Metal ceramic matrix composite used at temperature of below 2000 DEG C for long term

A metal-ceramic matrix and composite material technology, applied in the field of composite materials, can solve problems such as performance degradation, and achieve the effects of small residual stress, complex shape and high simplification of coating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

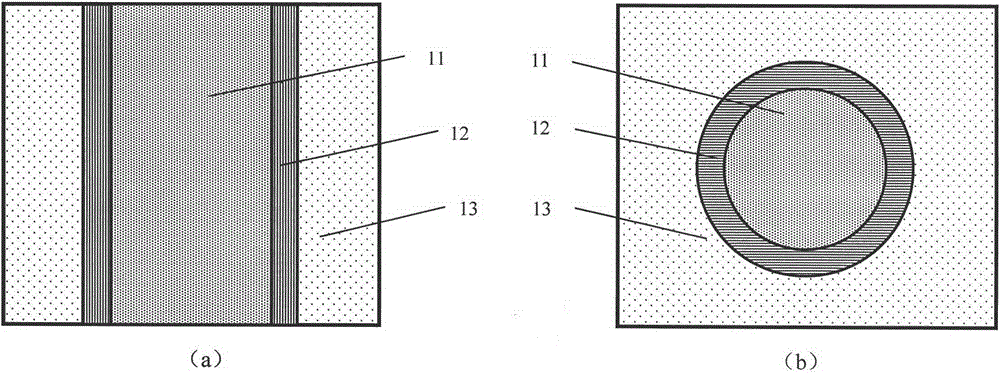

[0021] 30% of the carbon fiber with a diameter of 5 μm and 70% of the chopped niobium-tungsten alloy wire with a length of 10 cm are plied and twisted in the form of staggered lap joints. The diameter of the alloy wire is distributed within the range of 10 μm to 100 μm. The twisted fiber is woven into a three-dimensional preform, and the total fiber content is controlled to 50%; the molybdenum silicide anti-oxidation coating and the carbon interface layer are successively prepared by the CVI method, and the relevant process parameters are controlled so that the thickness of the molybdenum silicide anti-oxidation coating is 0.5 μm , The thickness of the interface layer is 0.3 μm; then in the same CVI equipment, trichloromethylsilane is used as the precursor, and SiC is decomposed under appropriate conditions to fill the gaps of the preform densely to form a metal-ceramic composite material.

Embodiment 2

[0023] 40% of the boron fibers with a diameter of 7 μm and 60% of the chopped niobium-tungsten alloy wires with a length of 6 cm are plied and twisted in the form of staggered lap joints. The diameters of the alloy wires are distributed within the range of 1 μm to 50 μm. The twisted fiber is woven into a three-dimensional preform, and the total fiber content is controlled to 70%; firstly, palladium is infiltrated into the alloy wire of the preform through double-glow plasma technology, and the infiltrated element content is controlled at about 1%, and then BN is prepared by the CVI method The thickness of the interface layer is controlled to be 0.5 μm; and then the silicon carbide and carbon mixed ceramic matrix is prepared by the CVI method, and finally a cermet matrix composite material is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com