Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Reduce thermomechanical stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

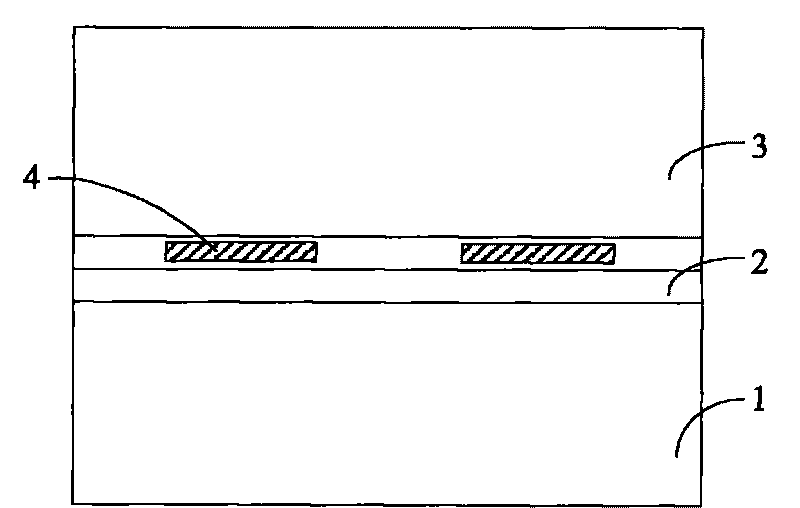

Direct bumping on integrated circuit contacts enabled by metal-to-insulator adhesion

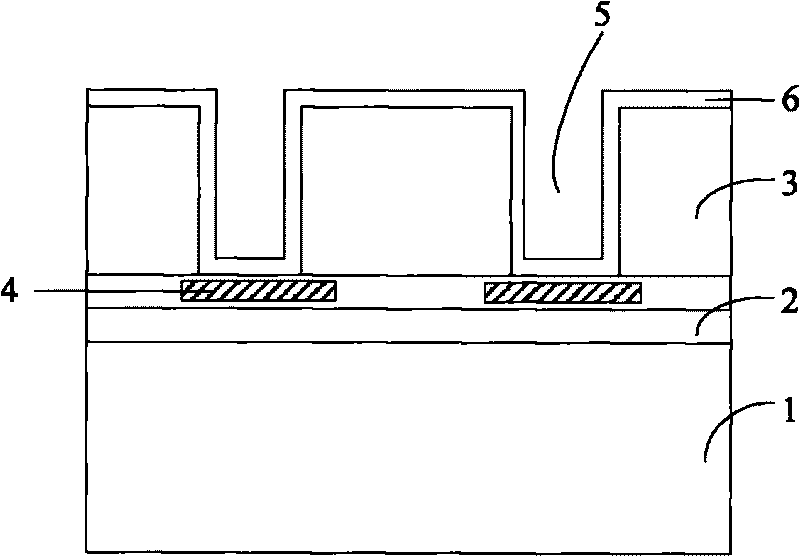

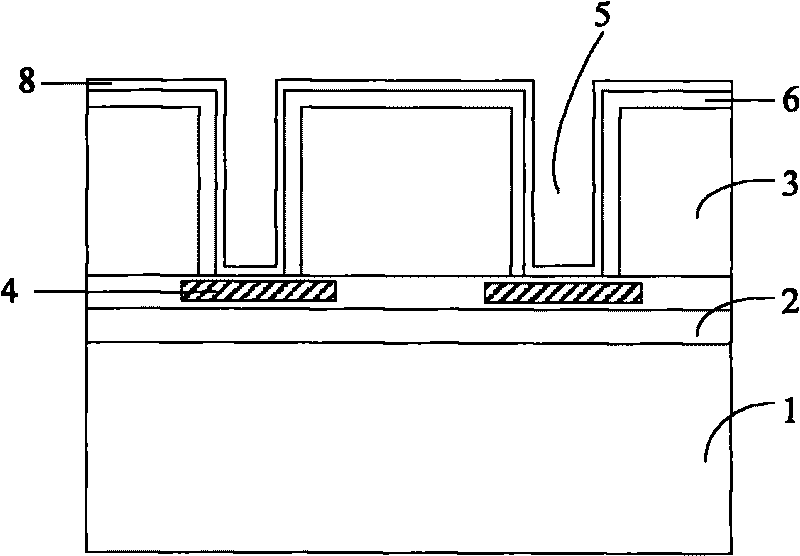

InactiveUS20050082685A1Less crowdedSmall sizeSemiconductor/solid-state device detailsSolid-state devicesContact padDevice material

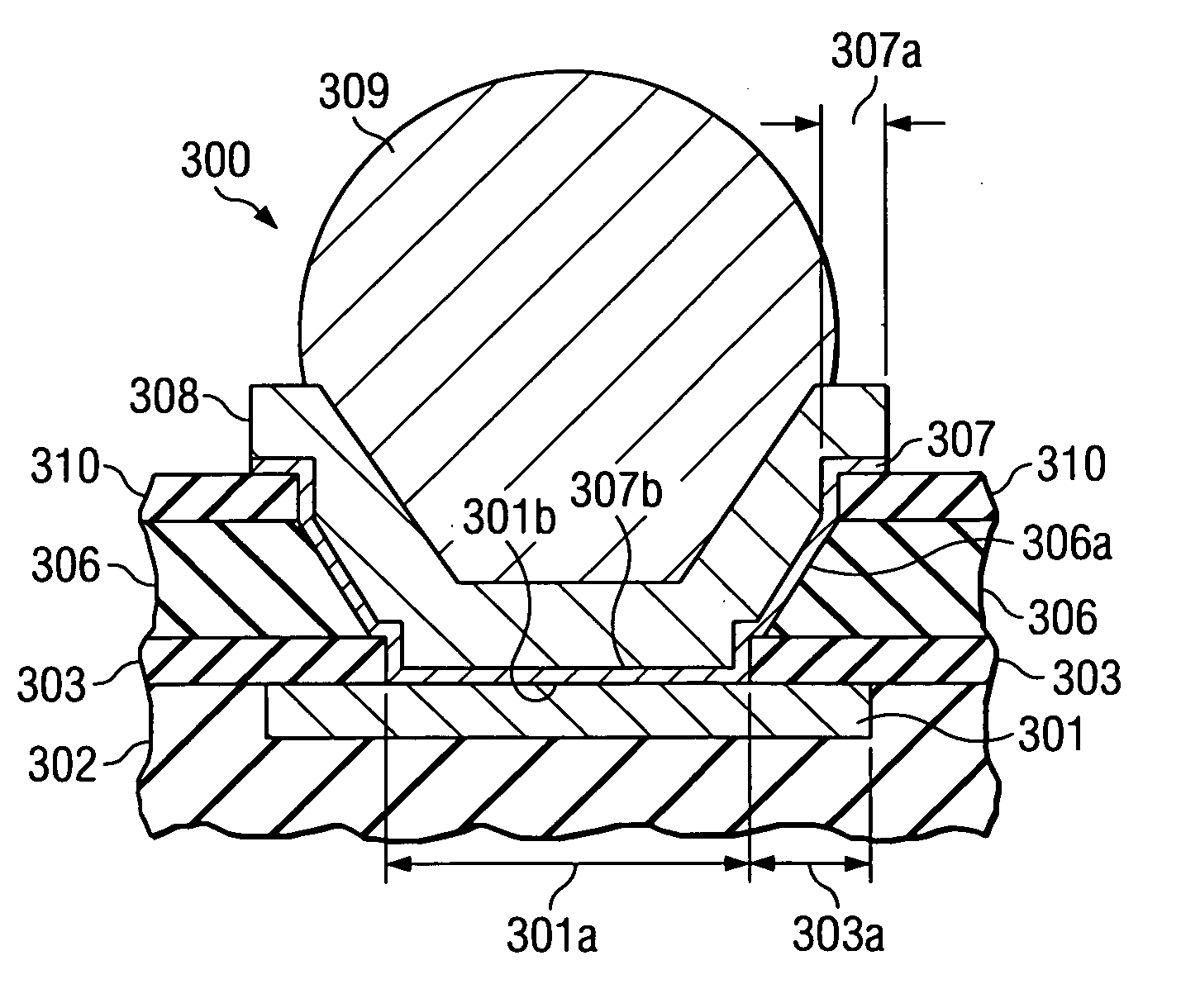

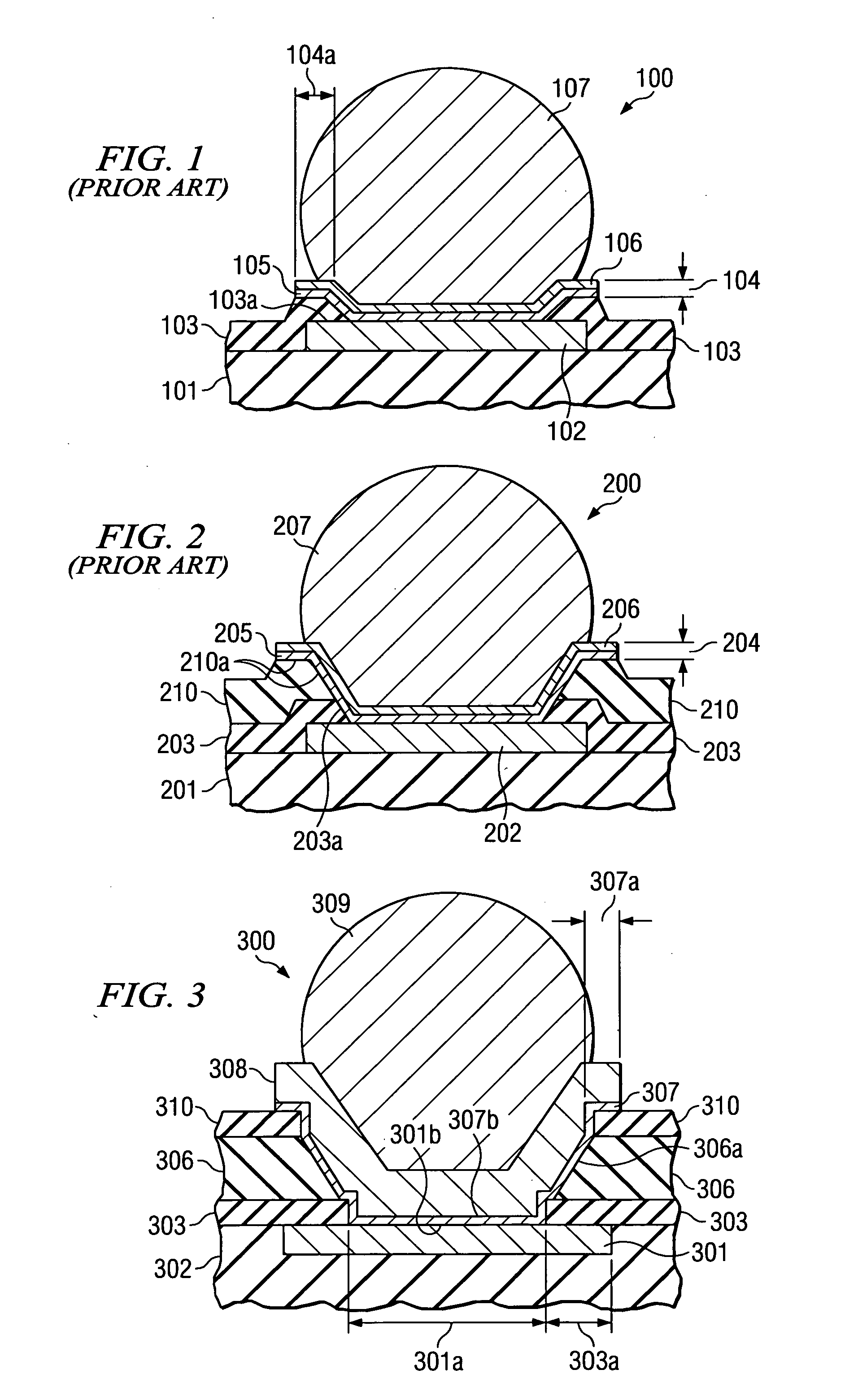

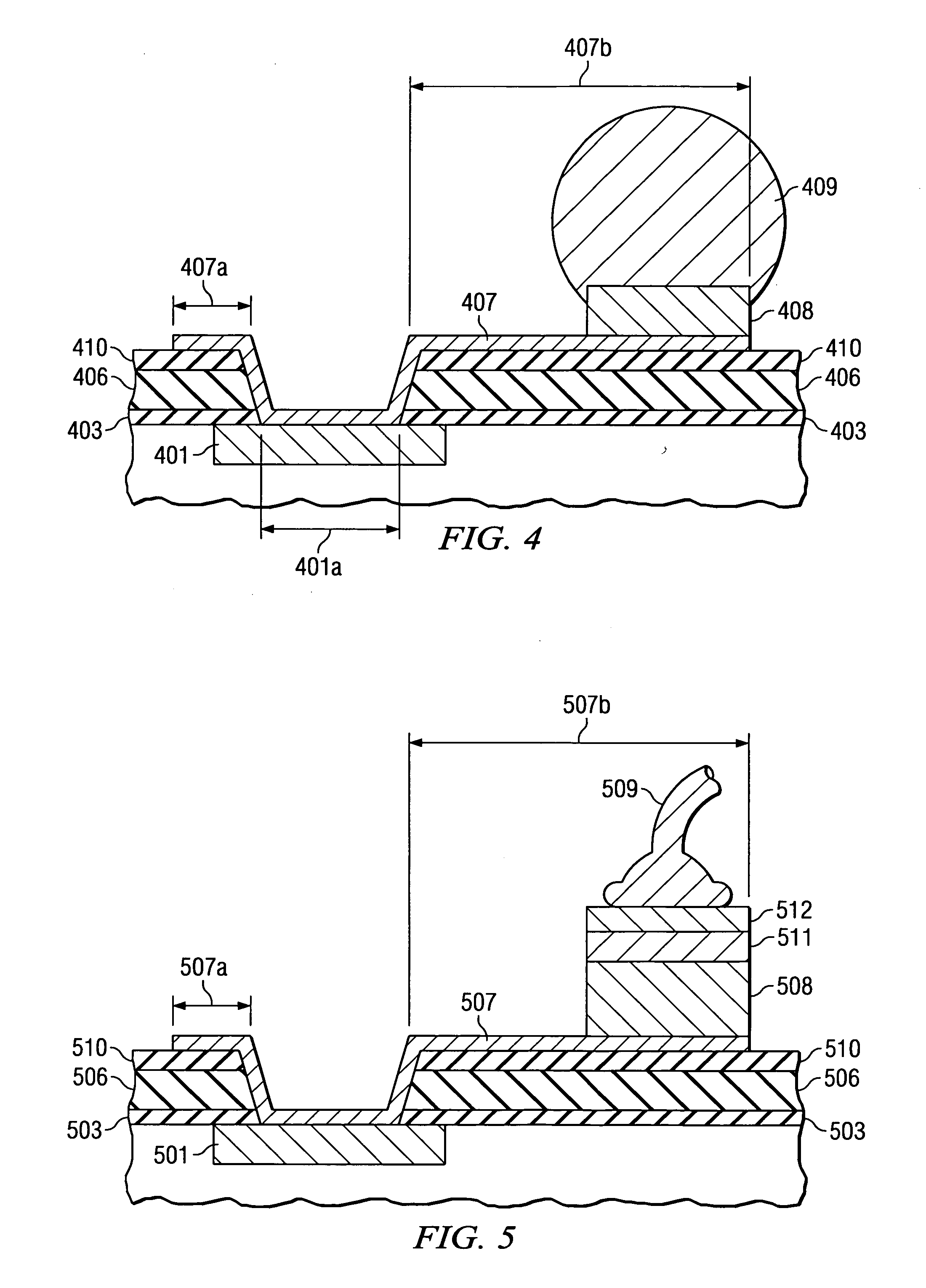

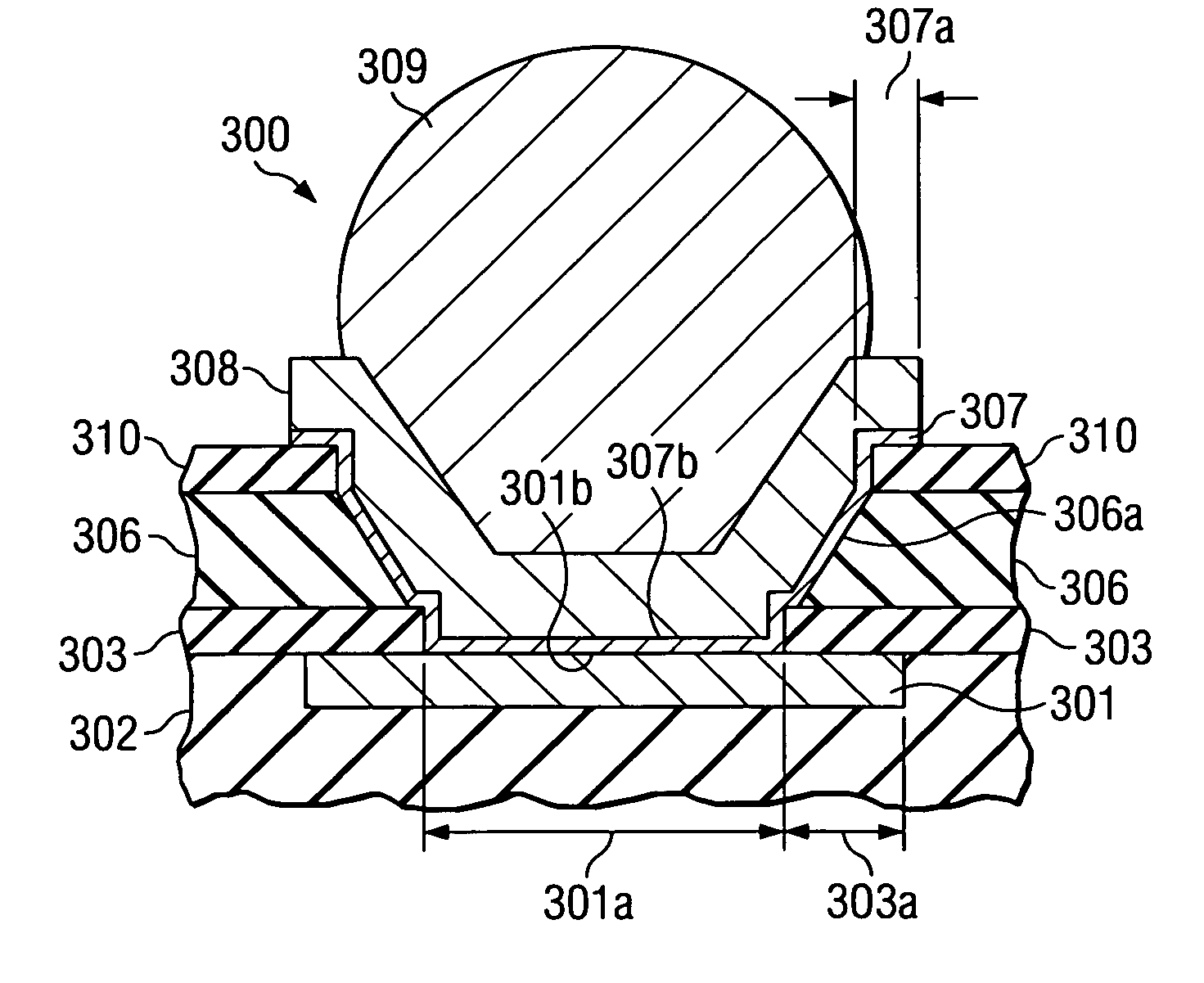

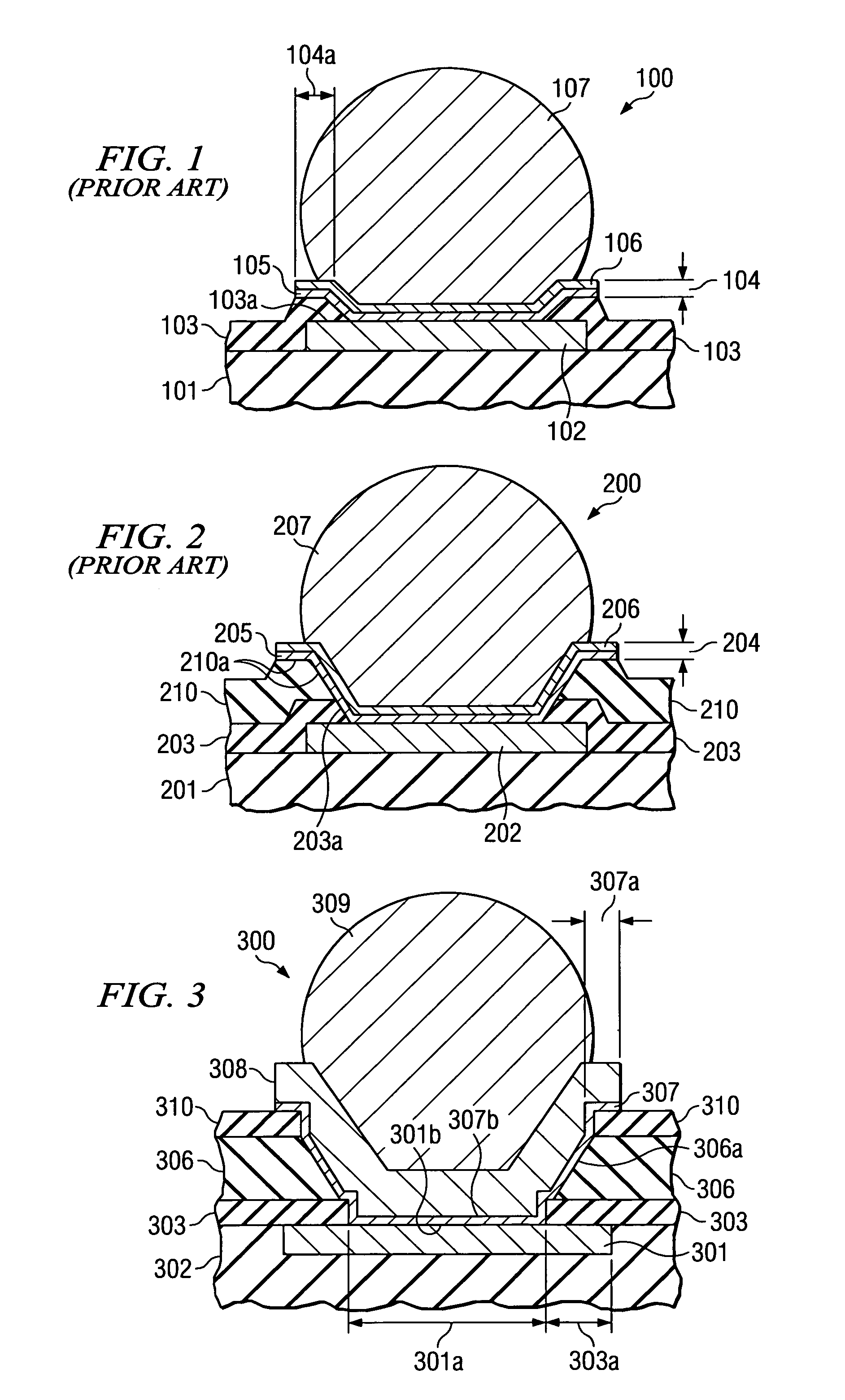

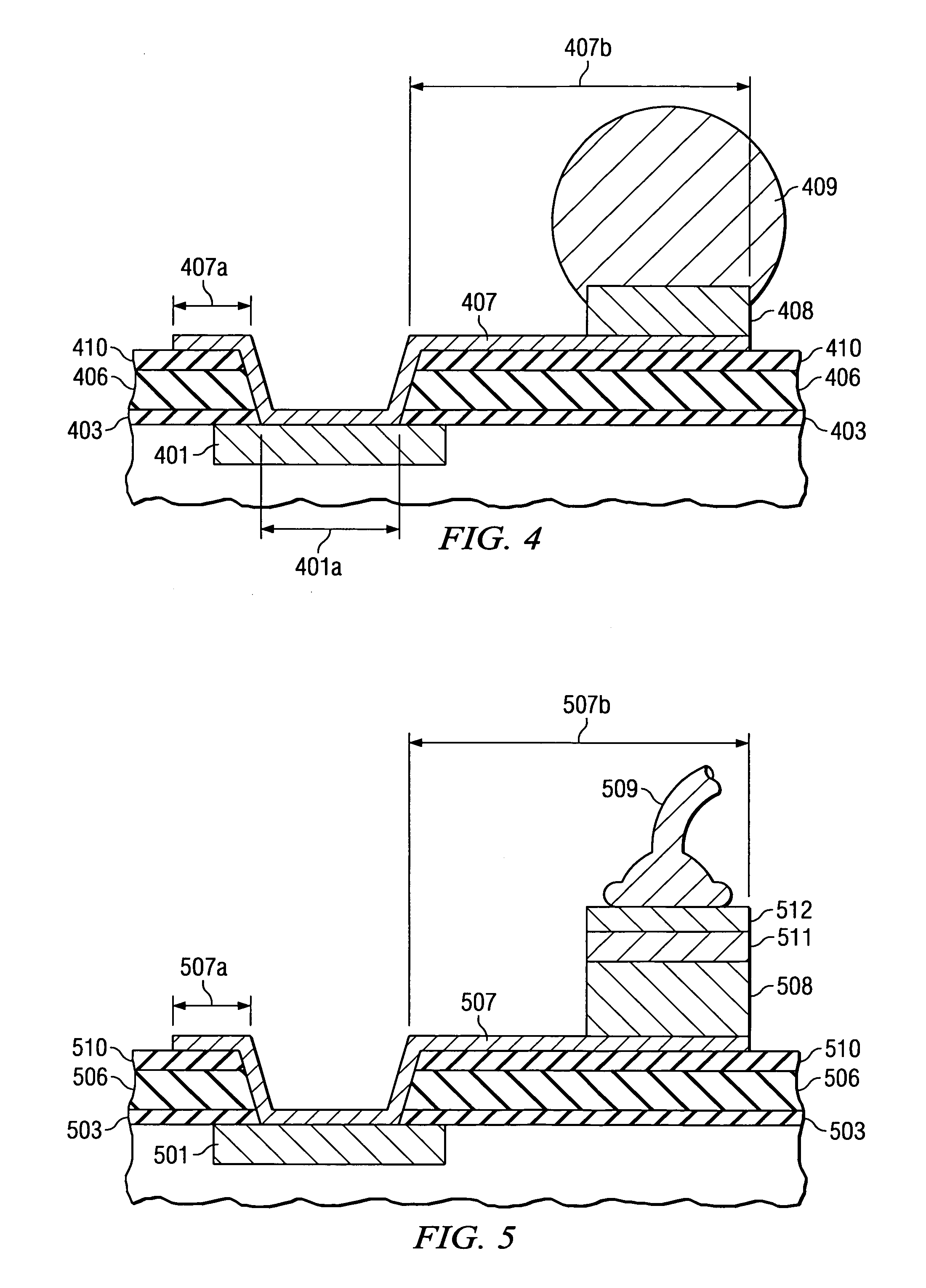

A semiconductor device including a contact pad and circuit metallization on the surface of an integrated circuit (IC) chip comprises a stack of protection layers over the surface of the chip. The stack consists of a first inorganic layer (303, preferably silicon nitride) on the chip surface, followed by a polymer layer (306, preferably benzocyclobutene) on the first inorganic layer (303), and finally an outermost second inorganic layer (310, preferably silicon dioxide) on the polymer layer (303). A window (301a) in the stack of layers exposes the metallization (301) of the IC. A patterned seed metal layer (307, preferably copper) is on the metallization (301) in the window and on the second inorganic layer (310) around the window. A buffer metal layer (308, preferably copper) is positioned on the seed metal layer (307). A metal reflow element (309) is attached to the buffer metal (308).

Owner:TEXAS INSTR INC

Production method for through wafer interconnection construction

ActiveCN101483149AMitigate Thermal MismatchThe process steps are simpleSemiconductor/solid-state device manufacturingParyleneParasitic capacitance

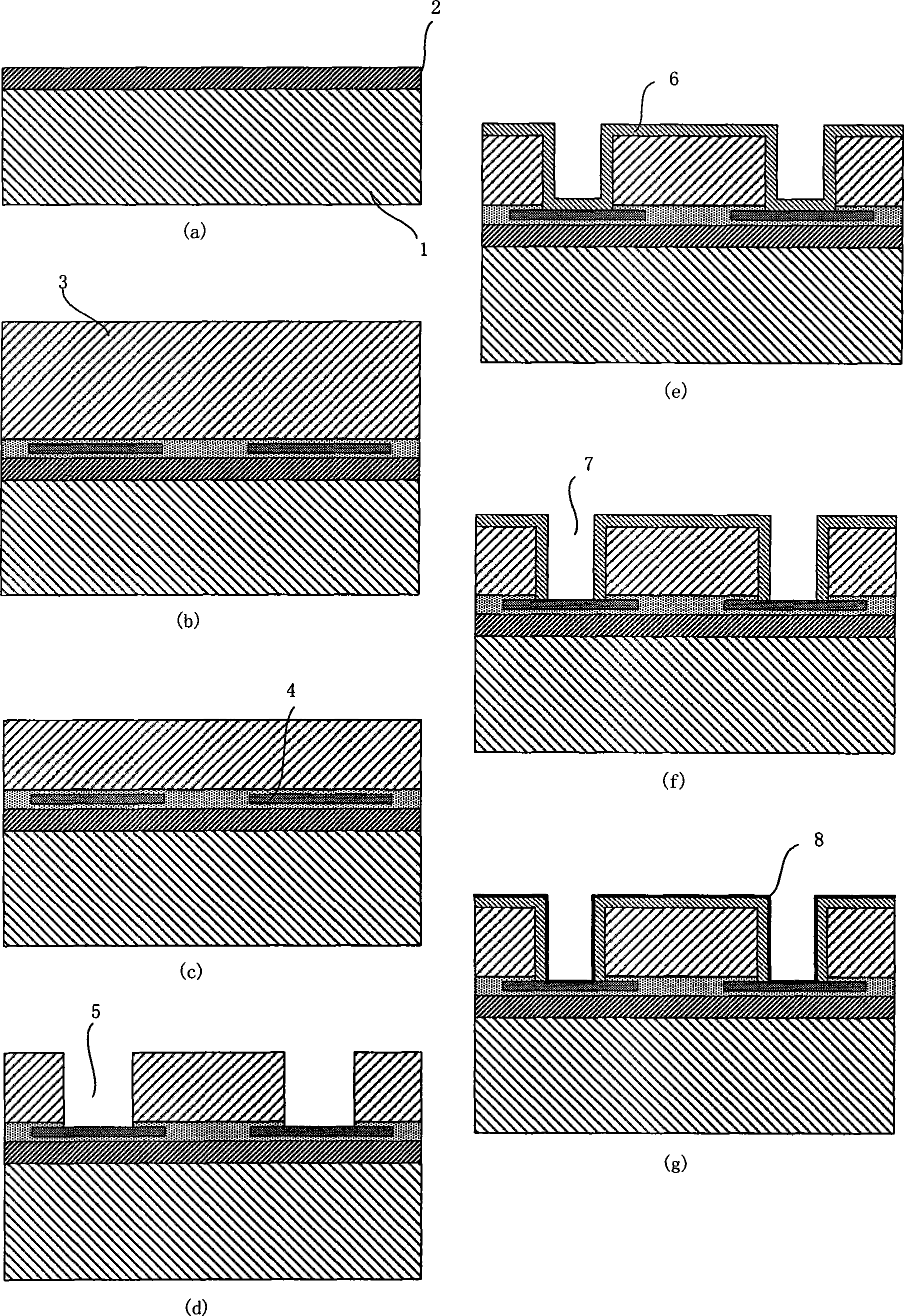

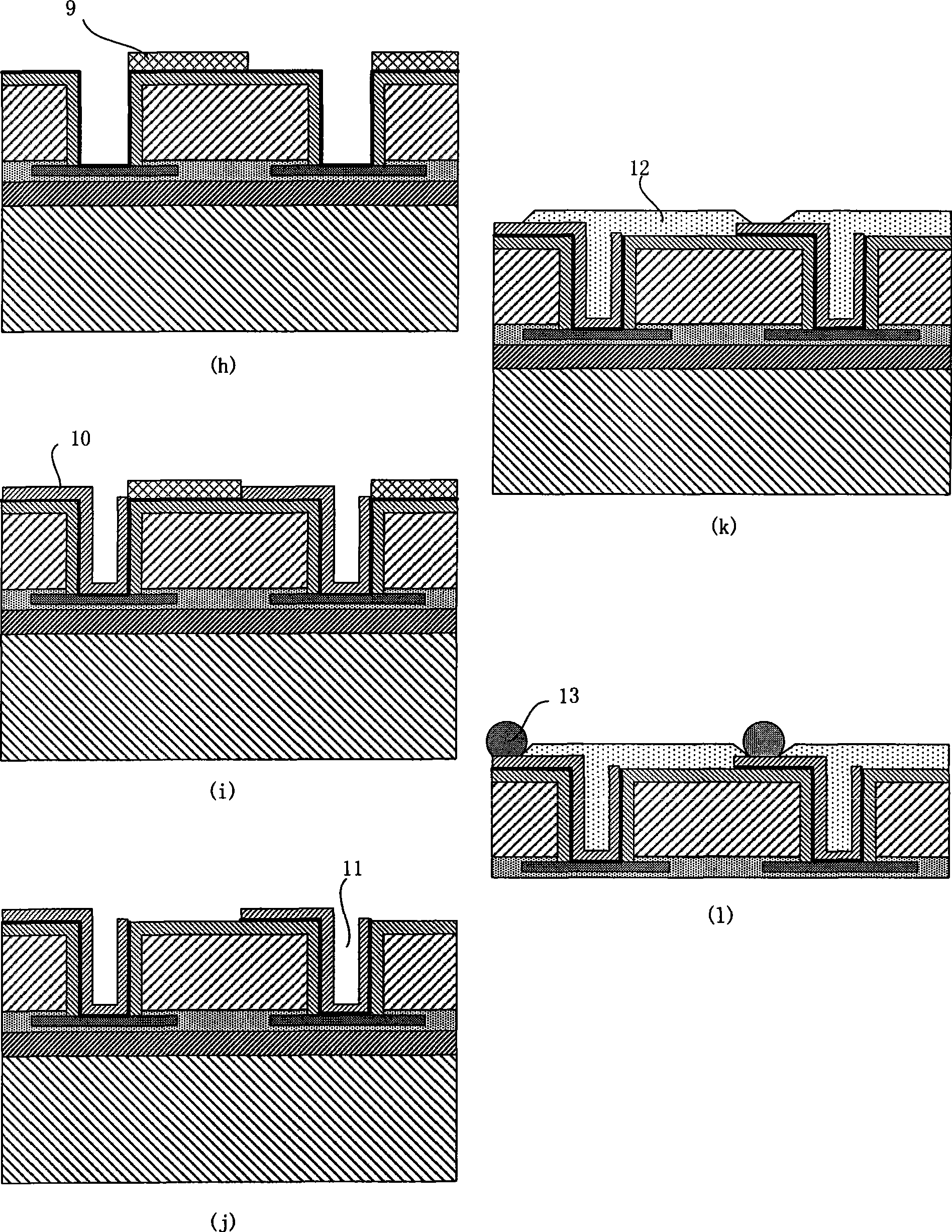

The invention discloses a through wafer interconnect structure preparation method comprising: 1. bonding a bonding silicon device wafer on a silicon wafer substrate; 2. thinning the silicon device wafer, etching the silicon device and forming a blind hole; 3. coating a layer of pattern dielectric material (such as poly-p-xylene) on the silicon device wafer; 4. etching the pattern dielectric substance layer, etching the dielectric material at the bottom of the blind hole, keeping a blind hole side wall; forming a dielectric substance hole on the substrate and enabling the dielectric substance hole and the blind hole coaxial; 5. depositing a layer of conductive material on the dielectric substance hole as a conductive layer and forming a conductive hole; 6. re-depositing a layer of pattern dielectric substance on the conductive layer; 7. forming a solder micro-convex point on the conductive layer. The invention simplifies the process steps, reduces the process time and the cost; depresses a parasitic capacitance, improves a interconnect electrical behavior, suits for the RF three-dimensional interconnection structure; releases the thermal mismatch between the conductive material and the silicon and greatly reduces the thermal mechanical stress.

