Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Fix interface issues" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

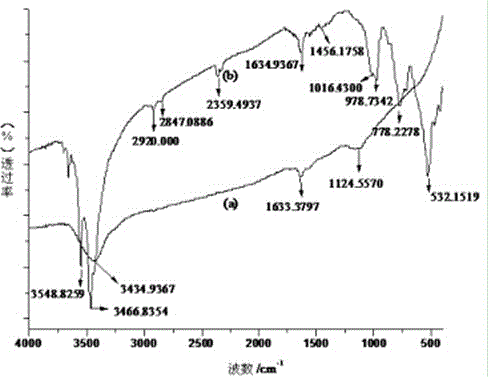

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

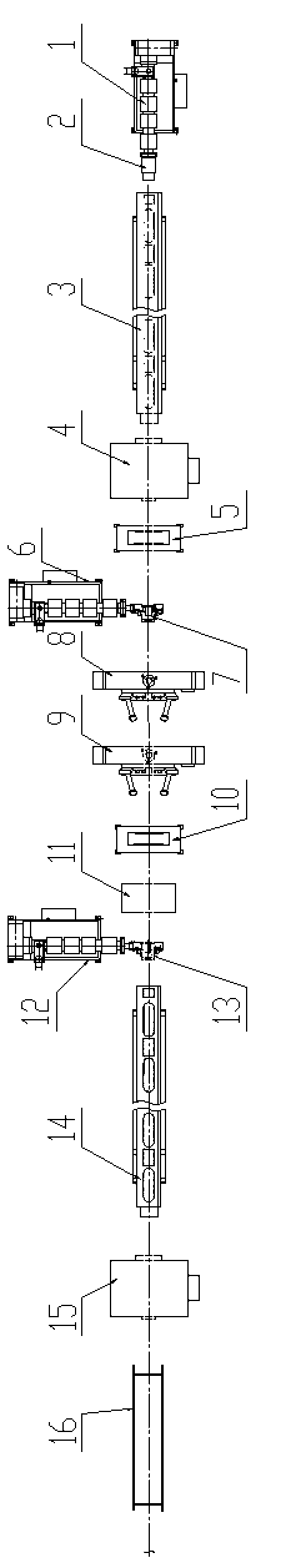

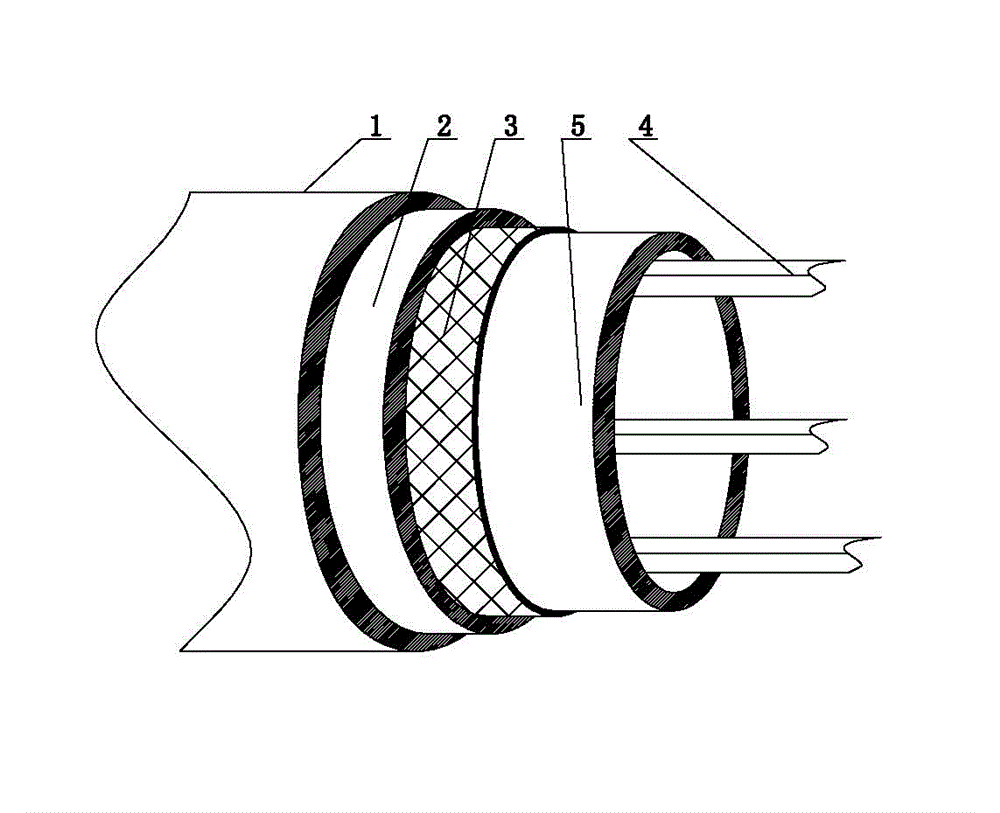

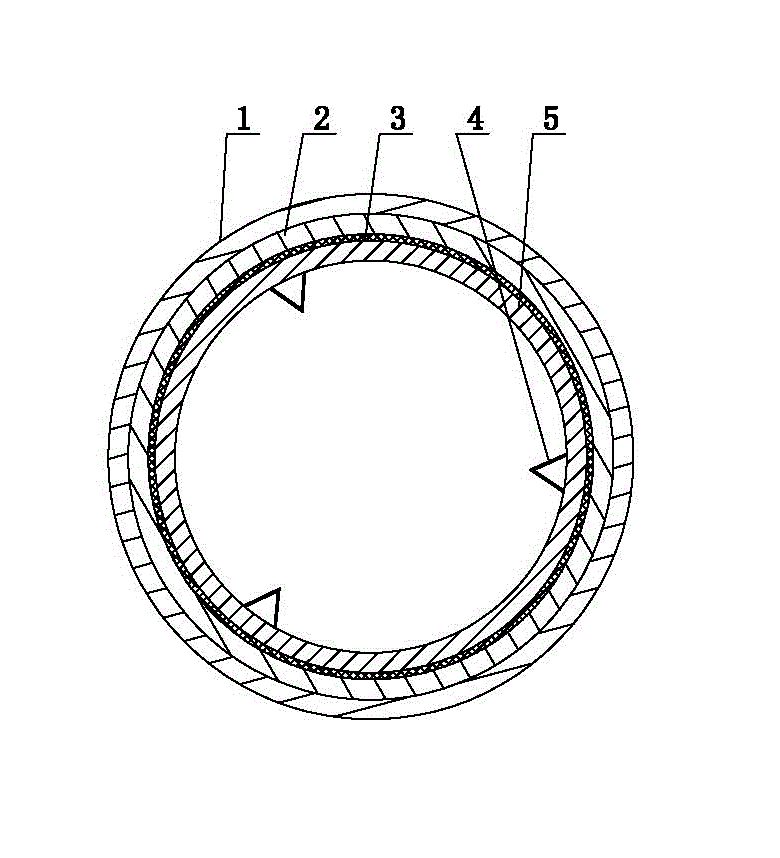

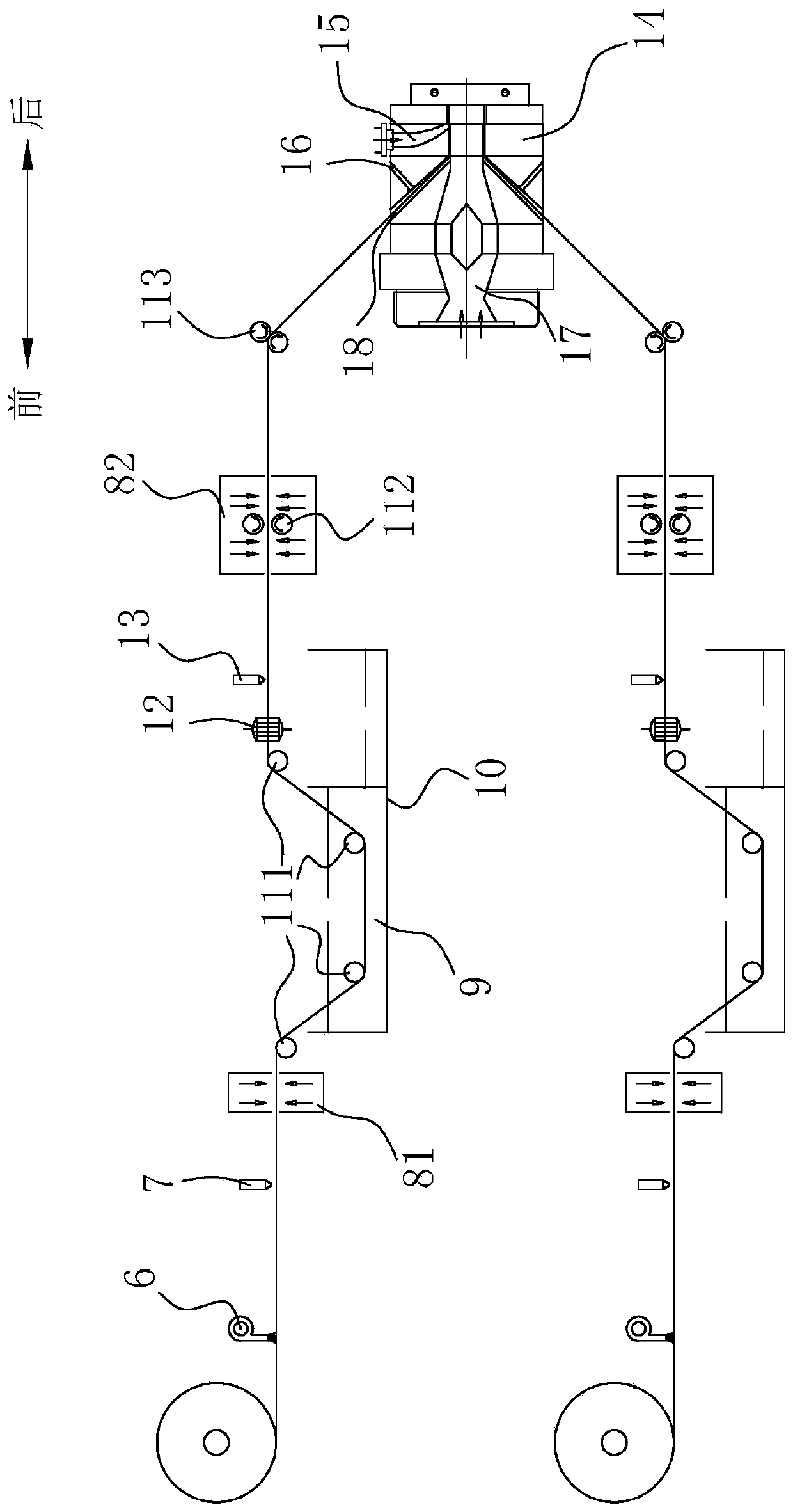

Fiber mesh tape-wound and reinforced composite pipe, preparation process and device

