gr/n-sic p Composite reinforced magnesium matrix composite material and preparation method thereof

A composite material and composite reinforcement technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high density of composite materials, difficulty in grasping, burning of alloy elements, etc., and achieve high wear resistance and wear reduction characteristics , Avoid microscopic defects, the effect of high-strength features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides the above-mentioned GR / N-SiC P A method for preparing a composite reinforced magnesium-based composite material, comprising the following steps:

[0045] Step 1, high energy ball milling:

[0046] Weigh the following raw materials according to weight percentage: GR powder 0.5-1.5%, N-SiC P Powder 0.5-10%, the balance is magnesium powder, the sum of the weight percentages of the above components is 100%;

[0047] The above weighed GR powder, N-SiC P Powder and magnesium powder are placed in a high-energy ball mill at 30-60 rpm under the protection of argon and mixed for 12-24 hours;

[0048] In step 1, the GR powder is a single-layer graphene dry powder; N-SiC P The powder is a spherical particle with a particle size of 50-200nm; the particle size of the magnesium powder is 100-200 mesh;

[0049] In step 1, the weight of the ball is GR powder to be milled, N-SiC P 20-50% of the sum of the weight of magnesium powder and pure magne...

Embodiment 1

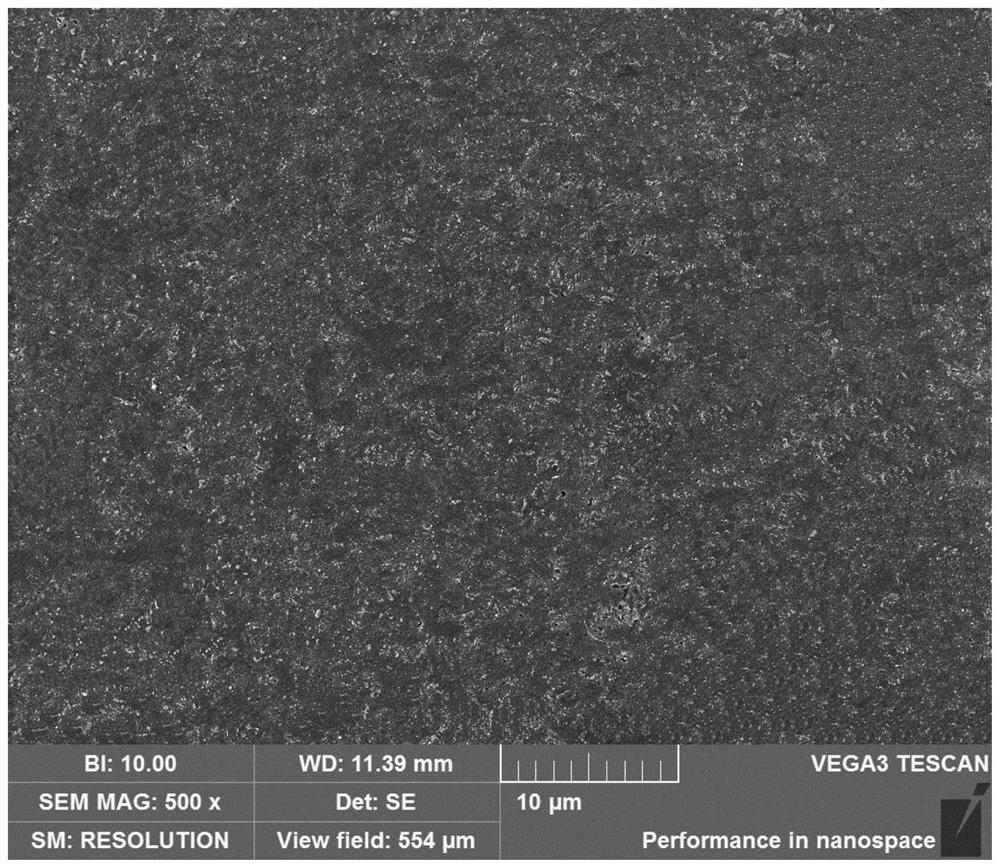

[0065] Weigh the following raw materials according to weight percentage: GR powder 0.5%, N-SiC P powder 0.5%, the balance is magnesium powder, the sum of the weight percentages of the above components is 100%; wherein, GR powder is single-layer graphene dry powder, N-SiC P The nominal particle size of the powder is 50nm, and 200 mesh pure magnesium powder is selected as the matrix of the composite material. Use Φ5mm Al 2 o 3 Grinding balls, wherein the weight of the grinding balls is GR powder to be milled, N-SiC P 20% of the weight of magnesium powder and pure magnesium powder.

[0066] Put the above powder and balls together into a ball mill pot, and ball mill the mixed powder in a high-energy ball mill at a speed of 30 rpm under the protection of argon for 24 hours. Mechanically mix by ball milling to avoid GR and N-SiC P reunion;

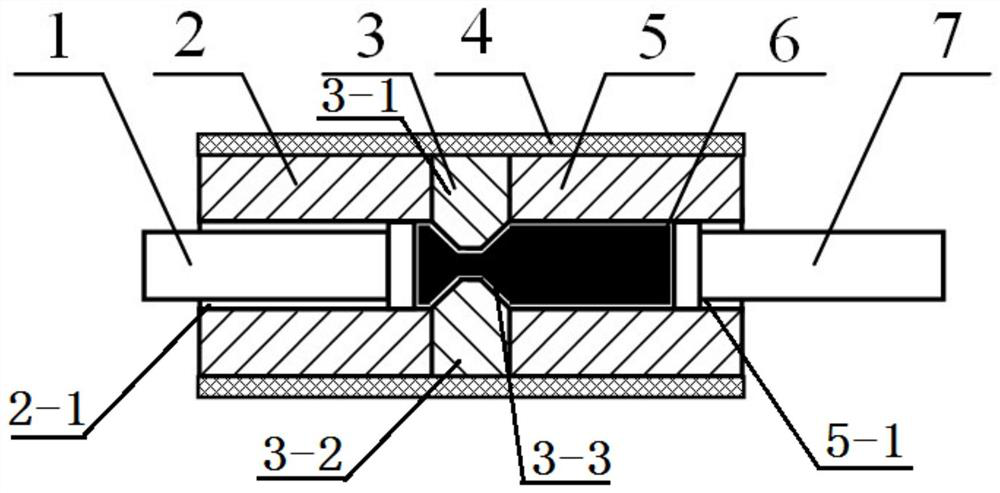

[0067] The completely mixed GR powder, N-SiC P The powder and pure magnesium powder mixture are placed in a special reciprocating extrus...

Embodiment 2

[0070] Weigh the following raw materials according to weight percentage: GR powder 1.5%, N-SiC P powder 10%, the balance is magnesium powder, the sum of the weight percentages of the above components is 100%; wherein, GR powder is single-layer graphene dry powder, N-SiC P The nominal particle size of the powder is 200nm, and 100 mesh pure magnesium powder is selected as the matrix of the composite material. Use Φ8mm Al 2 o 3 Grinding balls, wherein the weight of the grinding balls is GR powder to be ball milled, N-SiC P 50% of the weight of magnesium powder and pure magnesium powder.

[0071] Put the above-mentioned powder and balls together into a ball mill pot, and ball mill the mixed powder for 12 hours in a high-energy ball mill at a speed of 60 rpm under the protection of argon. Mechanically mix by ball milling to avoid GR and N-SiC P reunion;

[0072] The completely mixed GR powder, N-SiC P The powder and pure magnesium powder mixture are placed in a special recip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com