparation method of zrc coating on the surface of c/c composite material

The invention relates to a method for preparing a C / C composite material surface ZrC coating. The method comprises the step (1) of preprocessing a C / C composite material;the step (2) of preparing an alloy raw material, and smelting the alloy raw material to obtain a Si-Zr alloy for liquid-phase reaction sintering; the step (3) of placing the liquid-phase reaction sintering alloy and the C / C composite material in a graphite crucible, and placing the graphite crucible in a high vacuum carbon tube sintering furnace; performing vacuumizing, and performing heating to a liquid-phase reaction sintering temperature for heat insulation; after the heat insulation is over, performing cooling and discharging out of the furnace, and obtaining the C / C composite material surface ZrC coating. The method is simple to operate, short in period and low in cost, the prepared ZrC coating and a base body are high in bonding strength, and the thermal cycle resistance and impact resistance properties are good.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

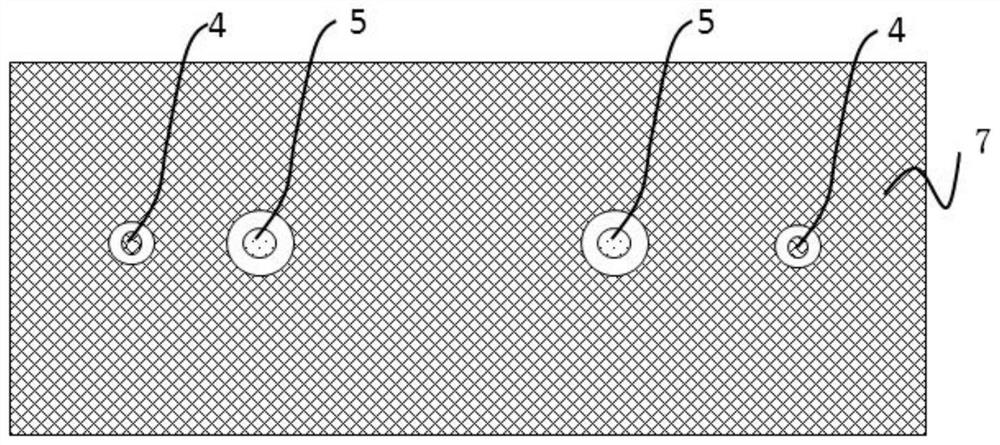

Process for treating silicon through-hole interconnection construction

ActiveCN101483150BMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParasitic capacitanceInterconnection

The invention discloses a through wafer interconnect structure processing method comprising: 1. etching a blind hole on a substrate; 2. etching a pattern dielectric substance layer on the substrate; 3. etching the pattern dielectric substance layer and the dielectric material at the bottom of the blind hole, keeping the dielectric material of a blind hole side wall; forming a dielectric substancehole on the substrate; 4. depositing a layer of conductive material on the dielectric substance hole and forming a conductive hole; 5. re-depositing a layer of pattern dielectric substance on the conductive layer and filling the conductive hole; 6. etching the back side of the plate to expose the conductive layer and forming a solder micro-convex point on the conductive layer, wherein the patterndielectric substance material is preferable poly-p-xylene. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance by using two layers of the pattern dielectric substance layers, improves a interconnect electrical behavior, suits for the high speed and RF three-dimensional interconnection structure; releases the thermal mismatch betweenthe conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

Three-layer alumina-magnesium aluminate spinel insulation coat and coating method thereof

InactiveCN103225054BEnhanced ability to withstand instantaneous high voltageMitigate Thermal MismatchMolten spray coatingMetallic oxidesPlasma sprayedMetallic substrate

Owner:YANSHAN UNIV

Graphite base with protective coating layer and preparation method thereof

InactiveCN101775590BNo porosityMitigate Thermal MismatchChemical vapor deposition coatingGas phaseGraphite

The invention provides a graphite base with a protective coating layer and a preparation method thereof. The invention prepares a silicon carbide coating layer on the surface of the porous graphite base through combining the in-situ chemical gas-phase reaction permeation and the chemical gas-phase deposition two-step method. The preparation method is carried out according to the following steps: placing the a base body of the graphite base in a reaction chamber, introducing SiCl4 gas and H2 gas into the reaction chamber according to the volume ratio that SiCl4 / H2 equals to 1 / 5 to 50 under thecondition of the reaction chamber temperature between 1300 and 1600 DEG C and the vacuum between 200 and 500 Pa, wherein the hydrogen flow rate is between 200 and 1000 ml / min, the gas introduction time is between 0.5 and 2 hours, and a primary SiC coating layer is permeated on the base body of the graphite base through the in-situ gas-phase reaction; and then b, introducing CH3SiCl3 gas and H2 gas into the reaction chamber according to the volume ratio that CH3SiCl3 / H2 equals to 1 / 5 to 100, controlling the hydrogen flow rate to be in a range between 200 and 1000 ml / m and the gas introduction time between 1 and 50 hours, and depositing a secondary SiC coating layer outside the surface of the primary SiC coating layer after schizolysis.