ActiveCN103016856AGuaranteed synchronicitySolve associativityRigid pipesMechanical propertyMaterials science

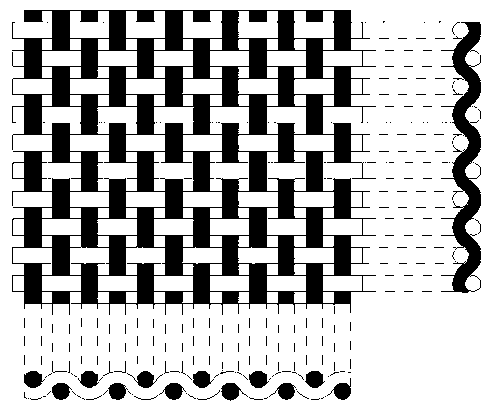

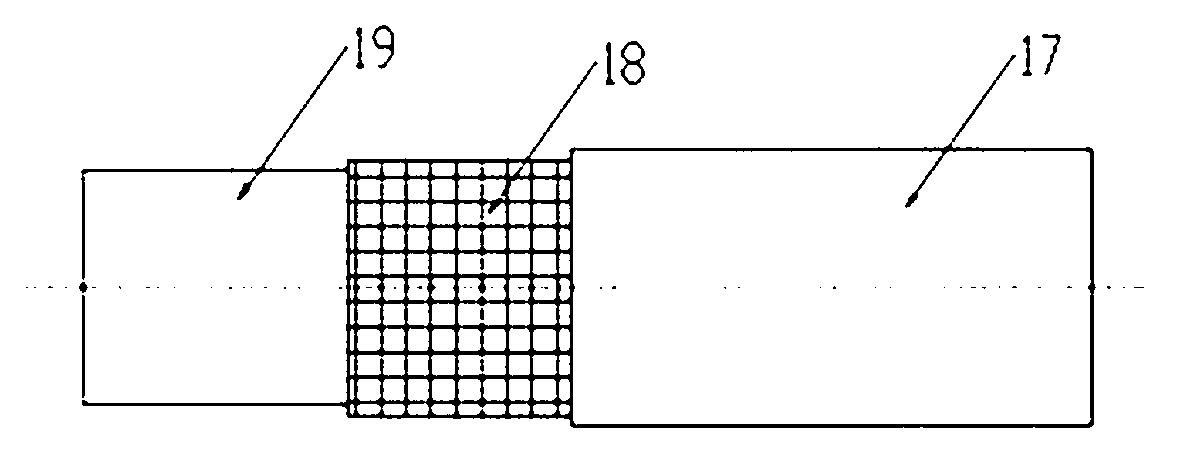

The invention relates to a fiber mesh tape-wound and reinforced composite pipe, a preparation process and a device, belonging to the technical field of forming processes of composite pipes. The composite pipe comprises an inner-layer core pipe and a post-coated layer, as well as a fiber mesh tape arranged between two layers, wherein the inner-layer core pipe is extruded by a core pipe extruding machine, the adhesive resin fiber mesh tape is heated through a post-heating box, and the composite pipe is finally obtained by traction through a post-traction machine, sizing through a vacuum spraying and sizing box and the like. According to the composite pipe disclosed by the invention, the technology is adopted, the preparation process is simple, the existing tape plastic covering treatment process and the composite pipe forming process are combined into a whole, the number of workers for production is reduced, and the degree of automation is improved; furthermore, the used device is a conventional device, and the cost is reduced; and in addition, adhesive resin is firstly coated on the outer surface of the core pipe, and the plain woven fiber mesh tape is further wounded, so that the interface problem in the pipe is effectively solved, the mechanical properties of the pipe are upgraded and the stability of the pipe during long-term use is also improved.

Owner:ZHEJIANG WEIXING NEW BUILDING MATERIALS CO LTD

Silicon carbide particle reinforcement aluminum-based composite for train brake disc and preparation method

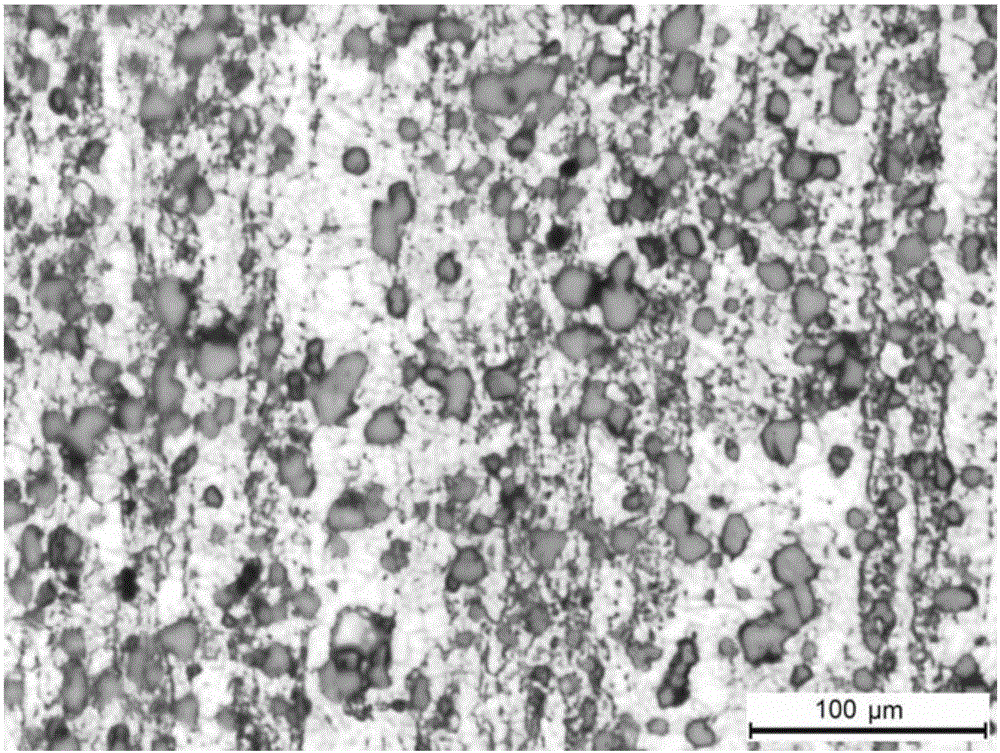

Disclosed are a silicon carbide particle reinforcement aluminum-based composite for a train brake disc and a preparation method. The composite includes the following components of, by mass percentage, 15-25% of SiC particles, 18-24% of Si, 0.6-3.5% of Mg, 0.15-0.35% of Zr, 0.12-0.45% of Sc, and the balance Al and unavoidable impurities. According to the preparation method, SiC, Mg, Si, Zr and Sc with the particle size being 10-15 [mu]m are added into molten aluminum in the form of intermediate alloy, SiC with the particle size being 15-25 [mu]m is added into the molten aluminum in the form of particles, and thus the silicon carbide particle reinforcement aluminum-based composite is obtained. The SiC thin particles are added in the form of Mg-SiC, so that the problems of uniform dispersing difficulty of silicon carbide particles in a matrix and poor interface bonding are effectively solved, the particle reinforcement effect is fully played, and the toughness of alloy is improved. Meanwhile, transitional element zirconium and rare earth element scandium are added to replace titanium fine grains, the roughness and heat resistance of the aluminum-based composite are remarkably improved, and occurrence of heat fatigue cracks is restrained. In addition, the added rare earth scandium has a good modification effect on the interfacial compatibility of the silicon carbide particles and aluminum alloy.