Owner:HUAZHONG UNIV OF SCI & TECH

Direct bumping on integrated circuit contacts enabled by metal-to-insulator adhesion

InactiveUS7005752B2Less crowdedSmall sizeSemiconductor/solid-state device detailsSolid-state devicesContact padCopper

A semiconductor device including a contact pad and circuit metallization on the surface of an integrated circuit (IC) chip comprises a stack of protection layers over the surface of the chip. The stack consists of a first inorganic layer (303, preferably silicon nitride) on the chip surface, followed by a polymer layer (306, preferably benzocyclobutene) on the first inorganic layer (303), and finally an outermost second inorganic layer (310, preferably silicon dioxide) on the polymer layer (303). A window (301a) in the stack of layers exposes the metallization (301) of the IC. A patterned seed metal layer (307, preferably copper) is on the metallization (301) in the window and on the second inorganic layer (310) around the window. A buffer metal layer (308, preferably copper) is positioned on the seed metal layer (307). A metal reflow element (309) is attached to the buffer metal (308).

Owner:TEXAS INSTR INC

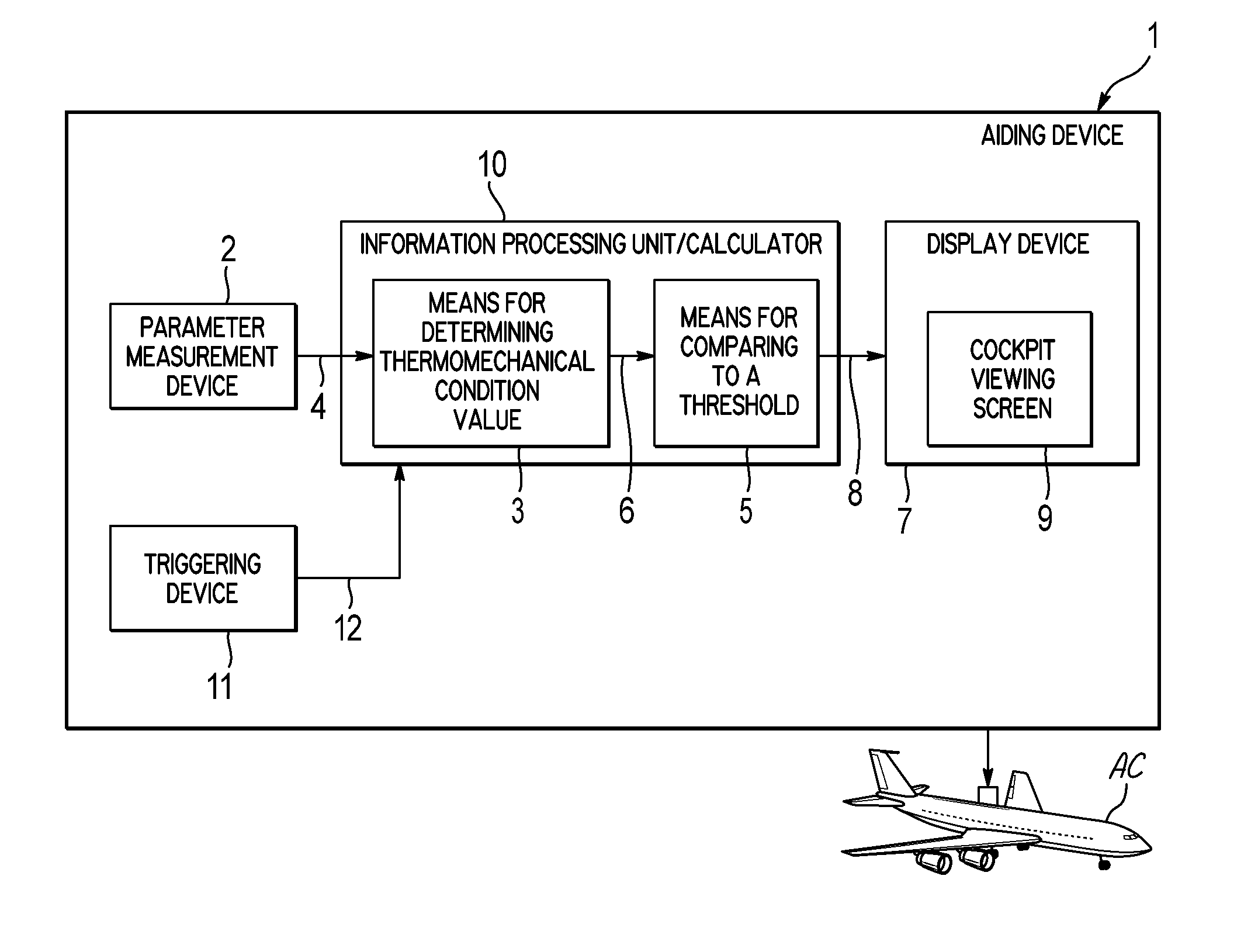

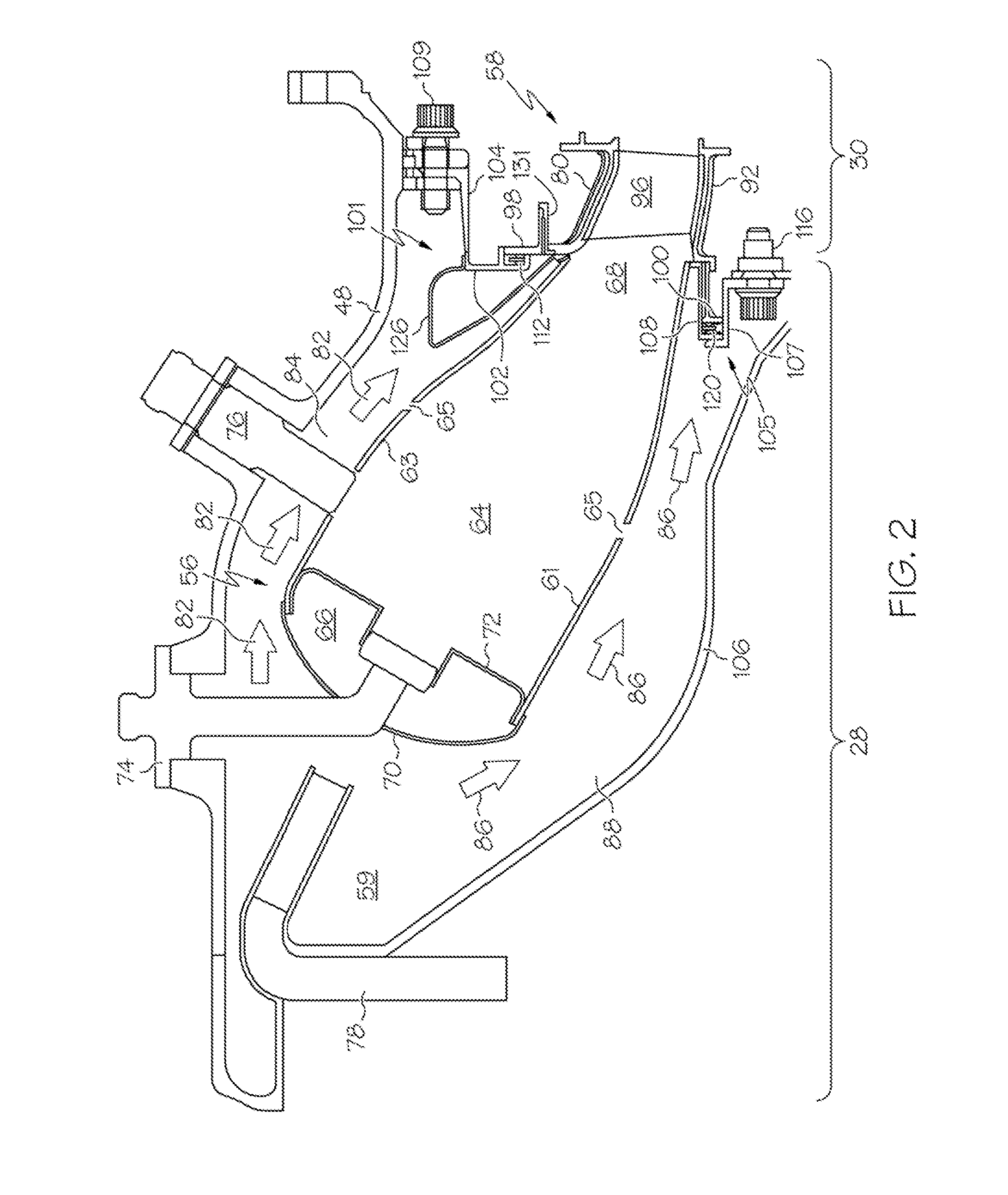

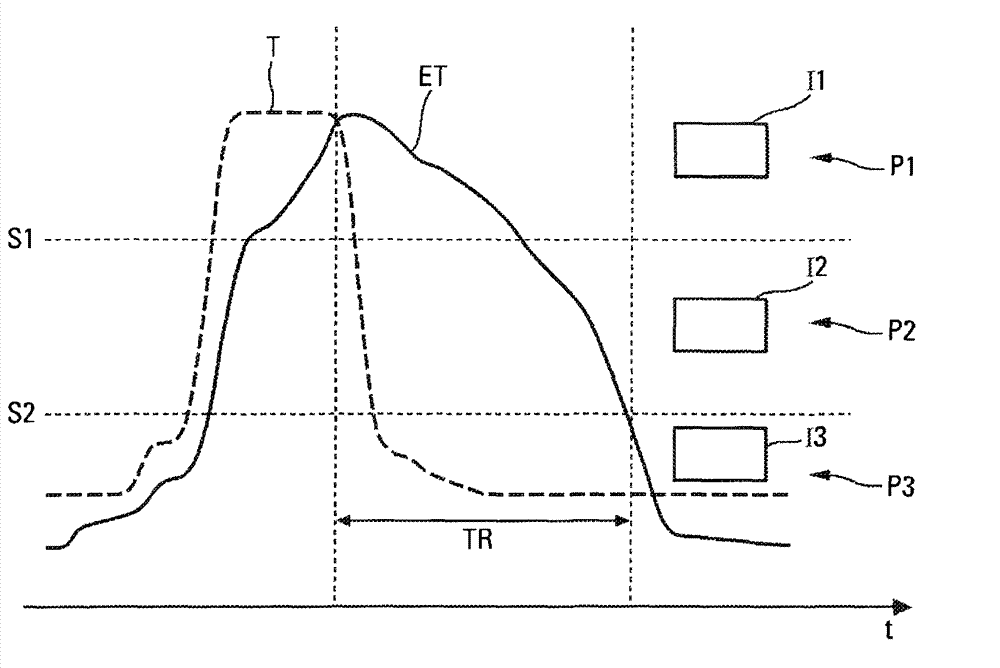

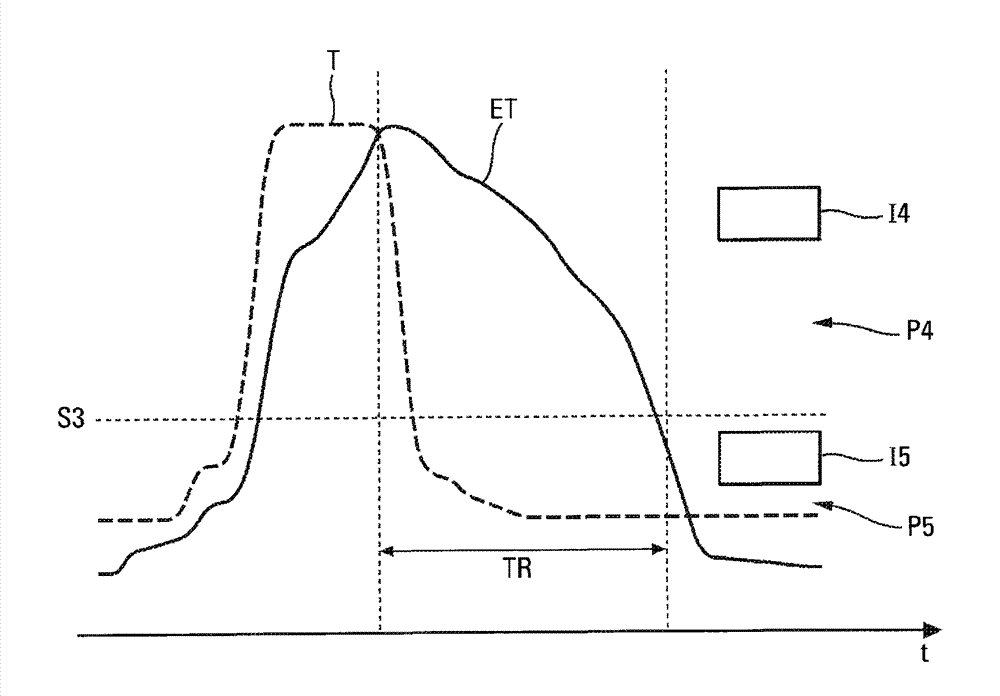

Method and device for monitoring a turbine engine of an aircraft

ActiveUS8918264B2Quick translationEasy to useAnalogue computers for vehiclesEngine fuctionsEngineeringTurbine

A method and device aids in monitoring at least one turbine engine in an aircraft. The method includes determining a value illustrating a thermomechanical state of the turbine engine, and comparing the determined value with at least one threshold. The method also includes displaying in the cockpit of the aircraft, at least one indication related to the operation of the turbine engine, according to this comparison. As a result, conditions that could result in mechanical degradation or failure of the turbine engine are identified for a crew of the aircraft.

Owner:AIRBUS OPERATIONS (SAS) +1

Packaging structure and packaging method of semiconductor device

ActiveCN101699622AImprove electrical performanceAvoid thermal mismatchSemiconductor/solid-state device detailsSolid-state devicesSeed crystalEngineering

The invention discloses a packaging structure and a packaging method of a semiconductor device. The packaging structure of the semiconductor comprises a chip, a passivation layer positioned above the chip, a pad positioned above the passivation layer, a first through hole running through the chip and the passivation layer along a thickness direction to the outside of the pad, a seed crystal layer positioned in the inner wall of the first through hole, a conductor layer positioned on the seed crystal layer, a conductive layer filling up the first through hole, a second through hole, an insulating medium layer, a convex point lower metal layer and convex points, wherein the seed crystal layer, the conductor layer and the conductive layer in the first hole form a first conductive plug; the second through hole runs through the chip and the passivation layer along the thickness direction to the outside of the pad, is positioned around the first through hole and shares a side wall with the first through hole; the insulating medium layer is positioned above the chip, fills up the second through hole and is exposed out of the first conductive plug; the convex point lower metal layer is positioned on the insulating medium layer on the first conductive plug and the periphery of the conductive plug; and the convex points are on the convex point lower metal layer. In the packaging structure and the packaging method, ultra high capacitance caused by TSV interconnection is avoided and the electrical property of the semiconductor packaging structure is improved.

Owner:CHINA WAFER LEVEL CSP

Turbine nozzle assembly including radially-compliant spring member for gas turbine engine

Owner:HONEYWELL INT INC

Active cooling panel of thermostructural composite material and method for its manufacture

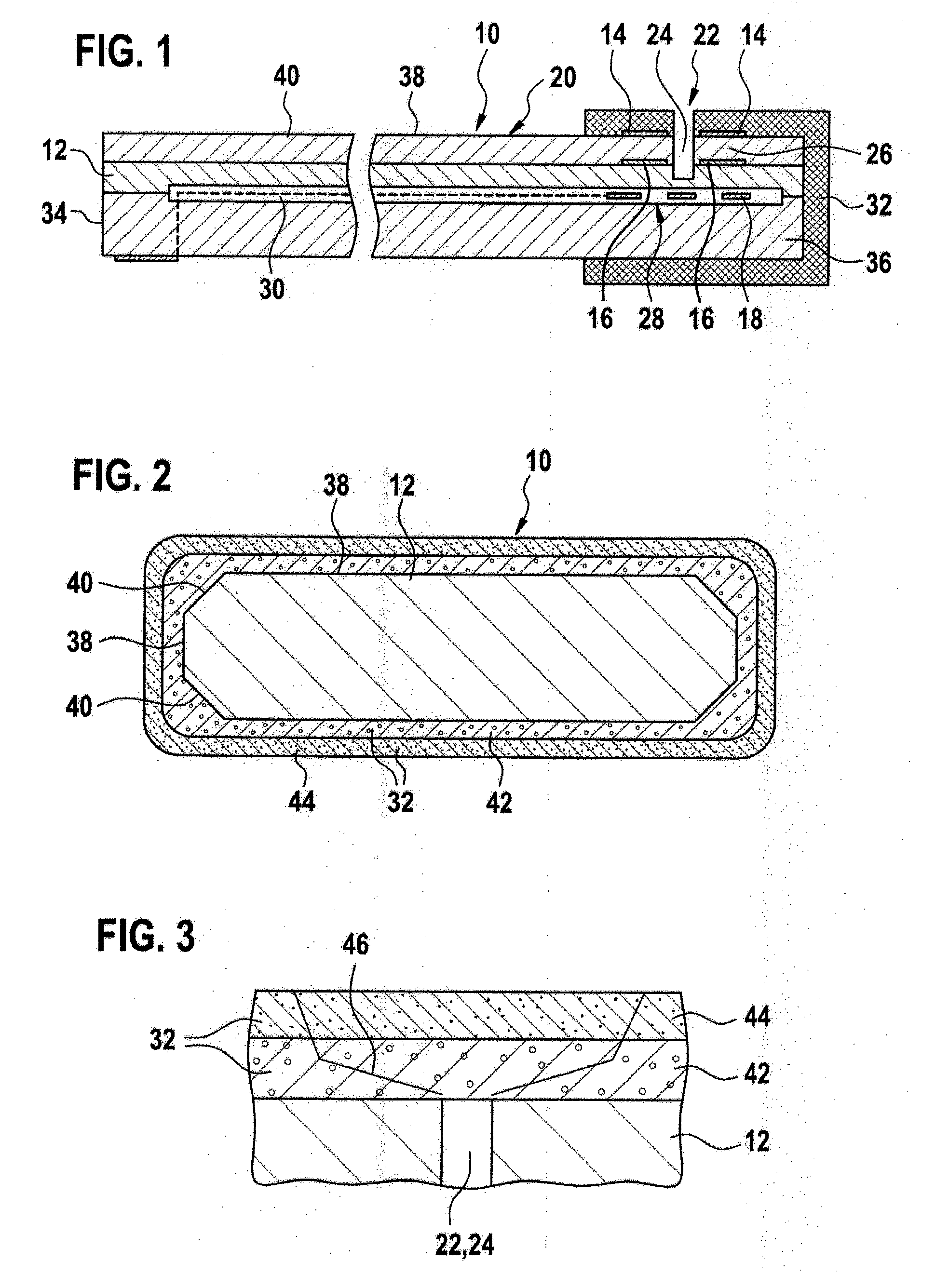

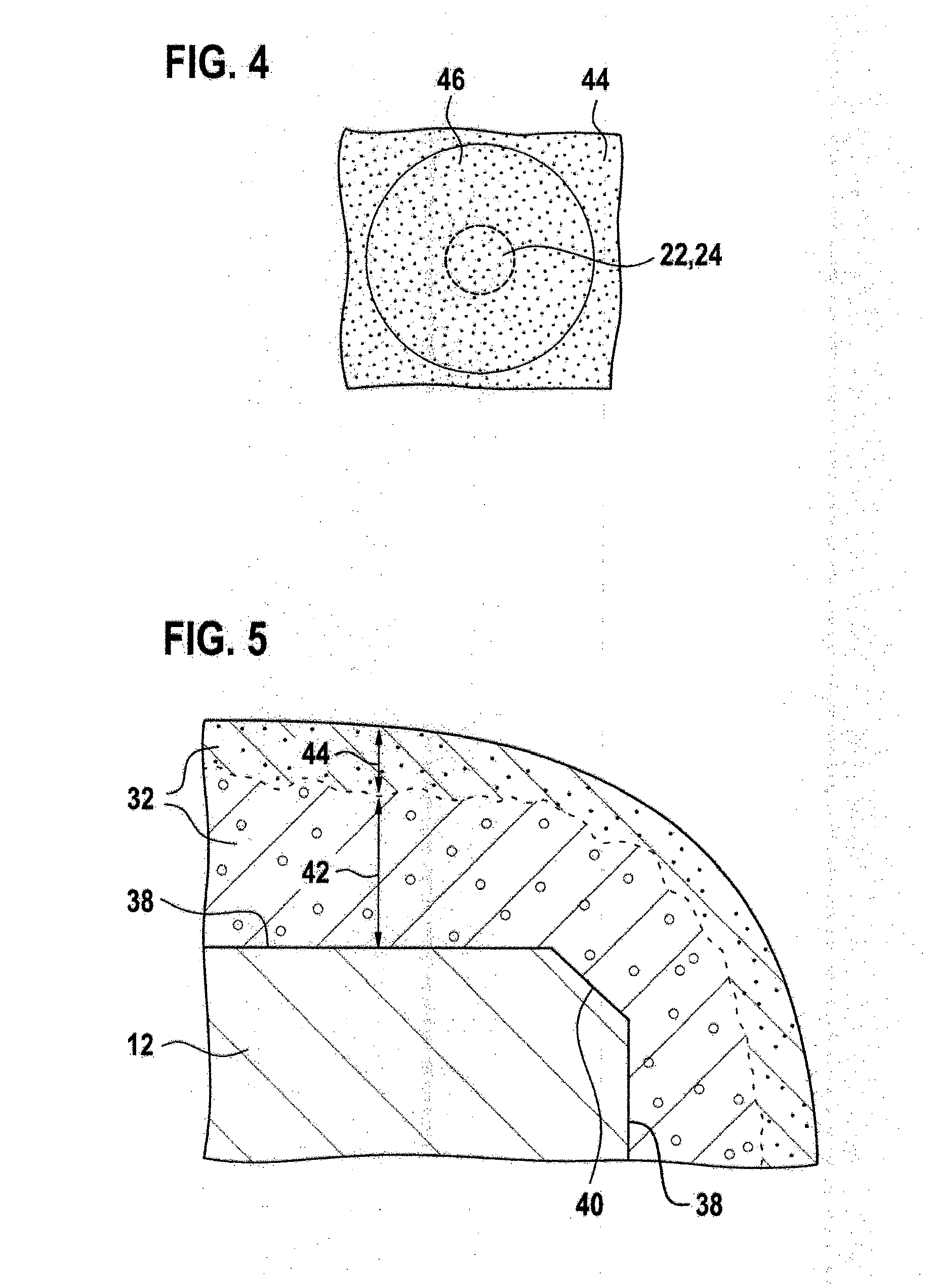

InactiveUS20040194941A1Reduce thermomechanical stressReduce surface porosityContinuous combustion chamberNuclear energy generationCombustion chamberActive cooling

Owner:SNECMA PROPULSION SOLIDE

Method for manufacturing a solid electrolyte sensor element for detecting at least one property of a measuring gas in a measuring gas chamber, containing two porous ceramic layers

InactiveUS20160061767A1Increasing thermal massImprove robustnessWave amplification devicesMaterial analysis by electric/magnetic meansMetallurgyGas chamber

A method for manufacturing a sensor element is provided for detecting at least one property of a measuring gas in a measuring gas chamber, in particular for detecting a proportion of a gas component in the measuring gas or a temperature of the measuring gas. The method includes the following steps: providing at least one solid electrolyte which includes at least one functional element; applying, at least in sections, at least one first layer made of a ceramic material to the solid electrolyte, the first layer having a first porosity after the application; and applying, at least in sections, at least one second layer made of a ceramic material, the second layer having a second porosity after the application, and the first layer differing from the second layer with respect to at least one material property. Moreover, a sensor element which is manufacturable according to this method is provided.

Owner:ROBERT BOSCH GMBH

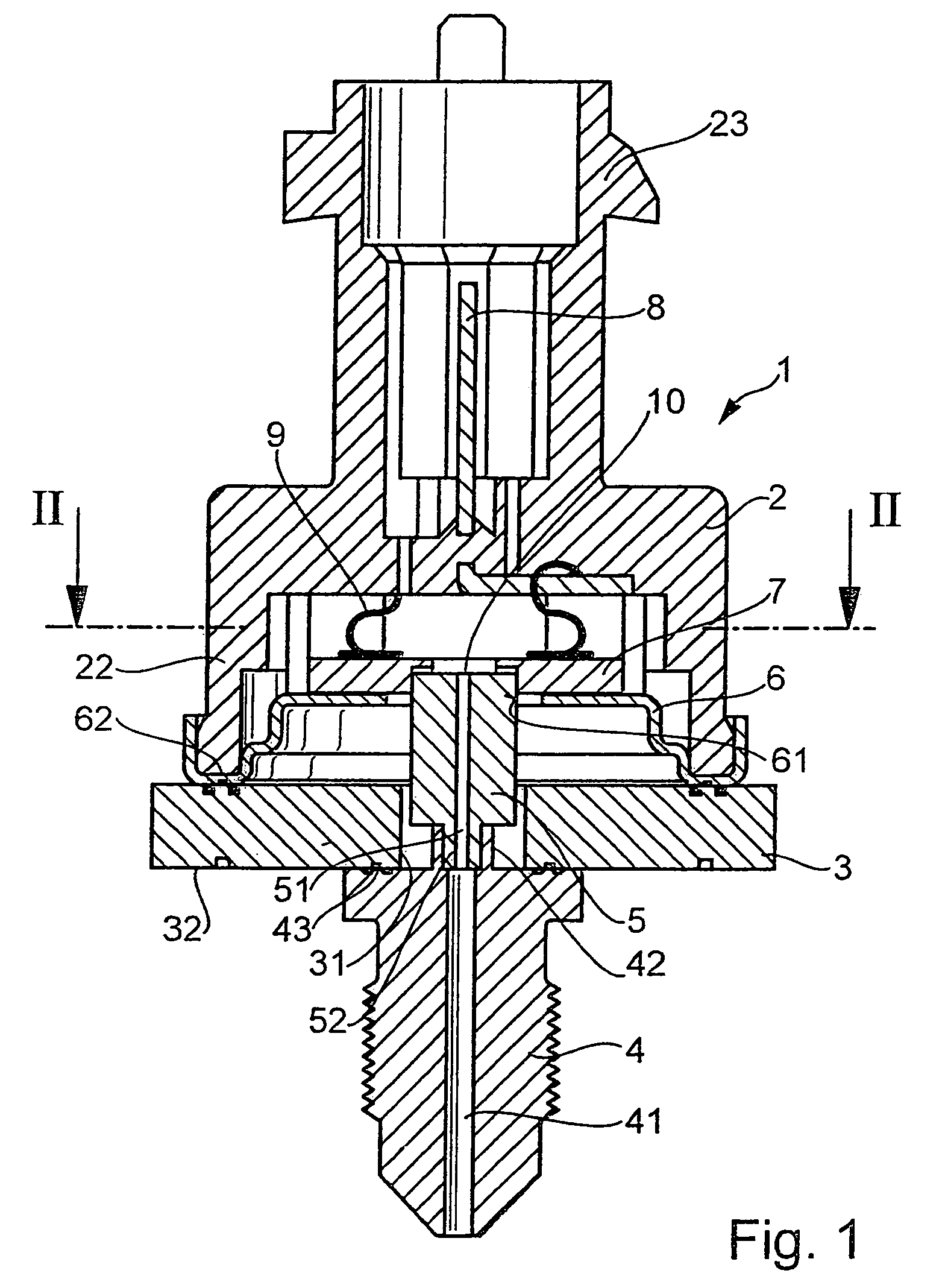

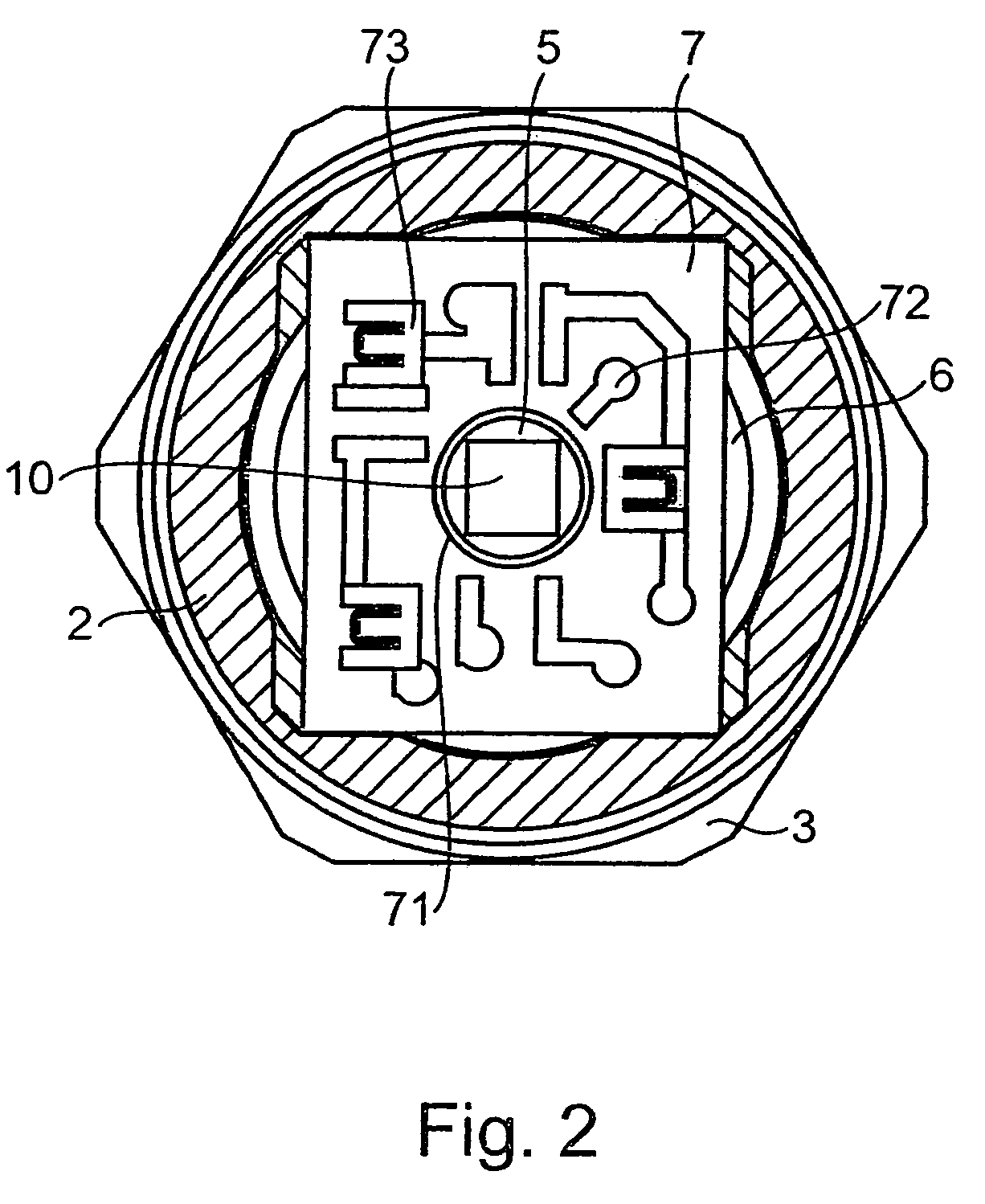

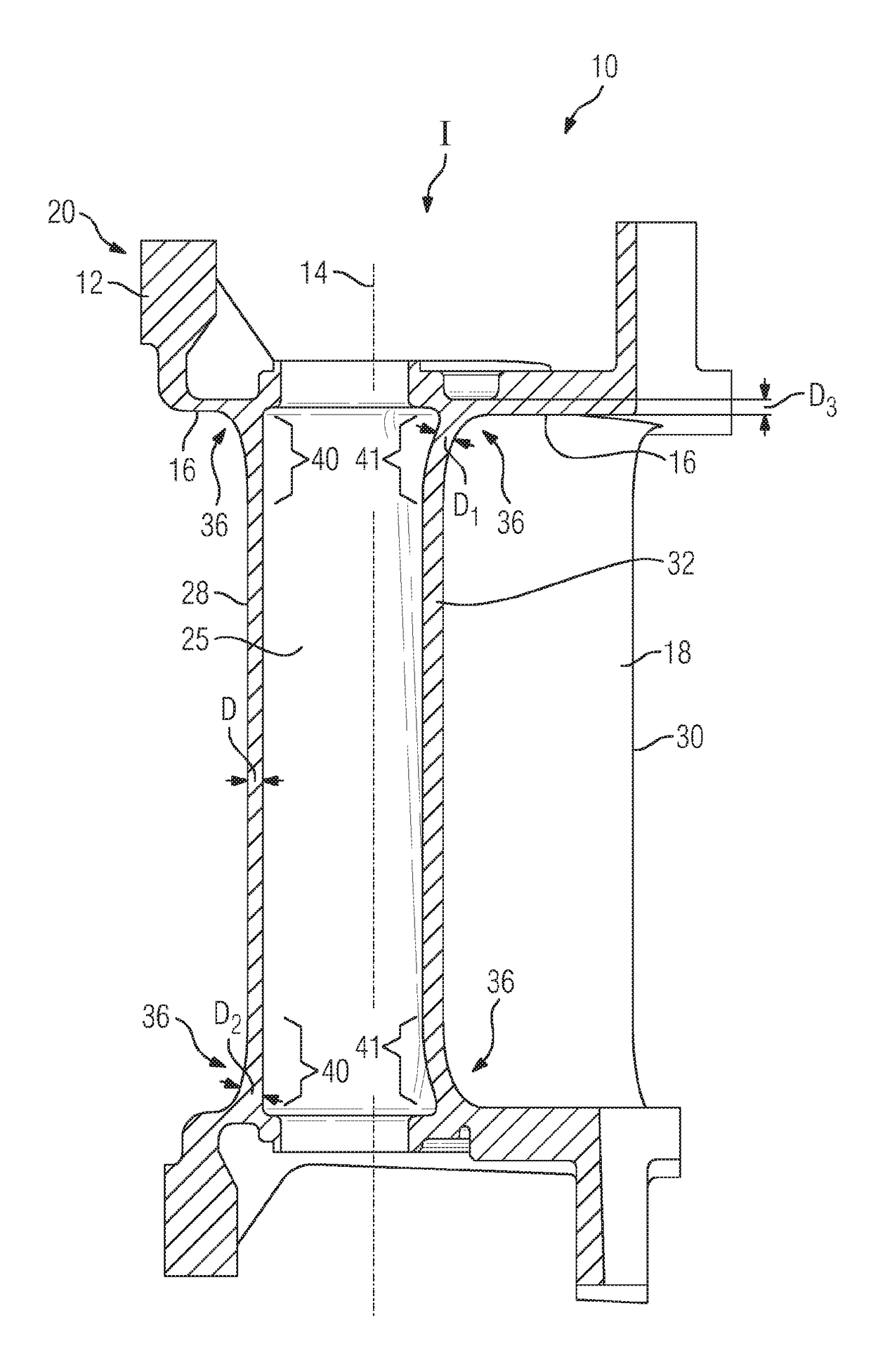

High pressure sensor comprising silicon membrane and solder layer

InactiveUS7152483B2Easy to integrateAvoid complex processFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsSilicon membraneTransducer

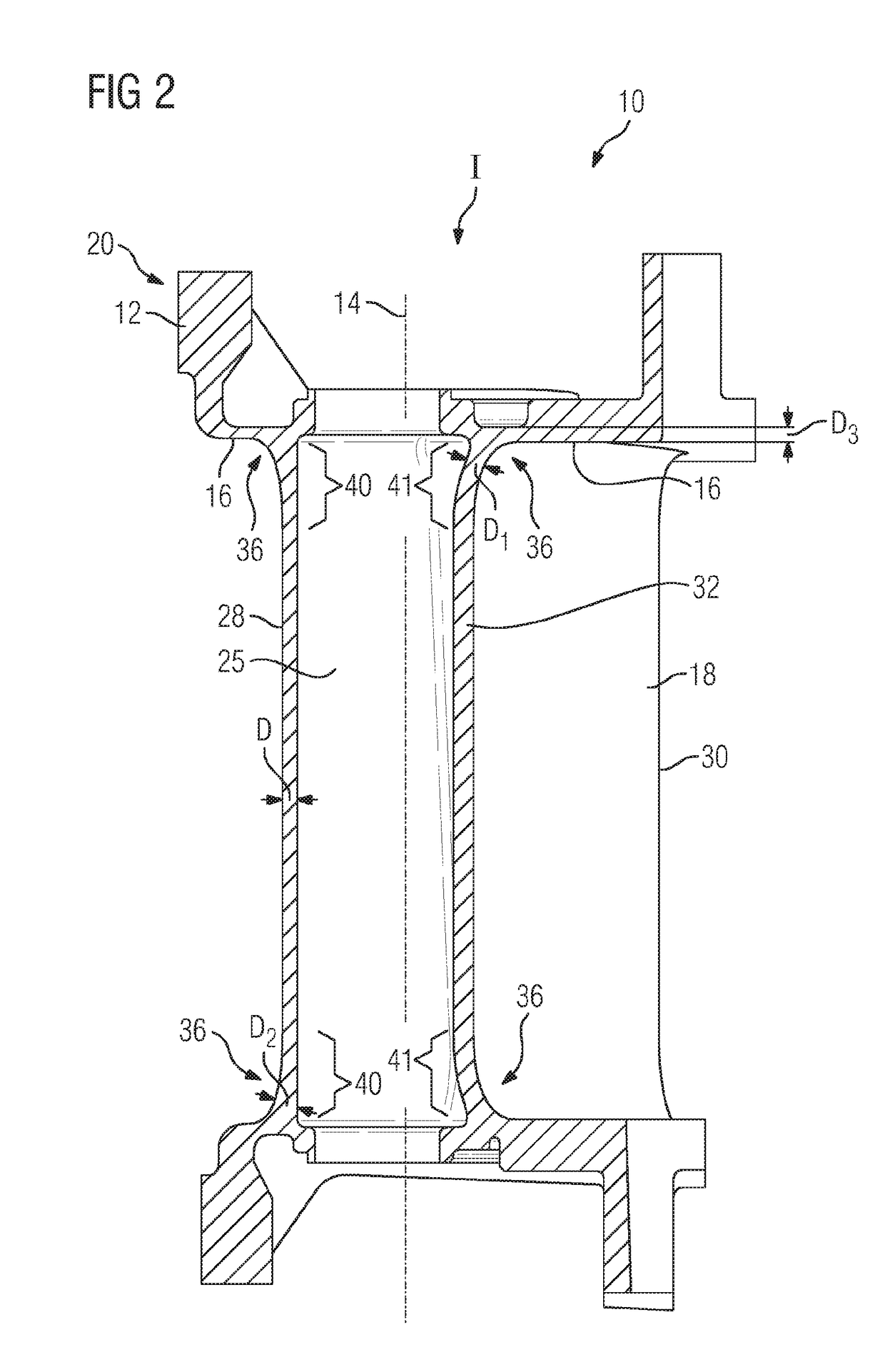

A device for measuring pressure, e.g., for measuring high pressure, including a pressure transducer that is arranged in a housing and includes sensor elements and a sensor diaphragm on a first side, and on a second side opposite the first side is provided with a cutout that extends from the second side to the sensor diaphragm. The pressure transducer is formed as a semiconductor pressure transducer and, with an edge area of the second side surrounding the cutout, is directly soldered onto a support part, provided with a first pressure-channel section, with the aid of a solder layer in such a manner that the first pressure-channel section and the cutout are interconnected.