Owner:刘锡潜 +1

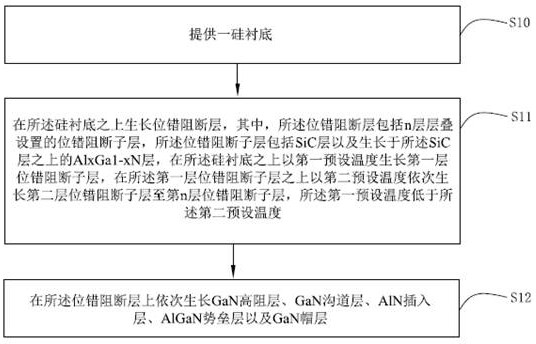

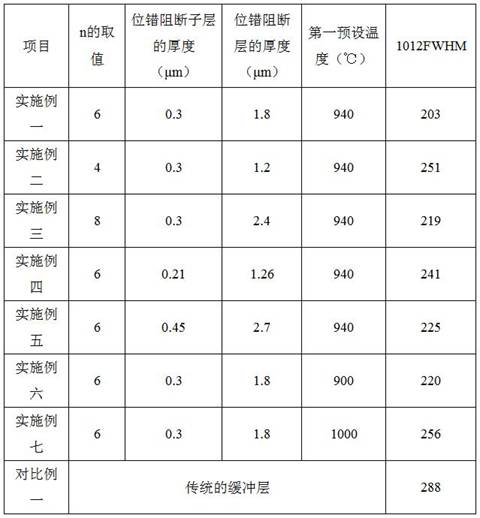

Gallium nitride-based high electron mobility transistor and preparation method thereof

ActiveCN114759082AImprove crystal qualityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryThin membrane

The invention discloses a gallium nitride-based high-electron-mobility transistor and a preparation method thereof, and the gallium nitride-based high-electron-mobility transistor comprises a silicon substrate, and also comprises a dislocation blocking layer, a GaN high-resistance layer, a GaN channel layer, an AlN insertion layer, an AlGaN barrier layer and a GaN cap layer which are sequentially stacked on the silicon substrate. Wherein the dislocation blocking layer comprises n layers of dislocation blocking sub-layers which are arranged in a stacked mode, and each dislocation blocking sub-layer comprises a SiC layer and an Al < x > Ga < 1-x > N layer arranged on the SiC layer. The silicon substrate and the gallium nitride thin film are provided with traditional buffer layers in the prior art, the crystal quality improvement amplitude of the gallium nitride thin film is limited, and a large number of dislocation and defects exist; and the performance of the gallium nitride-based high-electron-mobility transistor is influenced.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

A high-strength hole saw and its manufacturing method

ActiveCN113199209BImprove corrosion resistanceImprove wear resistanceVacuum evaporation coatingSputtering coatingCyclic testHole saw

Owner:无锡蓬天工具有限公司

Method for infiltrating tungsten carbide on the surface of carbon material

The invention provides a method for infiltrating tungsten carbide on the surface of carbon material, which is characterized in that high temperature heat treatment is conducted to the carbon material on which a thinner tungsten coating layer is deposited; and the heat treatment process comprises the following steps: firstly carrying out heat preservation for a period of time at the lower temperature and then carrying out heat preservation for a period of time at the higher temperature again. After the completion of heat treatment, a thinner tungsten coating layer is deposited on the surface of the material again, and then the heat treatment in the identical process is conducted to the material again. The processes are performed for 3 to 5 times, namely the tungsten carbide can be infiltrated on the surface of the carbon material. The preparation of the tungsten carbide on the surface can preferably select the methods such as chemical gas phase deposition, physical gas phase depositionand after-glow plasma. The tungsten carbide is infiltrated on the surface of the carbon material by adopting the high temperature heat treatment method; a tungsten element is transited from the surface of the carbon material in a tapered manner from inside to outside, so that the thermal mismatching of the tungsten carbide and the carbon material is effectively relieved, and a coating layer and abase body are combined stably.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of carbon fiber reinforced ceramic matrix composite material and preparation method thereof

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com