Owner:湖南中南智造新材料协同创新有限公司

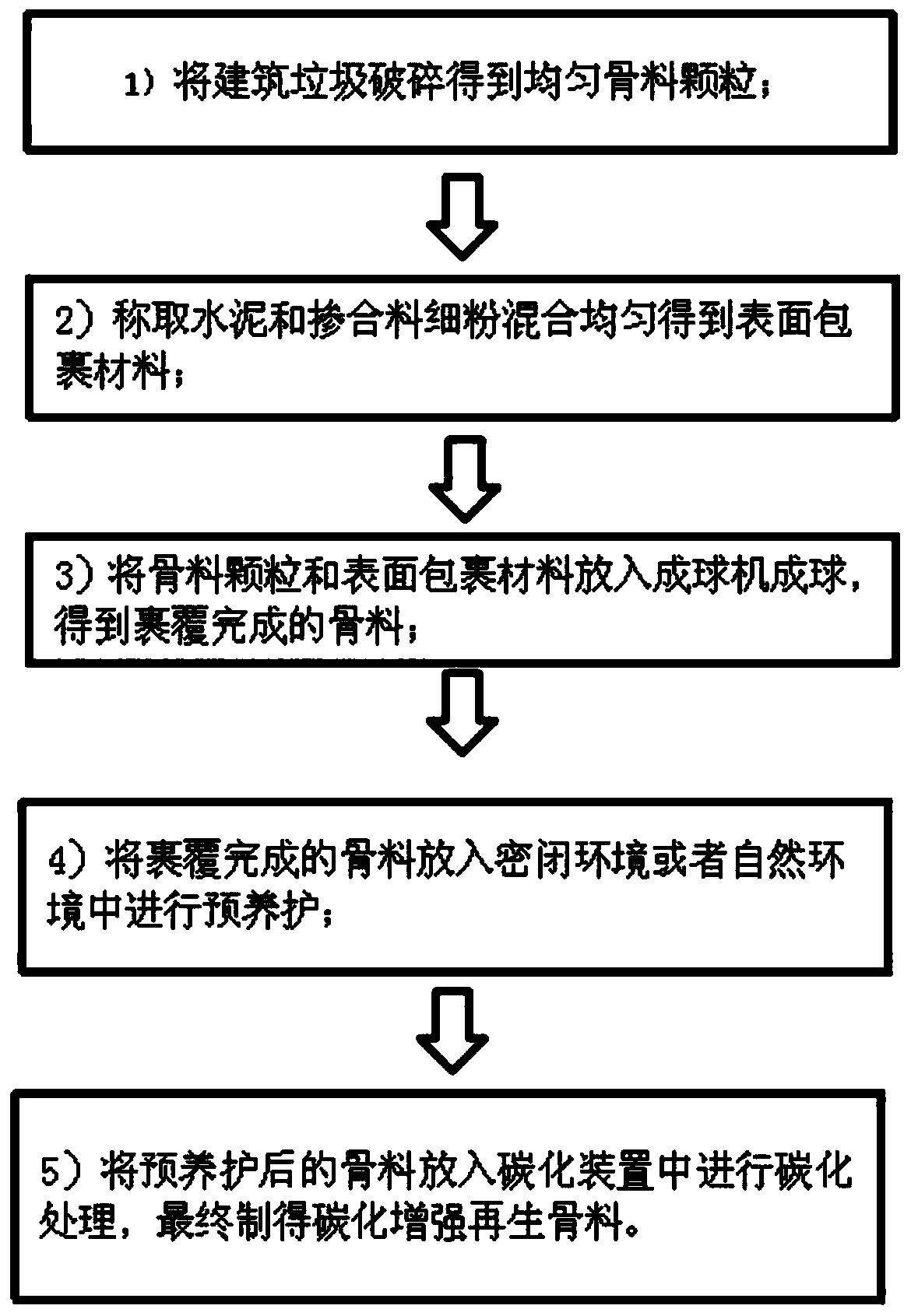

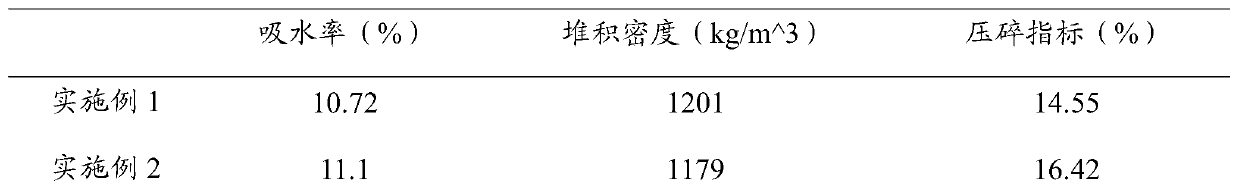

Carbonization reinforced regenerated aggregate, and preparation method and applications thereof

InactiveCN110357473ARealize resource utilizationPermanent storageSolid waste managementResource utilizationCarbonization

The invention discloses a carbonization reinforced regenerated aggregate, and a preparation method and applications thereof, and belongs to the technical field of building material. The preparation method comprises following steps: building garbage is crushed so as to obtain uniform aggregate particles; cement and admixture fine powder are weighted for uniform mixing so as to obtain a surface coated material; the prepared aggregate particles and the surface coated material are mixed, and are introduced into a granulator, water is sprayed uniformly for granulation so as to obtain a coated aggregate; the coated aggregate is introduced into a sealed environment or the natural environment for pre-curing; an aggregate obtained through pre-curing is introduced into a carbonization device for carbonization treatment so as to obtain the carbonization reinforced regenerated aggregate. The preparation method is adopted to prepare the light aggregate, so that aggregate light weight and high strength are achieved, aggregate cylinder compressive strength can be as high as 13.0MPa, and is higher than the using standard cylinder compressive strength 6.5MPa of common light aggregate. The production technology is simple; resource utilization of solid waste is realized; adsorption immobilization of carbon dioxide is realized; sintering is not needed; and low carbon emission and environment protection are realized.

Owner:NANJING UNIV OF TECH

Integrated composite electrode material, preparation method thereof and application thereof

InactiveCN110137560AIncrease contactImprove performanceElectrode manufacturing processesFinal product manufactureSolid state electrolytePolymer electrolytes

The invention discloses an integrated composite electrode material, a preparation method and application thereof. The integrated composite electrode material includes an electrode pole piece of an active material and a solid electrolyte layer which is located on a surface layer of the electrode pole piece and is integrated with the surface layer of the electrode pole piece to form an integrated structure. The solid electrolyte layer includes a solid electrolyte and a lithium salt, the solid electrolyte is a polymer electrolyte and / or an organic / inorganic composite solid electrolyte. Accordingto the composite electrode and the preparation method thereof provided by the invention, the wettability and contact between the electrode pole piece and the solid electrolyte can be improved, and thecycle performance of the battery is improved. The high-performance electrode material is achieved with an economical cost, the material is widely applicable to the preparation of positive and negative electrode pole pieces of a battery, and the invention has great significance for improving the cycle performance of a solid-state battery.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

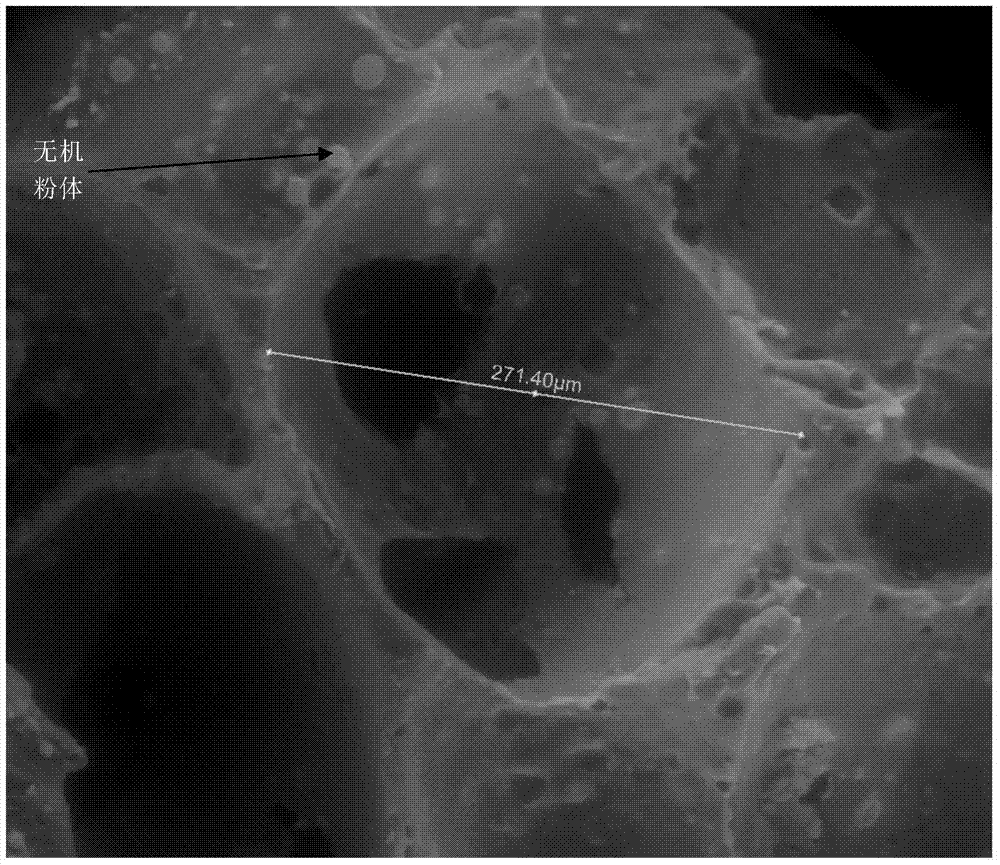

High molecular flame-retardant masterbatch

InactiveCN1699430AMechanical properties do not affectFix interface issuesFireproof paintsMechanical properties of carbon nanotubesPolyresin

Disclosed is a high molecular flame-retardant masterbatch including inorganic flame-proof stuffing and macromolecular resin, characterized in that the inorganic flame-proof stuffing is coated by organic monomer to form clad material, which comprises (by weight percent) clad material 80-85%, dispersing agent 1-3%, and balancing macromolecular resin. The invention also discloses the process for forming the clad material.

