An independent arch with support for high and low temperature connection structure

A technology of arch connection and connection structure, which is applied in the direction of fuselage, climate change adaptation, transportation and packaging, etc. It can solve the problems of increasing the overall structural mass, reduce thermal mismatch, enhance strength, and improve the ability to withstand external loads Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

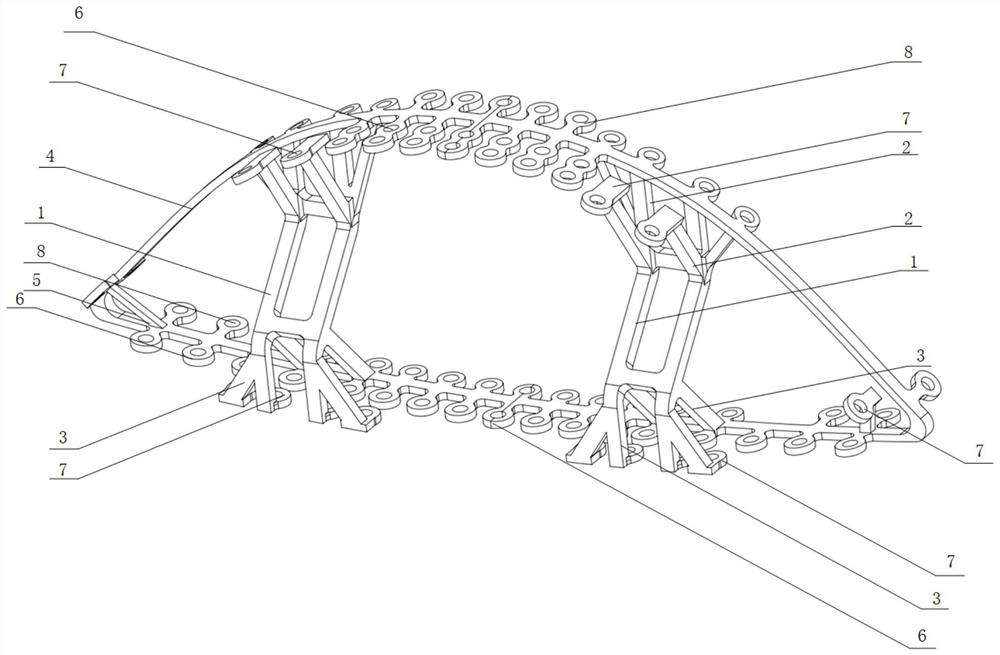

[0023] The present invention is an independent arched high-low temperature connection structure with support, which is characterized by primary supporting beam 1, secondary arc supporting beam 2, secondary bottom supporting beam 3, arched connecting beam 4, and tail end support Beam 5, supporting beam overhanging side bolt foot 6, supporting beam overhanging side bolt platform 7, non-supporting beam overhanging side bolt foot 8.

[0024] Each of the primary support beams 1 is respectively connected to three secondary arc support beams 2 and three secondary bottom support beams 3. There are two primary support beams 1 in total, and the two ends of each primary support beam 1 are respectively located at the secondary The intersection of the arc support beam 2 and the bottom three support beams 3 forms a certain angle with the vertical direction. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com