Owner:ROBERT BOSCH GMBH

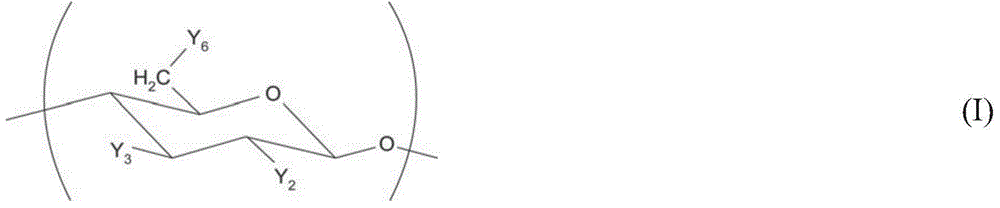

Conductive composition

InactiveCN104981911AExcellent adhesionGood dispersionApparatus for heat treatmentNon-conductive material with dispersed conductive materialParticulatesGlass particle

Disclosed is a conductive composition useful for the preparation of electrically conductive structures on a substrate comprising a plurality of metal particles, a plurality of glass particles and a vehicle comprising at least one cellulose derivative and at least one solid organopolysiloxane resin dissolved in a mutual organic solvent. The solid organopolysiloxane resin acts as adhesion promoter and assists in stably dispersing the metal and glass particles to avoid an agglomeration of such particles without degrading the rheological properties. From such conductive compositions uniform well adherent electrically conductive structures essentially free from defects in the form of cracks, bubbles or coarse particulates can be prepared on dielectric or semiconductor substrates such as silicon wafers in an efficient and cost-saving manner e.g. by screen printing, drying and sintering while inducing only low warping of the substrate. These characteristics render said conductive compositions particularly useful for the fabrication of electrodes of a semiconductor solar cell helping to increase the cell conversion efficiency.

Owner:NUTRITION & BIOSCIENCES USA 1 LLC

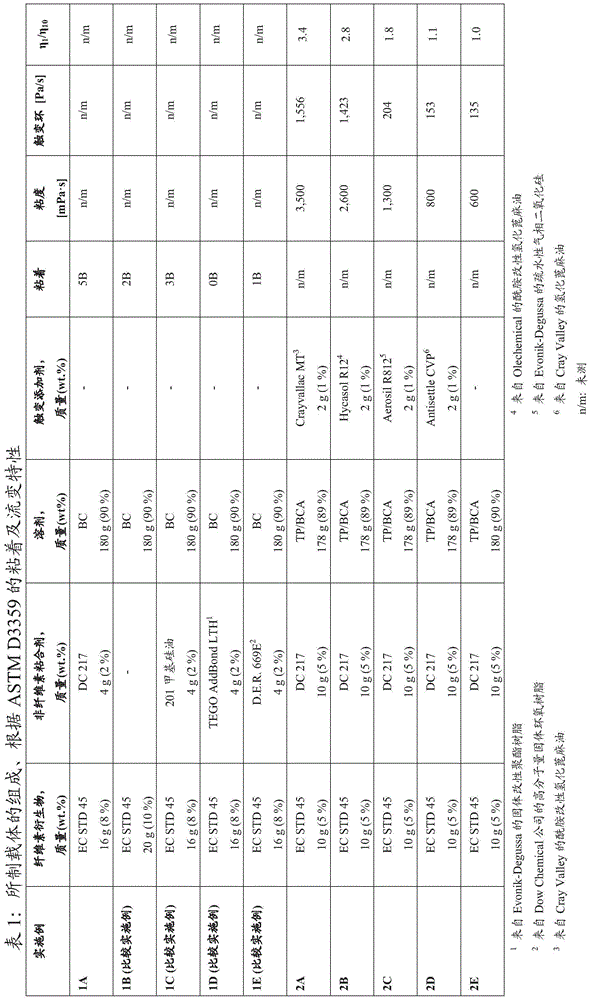

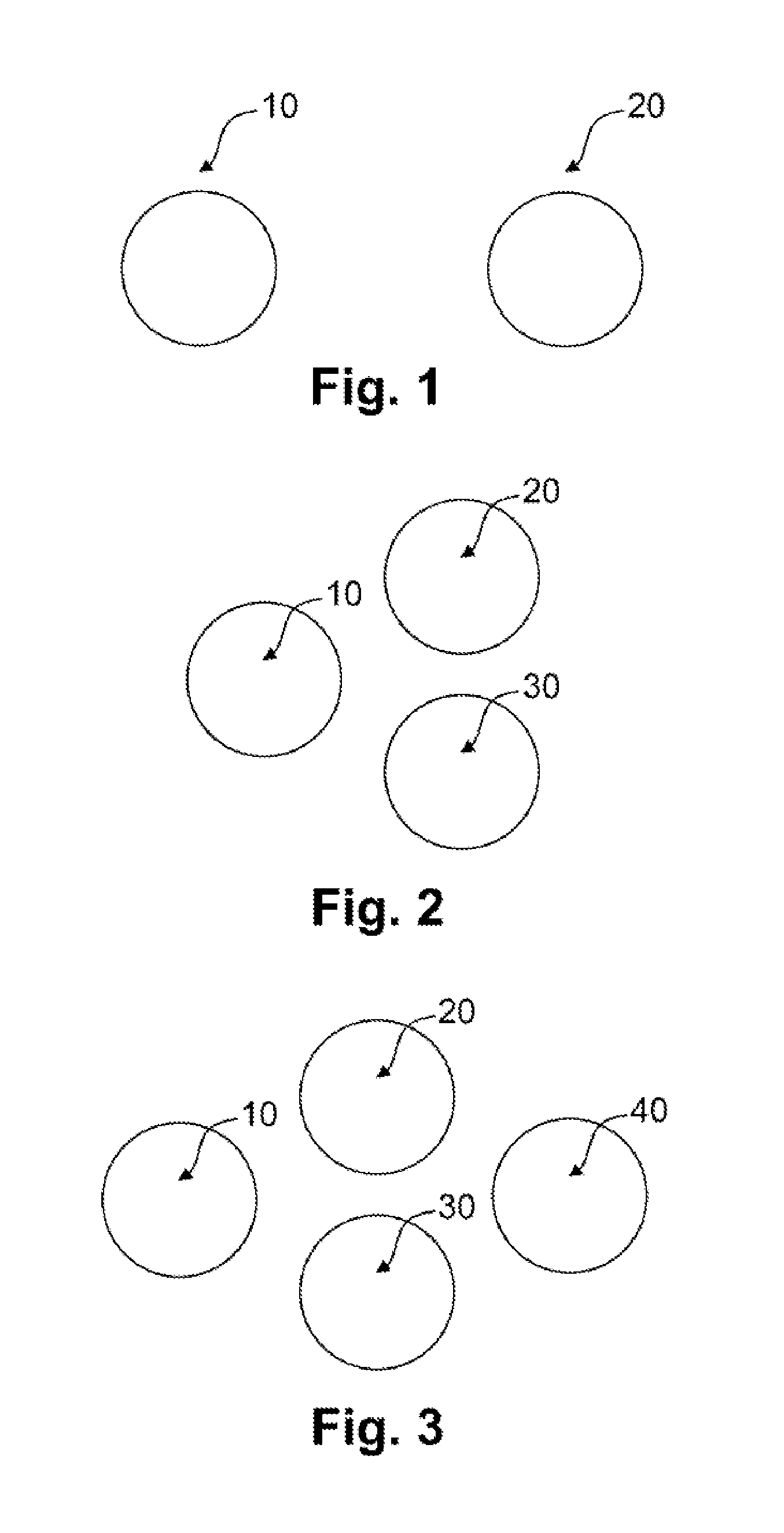

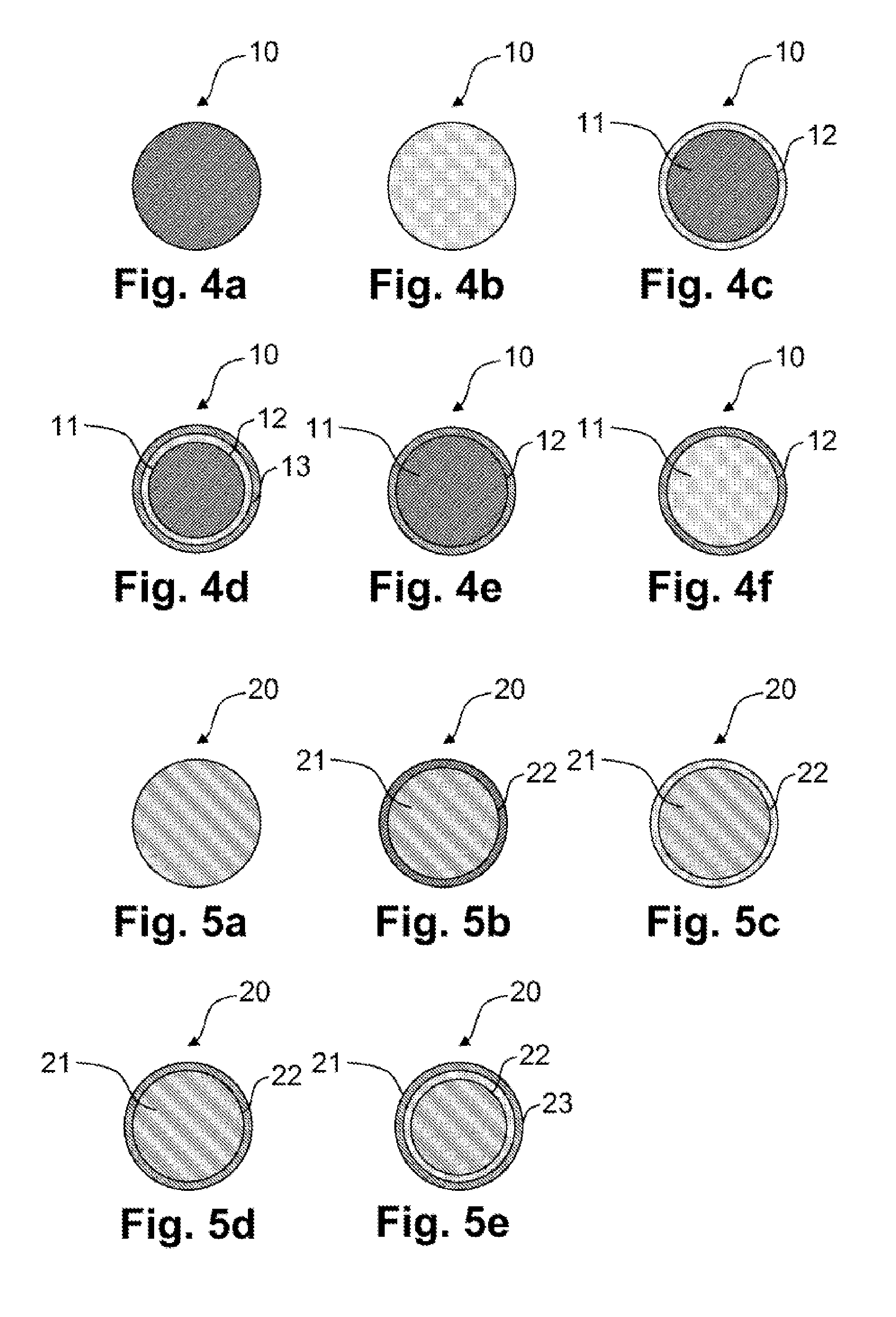

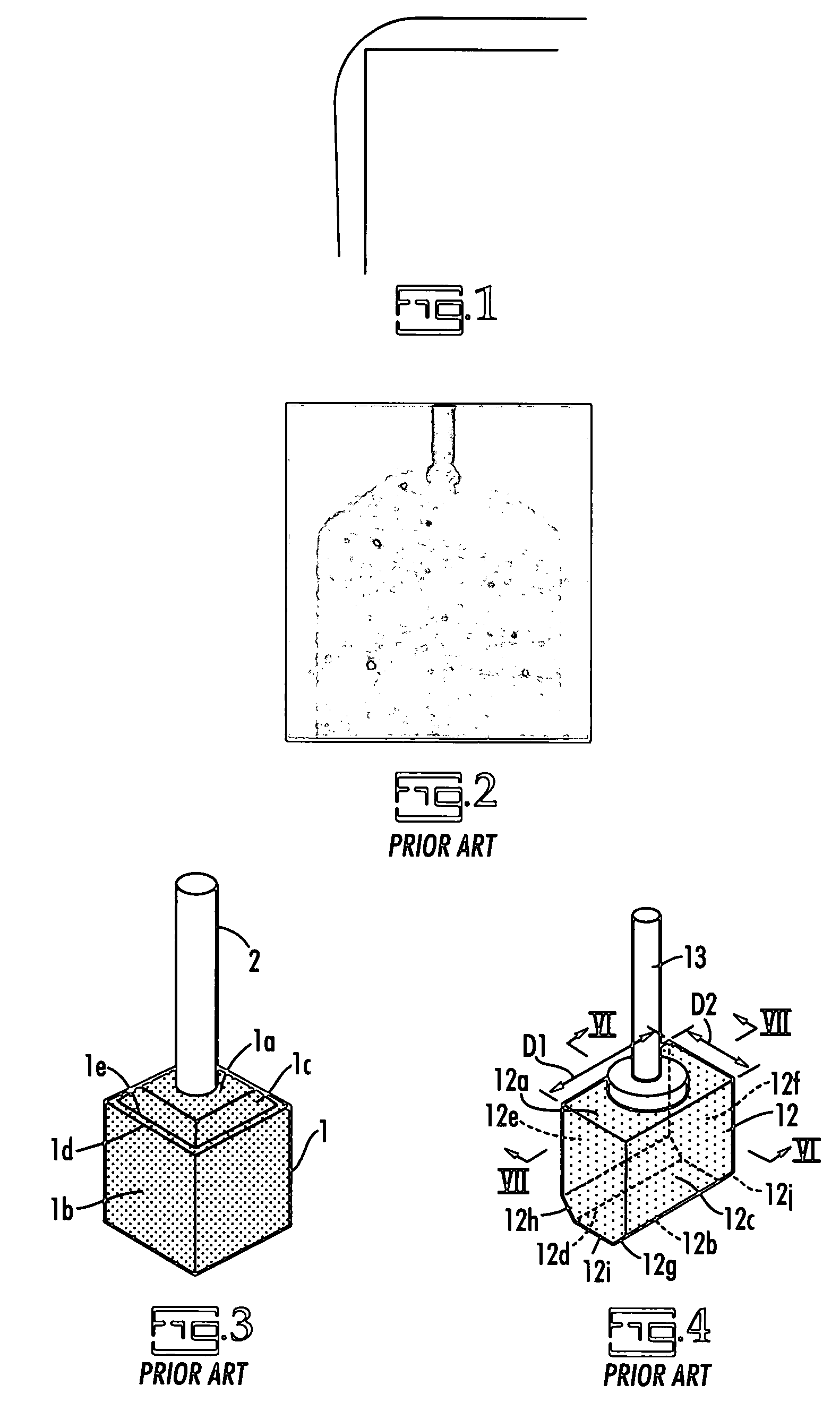

Starting material and process for producing a sintered join

InactiveUS20130216848A1Reduction factorAdvantageous effect elasticityPrinted circuits stress/warp reductionSolid-state devicesSiliconSILICONE DIOXIDE

The present invention relates to a starting material for producing a sintered join. In order to avoid the formation of cracks in the case of fluctuating thermal loading, the starting material comprises second particles 20, in addition to metallic first particles 10, which at least proportionately contain elemental silicon and / or silicon dioxide. In addition, the present invention relates to the use of elemental silicon and / or silicon dioxide for reducing the coefficient of thermal linear expansion α of a starting material 100 of a sintered join 100′ or of a sintered join 100′, in particular in a sintered paste, a sintered powder or a sintered material preform. Furthermore, the present invention relates to sintered joins 100′, to electronic circuits 70 and also to processes for forming a thermally and / or electrically conductive sintered join.

Owner:ROBERT BOSCH GMBH

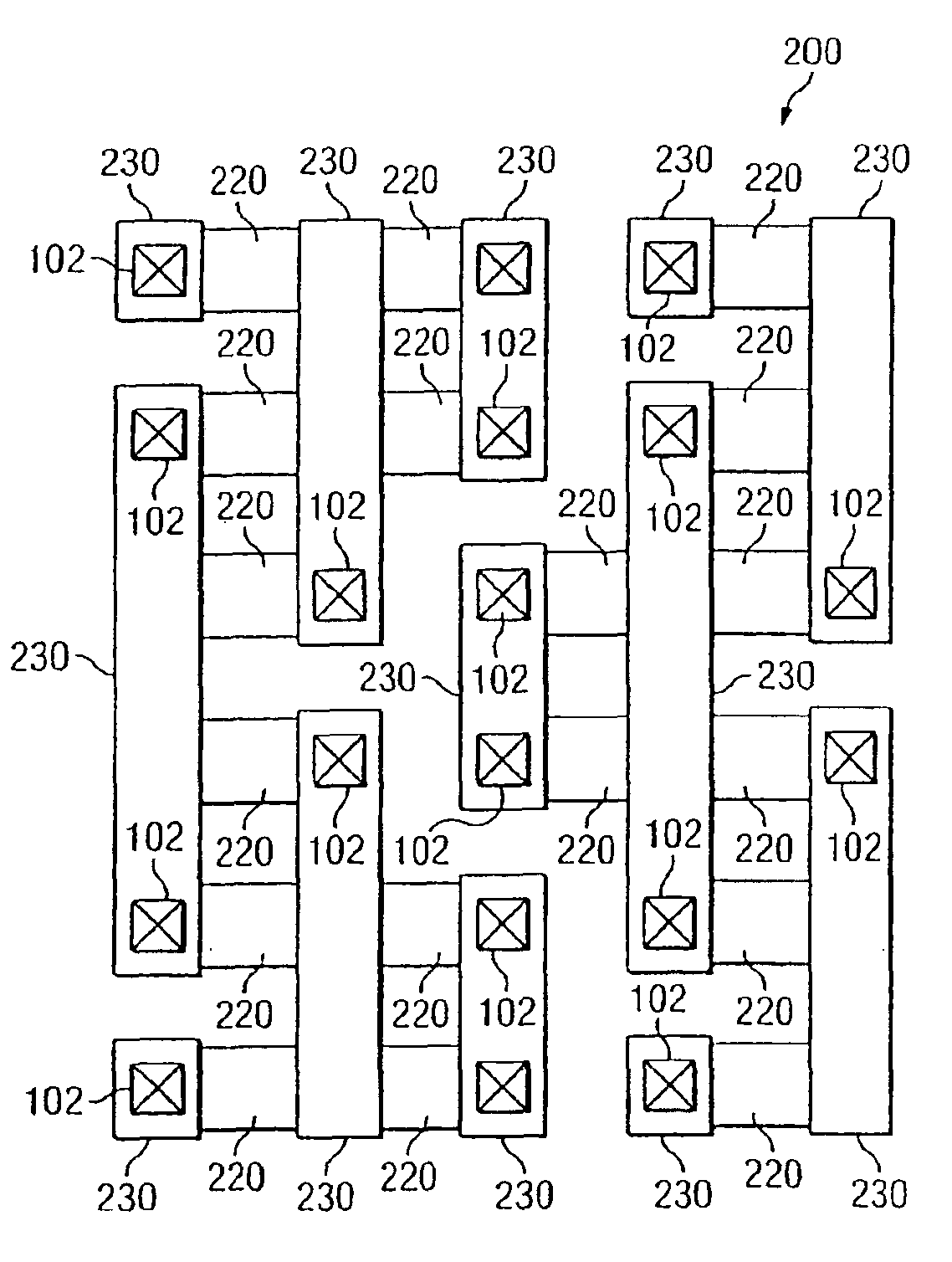

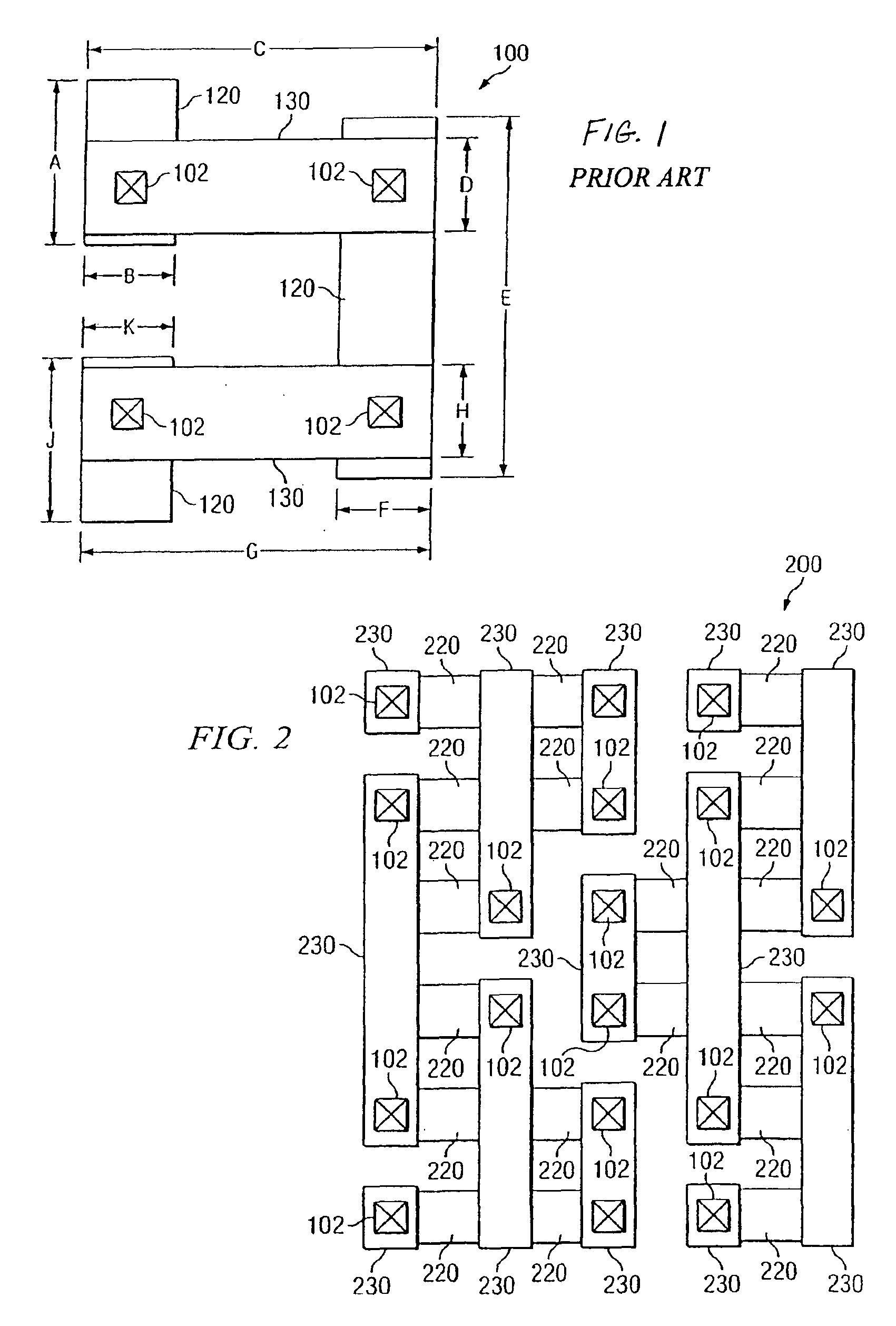

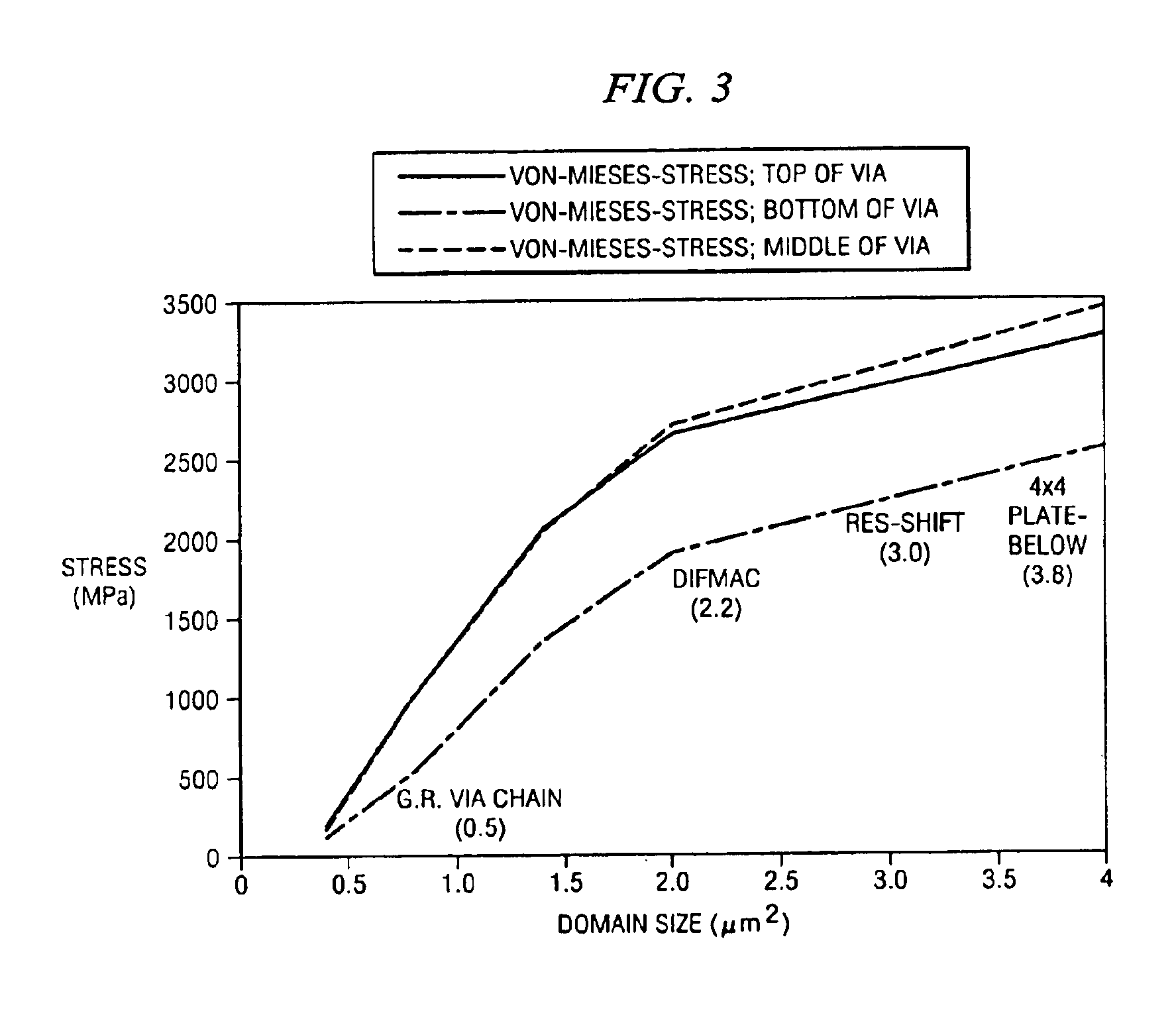

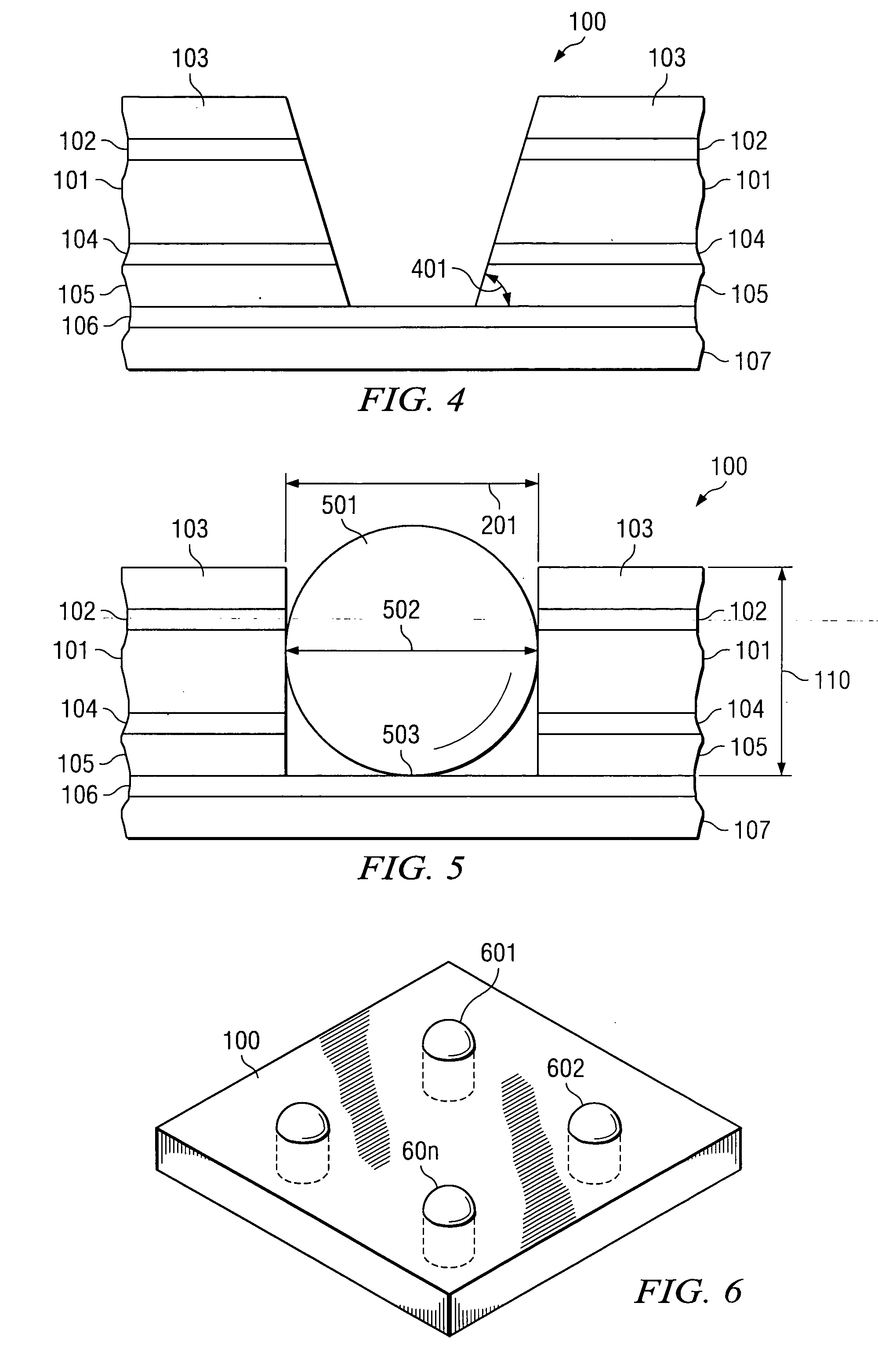

Via density rules

ActiveUS6864171B1Reduce thermomechanical stressReduce failureSemiconductor/solid-state device detailsSolid-state devicesEngineeringArea ratio

Thermo-mechanical stress on vias is reduced, thereby reducing related failures. This can be done by maintaining a via-to-metal area ratio at least as large as a predetermined value below which the additional stress on the vias does not significantly increase.

