Carbon fiber reinforced nickel-based composite material and producing method thereof

A composite material and carbon fiber technology, which is applied in the field of preparation technology of carbon fiber reinforced nickel-based composite materials, can solve the problems of difficult control of the impregnation temperature of reinforced fibers, unfavorable interface bonding state, and high complexity of manufacturing equipment, so as to improve the interface bonding state, The effect of low cost and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The carbon fiber used in the present invention is a domestic medium-strength polyacrylonitrile (PAN) carbon fiber with a single filament diameter of (6-8) μm and bundled (1000 / bundle), which can be selected according to the design volume ratio of 30-35%.

[0058] Its tensile strength is 2200MPa, elastic modulus is 200GPa, density is 1.78g / cm 3 , carbon content> 95%.

[0059] The base material is electrolytic nickel, the tensile strength is 317MPa, the alloy element copper is industrial pure copper, and the electrodeposition chemicals used are all chemically pure.

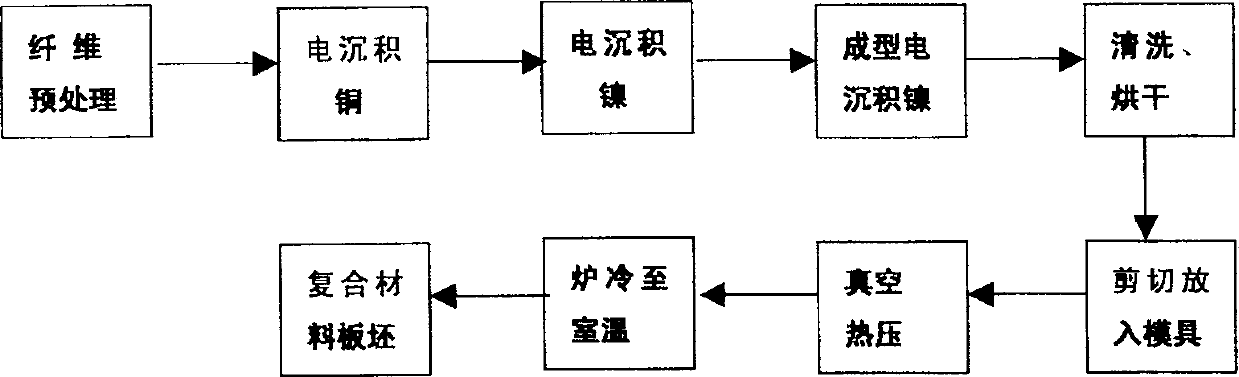

[0060] The process flow diagram of the present invention is as figure 1 shown.

[0061] 1. Carbon fiber pretreatment

[0062] In order to avoid the bonding between single fibers and the abrasion between fibers, the surface of the bundled carbon fibers purchased is coated with adhesive, which needs to be removed before use. First, the carbon fibers are wound on the steel wiring wheel. Then put it into a he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com