CrAlN thermal insulation coating for aluminum alloy piston combustor surface and preparation method thereof

A technology of thermal insulation coating and combustion chamber, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of poor bonding force between aluminum alloy and thermal insulation coating, corrosion, thermal fatigue, etc. , to achieve the effect of low intrinsic thermal conductivity, improved bonding force, and reduced stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

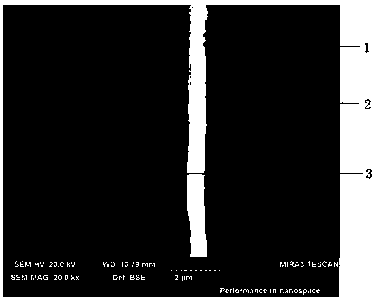

Image

Examples

Embodiment 1

[0053] 1) Preparation of transition layer

[0054] Put the pretreated aluminum alloy piston into the magnetic filter cathode vacuum chamber, adjust the positive bias voltage to 2.4V, the upper deflection current 2.4 A, the lower deflection current 3.2 A, and the duty cycle of 86.2±0.1%. 25 Al 75 The target is the cathode, and the arc starting current is adjusted to 100A, and five negative pressure points of -600 V, -500 V, -400 V, -300 V and -200 V are used in sequence, and the surface of the pretreated substrate is sputtered The CrAl transition layer was deposited in the manner of ", and each negative pressure point was maintained for 30 s to 60 s, and then the negative bias was selected to be -50V to continue depositing the CrAl transition layer. The deposition time was 20 min, and CrAl was deposited on the surface of the aluminum alloy piston. form a transition layer.

[0055] 2) Preparation of insulation layer

[0056] On the transition layer obtained in step 1), contin...

Embodiment 2

[0061] 1) Preparation of transition layer

[0062] Put the pretreated aluminum alloy piston into the magnetic filter cathode vacuum chamber, adjust the positive bias voltage to 2.4 V, the upper deflection current to 2.4 A, the lower deflection current to 3.2 A, and the duty cycle to be 86.2±0.1%. 25 Al 75 The target is the cathode, the arc starting current is adjusted to 100 A, and five negative pressure points of -600 V, -500 V, -400 V, -300 V and -200 V are sequentially used to sputter The CrAl transition layer was deposited in the manner of ", and each negative pressure point was maintained for 30 s to 60 s, and then the negative bias was selected to be -50V to continue depositing the CrAl transition layer. The deposition time was 20 min, and CrAl was deposited on the surface of the aluminum alloy piston. form a transition layer;

[0063] 2) Preparation of insulation layer

[0064] On the transition layer obtained in step 1), continue to use the magnetic filter cathode v...

Embodiment 3

[0069] 1) Preparation of transition layer

[0070] Put the pretreated aluminum alloy piston into the magnetic filter cathode vacuum chamber, adjust the positive bias voltage to 2.4V, the upper deflection current to 2.4A, the lower deflection current to 3.2A, and the duty cycle to be 86.2±0.1%. 25 Al 75 The target is the cathode, the arcing current is adjusted to 100A, and 5 negative pressure points of -600 V, -500 V, -400 V, -300 V and -200 V are sequentially used to "sputter" on the surface of the pretreated substrate The CrAl transition layer was deposited in the same way, and each negative pressure point was kept for 30 s to 60 s, and then the negative bias was selected to be -50 V to continue depositing the CrAl transition layer. The deposition time was 20 min, and CrAl was deposited on the surface of the aluminum alloy piston. form a transition layer;

[0071] 2) Preparation of insulation layer

[0072] On the transition layer obtained in step 1), continue to use the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com