Owner:INFINEON TECH AG

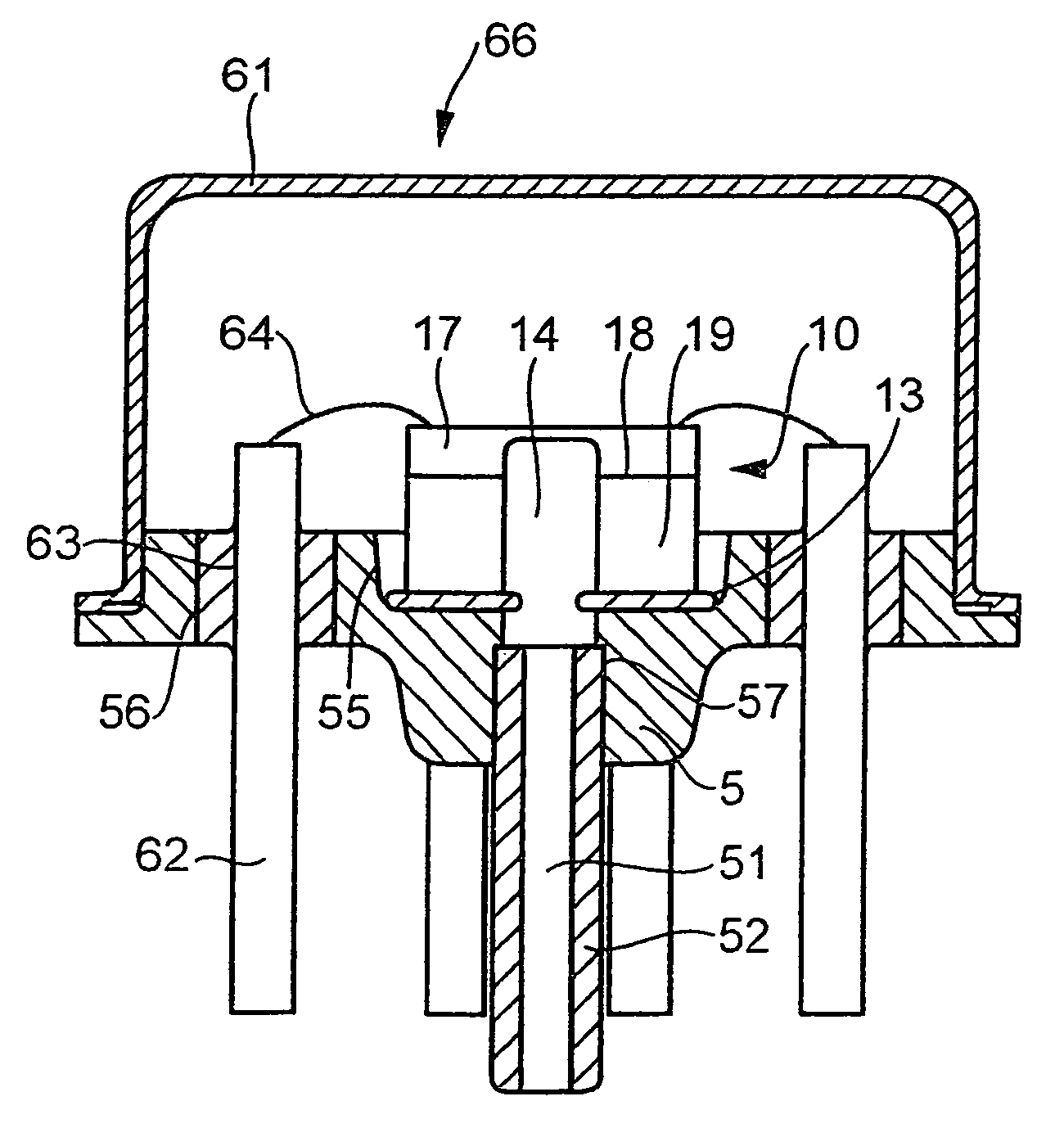

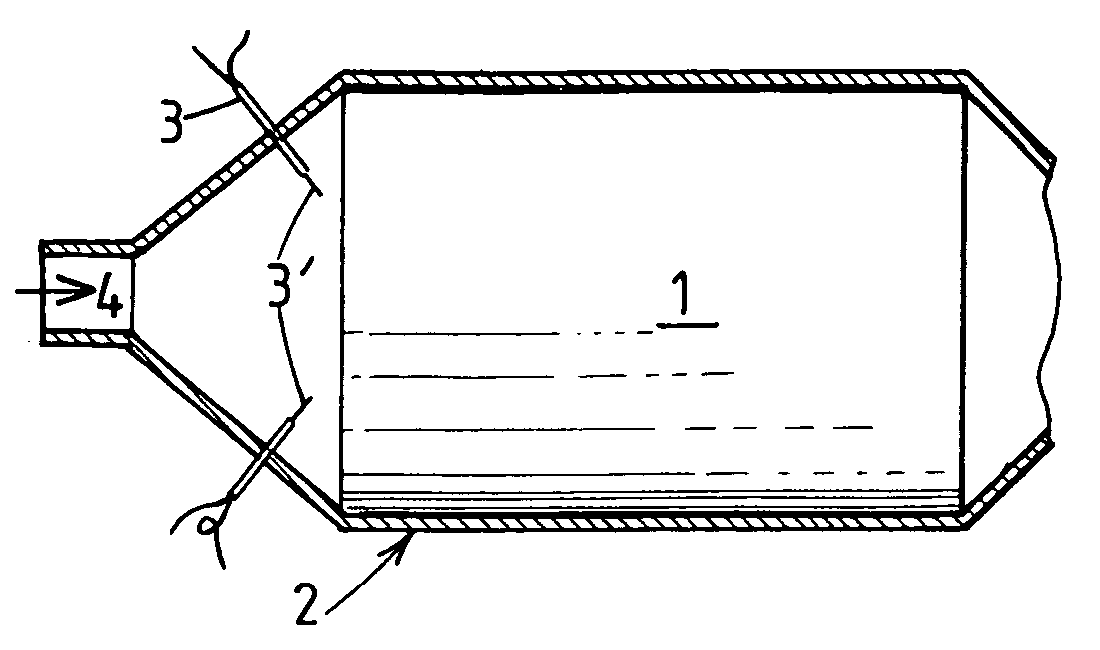

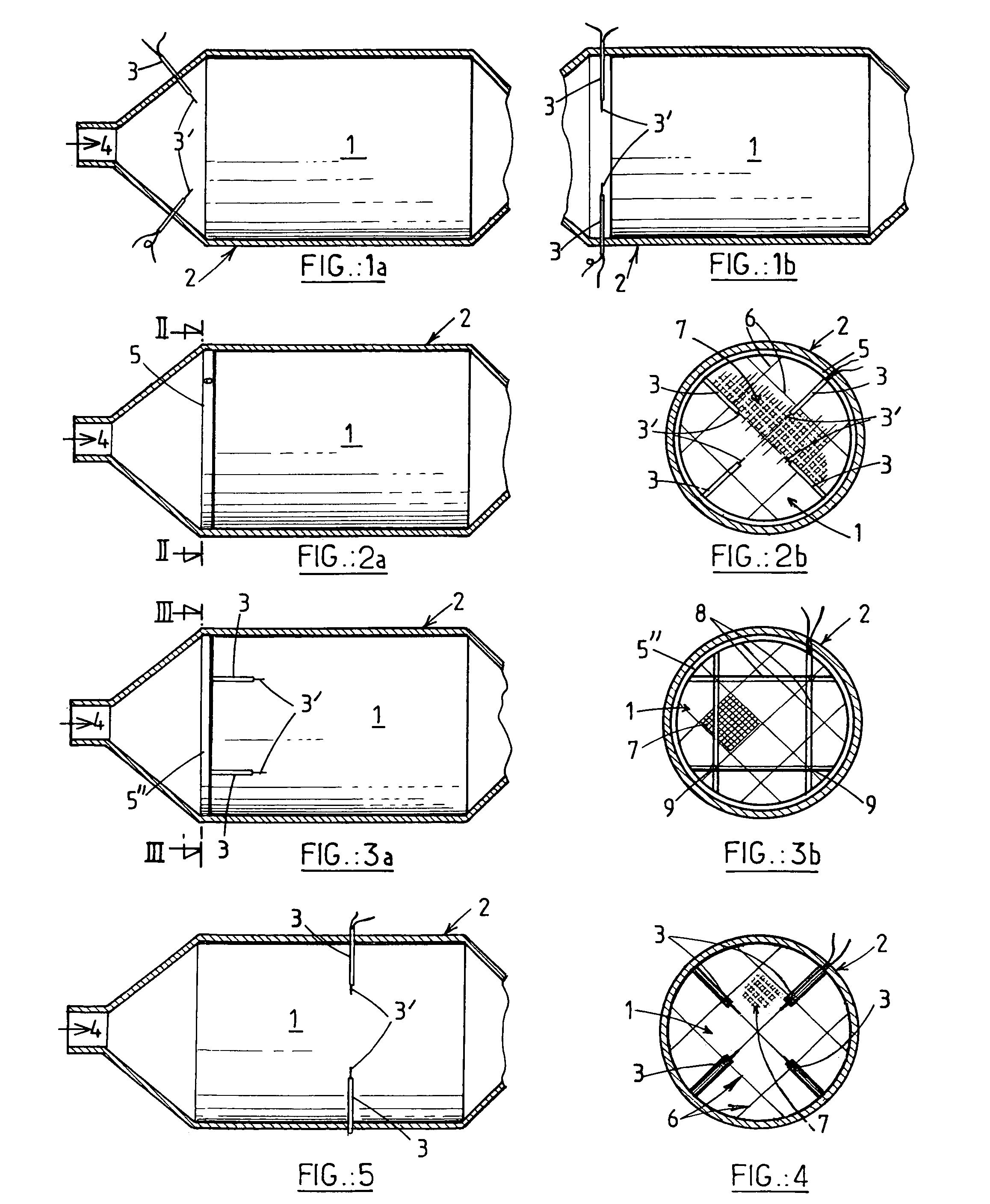

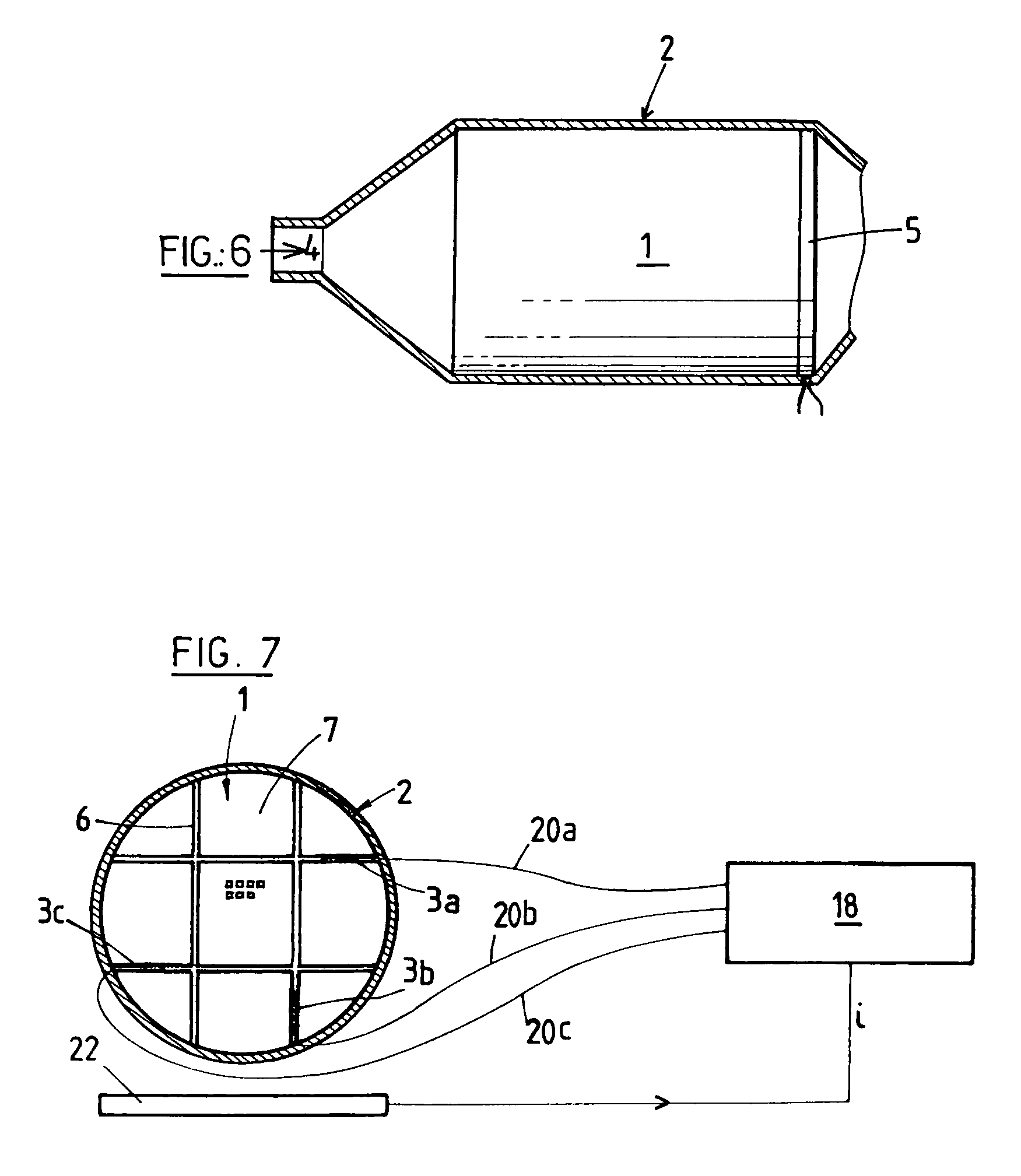

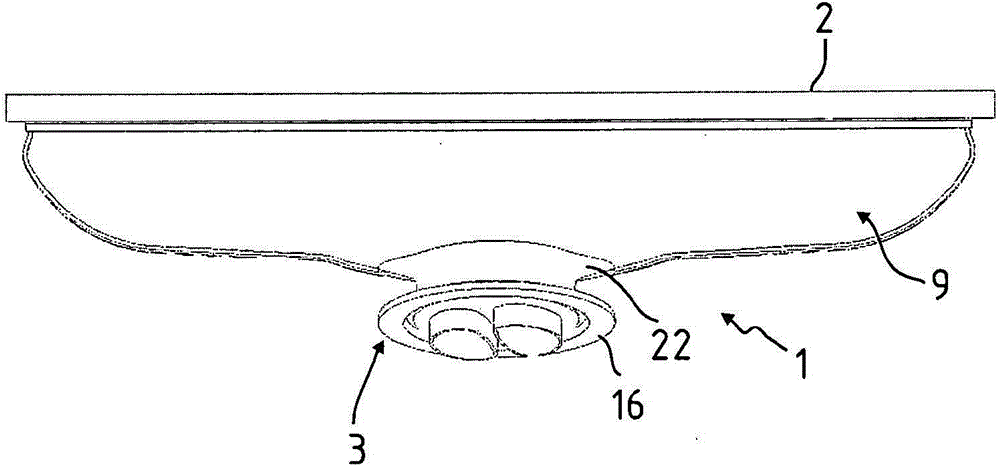

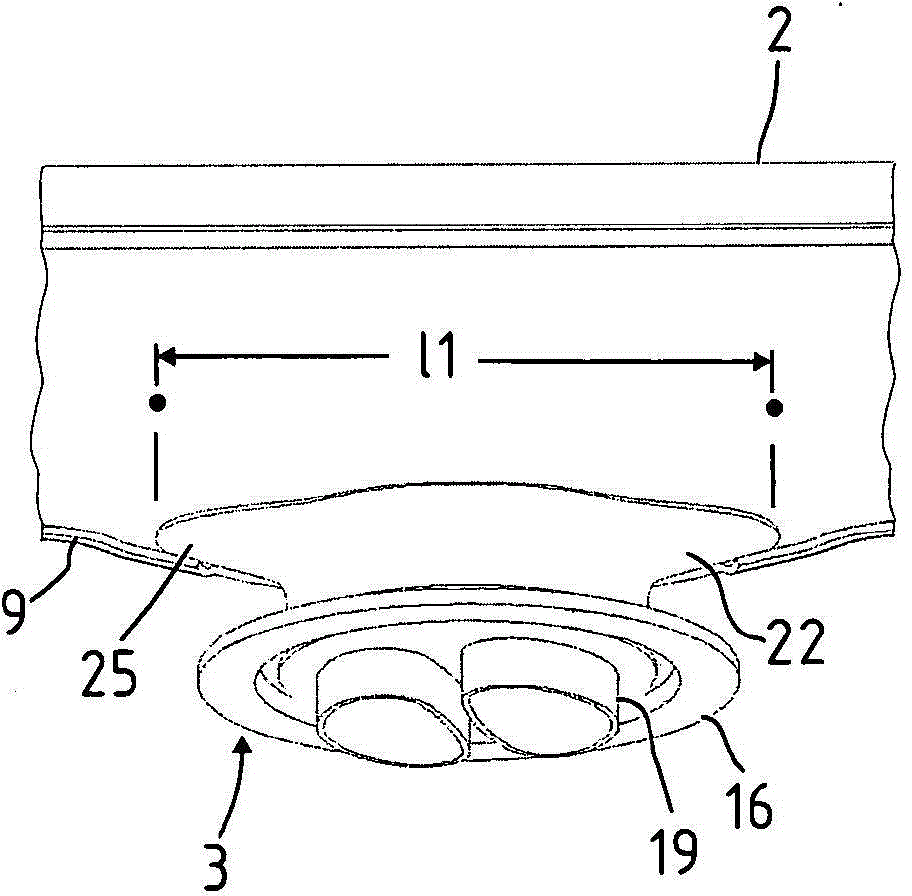

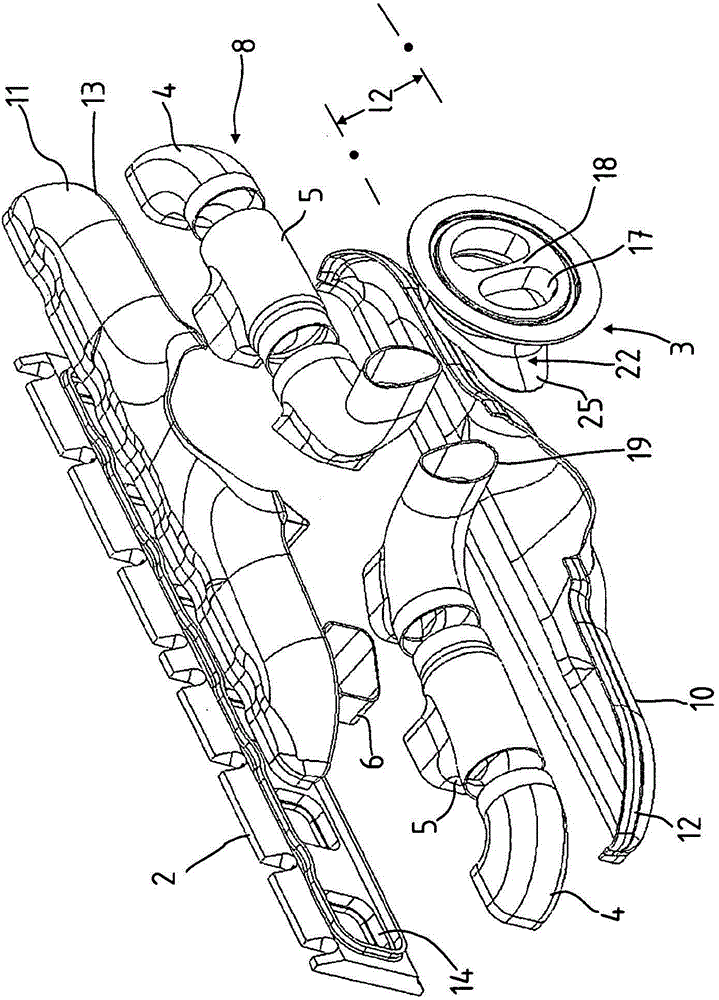

Particulate filter for purifying exhaust gases of internal combustion engines comprising hot spot ceramic ignitors

InactiveUS6989048B2Short response timeReduce riskCombination devicesAuxillary pretreatmentParticulatesExternal combustion engine

A particulate filter for purifying exhaust gases of an internal combustion engine, in particular of a diesel engine, comprises a filtering body and heating elements for initiating combustion of soot particles accumulated on and in the filtering body. The heating elements comprise at least a hot spot ceramic ignitor (3). The invention is applicable in the automotive industry.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Semiconductor devices and methods of forming same

InactiveCN108028245ASimple technologyEasy to controlSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceElectrical conductor