Owner:SHANDONG TIANYE PLASTICIZATION

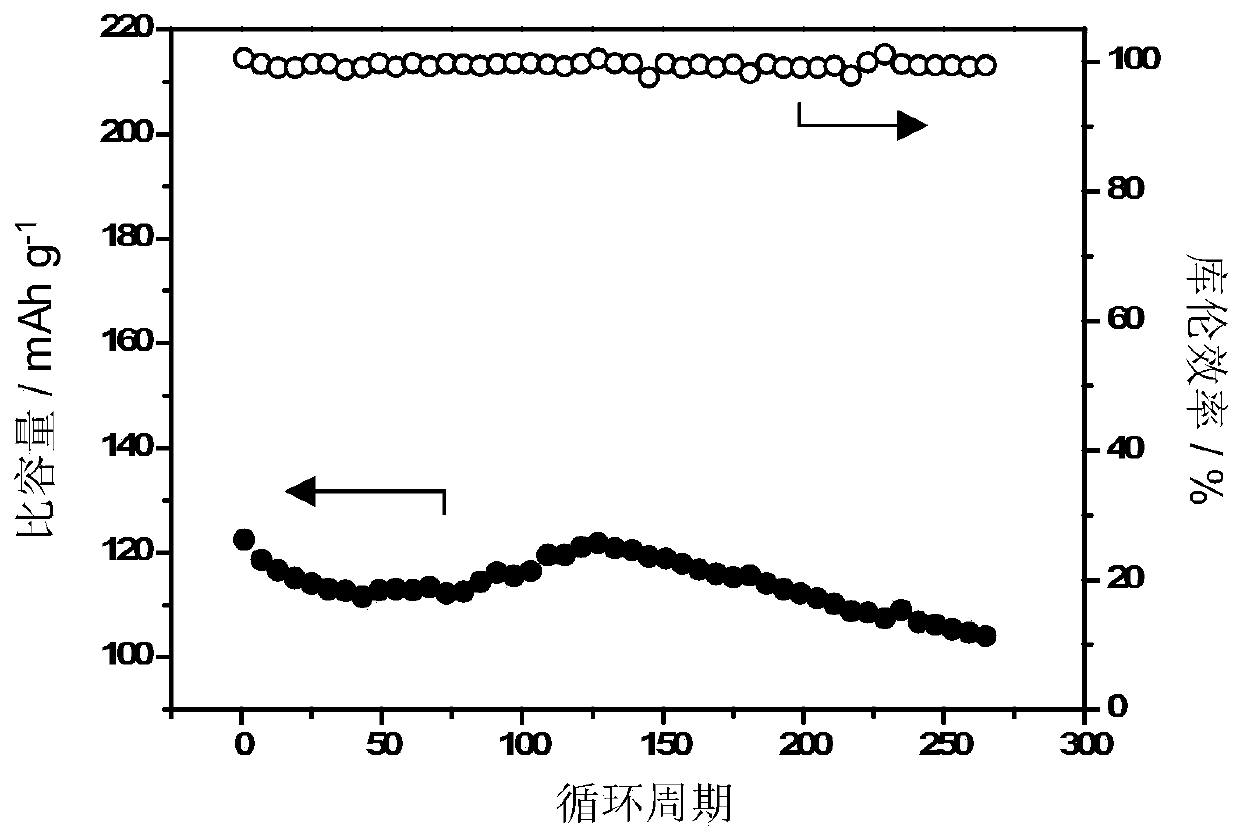

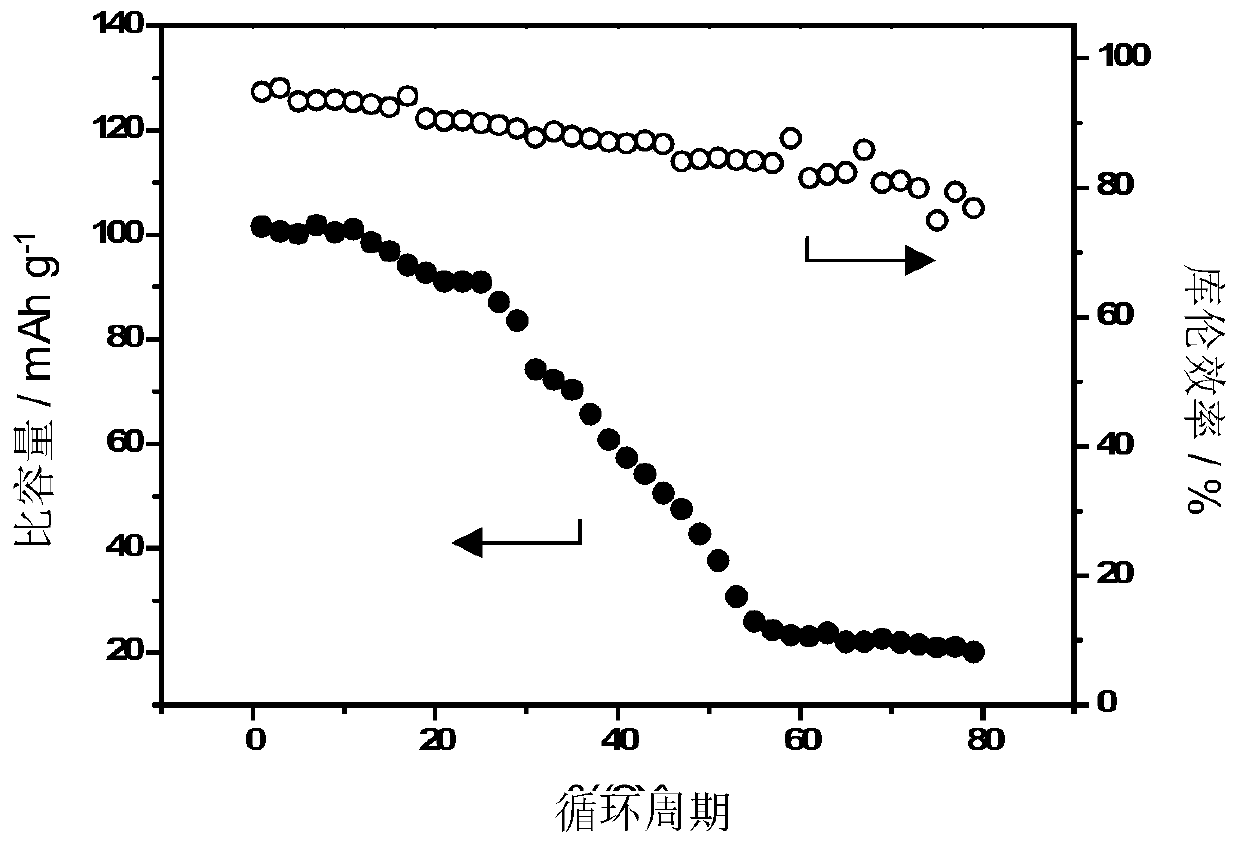

Lithium ion all-solid all-battery and preparation method thereof

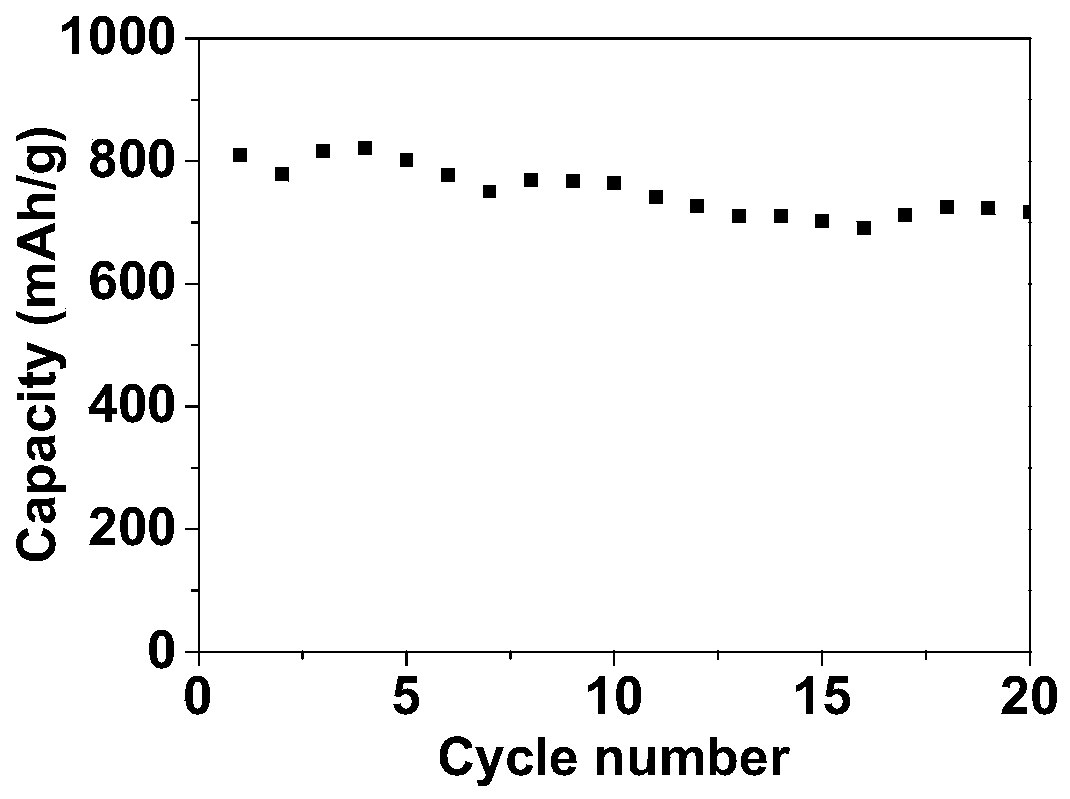

ActiveCN109921090AInhibition of volume expansionIncrease profitCell electrodesLi-accumulatorsCarbon compositesSolid state electrolyte

The invention relates to lithium sulfide / silicon solid-state all-battery positive and negative electrode materials with high cycling performance and preparation method thereof. A silicon / sulfur-basedsolid-state electrolyte composite negative electrode material is prepared through a solution in-situ synthesis one-step method; and the method is simple and convenient to operate, and the electrochemical performance stability and the electrochemical cycling performance are improved through sulfur-based solid-state electrolyte coating. A lithium sulfide / carbon composite positive electrode materialis prepared, and the carbon material can effectively improve the electronic conductivity of a lithium sulfide material and inhibit the volume expansion of lithium sulfide in charging and discharging;meanwhile, the utilization rate of the active substances can be improved by lithium sulfide nano-crystallization, so that the electrochemical performance is improved. The assembled lithium sulfide / silicon solid-state all-battery has high electrochemical cycling performance, and meanwhile, the interface problem of a lithium-sulfur battery and a solid electrolyte can be effectively solved, and potential safety hazards caused by metal lithium are avoided.