Owner:NANYANG TECH UNIV

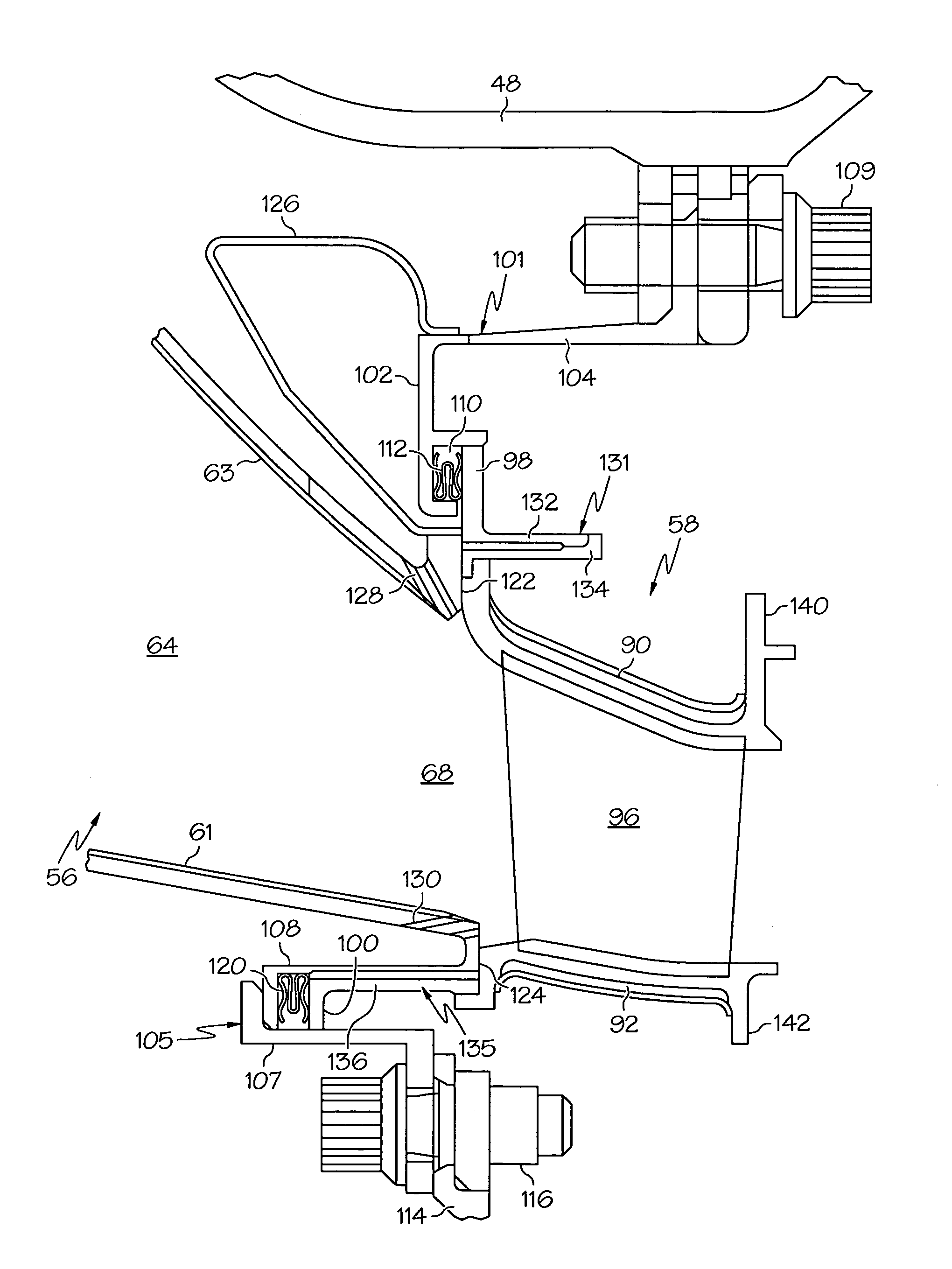

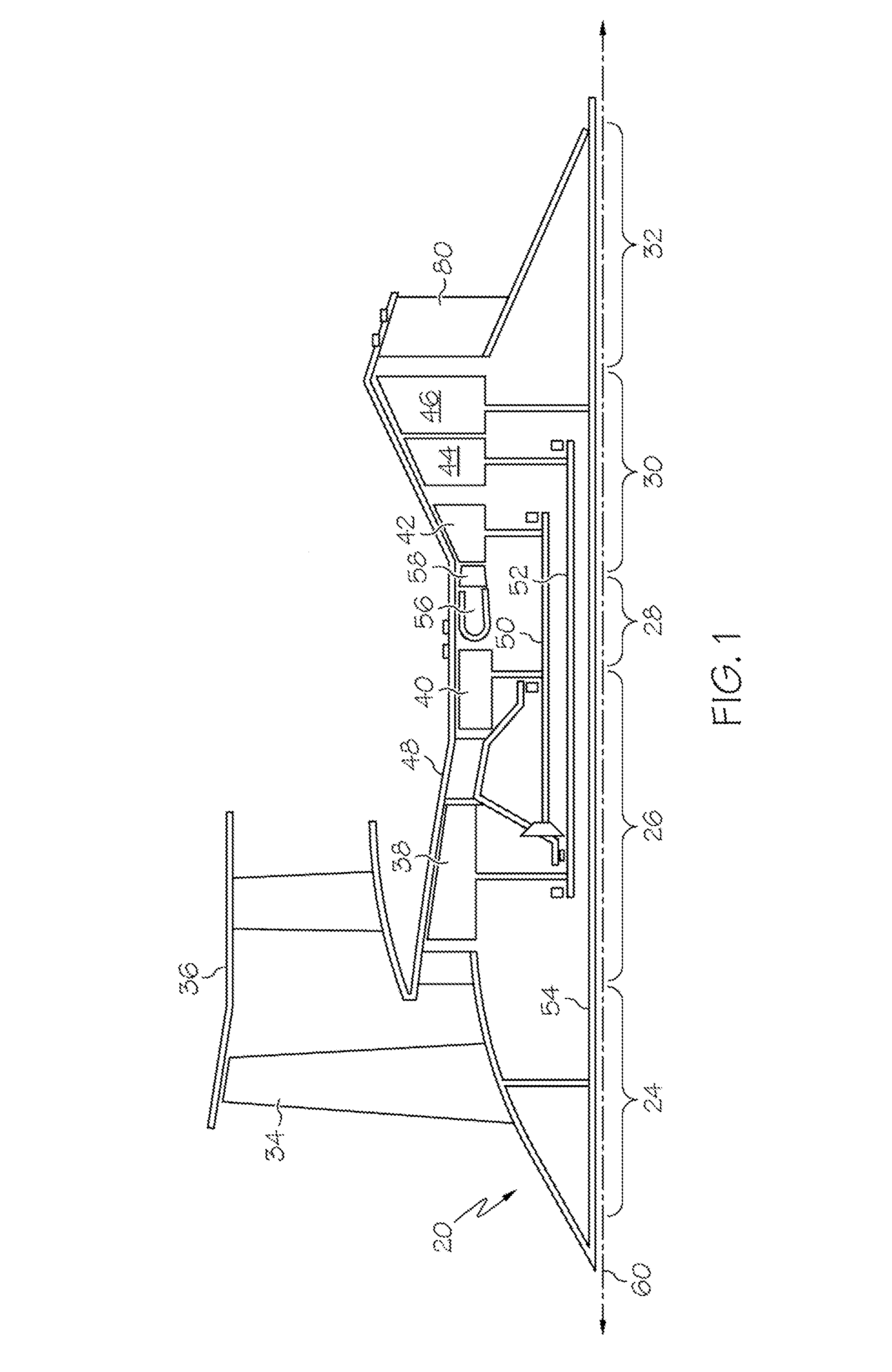

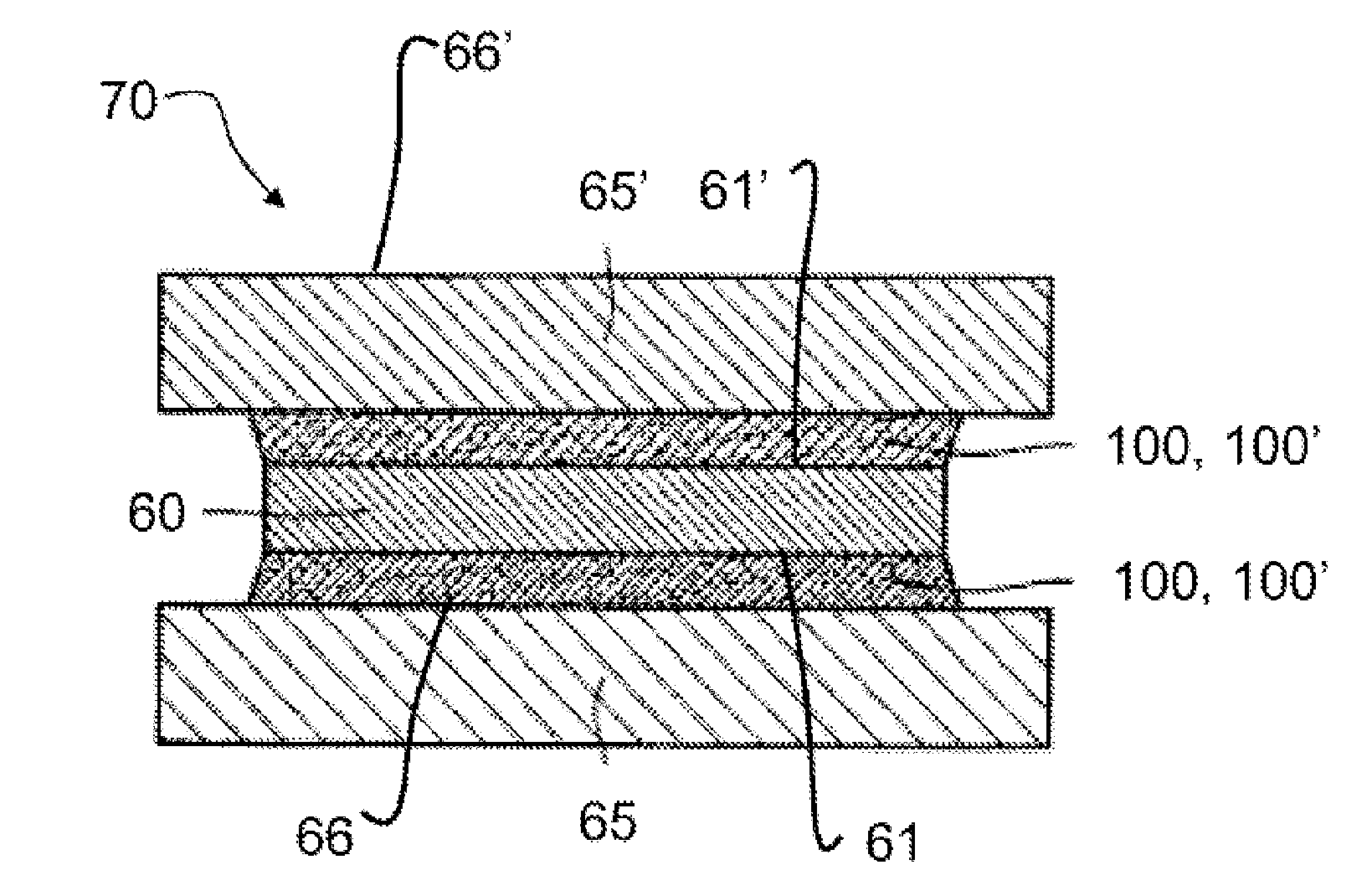

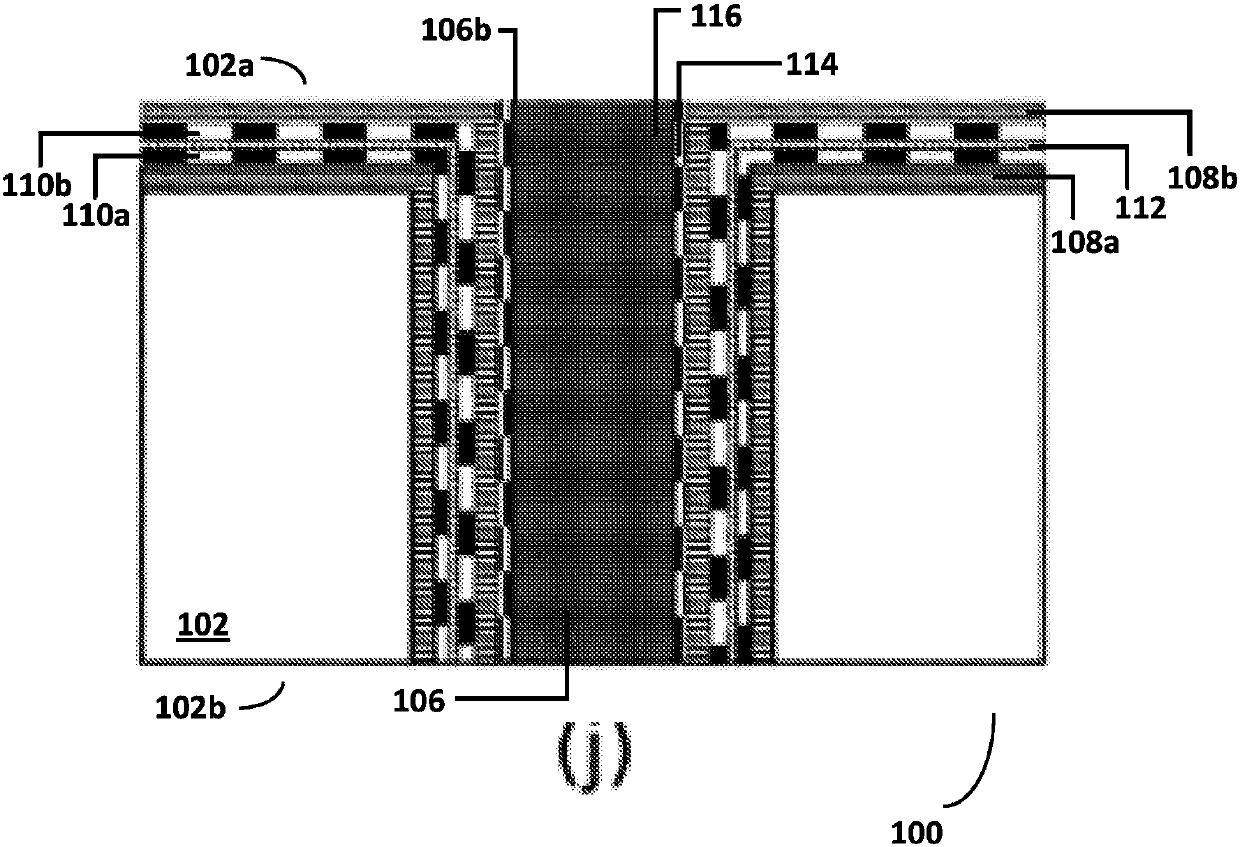

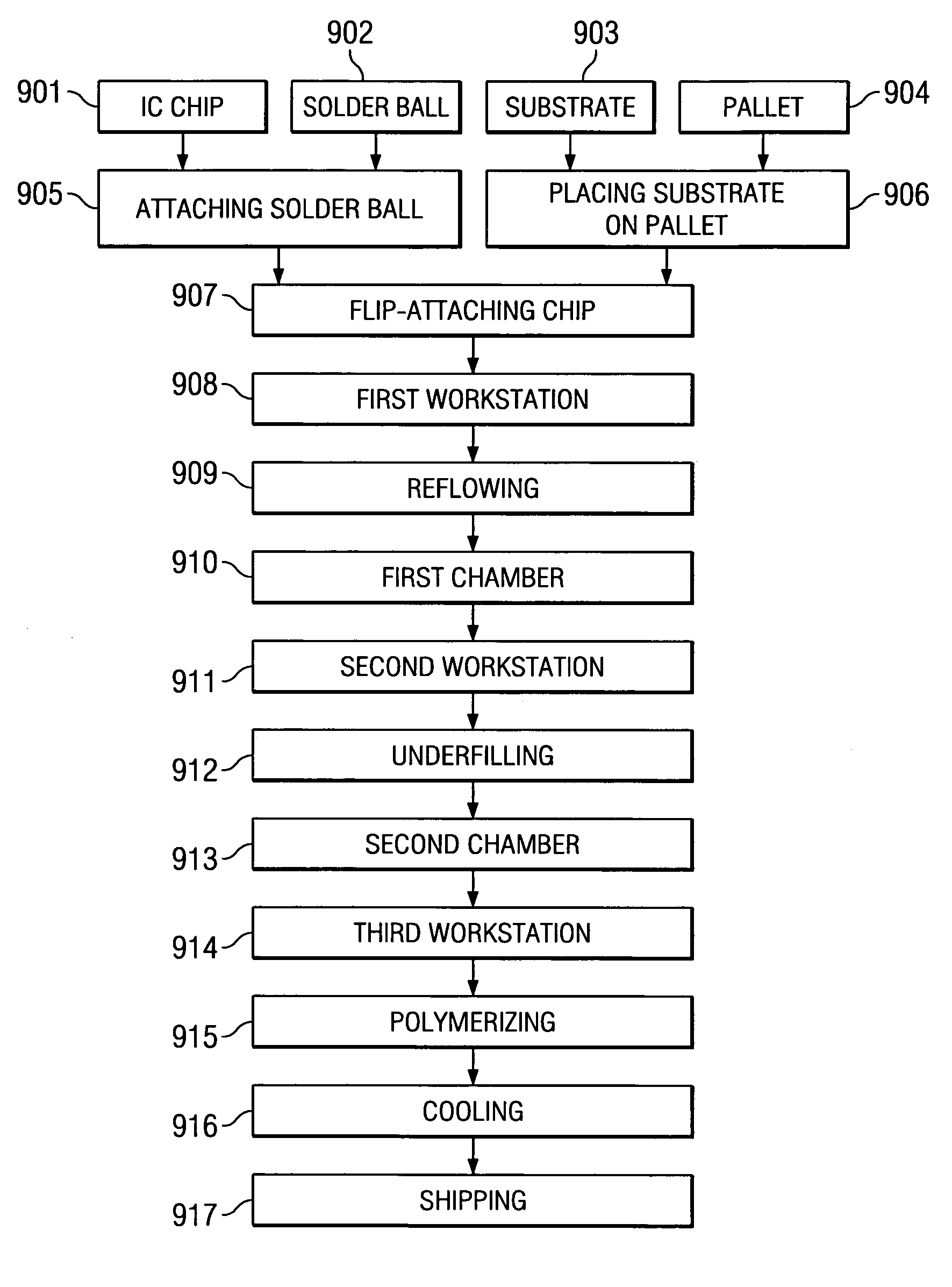

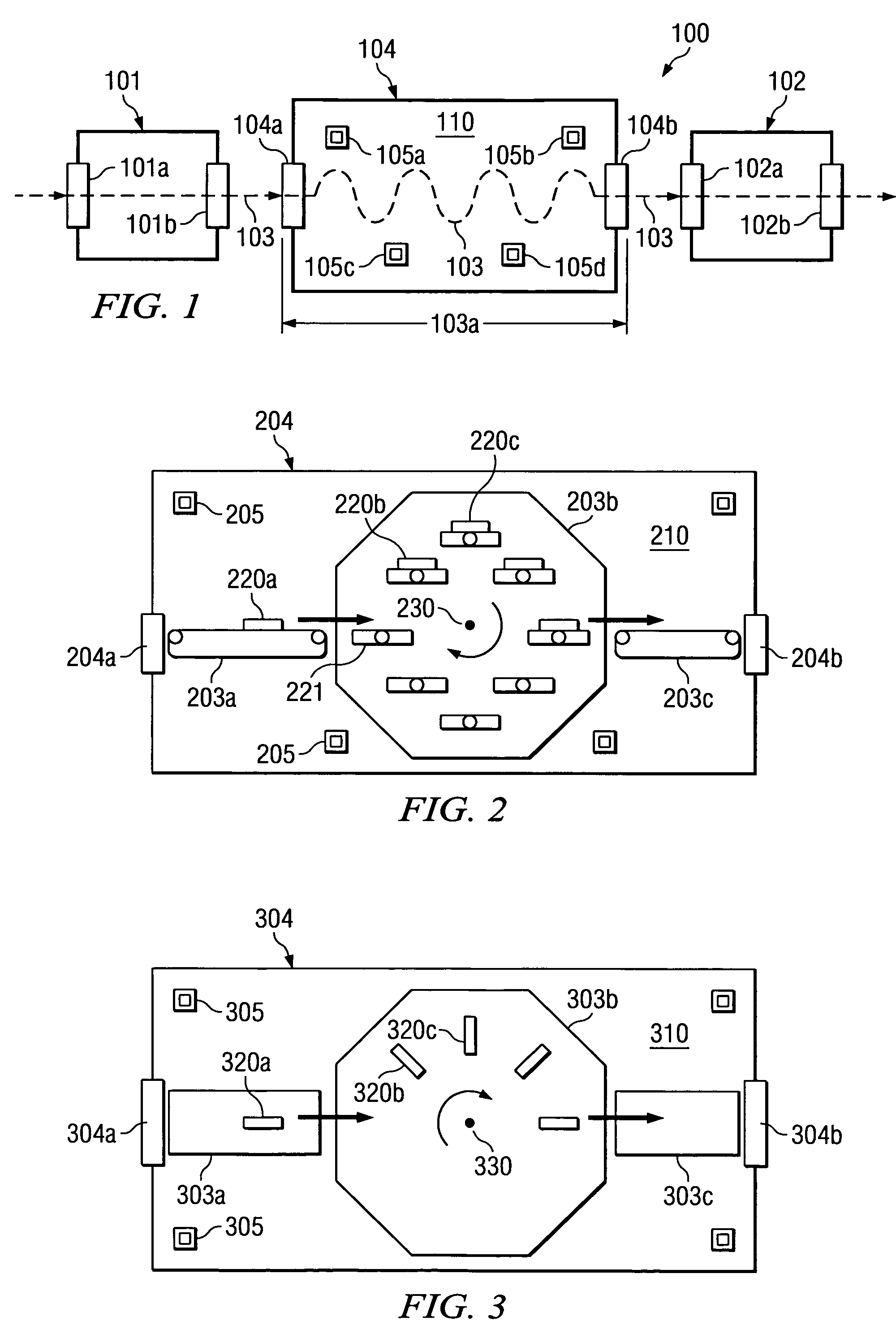

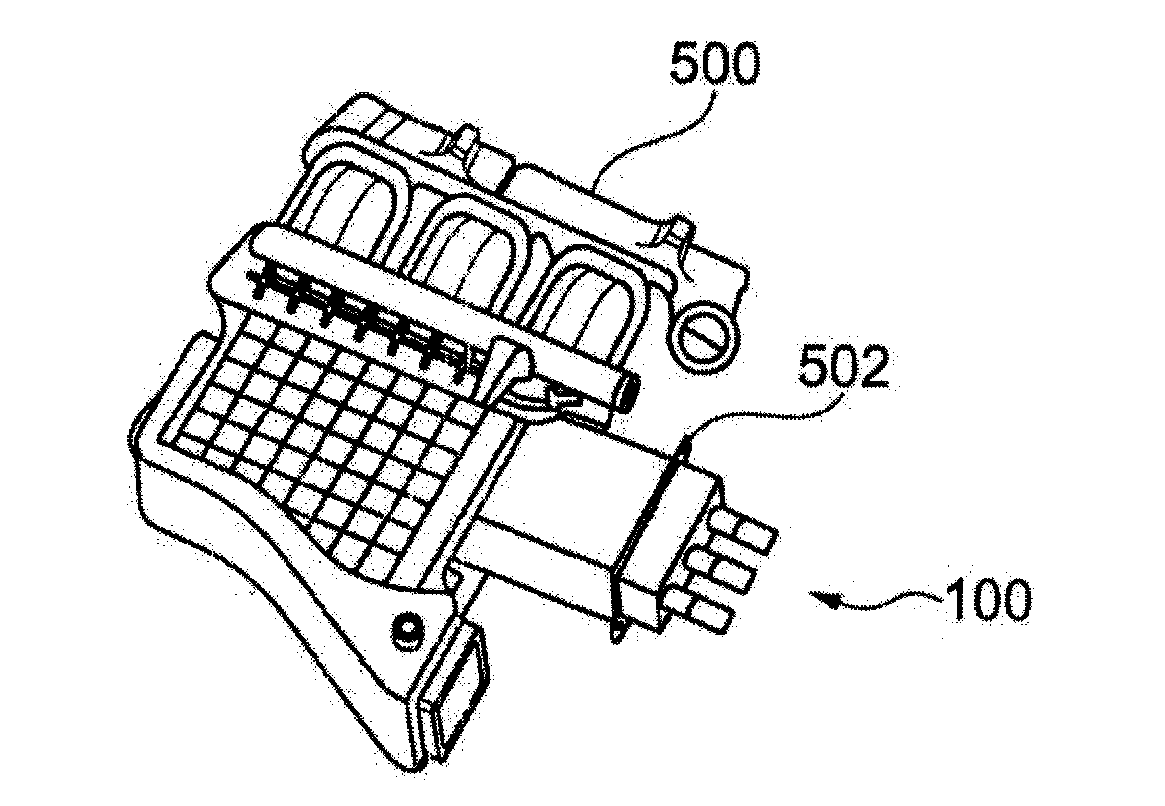

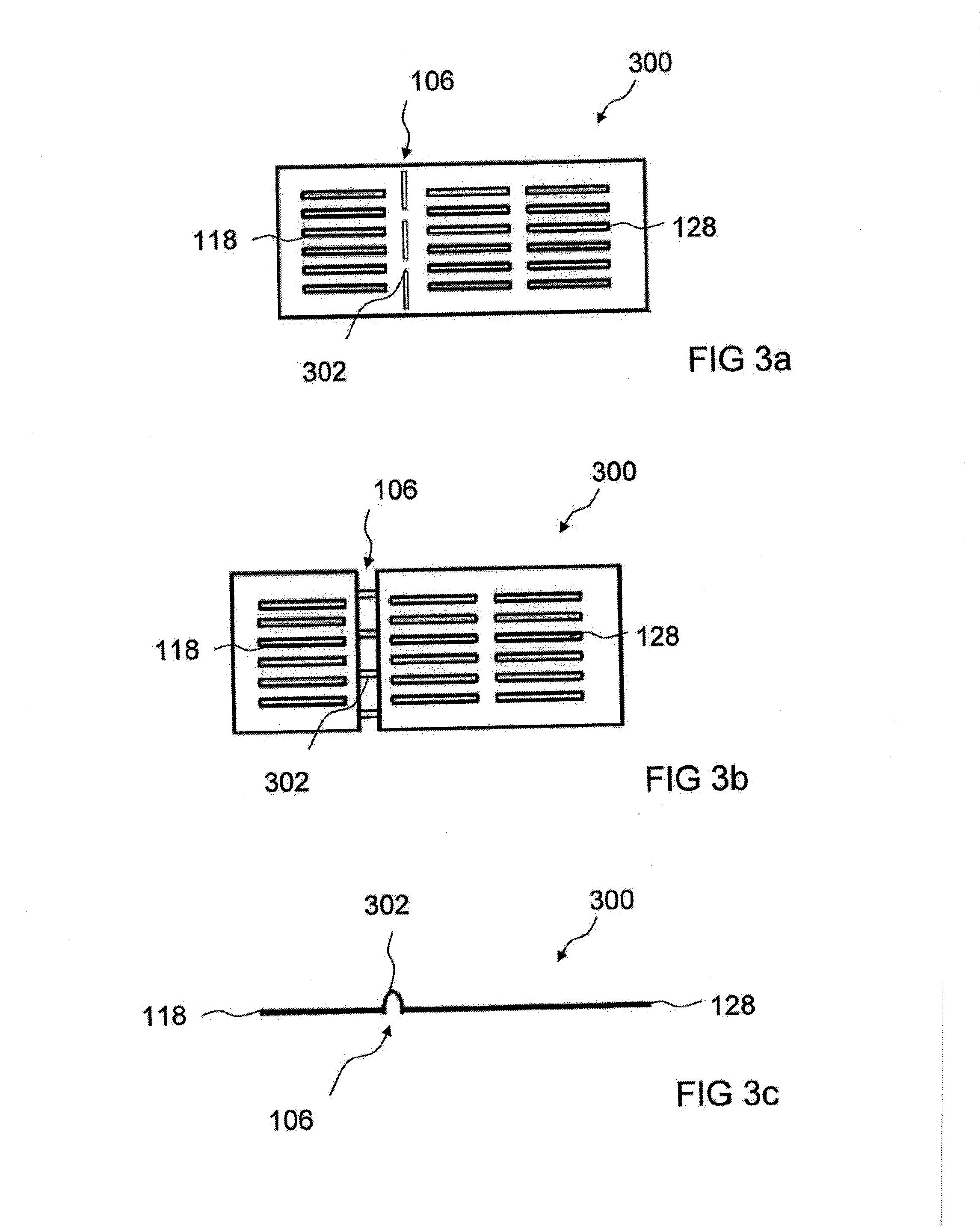

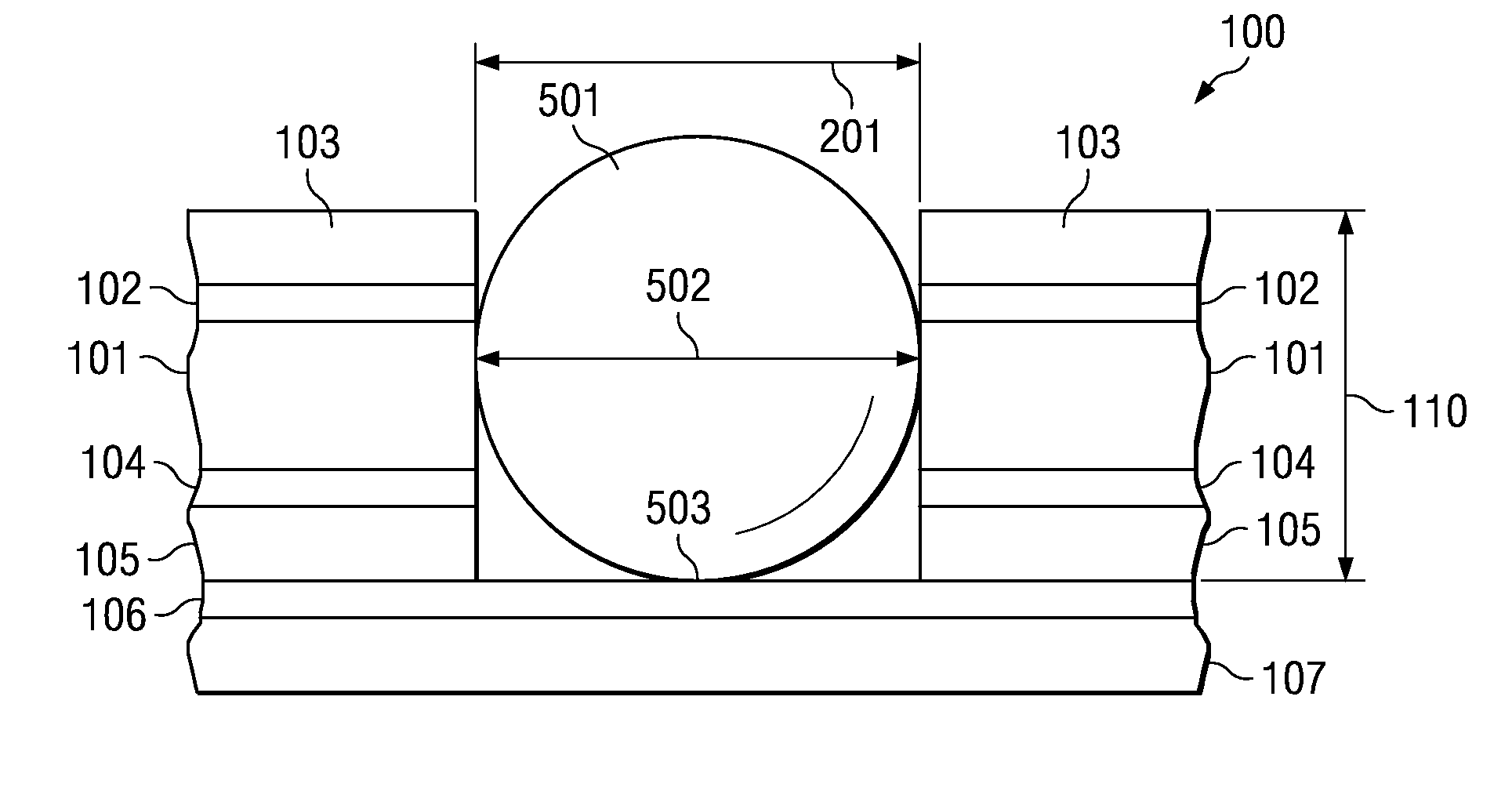

Manufacturing system and apparatus for balanced product flow with application to low-stress underfilling of flip-chip electronic devices

ActiveUS6977429B2Reduce thermomechanical stressLow-stress and reliable productDigital data processing detailsSemiconductor/solid-state device detailsManufacturing systemsProduct Part

A system (100) for manufacturing product, in which a first work station (101) is operable to perform a first manufacturing action on the product parts; this first station has a first entrance (101a) and a first exit 101b). A second work station (102) is operable to perform a second manufacturing action on the product parts; this second station has a second entrance (102a) and a second exit (102b). A transport line (103) between the first exit and the second entrance is operable to move the product parts under computer control. A chamber (104) encloses a portion of the line and is constructed so that the transport achieves a balanced throughput from the first station to the second station, while the product parts are exposed to computer-controlled environmental conditions (110) during transport through the chamber. The balanced throughput in the chamber is achieved by waiting lines for the product with computer-controlled monitors (105a) for product parts' positions and times in the chamber.

Owner:TEXAS INSTR INC

Method of operating turbine engine after flame off

InactiveCN104169531AQuick restartQuick Shutdown ProcedureEngine fuctionsGas turbine plantsElectric generatorBraking system

The present invention relates to a method of decelerating a turbine rotor (12) of a turbine engine (1), wherein at least one electric motor (30) is engaged with the turbine rotor (12), wherein a braking system (40), preferably the starting system, is engaged with the at least one electric motor (30), preferably the generator of the turbine engine (1), so as to use the at least one electric motor (30) to apply a negative (braking) torque on the turbine rotor (12). The method is characterized in that, after flame off, the braking system (40) is used for dissipating kinetic energy available in the turbine engine (1) after flame off by means of the at least one electric motor (30).

Owner:ANSALDO ENERGIA IP UK LTD

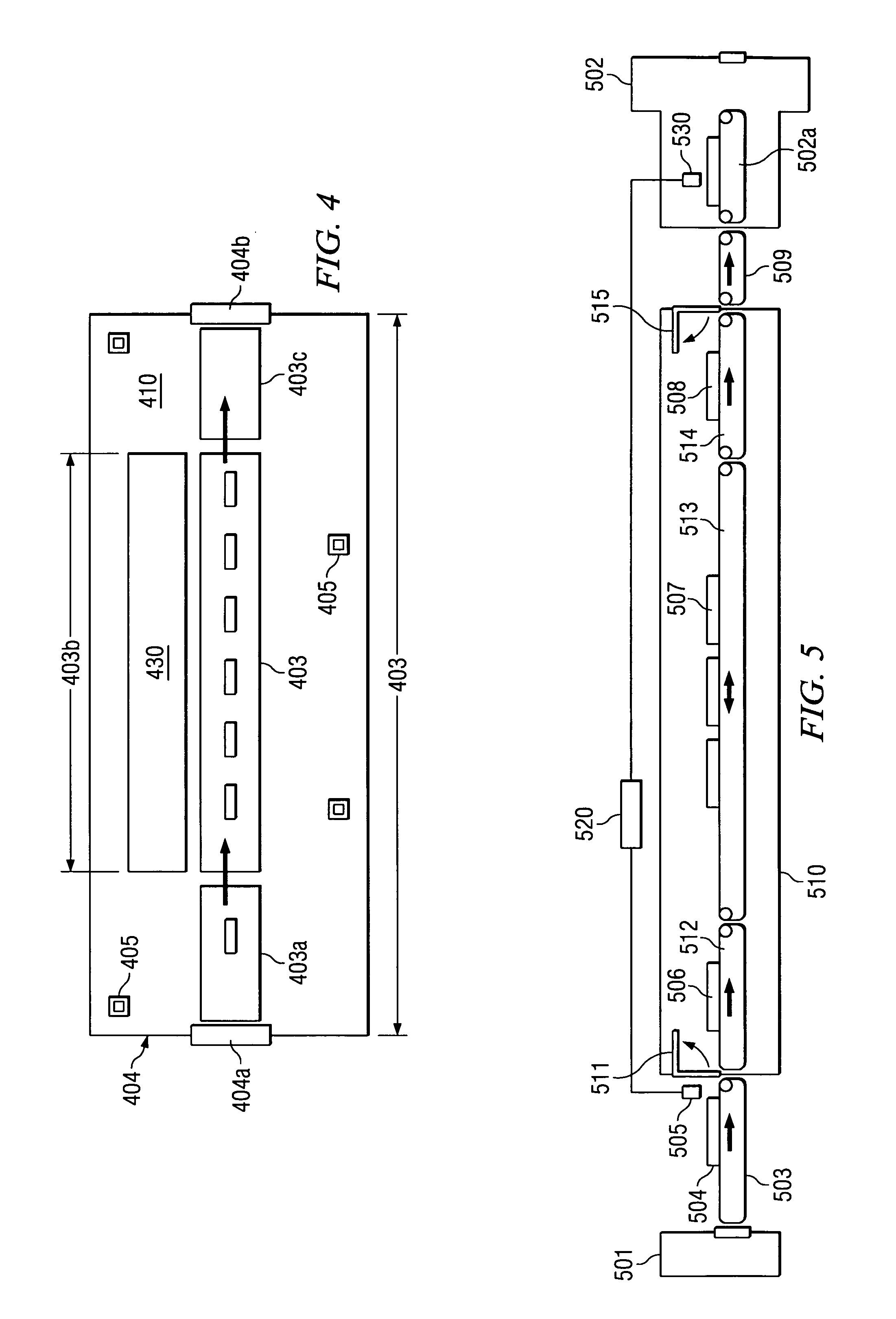

Anodes with corner and edge modified designs

InactiveUS20080299371A1Reduce and distribute stressReduces reliability of deviceSolid electrolytic capacitorsLiquid electrolytic capacitorsElectrolysisOptoelectronics

Porous sintered anode bodies for capacitors formed from valve metals are treated by electrolysis to form a dielectric layer and coated with cathode layers. When standard parallelpiped shapes are used, cathode coverage at the edges and corners is non-uniform and failures occur at those locations. Rectangular prisms, obround prisms and cylindrical prisms are formed with transition surfaces at edges and corners, such as chamfers and curves, to enhance cathode layer uniformity. The transition surface greatly enhances the application of polymer slurries.

Owner:KEMET ELECTRONICS CORP

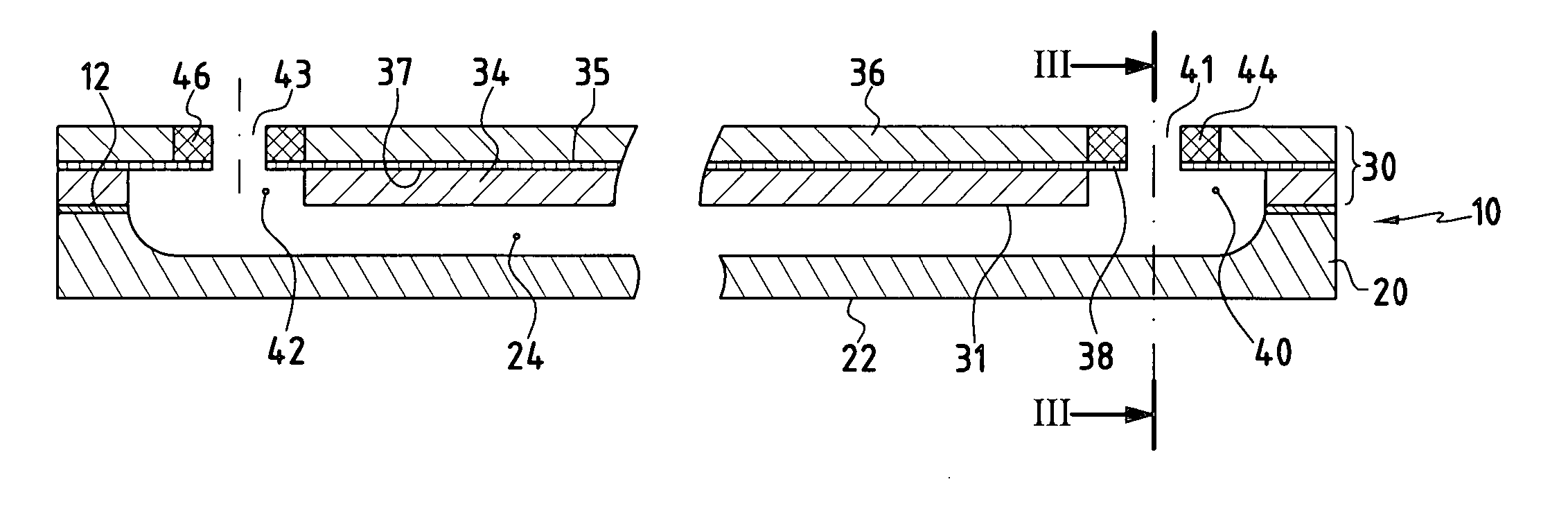

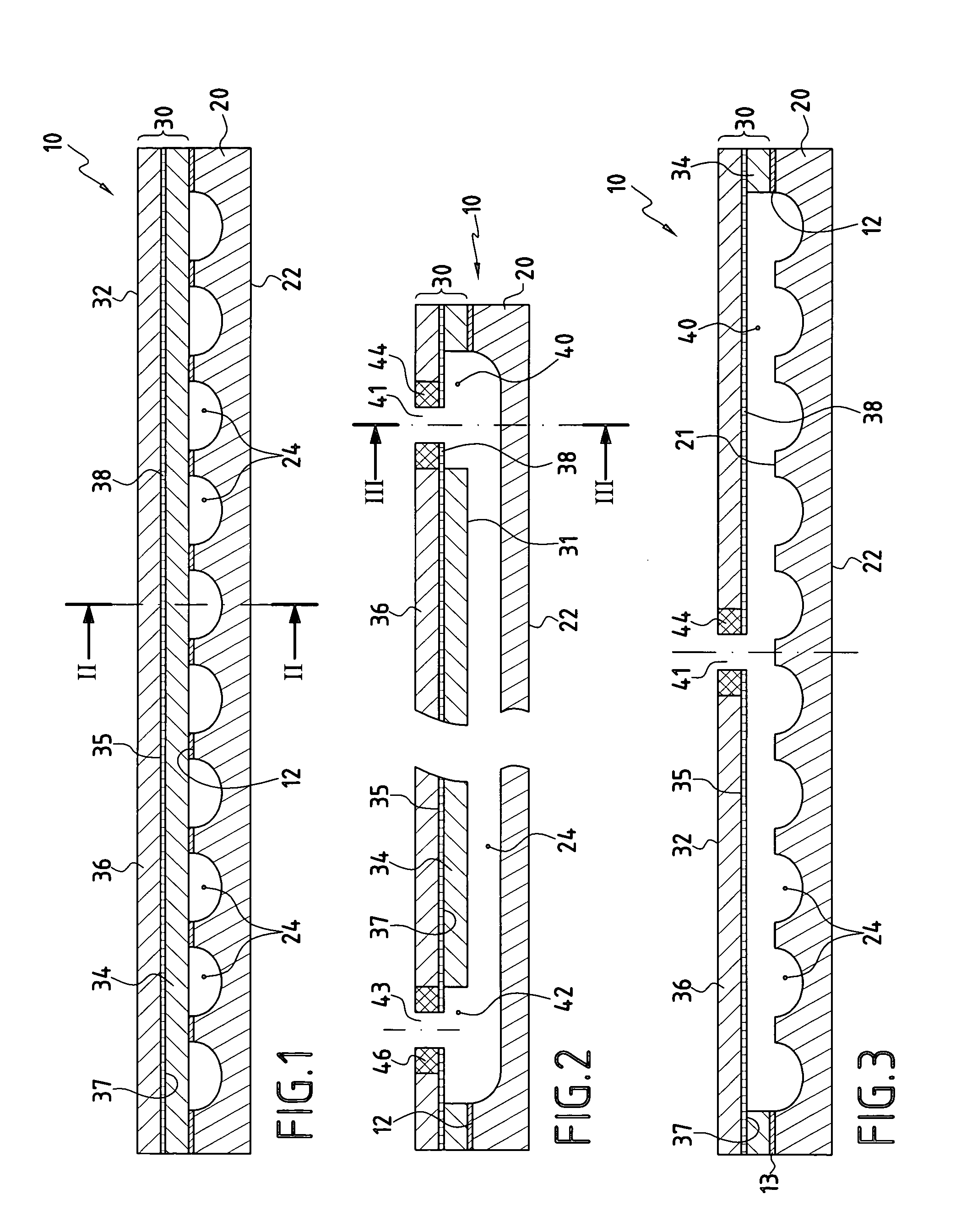

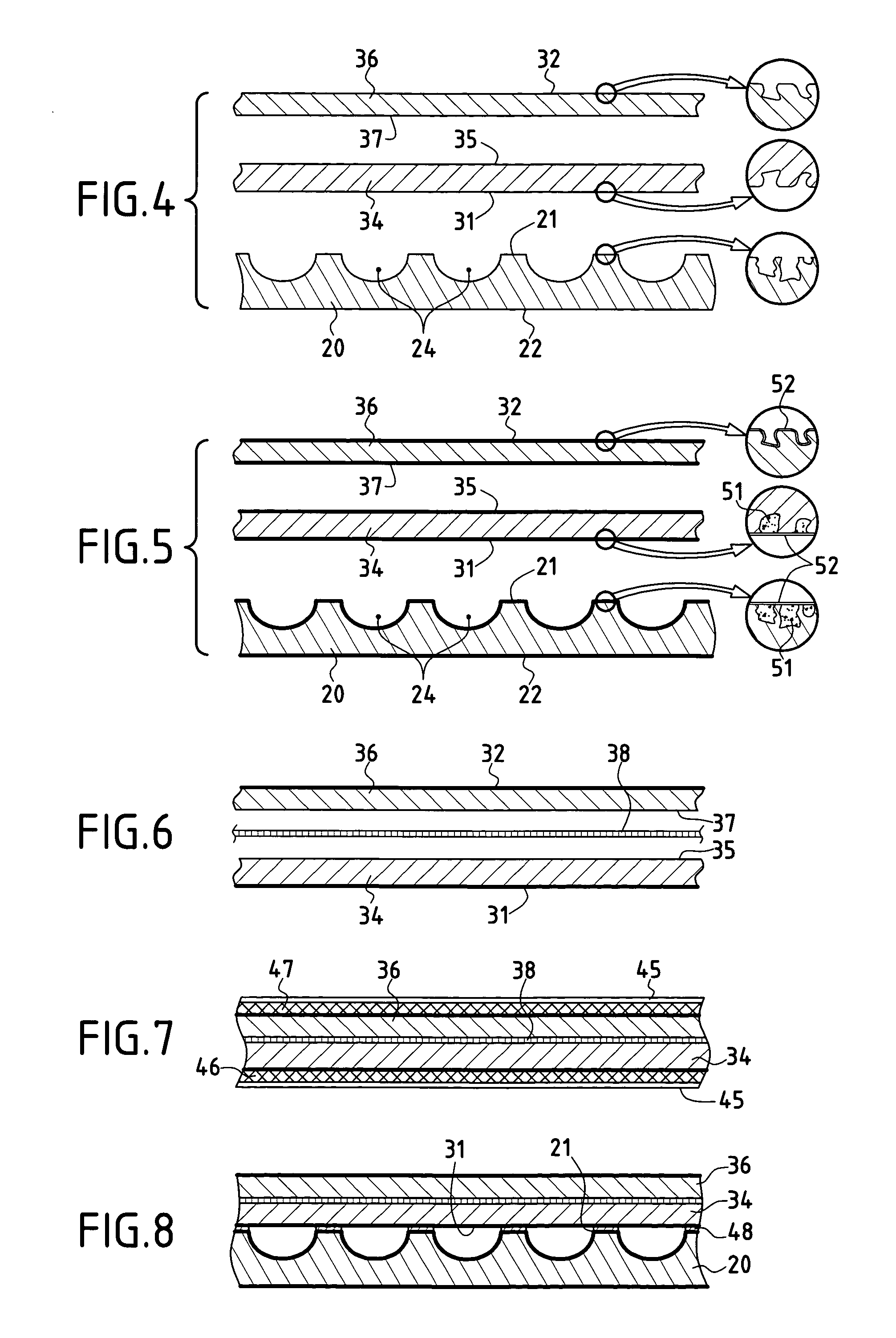

Method for fabricating flip-attached an underfilled semiconductor devices

ActiveUS20060214314A1Reduce thermomechanical stressSimplify process flowFinal product manufactureSemiconductor/solid-state device detailsContact padFilling materials

A semiconductor device (1700), which comprises a workpiece (1201) with an outline (1711) and a plurality of contact pads (1205) and further an external part (1701) with a plurality of terminal pads (1702). This part is spaced from the workpiece, and the terminal pads are aligned with the workpiece contact pads, respectively. A reflow element (1203) interconnects each of the contact pads with its respective terminal pad. Thermoplastic material (1204) fills the space between the workpiece and the part; this material adheres to the workpiece, the part and the reflow elements. Further, the material has an outline (1711) substantially in line with the outline of the workpiece, and fills the space (1707) substantially without voids. Due to the thermoplastic character of the filling material, the finished device can be reworked, when the temperature range for reflowing the reflow elements is reached.

Owner:TEXAS INSTR INC

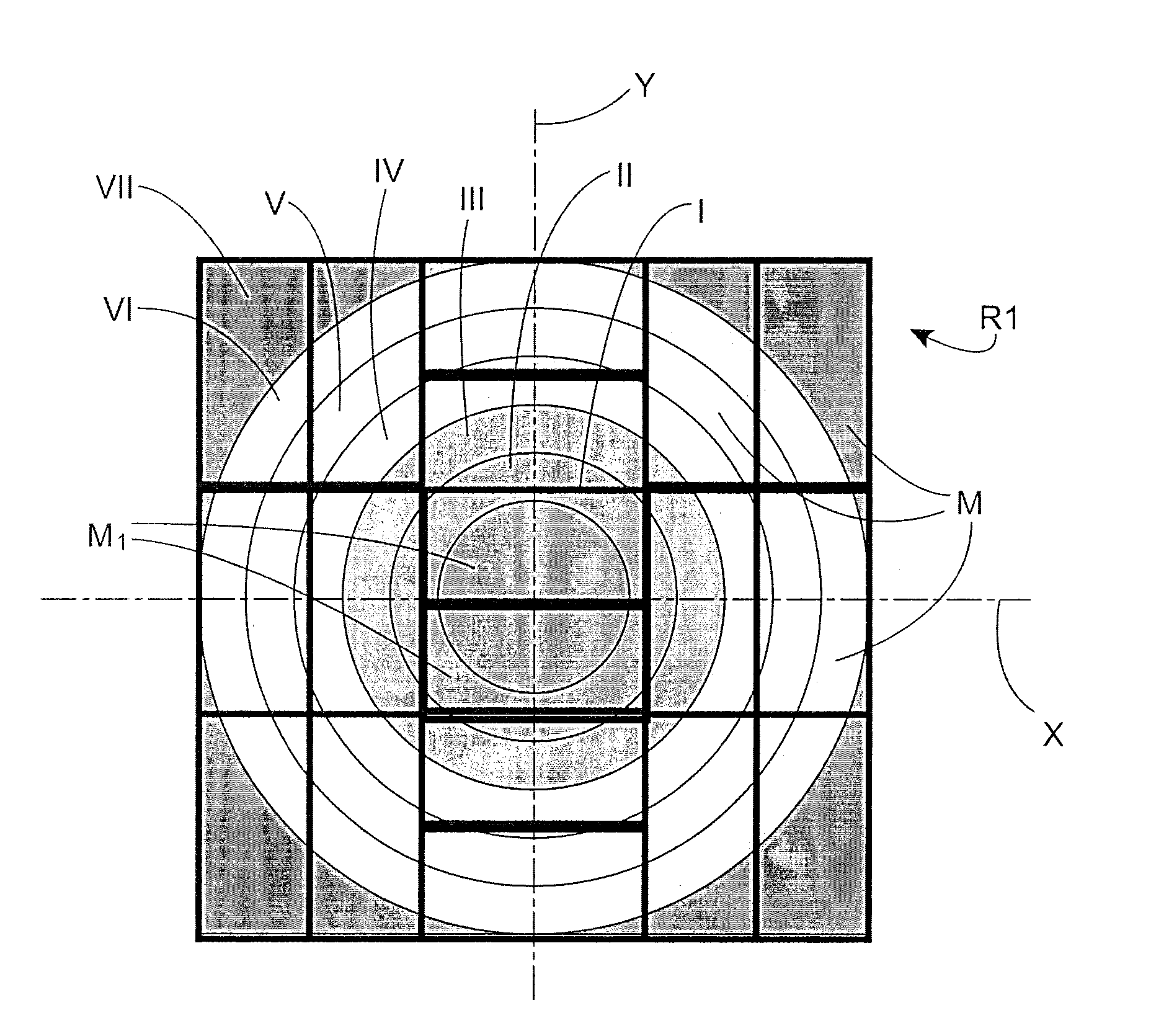

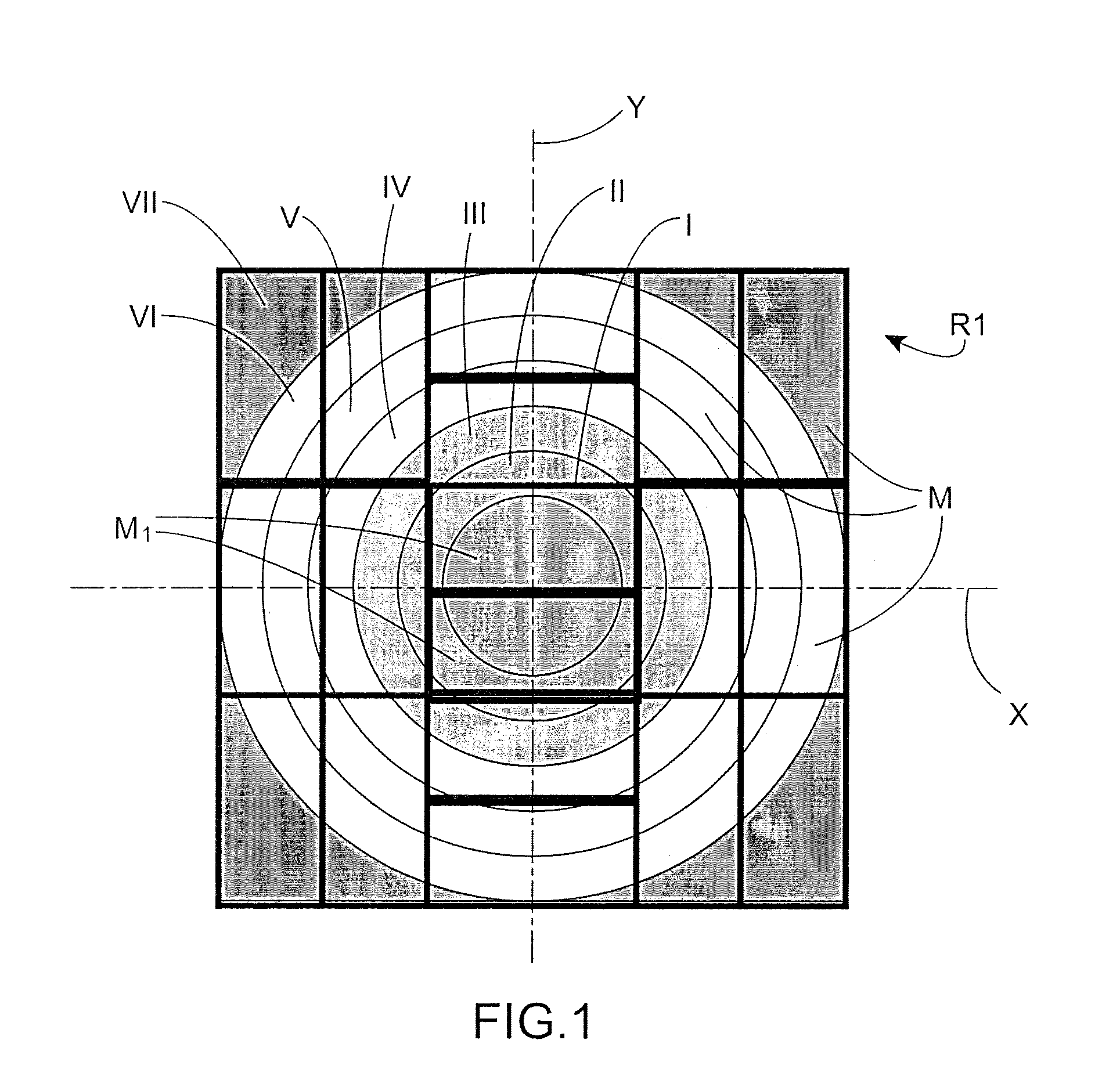

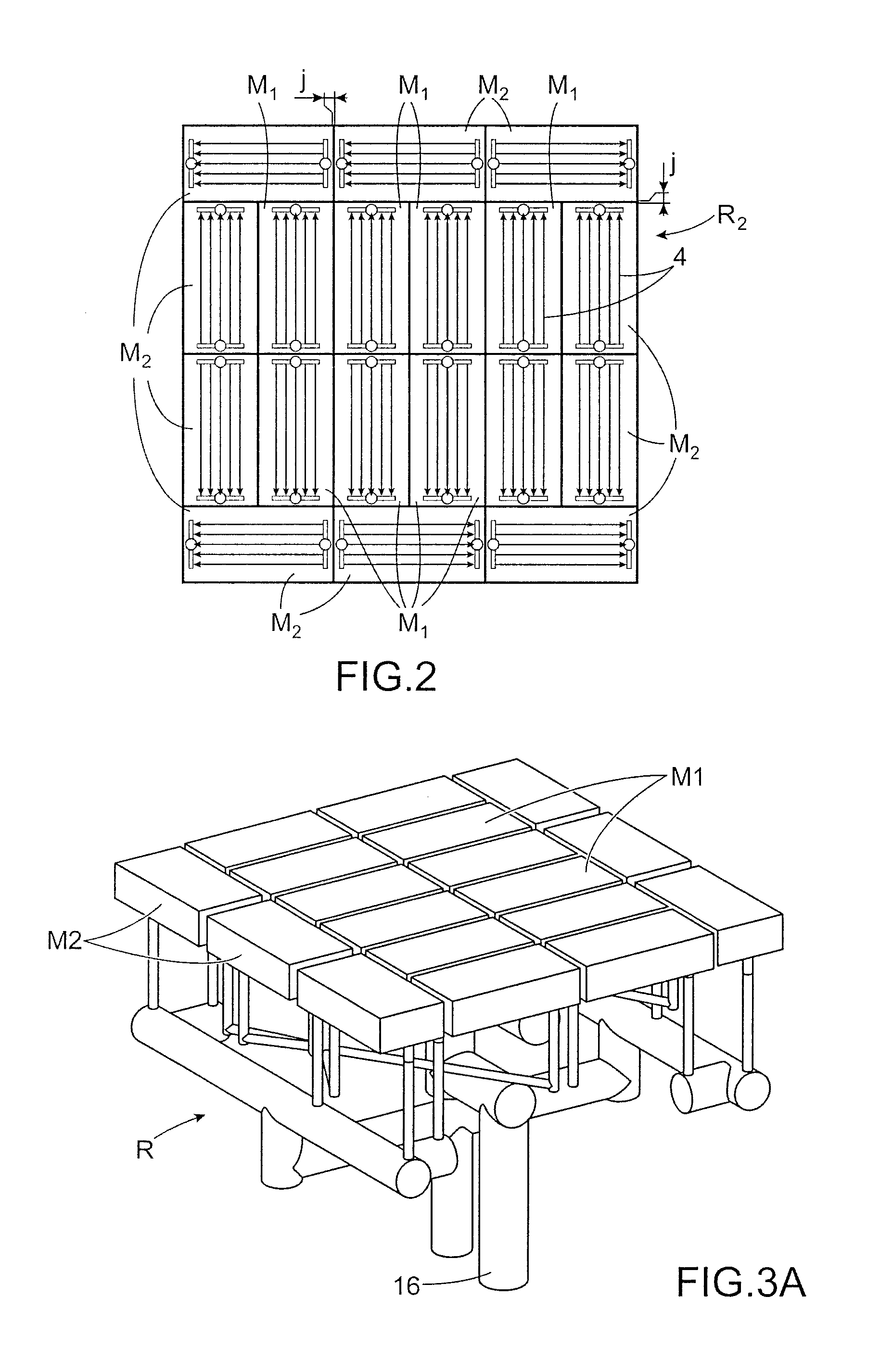

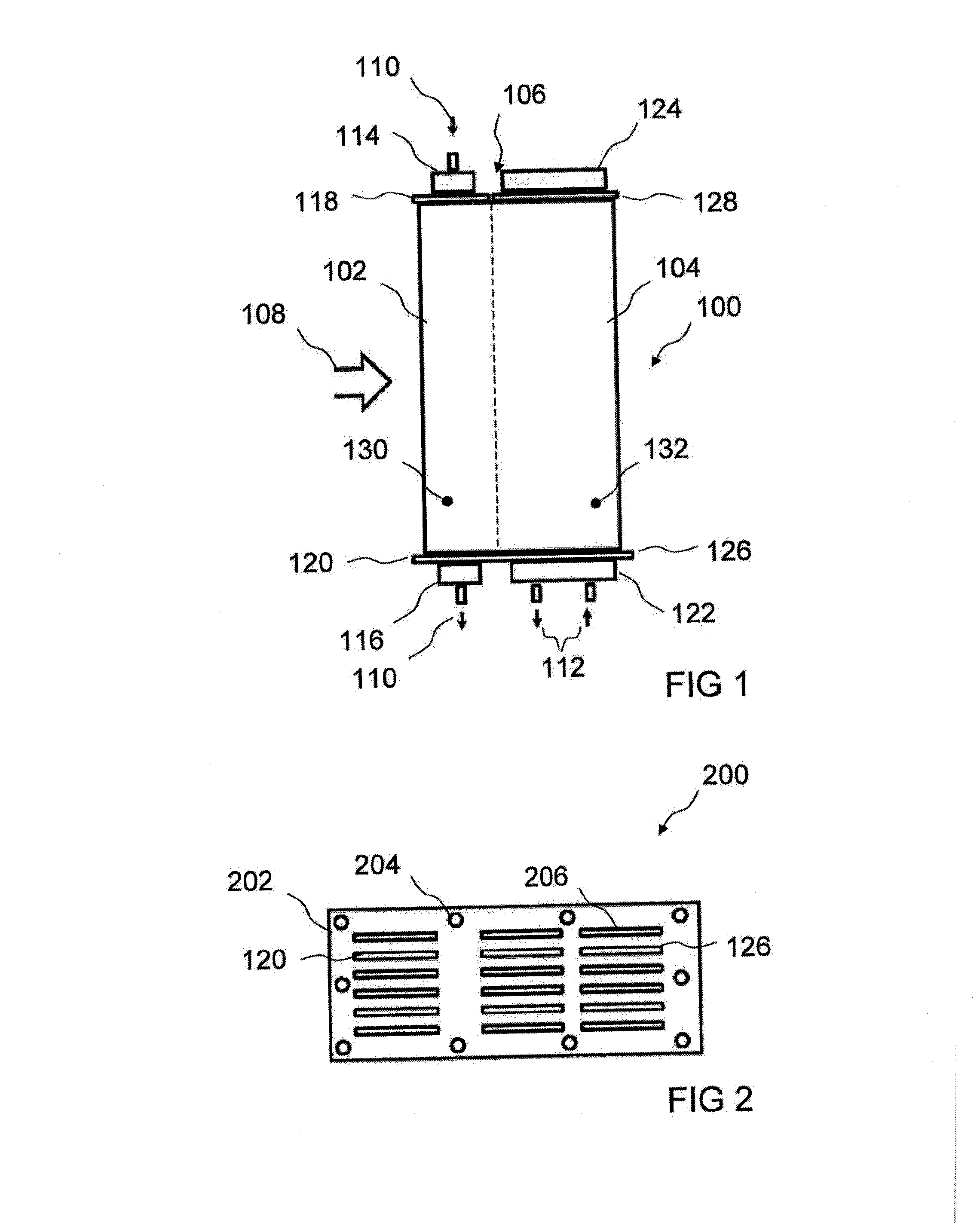

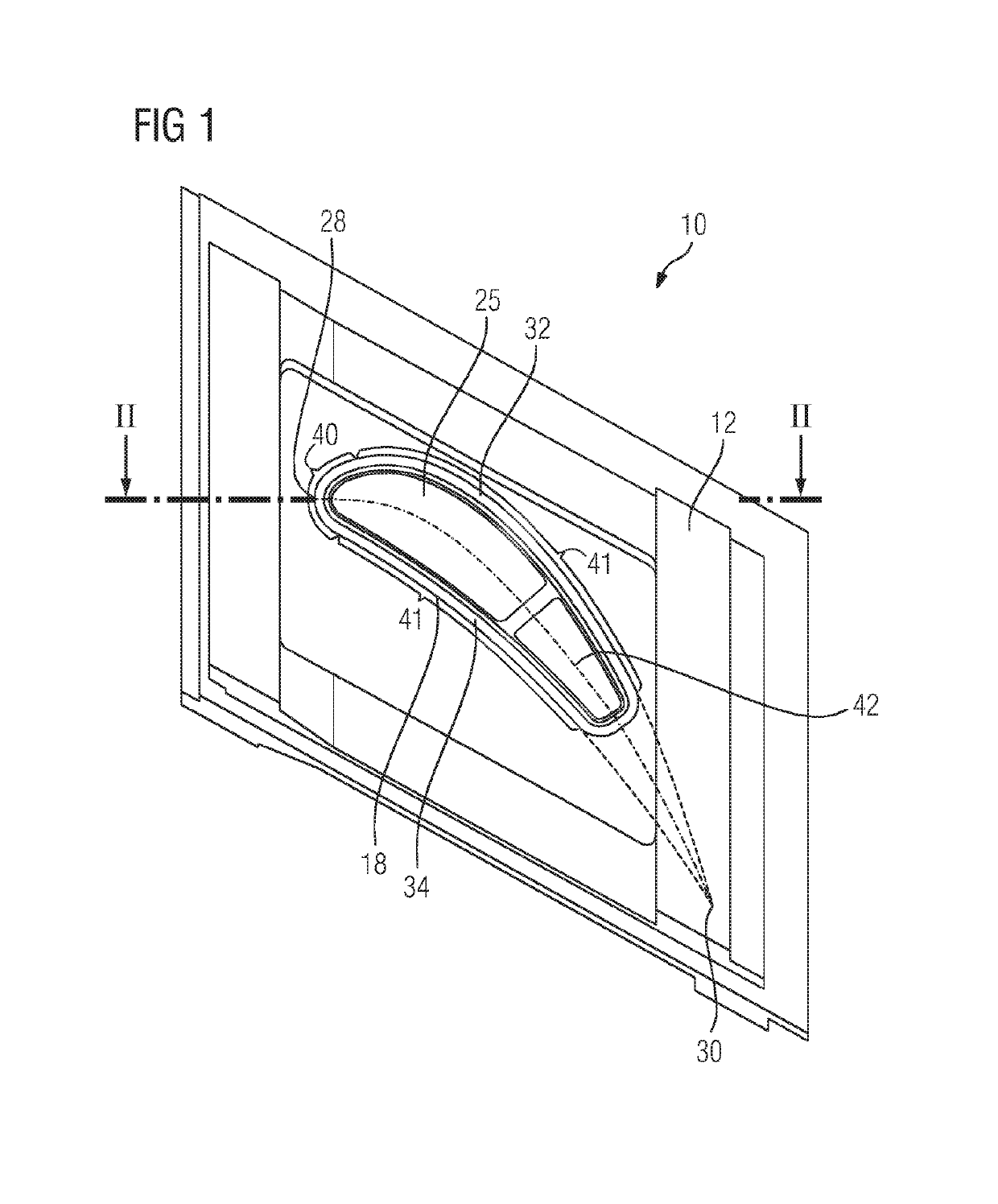

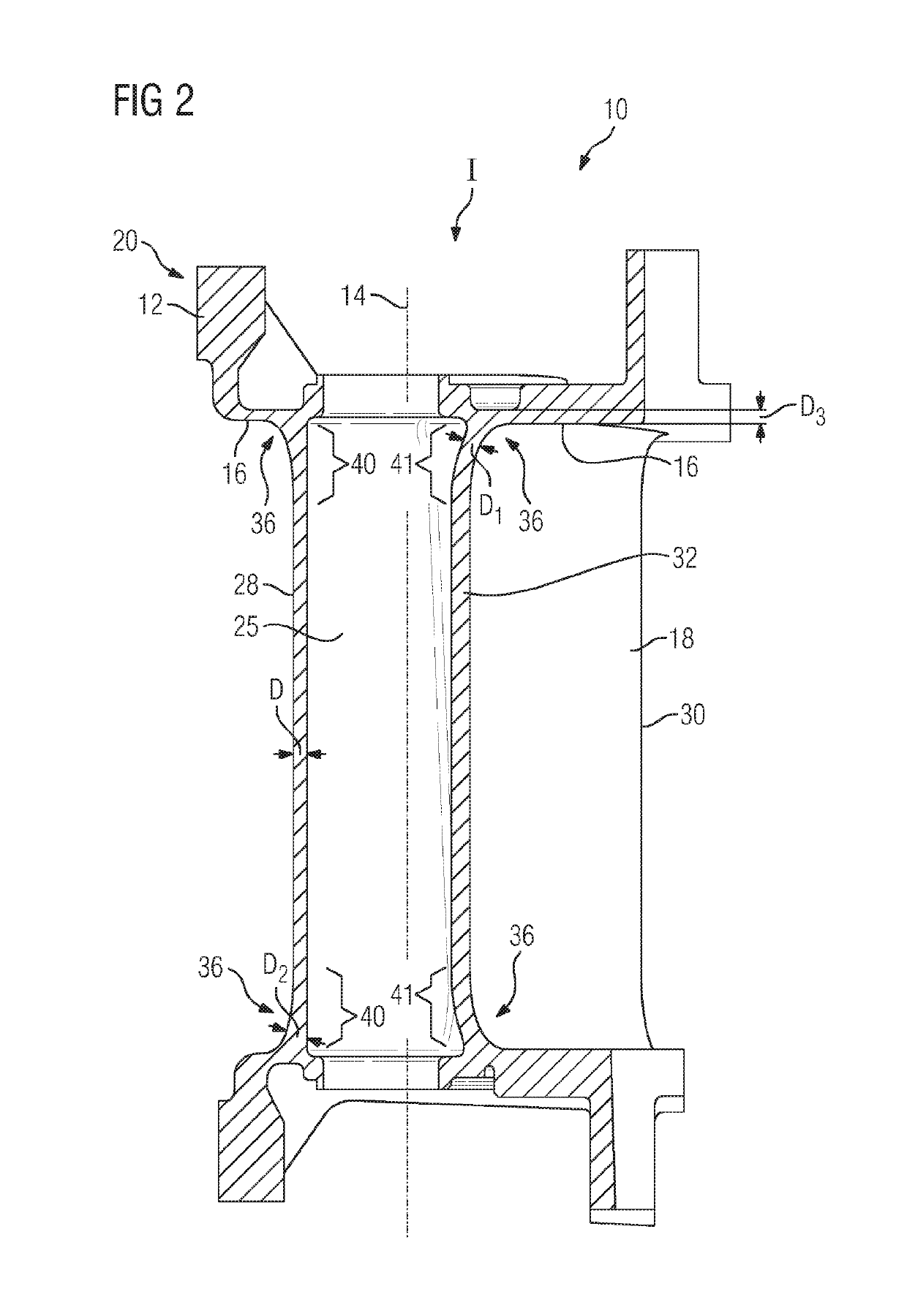

Modular solar receiver and solar power plant comprising at least one such receiver

ActiveUS20130125873A1Reduce thermomechanical stressEasy maintenanceSolar heating energySolar heat devicesEngineeringSolar power plant

A solar receiver for a thermal power plant including a plurality of absorber modules, each absorber module including at least one face configured to be illuminated by a solar flux, wherein the modules are arranged side by side forming a paving. Each absorber module further includes its own fluid circuit in which a fluid to be heated by the solar flux can flow, the fluid circuits of the absorber modules being connected to one another.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