Owner:SHANDONG UNIV

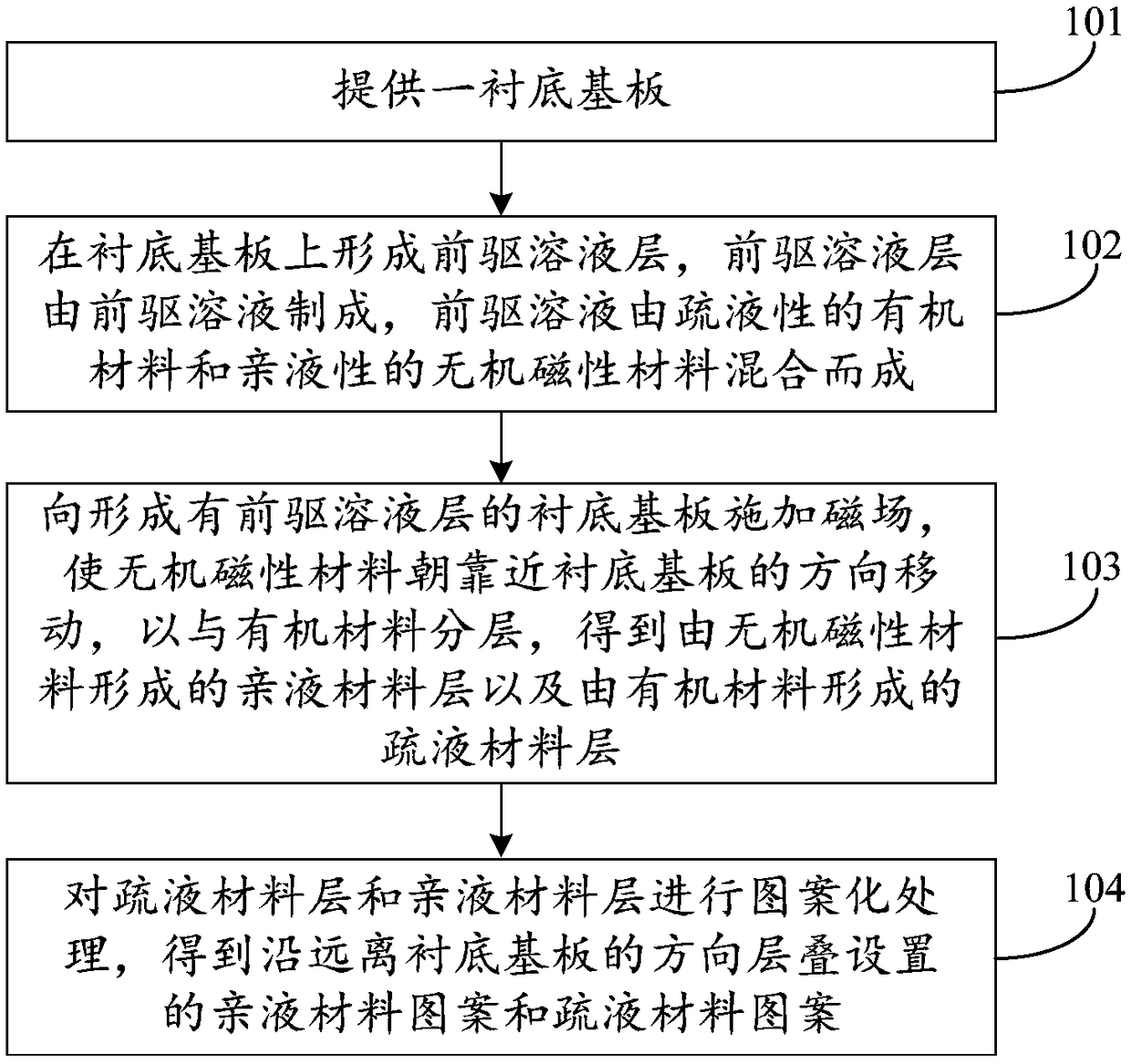

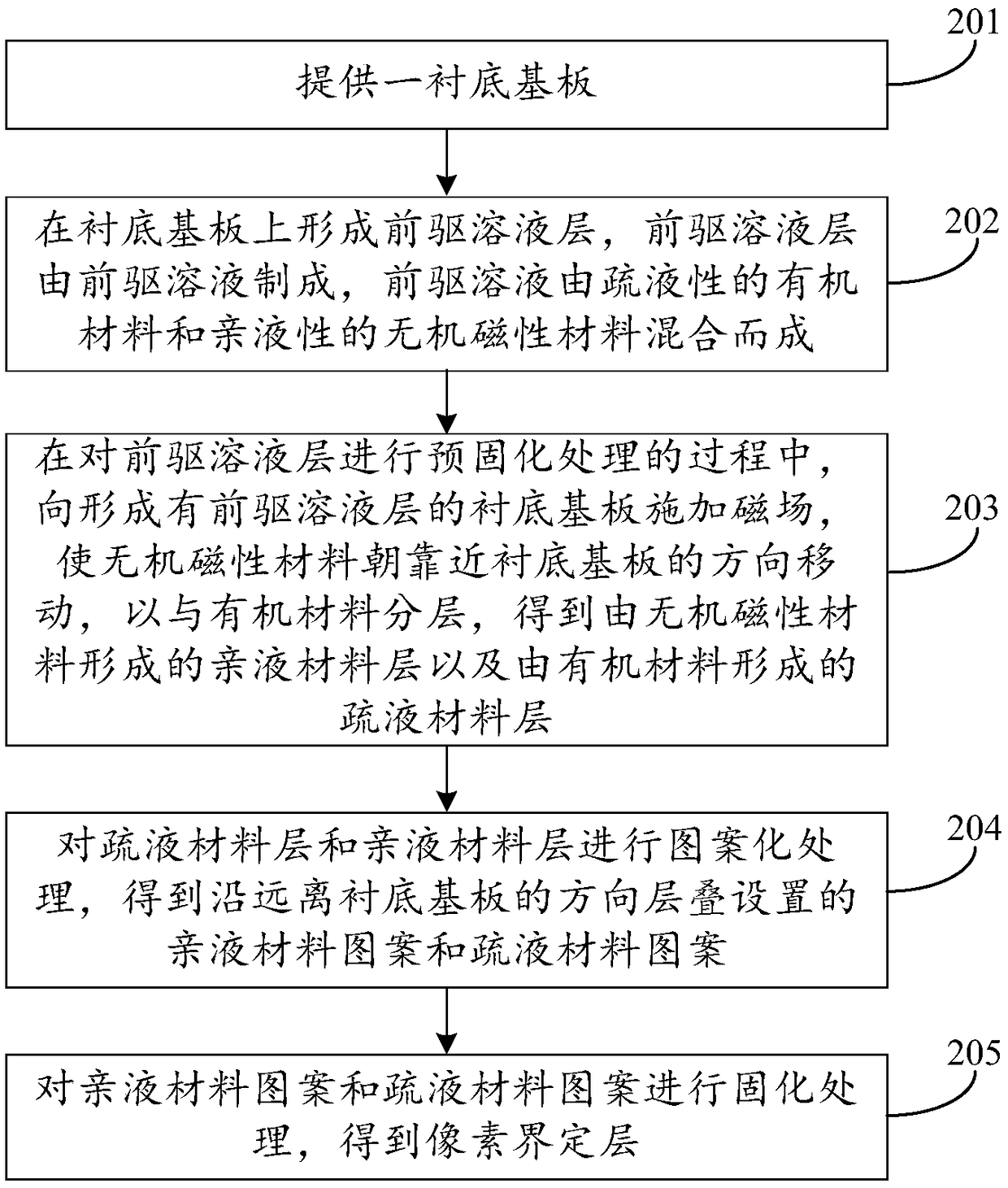

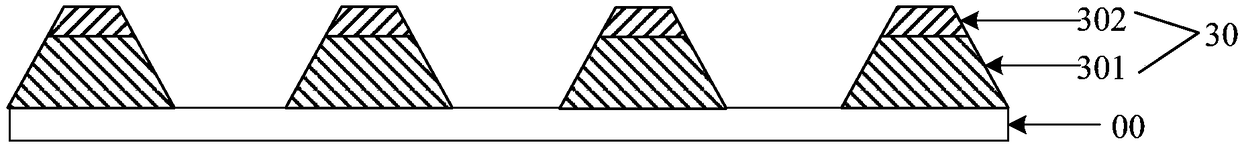

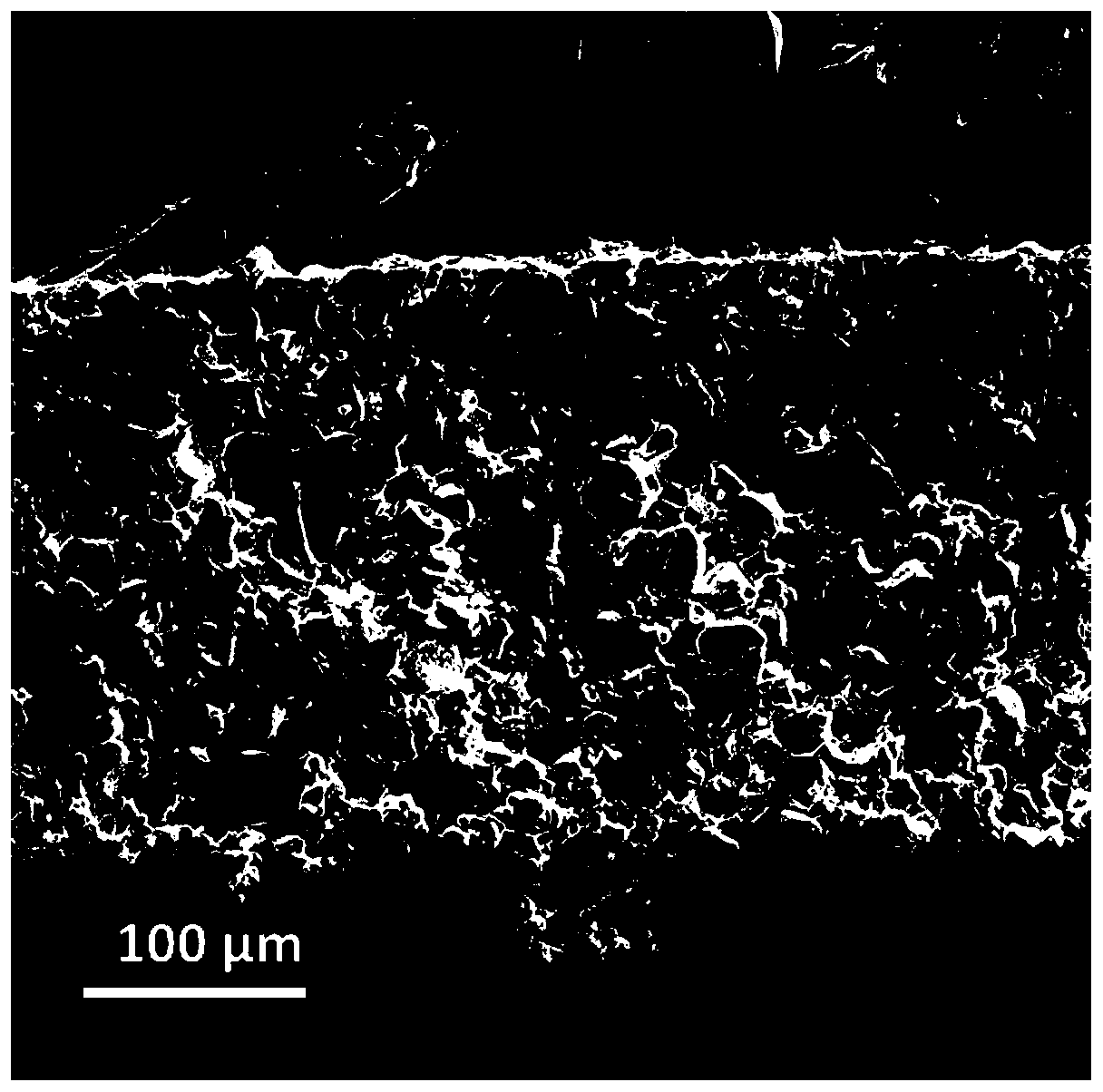

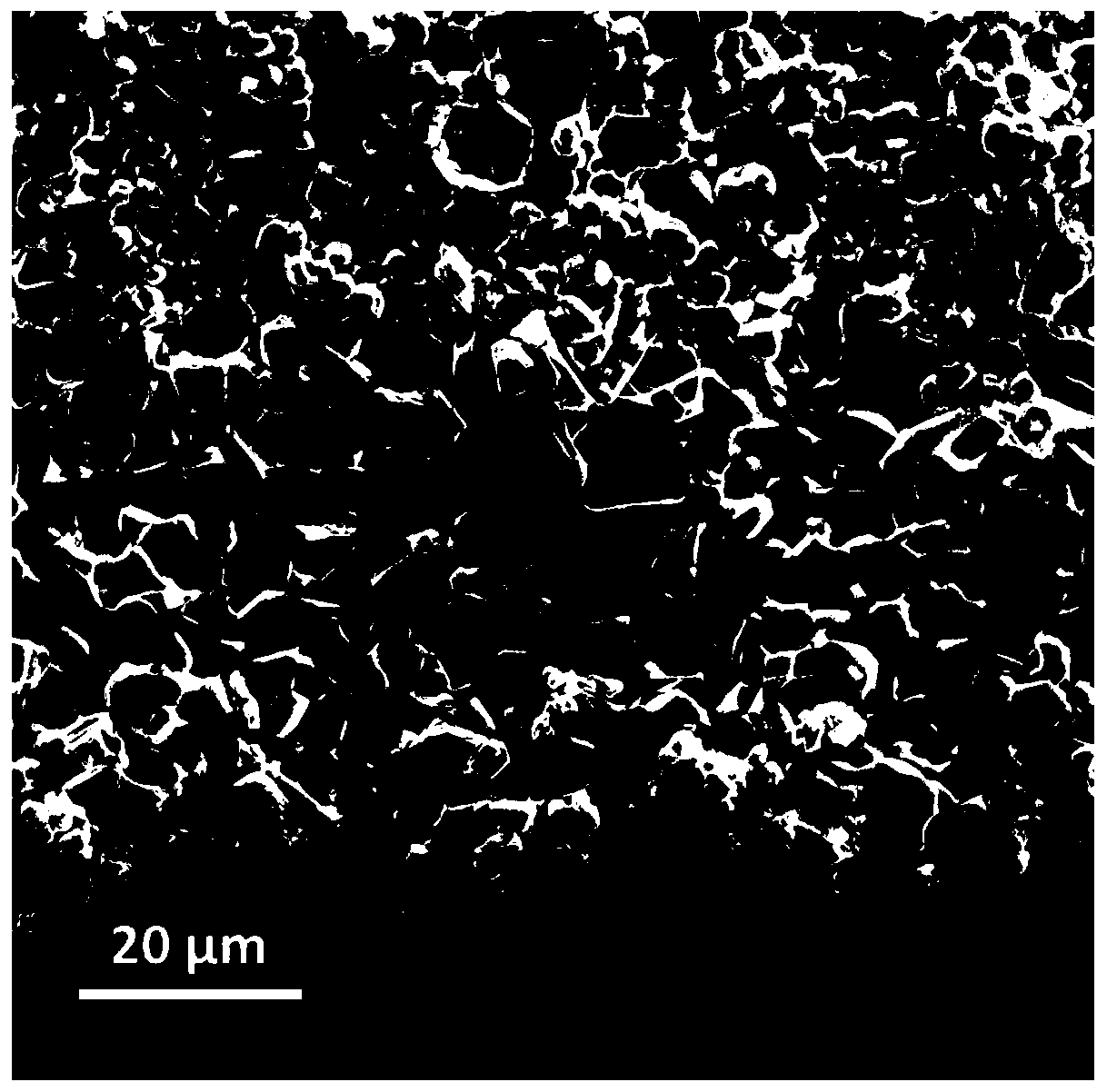

Pixel demarcation layer and manufacturing method thereof, and display substrate

ActiveCN108987449ASimple manufacturing processIncrease productivitySolid-state devicesSemiconductor devicesStructural stabilityNanotechnology

The invention discloses a pixel demarcation layer and a manufacturing method thereof and a display substrate, belongs to the technical field of display. The manufacturing method of the pixel demarcation layer includes providing a substrate substrate; Forming a precursor solution layer on the substrate, wherein the precursor solution layer is made of a precursor solution, and the precursor solutionis formed by mixing a hydrophobic organic material and a hydrophilic inorganic magnetic material; Applying a magnetic field to a substrate on which the precursor solution layer is formed to obtain ahydrophilic material layer formed of the inorganic magnetic material and a hydrophobic material layer formed of the organic material; The liquid-repellent material layer and the liquid-repellent material layer are patterned to obtain a liquid-repellent material pattern and a liquid-repellent material pattern stacked in a direction away from the substrate. The invention simplifies the preparation process of the pixel bounding layer, improves the production efficiency of the pixel bounding layer, and improves the structural stability of the pixel bounding layer. The present invention is used tofabricate a pixel bounding layer.

Owner:BOE TECH GRP CO LTD

Phase-change energy storage floor tile and manufacturing method thereof