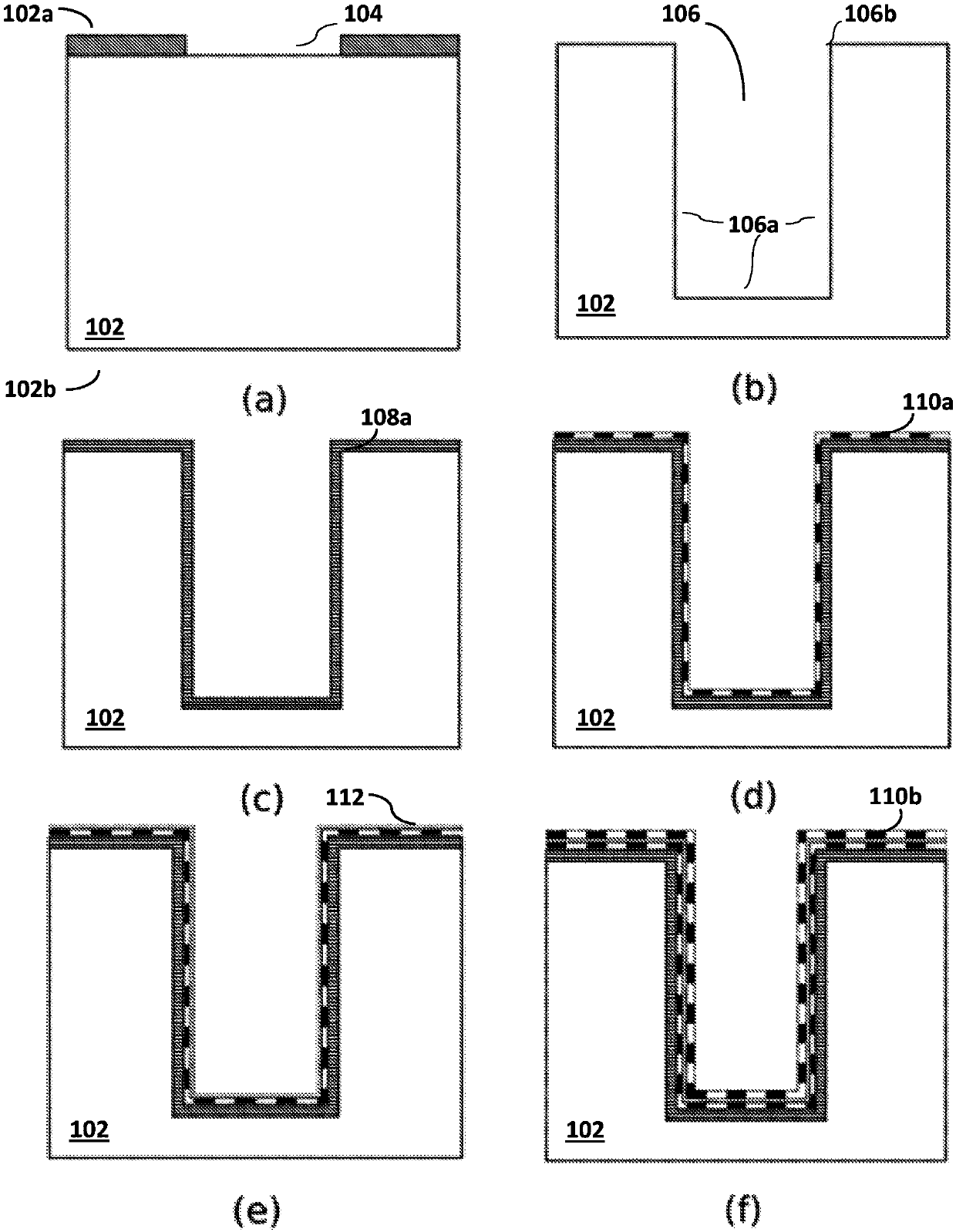

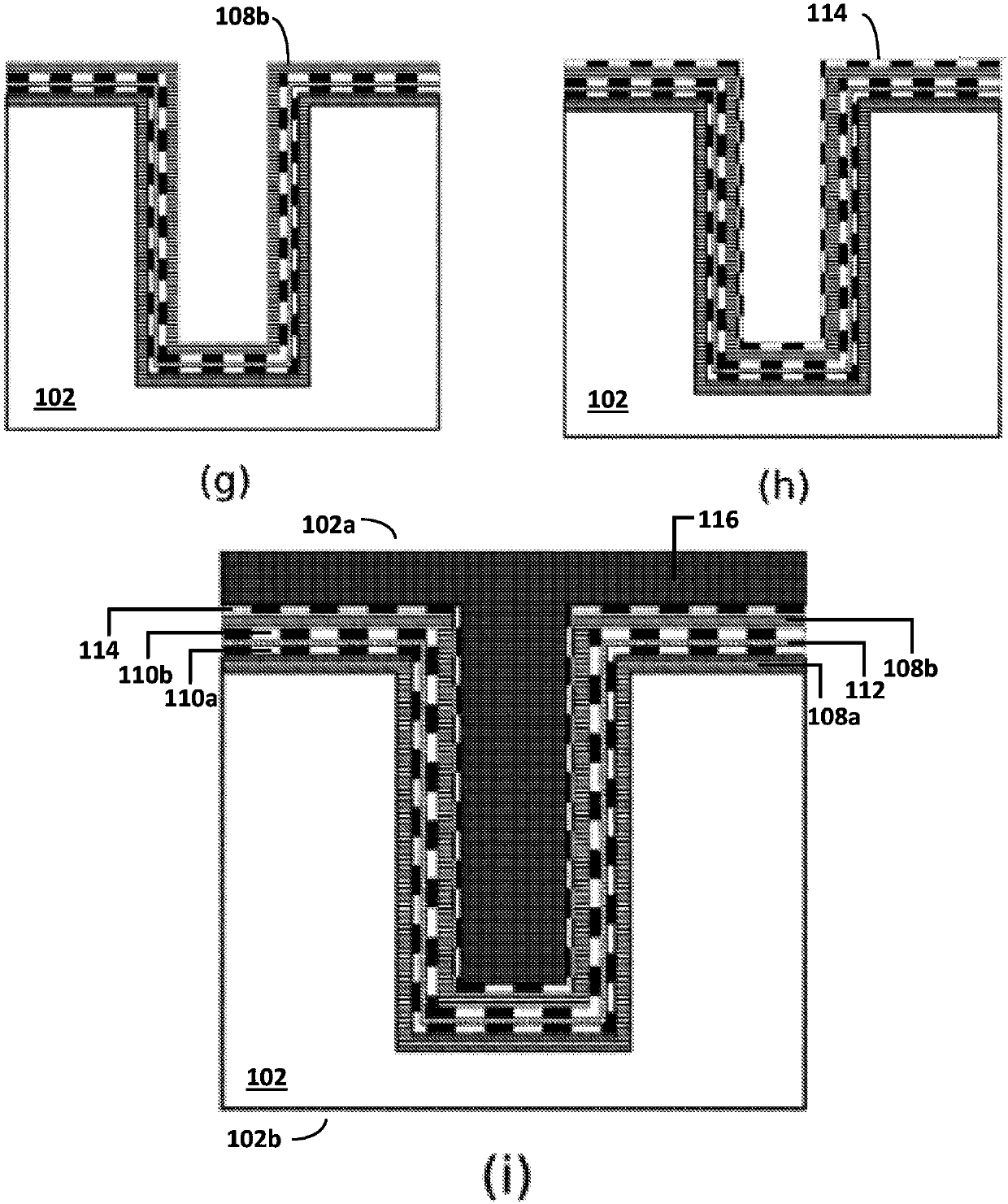

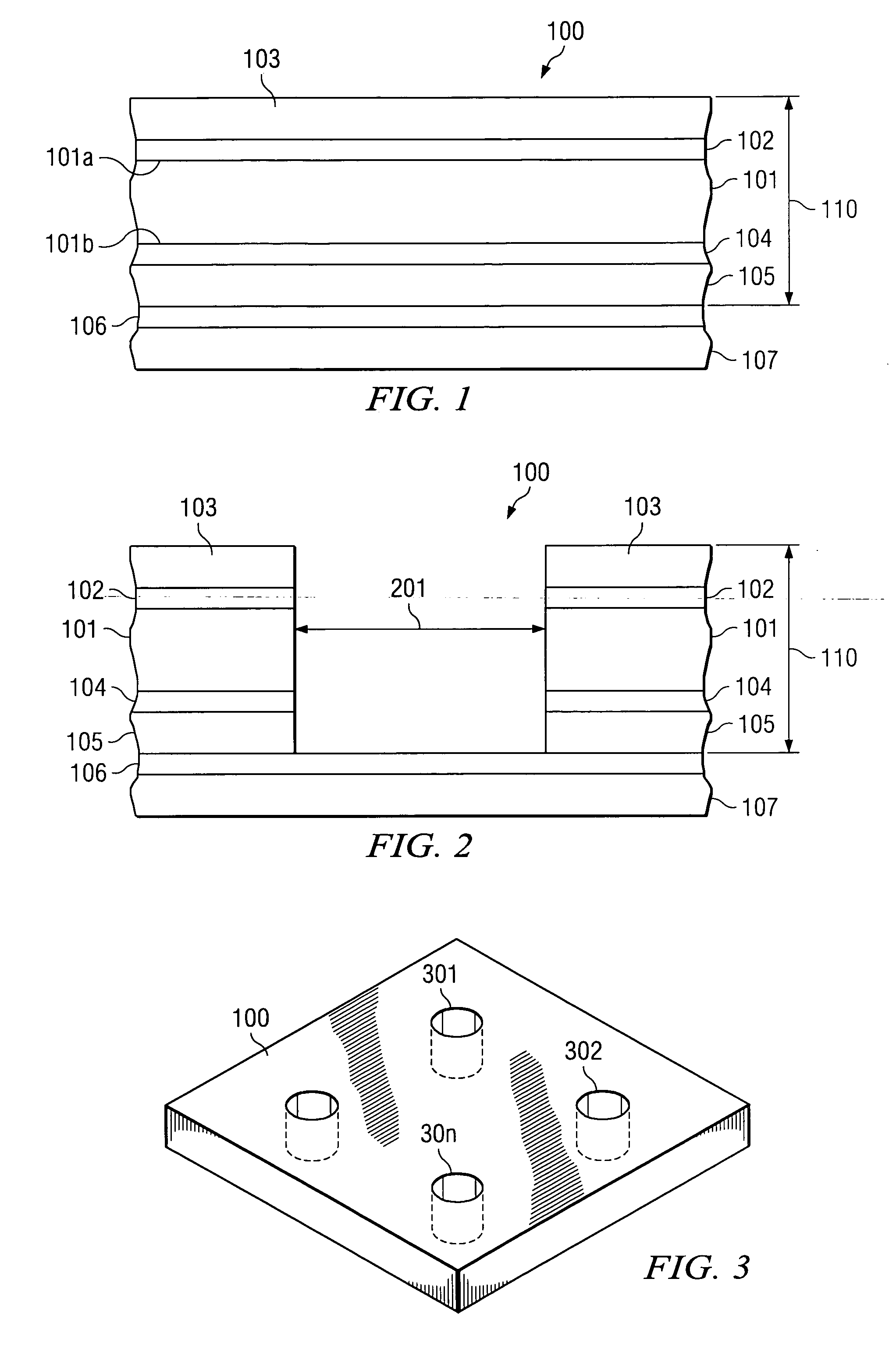

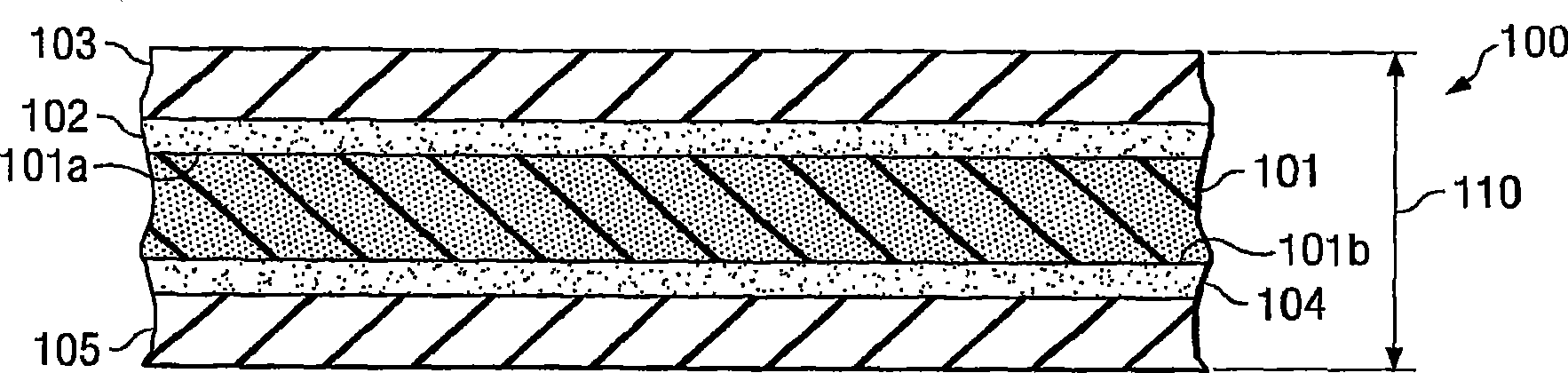

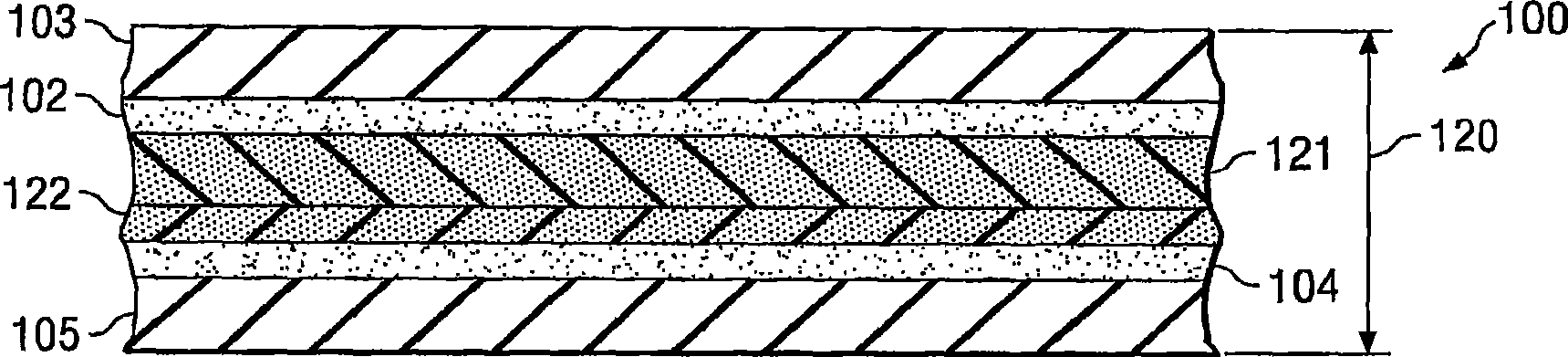

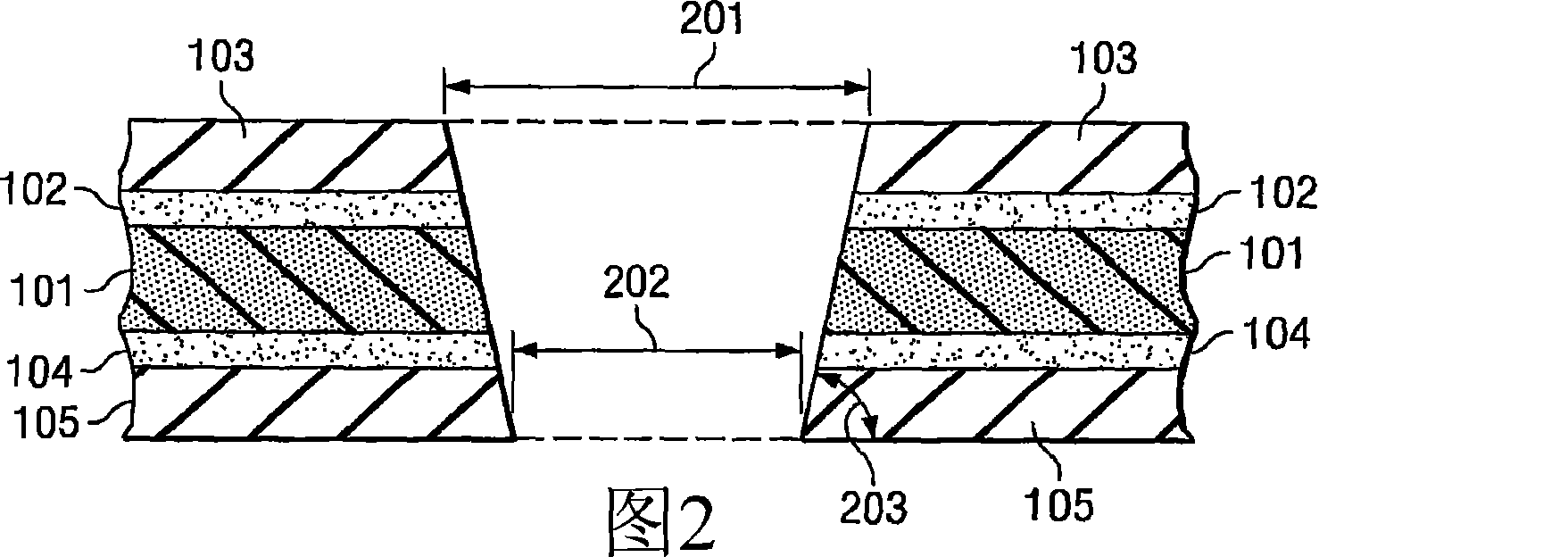

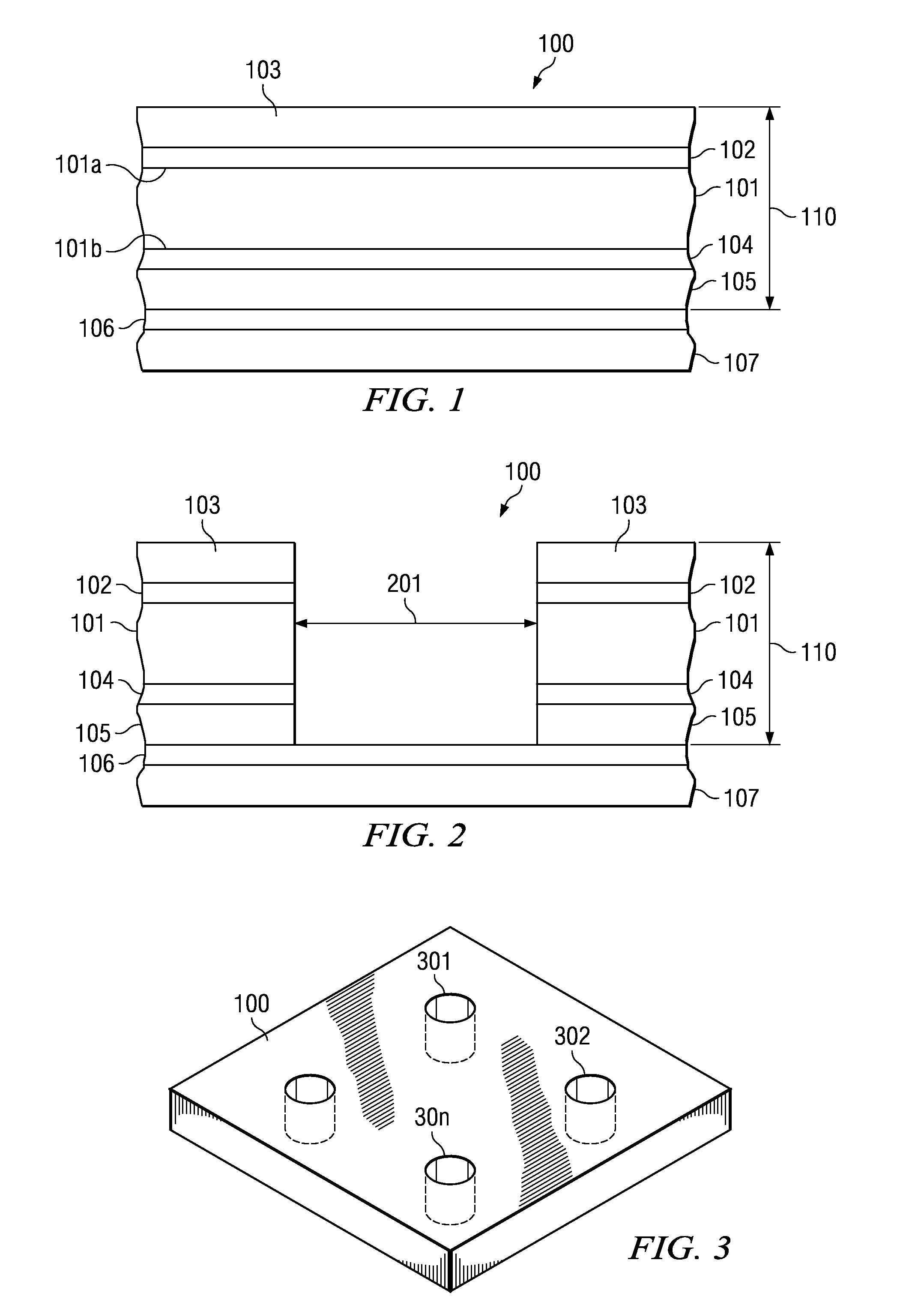

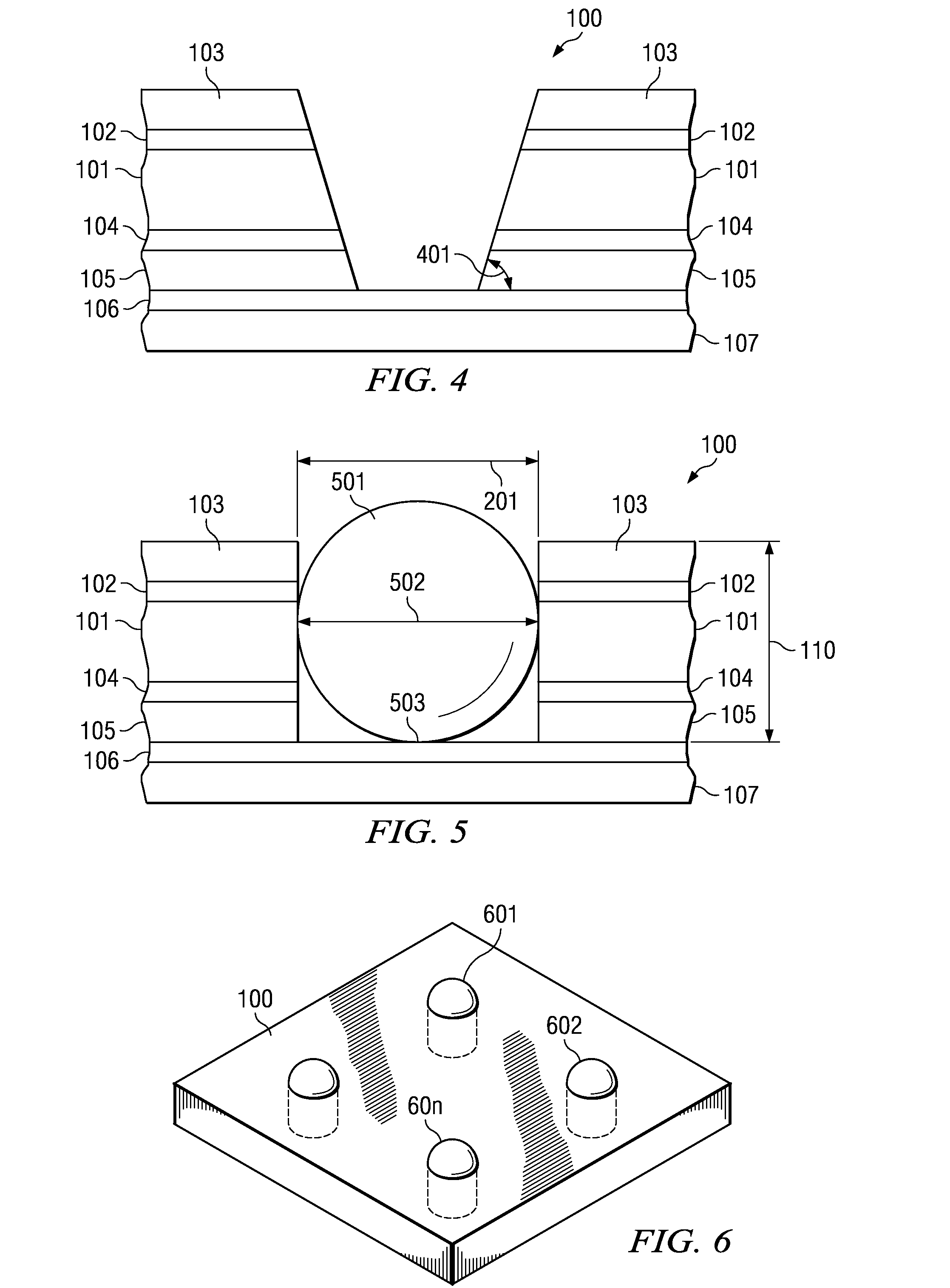

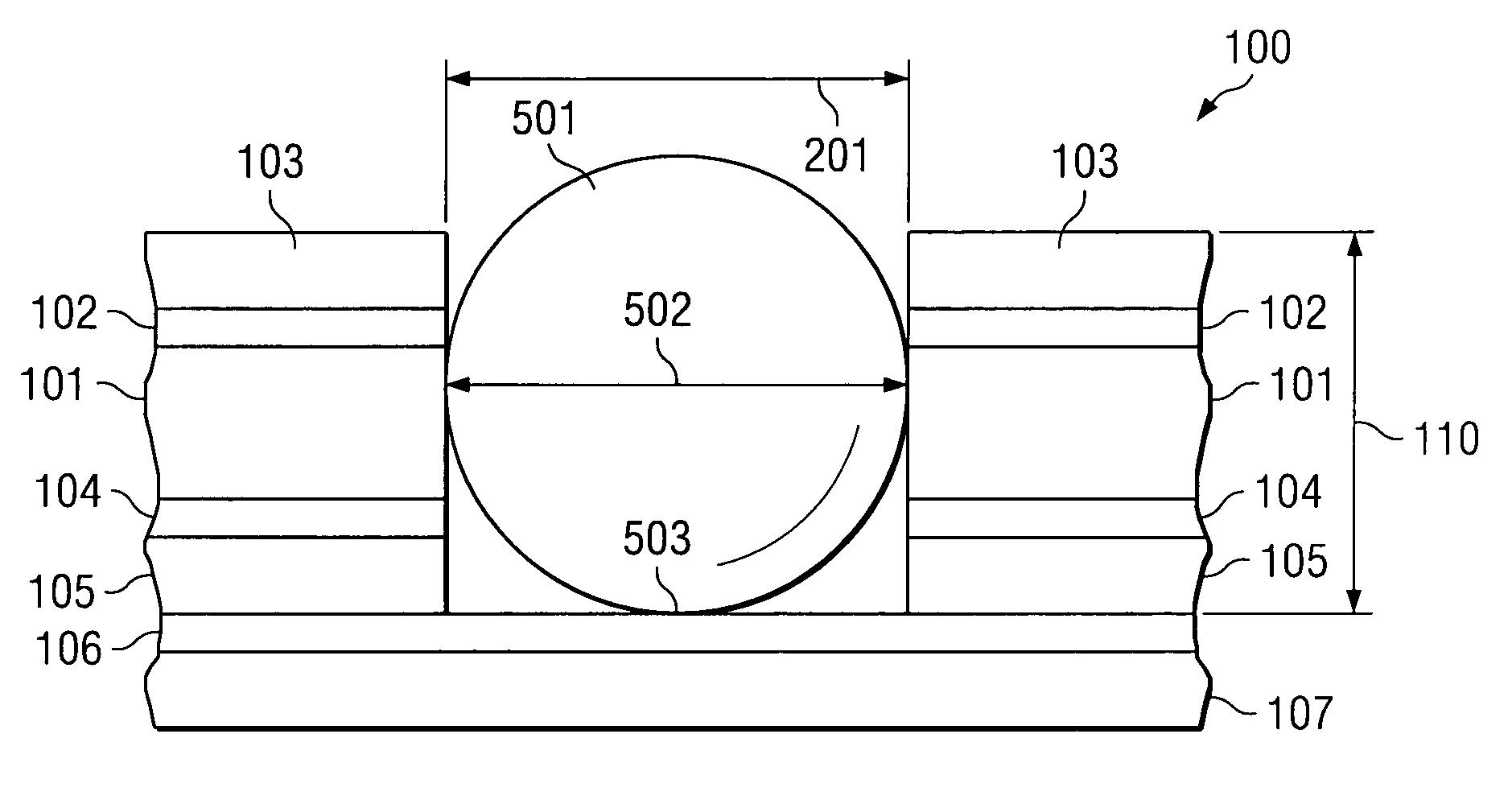

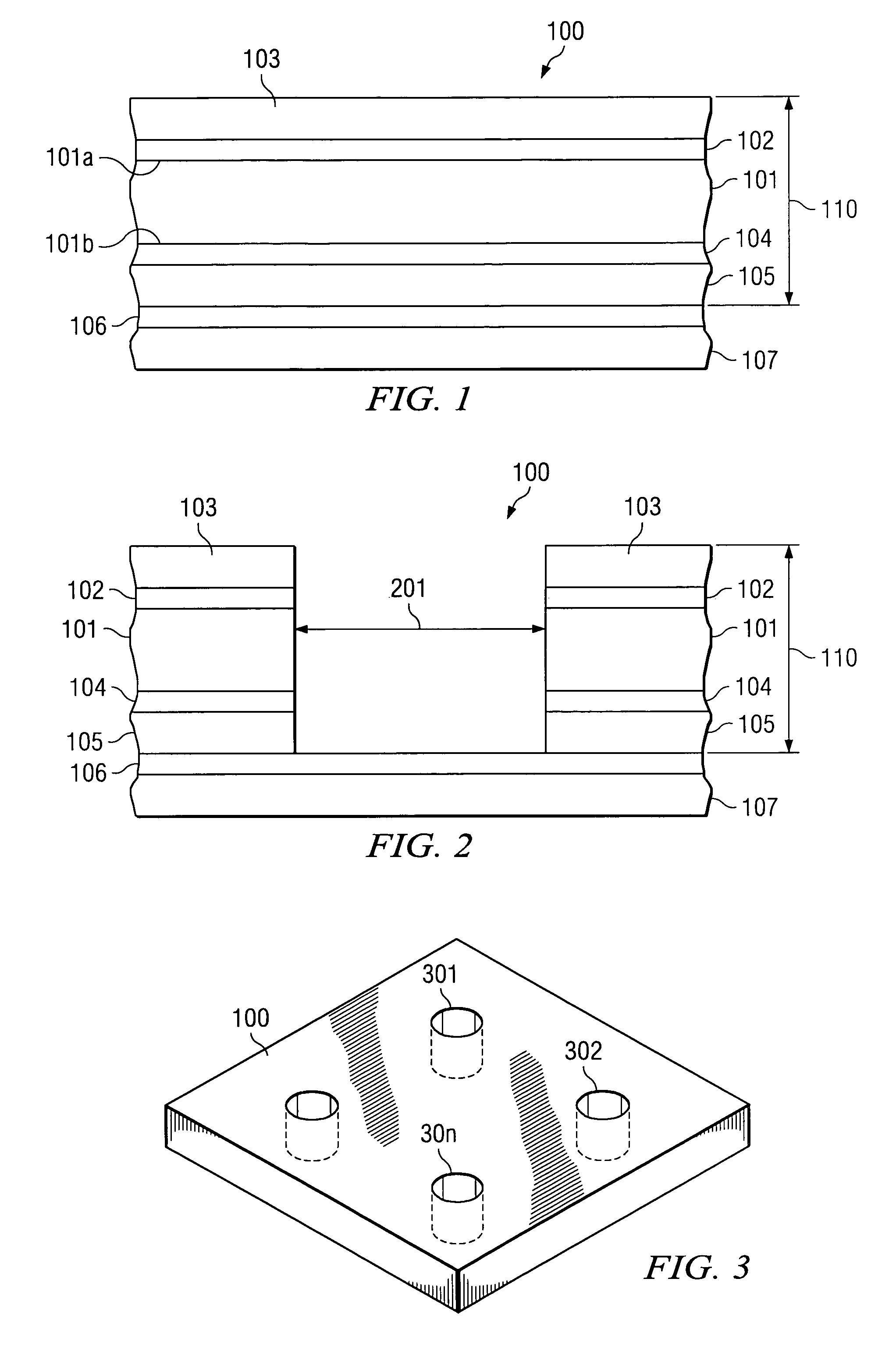

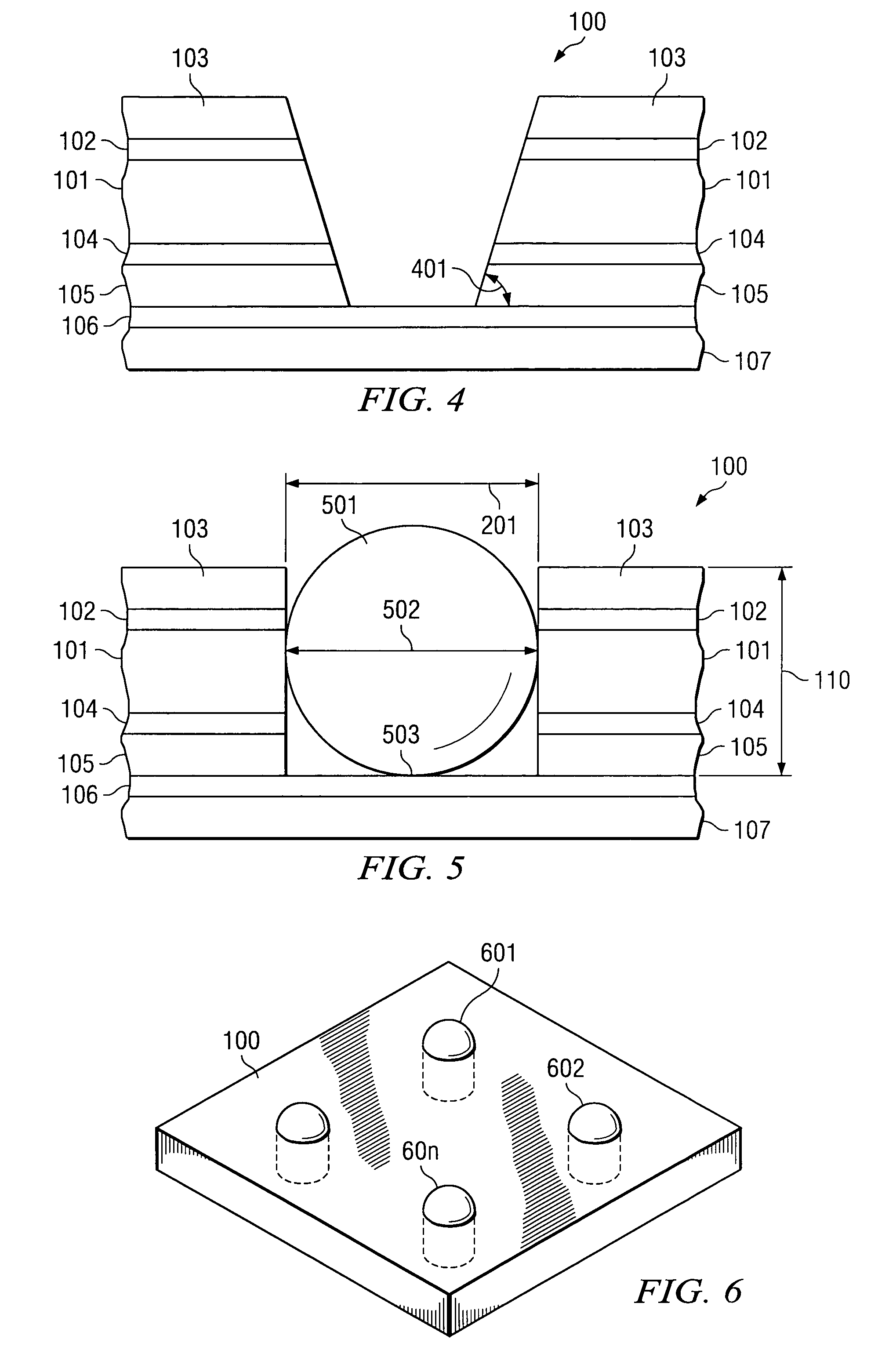

Flip-attached and underfilled stacked semiconductor devices

InactiveCN101371354AReduce thermomechanical stressSimple processFinal product manufactureSemiconductor/solid-state device detailsEngineeringSemiconductor

The invention discloses a tape for use as a carrier in semiconductor assembly, which has one or more base sheets (101) of polymeric, preferably thermoplastic, material having first (101a) and second (101b) surfaces. A polymeric adhesive film (102, 104) and a foil (103, 105) of different, preferably inert, material are attached to the base sheet on both the first and second surface sides; they thus provide a thickness (120) to the tape. A plurality of holes is formed through the thickness of the tape; the holes are preferably tapered with an angle between about 70 DEG and 80 DEG with the second tape surface. A reflow metal element (301), with a preferred diameter (302) about equal to the tape thickness, is held in each of the holes.

Owner:TEXAS INSTR INC

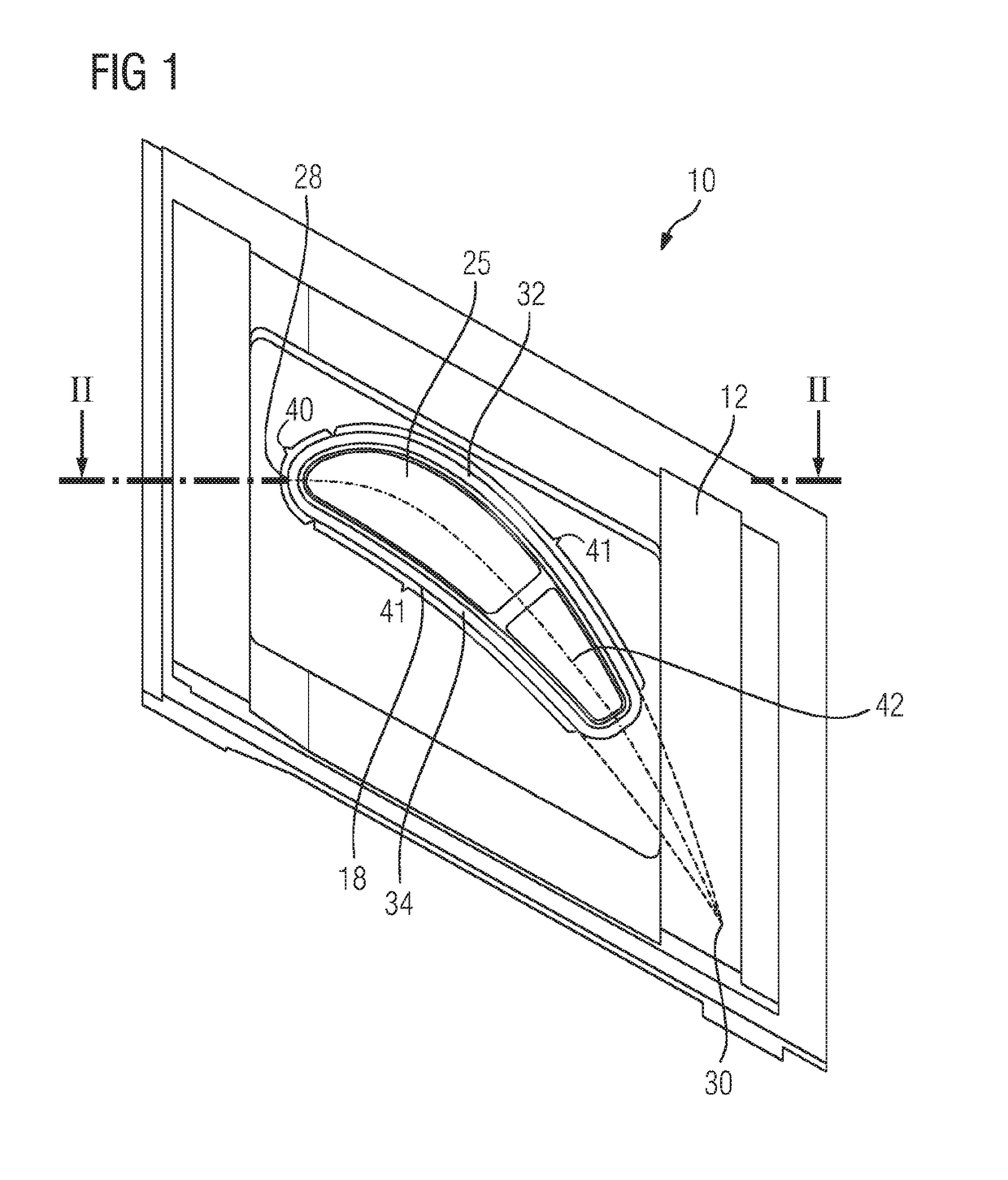

Heat exchanger for cooling charge air

InactiveUS20130067912A1Increase effective lengthGreat absolute change in lengthInternal combustion piston enginesSafety devices for heat exchange apparatusEngineeringInternal combustion engine

A heat exchanger for cooling of charge air for an internal combustion engine of a motor vehicle is provided. The heat exchanger has a preliminary stage, a main stage, and a compensating component. The preliminary stage has at least one preliminary stage fixed bearing base and a preliminary stage floating bearing base. The main stage has at least one main stage fixed bearing base and a main stage floating bearing base. In a heat transfer region of the main stage, at least one main stage channel for a main stage coolant is disposed. The compensating component is configured to compensate a position difference between corresponding components of the preliminary stage and the main stage, whereby the position difference is based on a thermally induced elongation difference between the at least one preliminary stage channel and the at least one main stage channel.

Owner:MAHLE INT GMBH

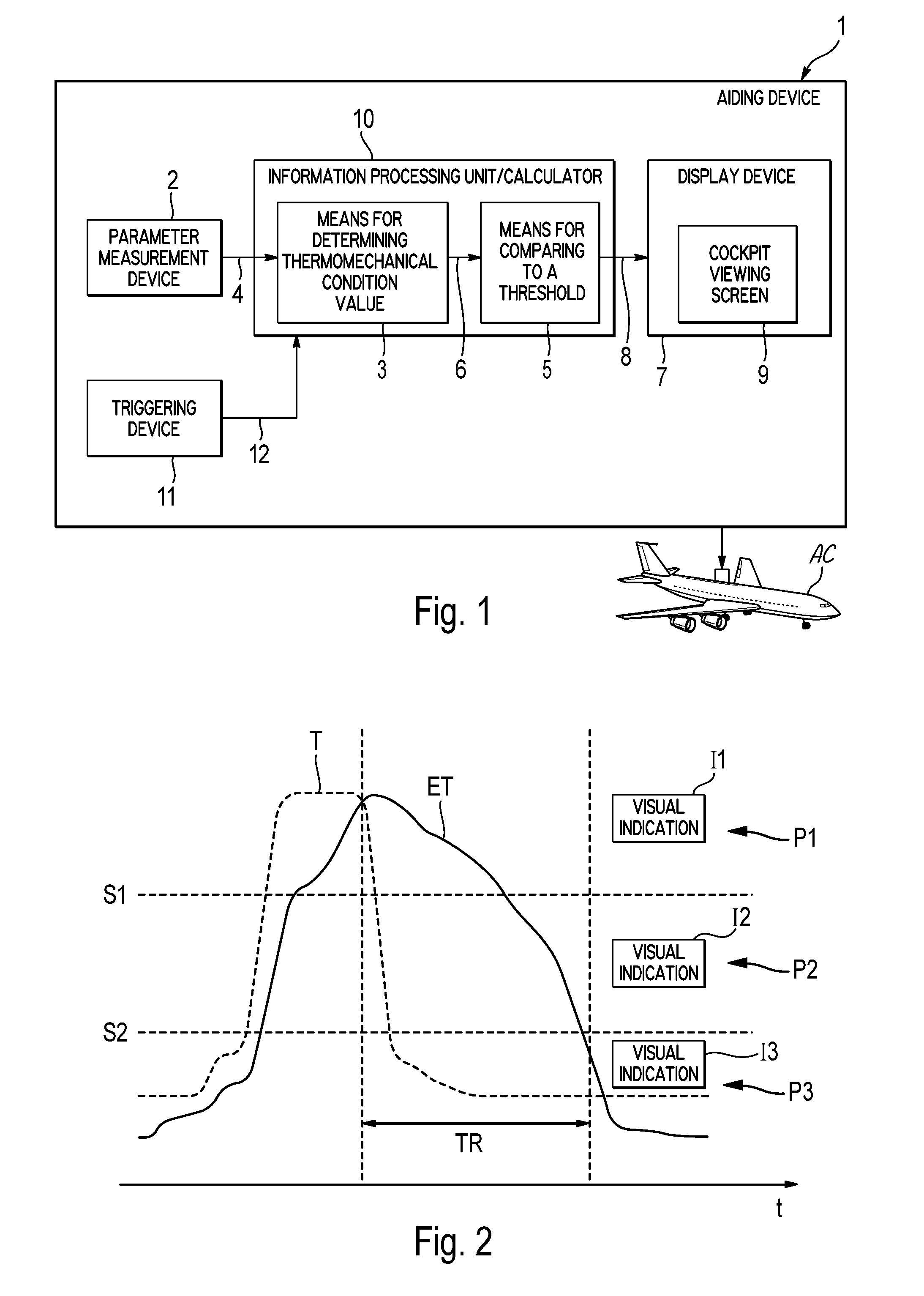

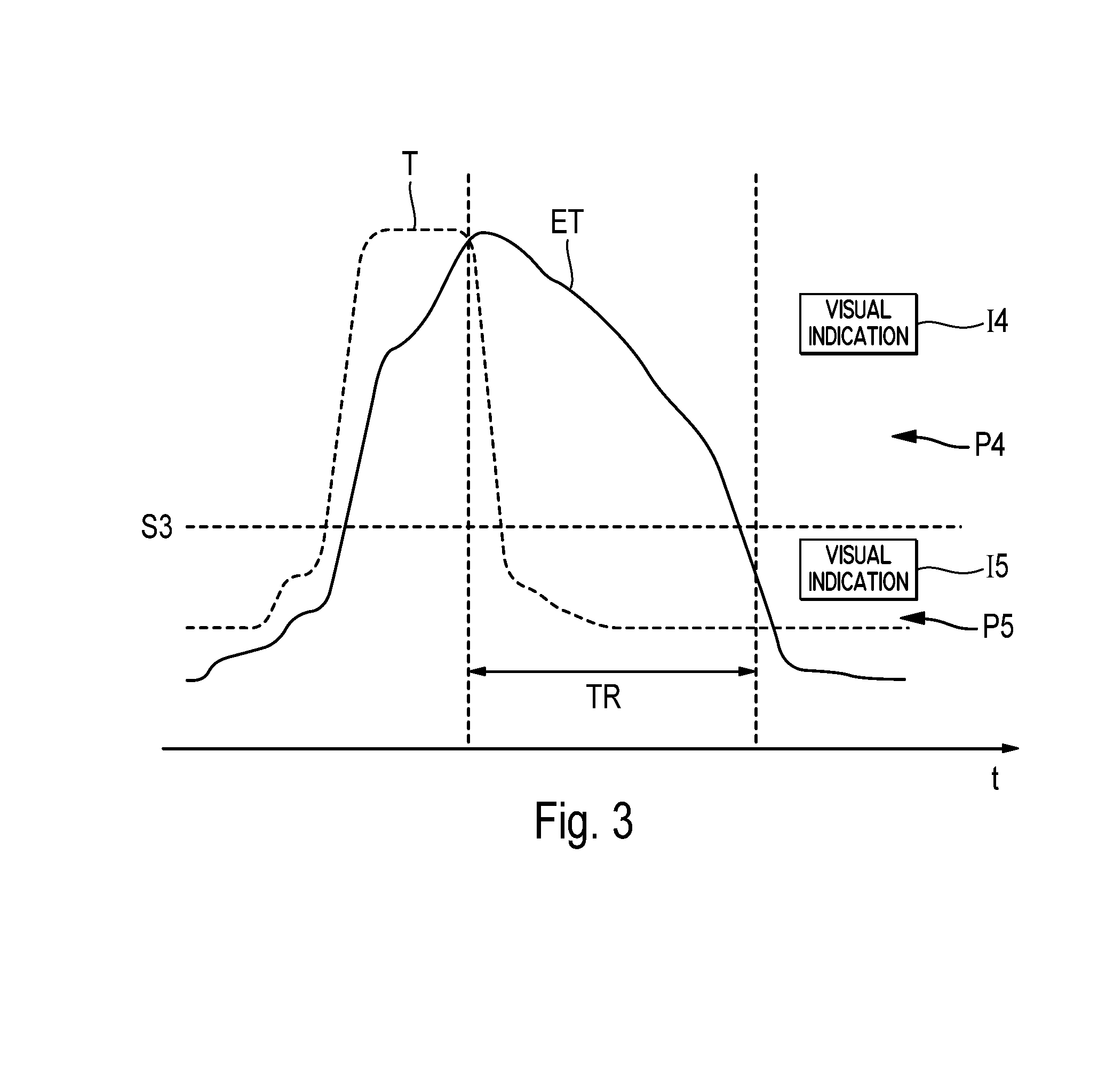

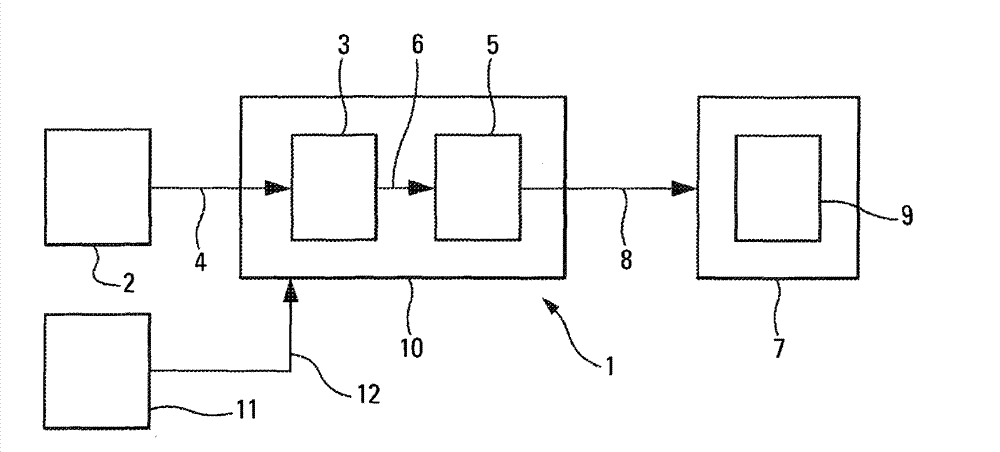

Method and device for monitoring a turbine engine of an aircraft

ActiveCN102815403AHigh thermomechanical stateEasy to useAircraft power plantsEngine fuctionsEngineeringTurbine

The invention relates to a method and a device for monitoring a turbine engine of an aircraft. The device includes means for determining a value illustrating a thermomechanical state (ET) of the turbine engine, means for comparing this value with at least one threshold (S1, S2) and means for displaying in the cockpit of the aircraft, at least one indication (I1 to I3) related to the operation of the turbine engine, according to this comparison.

Owner:AIRBUS OPERATIONS (SAS) +1

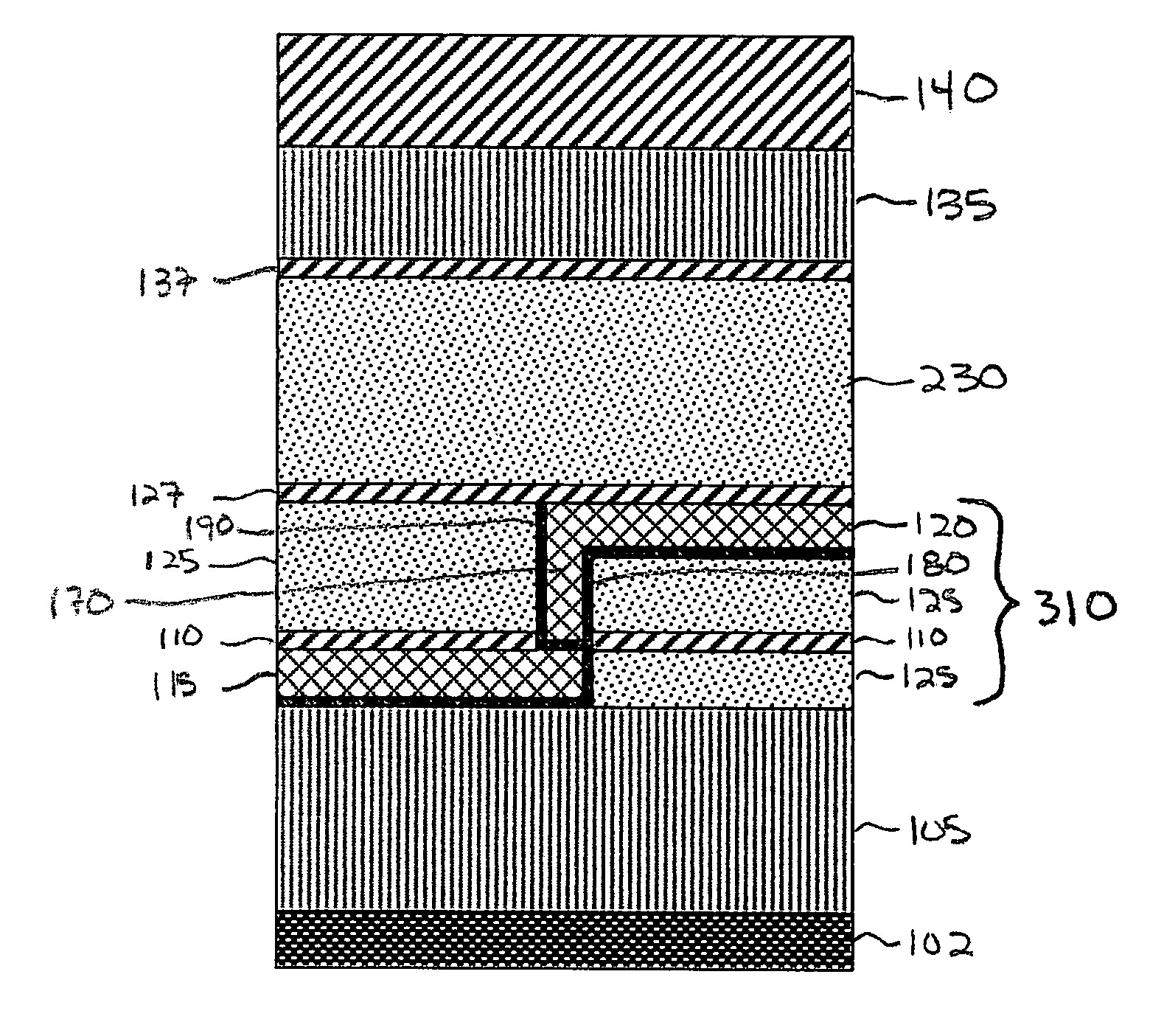

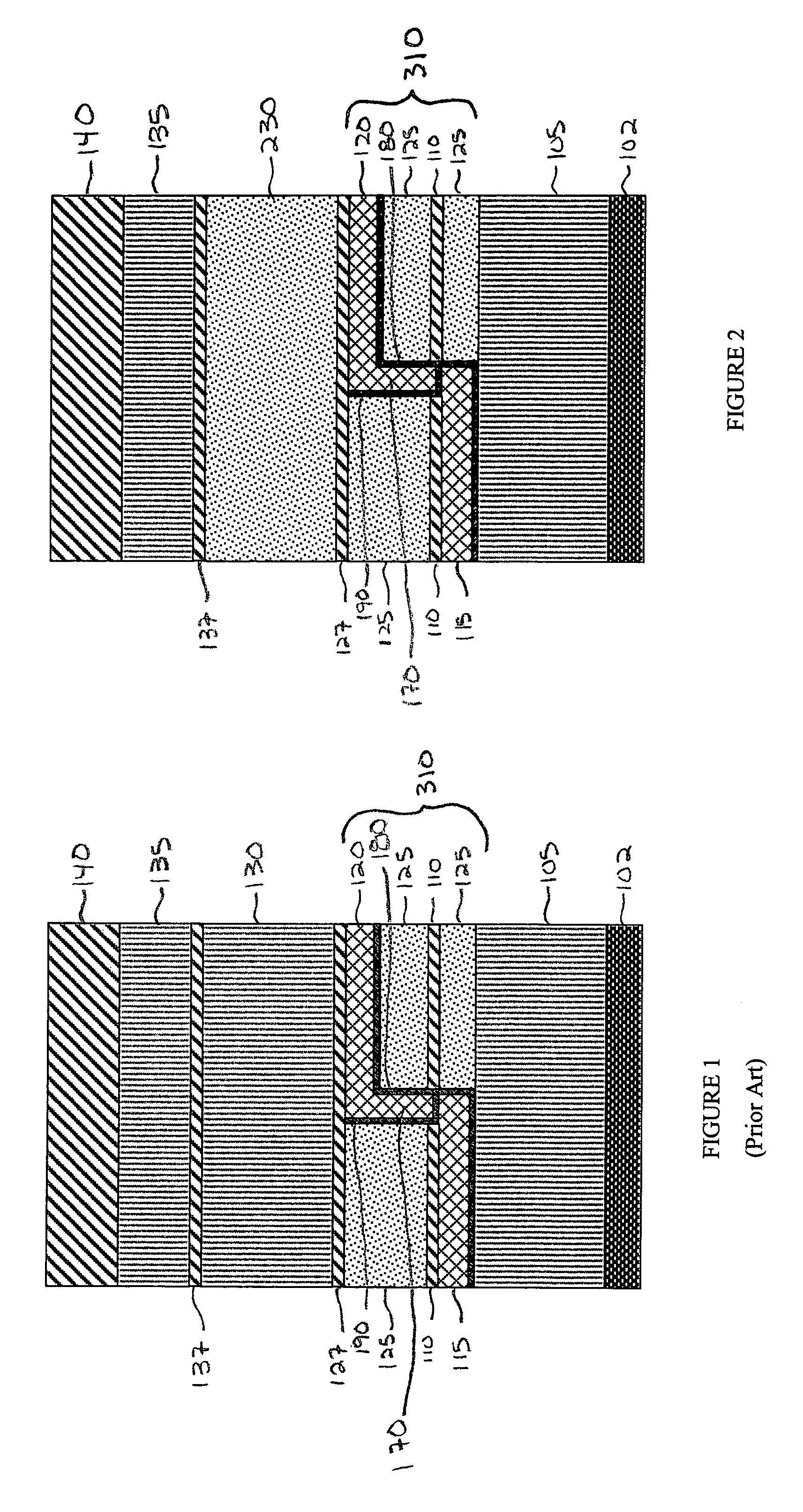

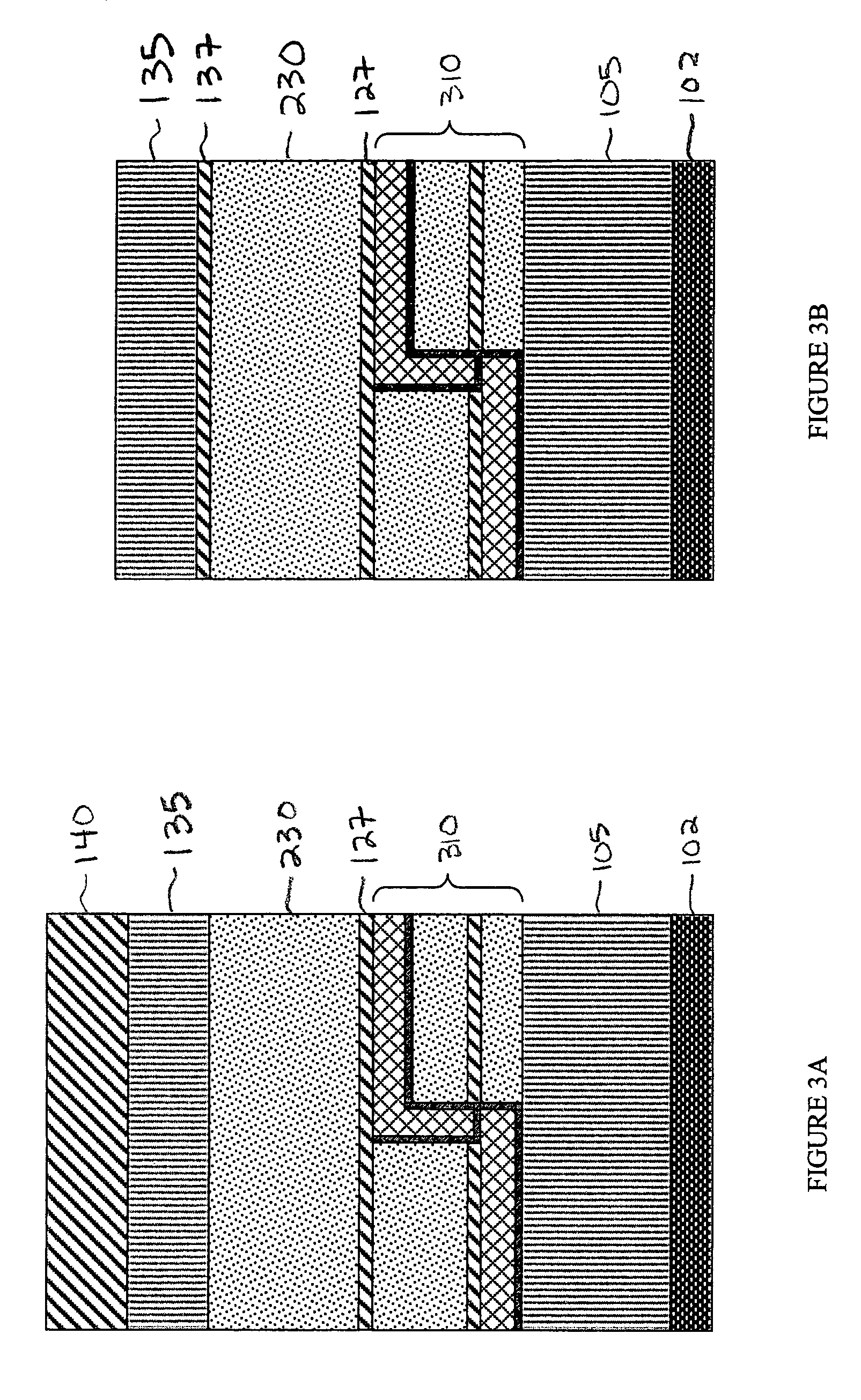

Stress-relief layer for semiconductor applications

InactiveUS6960835B2Reduce thermomechanical stressReduce crackingSemiconductor/solid-state device detailsSolid-state devicesStress reliefDielectric layer

In a semiconductor integrated circuit device, thermo-mechanical stresses on the vias can be reduced by introducing a stress relief layer between the vias and a hard dielectric layer that overlies the vias.

Owner:UNITED MICROELECTRONICS CORP +1

Method for Fabricating Flip-Attached and Underfilled Semiconductor Devices

ActiveUS20120220080A1Reduce thermomechanical stressSimple process flowSemiconductor/solid-state device detailsSurgeryContact padFilling materials

A semiconductor device, which comprises a workpiece with an outline and a plurality of contact pads and further an external part with a plurality of terminal pads. This part is spaced from the workpiece and the terminal pads are aligned with the workpiece contact pads, respectively. A reflow element interconnects each of the contact pads with its respective terminal pad. Thermoplastic material fills the space between the workpiece and the part; this material adheres to the workpiece, the part and the reflow elements. Further, the material has an outline substantially in line with the outline of the workpiece, and fills the space substantially without voids. Due to the thermoplastic character of the filling material, the finished device can be reworked, when the temperature range for reflowing the reflow elements is reached.

Owner:TEXAS INSTR INC

Turbine blade

ActiveUS20180187551A1Reduce thermomechanical stressAvoid accumulationBlade accessoriesStatorsLeading edgeTurbine blade

A cast turbine blade having a platform and hollow blade airfoil arranged thereon, wherein the blade airfoil has a pressure-side blade wall and a suction-side blade wall that extend, along a centrally arranged curved profile centerline, from a common leading edge to a common trailing edge, and having a transition, with an outer contour profile, between the blade airfoil and the platform. The blade walls each have a locally determined blade wall thickness, wherein the turbine blade has, internally, a contour profile that partially matches the outer contour profile of the transition such that the region of the transition has an essentially constant blade wall thickness. In the transition, the contour profile at a surface section of the blade airfoil facing the leading edge is such that the blade wall thickness is increased there in comparison to the blade wall thickness of the transition away from the leading edge.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Method for fabricating flip-attached and underfilled semiconductor devices

ActiveUS7701071B2Improve equipment reliabilityReduced production cycle timeSemiconductor/solid-state device detailsSolid-state devicesContact padFilling materials

A semiconductor device (1700), which comprises a workpiece (1201) with an outline (1711) and a plurality of contact pads (1205) and further an external part (1701) with a plurality of terminal pads (1702). This part is spaced from the workpiece, and the terminal pads are aligned with the workpiece contact pads, respectively. A reflow element (1203) interconnects each of the contact pads with its respective terminal pad. Thermoplastic material (1204) fills the space between the workpiece and the part; this material adheres to the workpiece, the part and the reflow elements. Further, the material has an outline (1711) substantially in line with the outline of the workpiece, and fills the space (1707) substantially without voids. Due to the thermoplastic character of the filling material, the finished device can be reworked, when the temperature range for reflowing the reflow elements is reached.

Owner:TEXAS INSTR INC

Turbine blade

ActiveUS10301944B2Avoid accumulationExtended service lifeBlade accessoriesStatorsLeading edgeTurbine blade

A cast turbine blade having a platform and hollow blade airfoil arranged thereon, wherein the blade airfoil has a pressure-side blade wall and a suction-side blade wall that extend, along a centrally arranged curved profile centerline, from a common leading edge to a common trailing edge, and having a transition, with an outer contour profile, between the blade airfoil and the platform. The blade walls each have a locally determined blade wall thickness, wherein the turbine blade has, internally, a contour profile that partially matches the outer contour profile of the transition such that the region of the transition has an essentially constant blade wall thickness. In the transition, the contour profile at a surface section of the blade airfoil facing the leading edge is such that the blade wall thickness is increased there in comparison to the blade wall thickness of the transition away from the leading edge.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Exhaust manifold for exhaust device of internal combustion engine

InactiveCN104929747AImprove robustnessAchieve weight lossSleeve/socket jointsFlanged jointsCombustionFlange

An exhaust manifold for an exhaust system of a combustion engine includes an internal pipe system having a plurality of pipe sections and an outer shell which is disposed in spaced-apart surrounding relationship to the internal pipe system and joined to an outlet flange. The outlet flange includes a neck portion, an outer flange portion adjacent to the neck portion, and an inwardly directed shoulder portion which extends from the neck portion outwards, with the outer shell being joined at the shoulder portion to the outlet flange.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

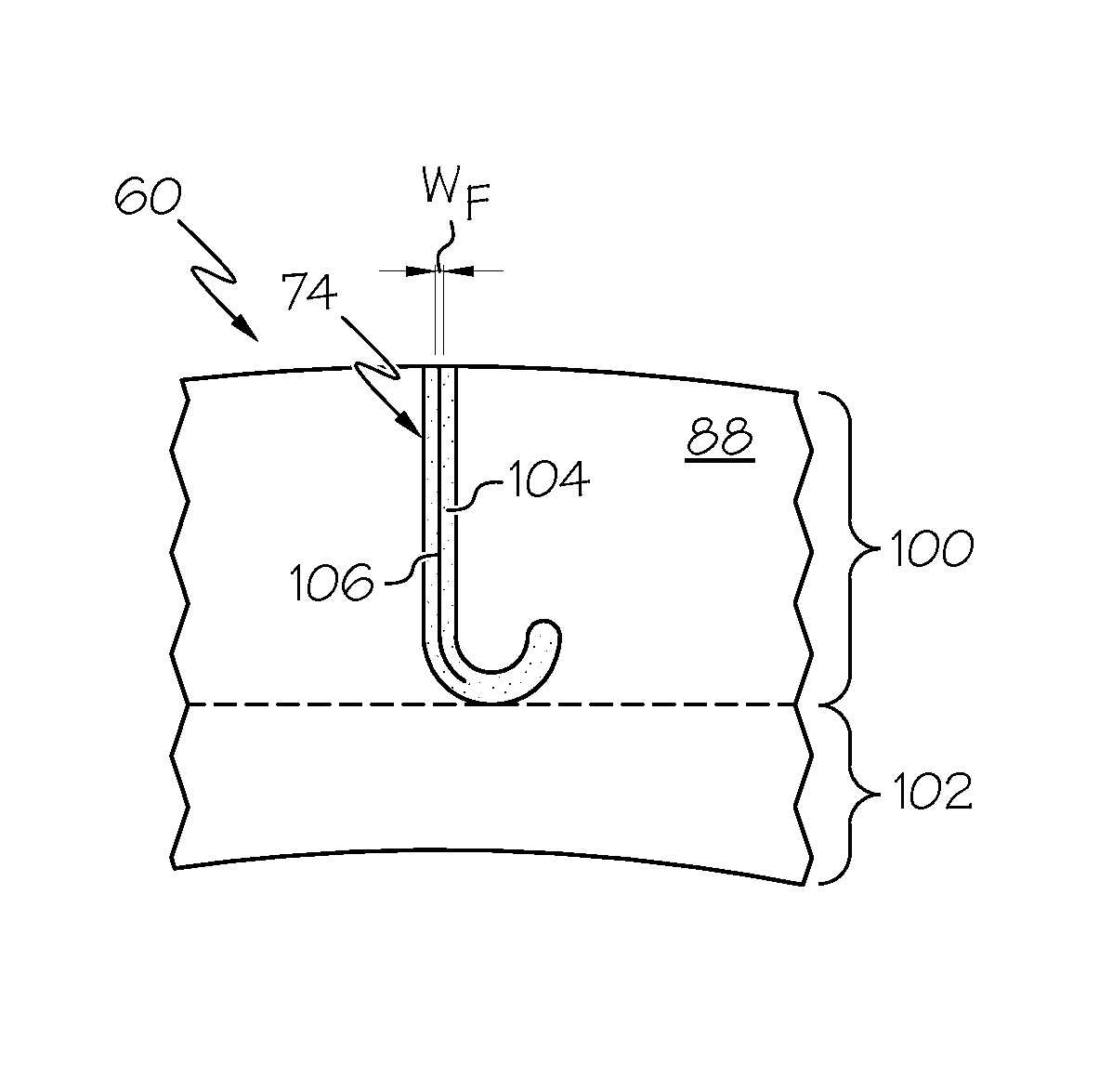

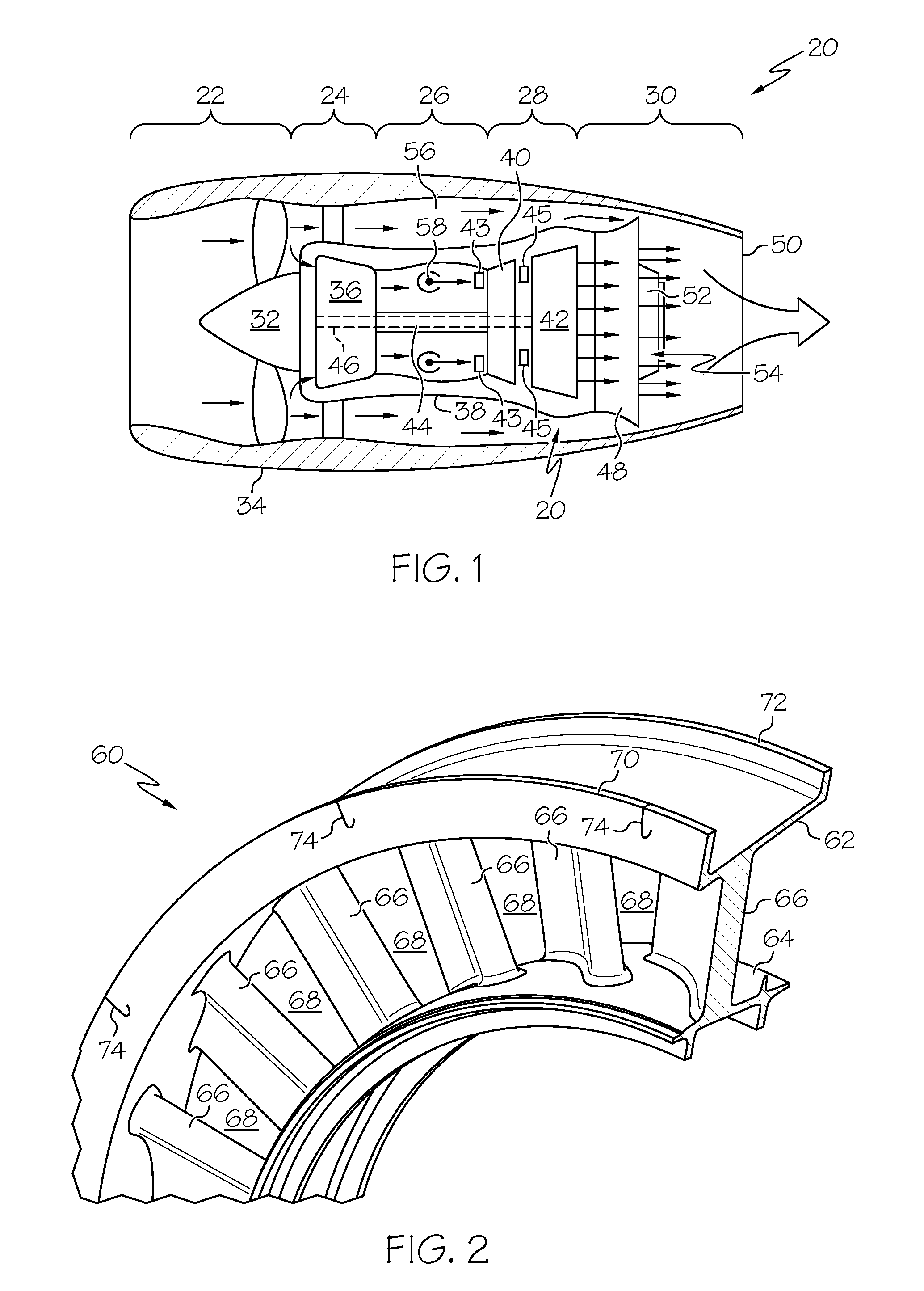

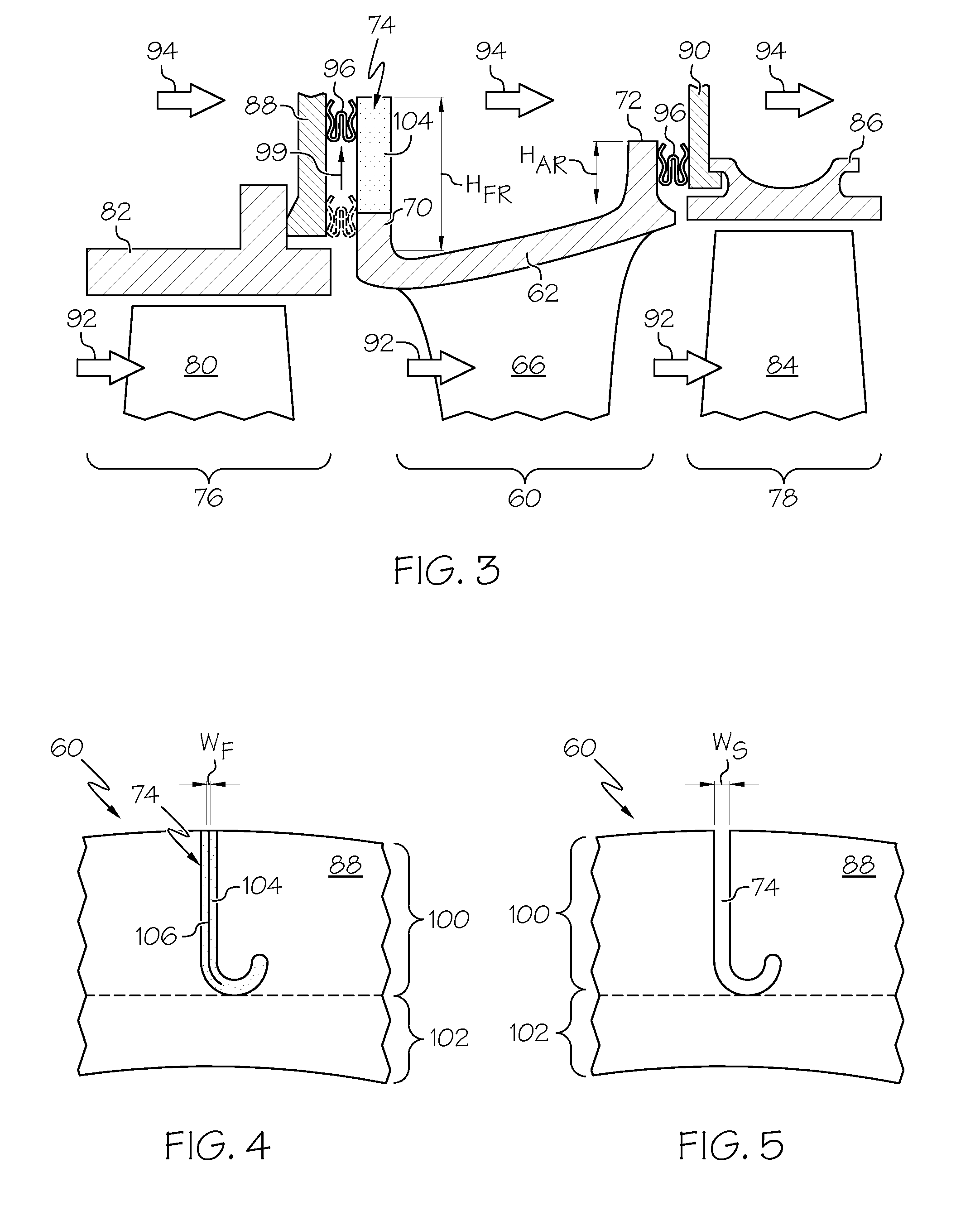

Gas turbine engine components having sealed stress relief slots and methods for the fabrication thereof

ActiveUS9506365B2Reduce thermomechanical stressPrevent leakageEngine fuctionsLeakage preventionProduct gasStress relief

Owner:HONEYWELL INT INC

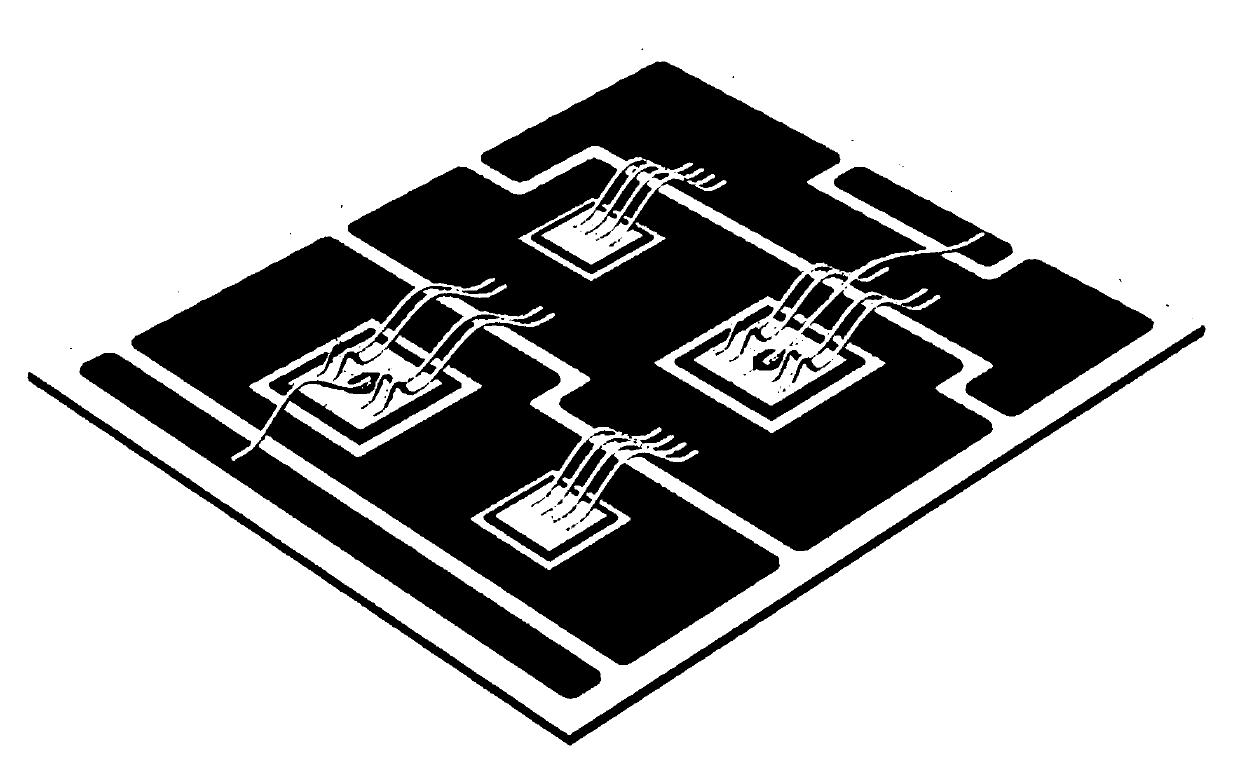

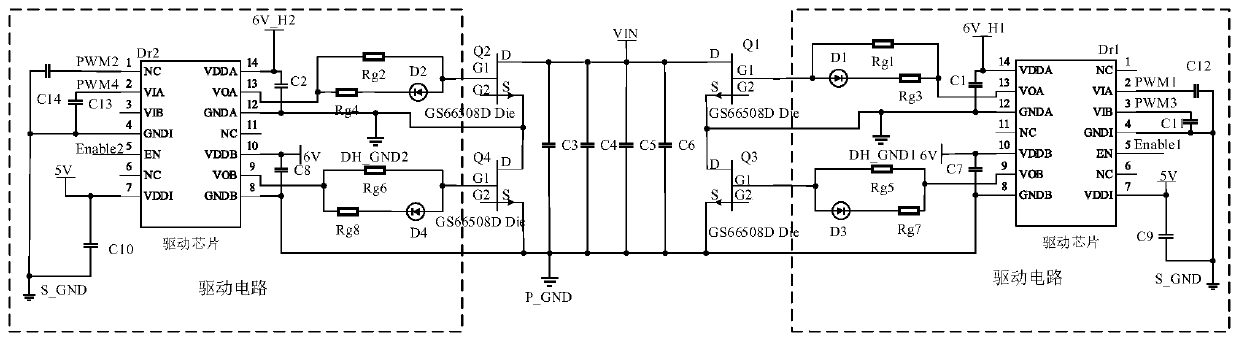

Full-bridge integration module based on PCB embedding process

ActiveCN110012590ALow costImprove space utilizationHigh frequency circuit adaptationsPrinted circuit non-printed electric components associationCapacitancePower circuits

The invention discloses a full-bridge integration module based on PCB embedding process. The full-bridge integration module comprises a full-bridge power circuit, high-frequency decoupling capacitors,a drive circuit, power devices and a radiator which are arranged on a PCB embedding module. The power devices are four gallium nitride devices or four silicon carbide devices which are connected in series and in parallel to form a full-bridge circuit, the full-bridge circuit is connected with the high-frequency decoupling capacitors and the drive circuit, and the full-bridge circuit, the high-frequency decoupling capacitors and the drive circuit are connected with the radiator to form an embedded full-bridge integration module. The full-bridge integration module greatly reduces the parasiticinductance, can promote the high-frequency operation of the wide bandgap device and is beneficial to the promotion of the power density of the system.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com