The invention discloses a phase-change energy storage floor tile and a manufacturing method thereof. According to a formula, the floor tile comprises: 50-100 parts of a phase change material, 100 parts of an inorganic flame retardant and 40-100 parts of a high polymer elastomer, wherein the phase change material consists of: 30-70 parts of cement, 30-50 parts of fly ash, 5-20 parts of gamma-alumina, and 50-100 parts of a phase change substance. The floor tile is manufactured by: first adsorbing the phase change substance into a porous substance composed of cement, fly ash and gamma-alumina in a proper portion, and then subjecting the adsorbed porous substance, the flame retardant and the high polymer elastomer to mixing. The obtained floor tile has the characteristics of high strength, good thermal shock resistance and wear resistance, difficult breackage, stable chemical properties, and strong thermal storage / refrigeration capability, and can prevent the phase change substance from seeping from the energy storage floor tile. And the phase change material has the advantages of long service life, good flame retardance and environmental performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

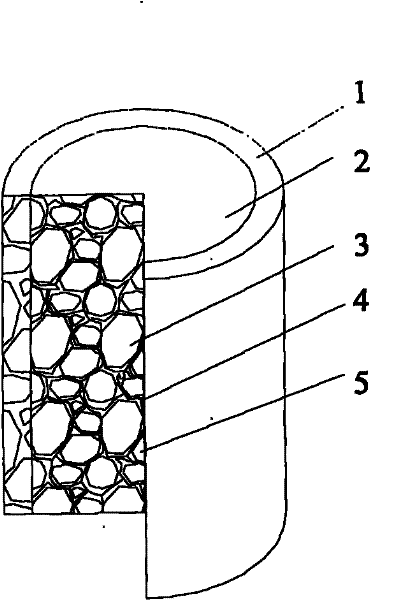

Low-impedance interface processing method of solid-state lithium battery positive electrode and positive electrode structure

ActiveCN109768215AImprove securityAvoid punctureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteEngineering

The invention discloses a low-impedance interface processing method of a solid-state lithium battery positive electrode and a positive electrode structure. By the method, impedance of two interfaces between active material particle in a positive electrode plate and solid-state electrolyte particle and between the positive electrode plate and an electrolyte piece can be effectively reduced, so thatthe capacity of active positive electrode particle in the solid-state lithium battery can be effectively developed. The dual-layer structure ceramic piece comprising a solid-state electrolyte layer and a positive electrode layer and fabricated by the method is excellent in performance and has favorable application prospect in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

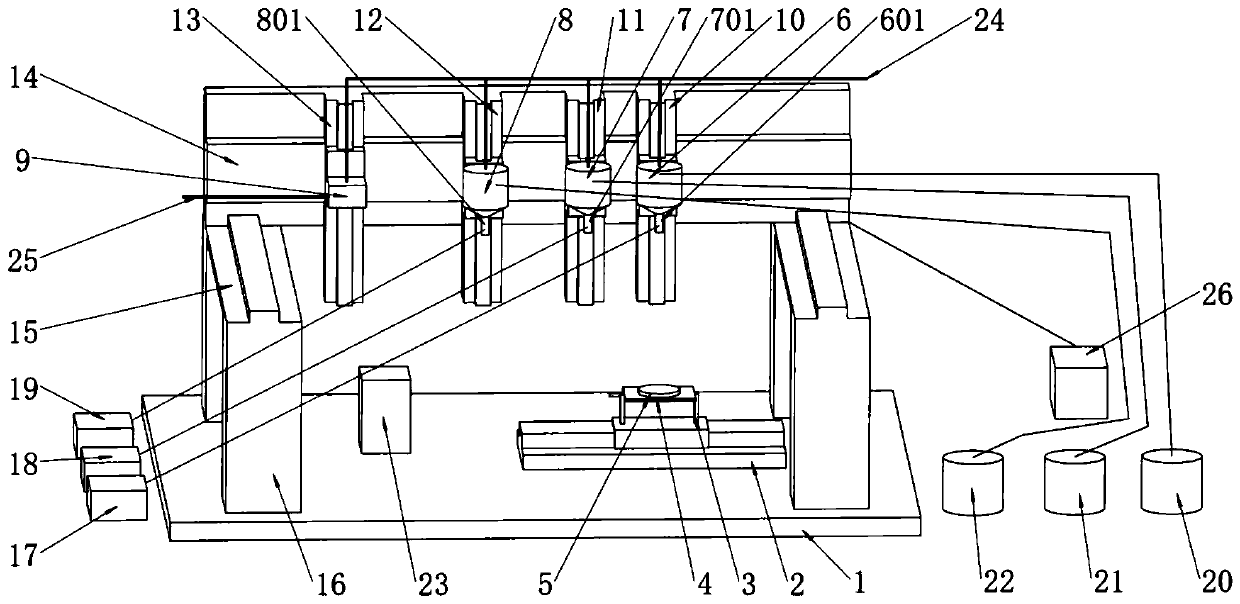

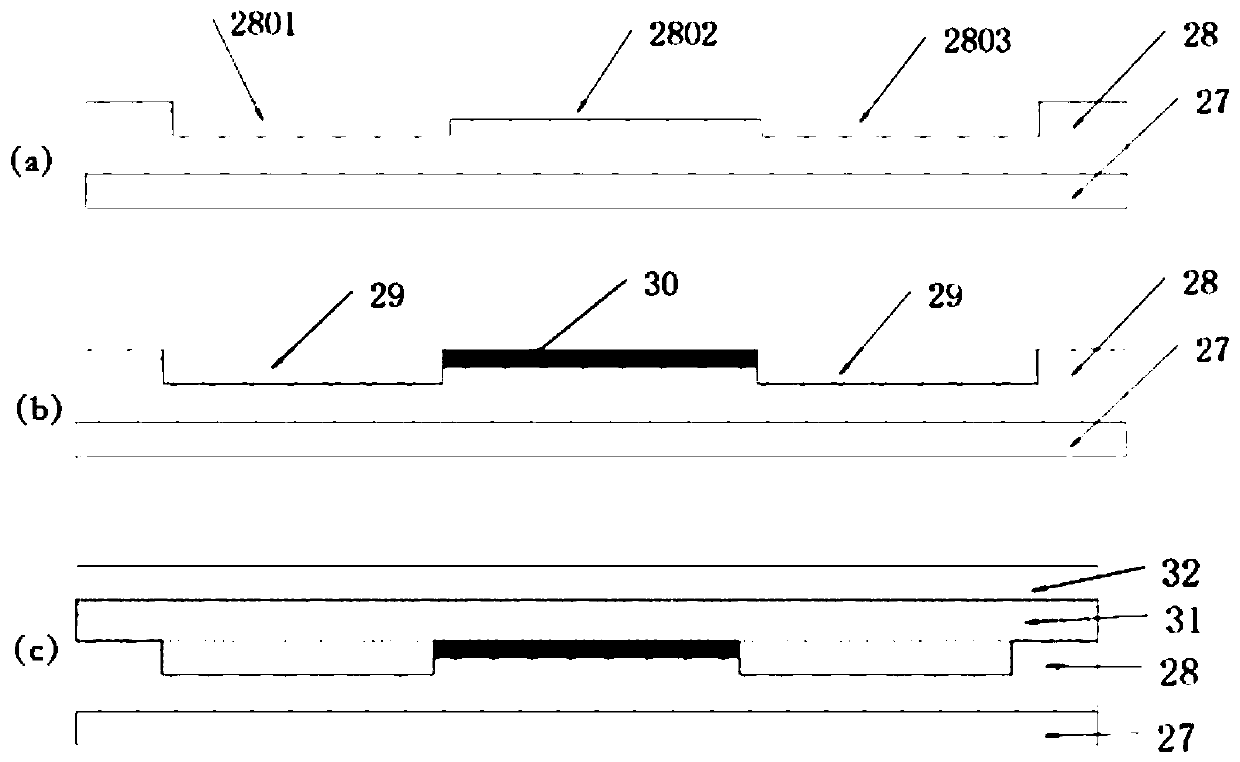

Multi-material 3D printing device for integrally manufacturing stretchable electronic product and working method

PendingCN109732900AAchieving heat curingReduce printing timeManufacturing platforms/substratesManufacturing heating elementsStretchable electronicsMulti material

The invention provides a multi-material 3D printing device for integrally manufacturing a stretchable electronic product and a working method. The device comprises a base and a control module; the base is provided with a three-dimensional workbench, a placing platform, a swing table and a printing bed, wherein the printing bed is arranged on the swing table, and the swing table drives the printingbed with vacuum adsorption and electric heating functions to swing and rotate; and the three-dimensional workbench comprises at least four Z-direction workbenches, the first Z-direction workbench isprovided with a mechanical arm used for grabbing and placing electronic elements, and each of the remaining Z-direction workbenches is provided with a printing nozzle. Movement of the three-dimensional workbench, the swinging table, the mechanical arm and a feeding module are controlled, each printing nozzle executes printing of a flexible base plate, a protective layer, a connecting circuit, an embedded electronic element and a packaging layer of the stretchable electronic product according to a set sequence, and thus integrated manufacturing is realized.

Owner:QINGDAO 5D INTELLIGENT ADDITIVE MFG TECH CO LTD

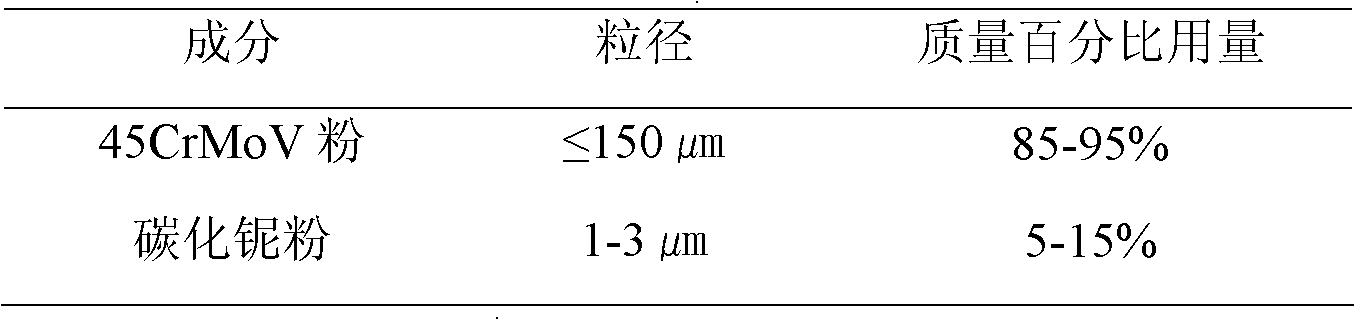

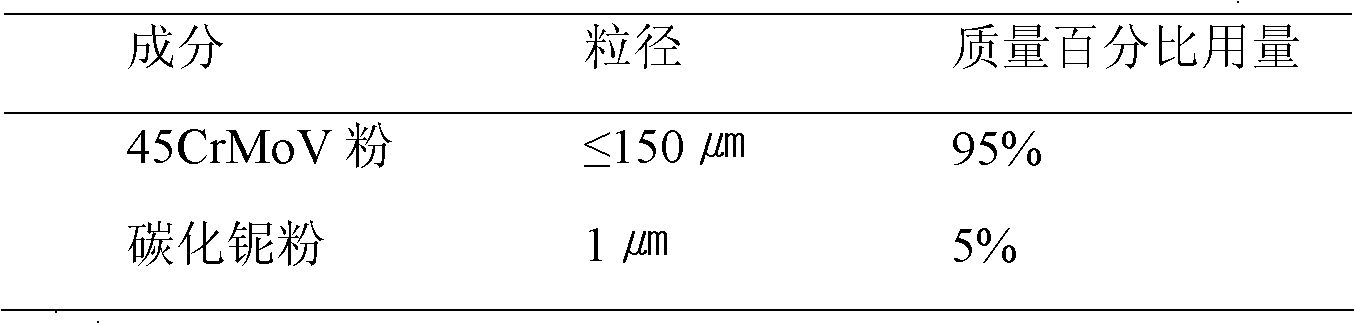

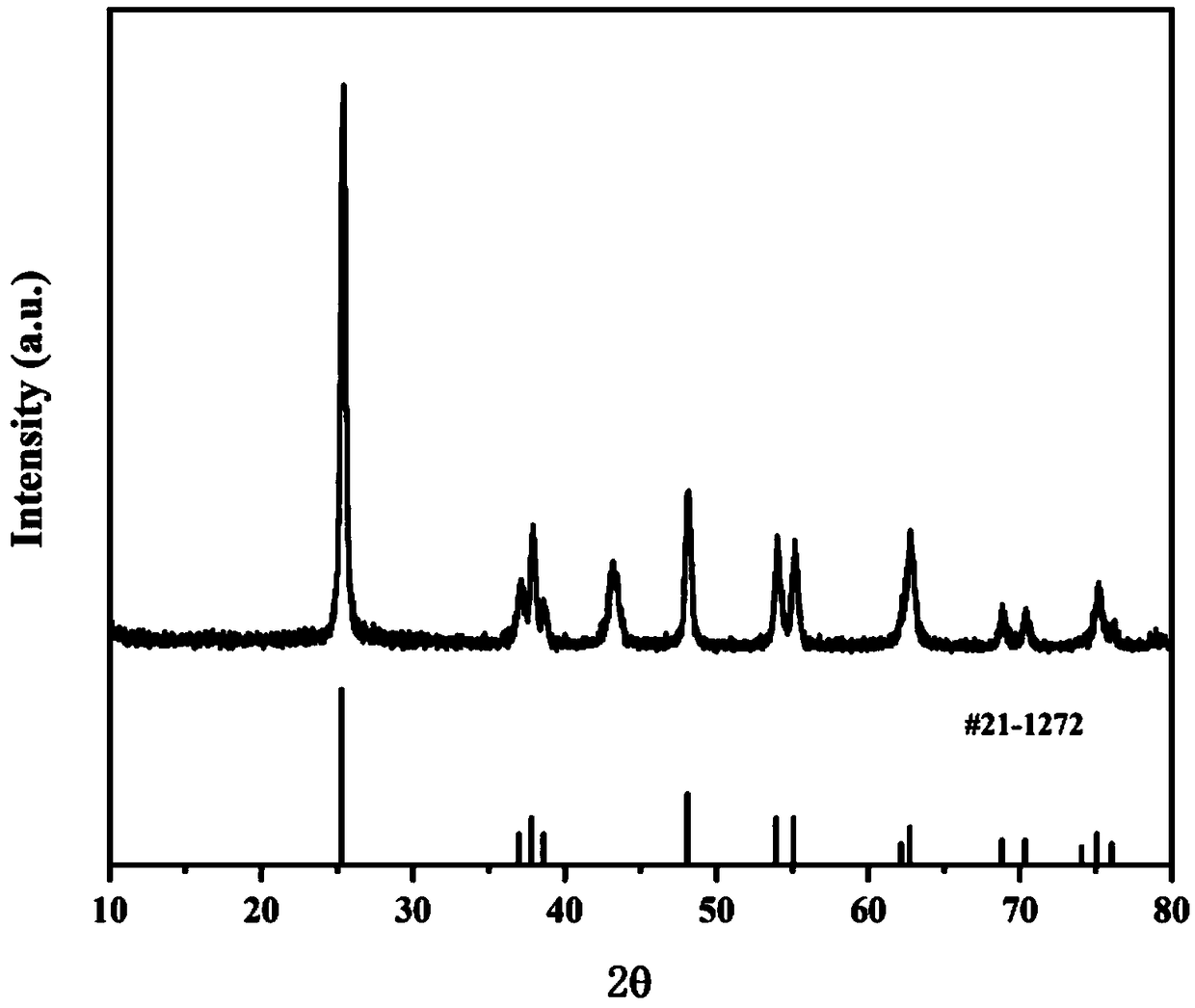

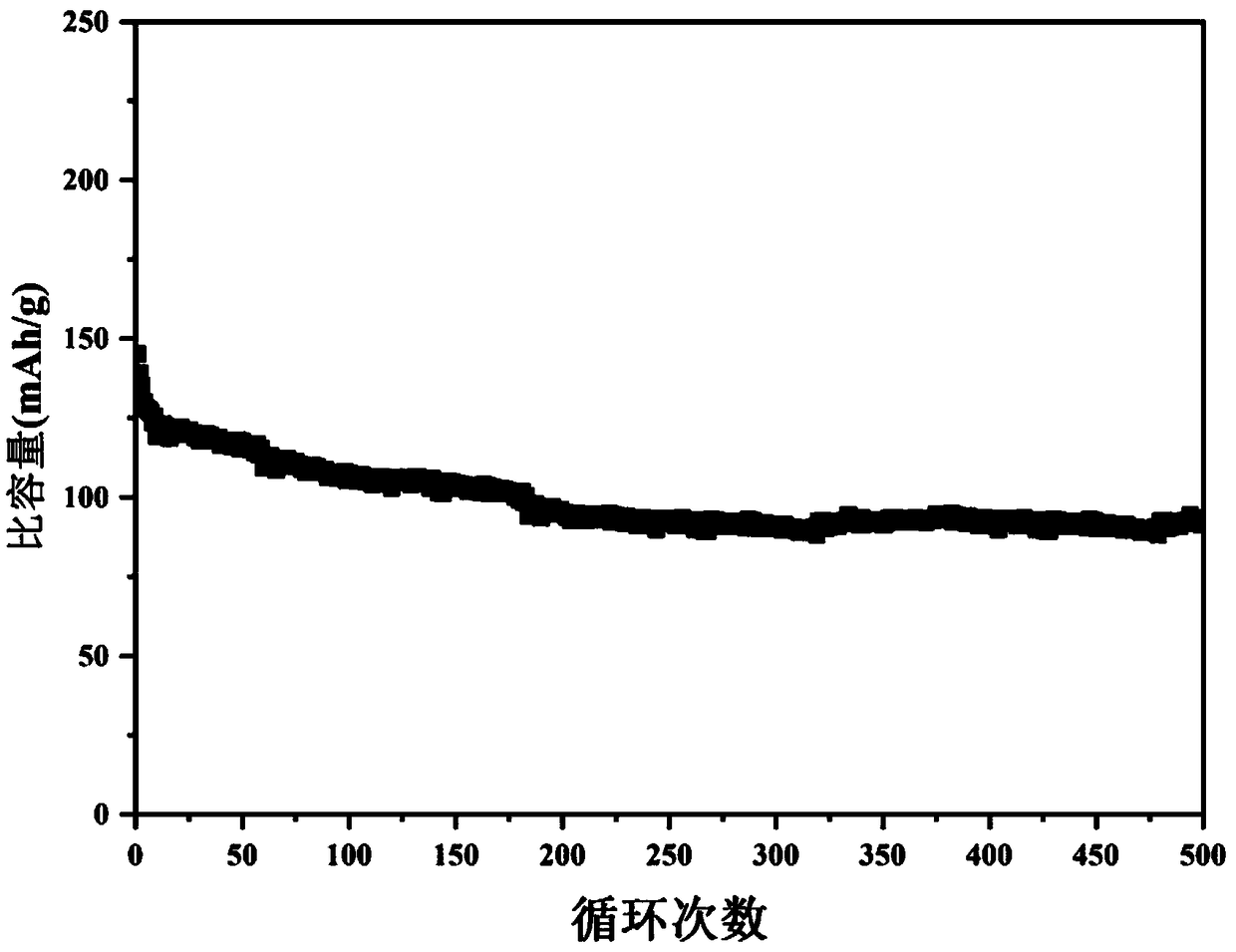

Powder metallurgy spring steel composite material and preparation method thereof

The invention discloses a powder metallurgy spring steel composite material and a preparation method thereof. The composite material comprises the components with the content by mass percent: 85-95% of 45CrMoV and 5-15% of carbonized niobium powder; and the powder metallurgy spring steel composite material is prepared by the method combining high-energy ball-milling and thermal isostatic pressing sintering. The invention adopts the high-energy ball-milling to lead NbC to be evenly dispersed on a 45CrMoV spring steel base body, and greatly improves the wear resistance of the material under the condition of ensuring the mechanical property of the material; and furthermore, by adopting the method combining the high-energy ball-milling and the thermal isostatic pressing sintering, the invention effectively solves the problem of enhancing the fusion and interface of particles and the base body, thus leading the enhanced particles and base body to be more closely combined with each other. The spring steel composite material is especially applicable for manufacturing an elastic element.

Owner:SOUTH CHINA UNIV OF TECH

High molecular antistatic masterbatch

InactiveCN1699465AMechanical properties do not affectFix interface issuesOther chemical processesMasterbatchPolyresin

Disclosed is a high molecular antistatic masterbatch including inorganic electrostatic resistant gasket material and macromolecular resin, wherein the inorganic electrostatic resistant gasket material being coated by organic monomer to form clad material, comprising (by weight percent) clad material 50-80%, lubricating agent 3-5%, and balancing macromolecular resin. The forming process for the clad material comprises, mixing 100 weight parts of inorganic electrostatic resistant filling material, 2-15 weight parts of polymerisable monomer, 0.1-1 weight part of initiating agent, carrying out polymerization reaction, finally disintegrating.

Owner:SHANDONG TIANYE PLASTICIZATION

Full-solid-state lithium battery negative electrode material, preparation method and all-solid-state lithium battery

ActiveCN108987731AImprove conductivityImprove electrochemical performanceNegative electrodesSecondary cellsAll solid stateCore shell

The invention discloses an all-solid-state lithium battery negative electrode material, a preparation method and an all-solid-state lithium battery, wherein, the negative electrode material is TiO2 with a core-shell structure; The nucleus is oxygen-free titanium dioxide, and the particle size of the nucleus is 200- 1000nm; The shell is oxygen-defective titanium dioxide, and the thickness of the shell is 20- 200nm. The all-solid-state lithium battery negative electrode material prepared by the invention has higher lithium ion conductivity compared with the pure titanium dioxide electrode, and has better conductivity and stability compared with the pure oxygen-defective titanium dioxide. The method for preparing all-solid-state lithium battery negative electrode material has the advantages of high repeatability, simple process and large-scale production.

Owner:湖南恩捷前沿新材料科技有限公司

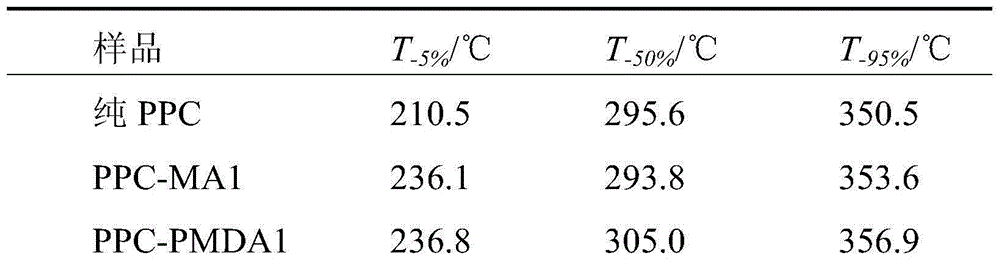

Method for preparing completely-degradable composite material through acid anhydride and microcrystalline cellulose synergetic modification on poly(propylene carbonate)

InactiveCN105061971ASmall sizeComplete crystalline structurePropylene carbonateMicrocrystalline cellulose

The present invention discloses a method for preparing a completely-degradable composite material through acid anhydride and microcrystalline cellulose synergetic modification on poly(propylene carbonate), wherein 50-95 parts by mass of degradable poly(propylene carbonate), 0.1-10 parts by mass of an acid anhydride and 5-50 parts by mass of microcrystalline cellulose are subjected to melt mixing to form a master batch of a completely-degradable composite material, and mold pressing molding is performed to obtain the sample. According to the present invention, the completely-degradable composite material prepared through the method has characteristics of good mechanical property and good thermal stability, and the processing stability and the mechanical property of the prepared product can be effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

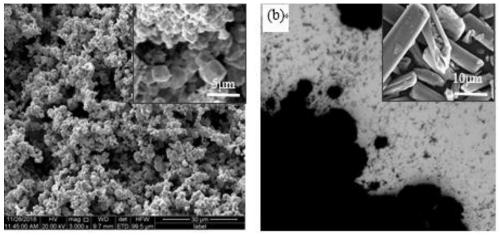

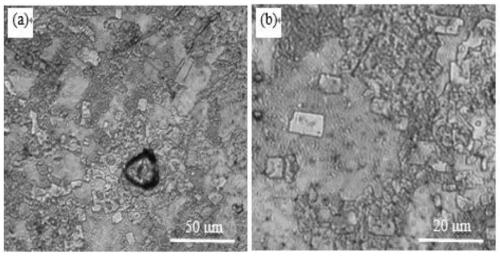

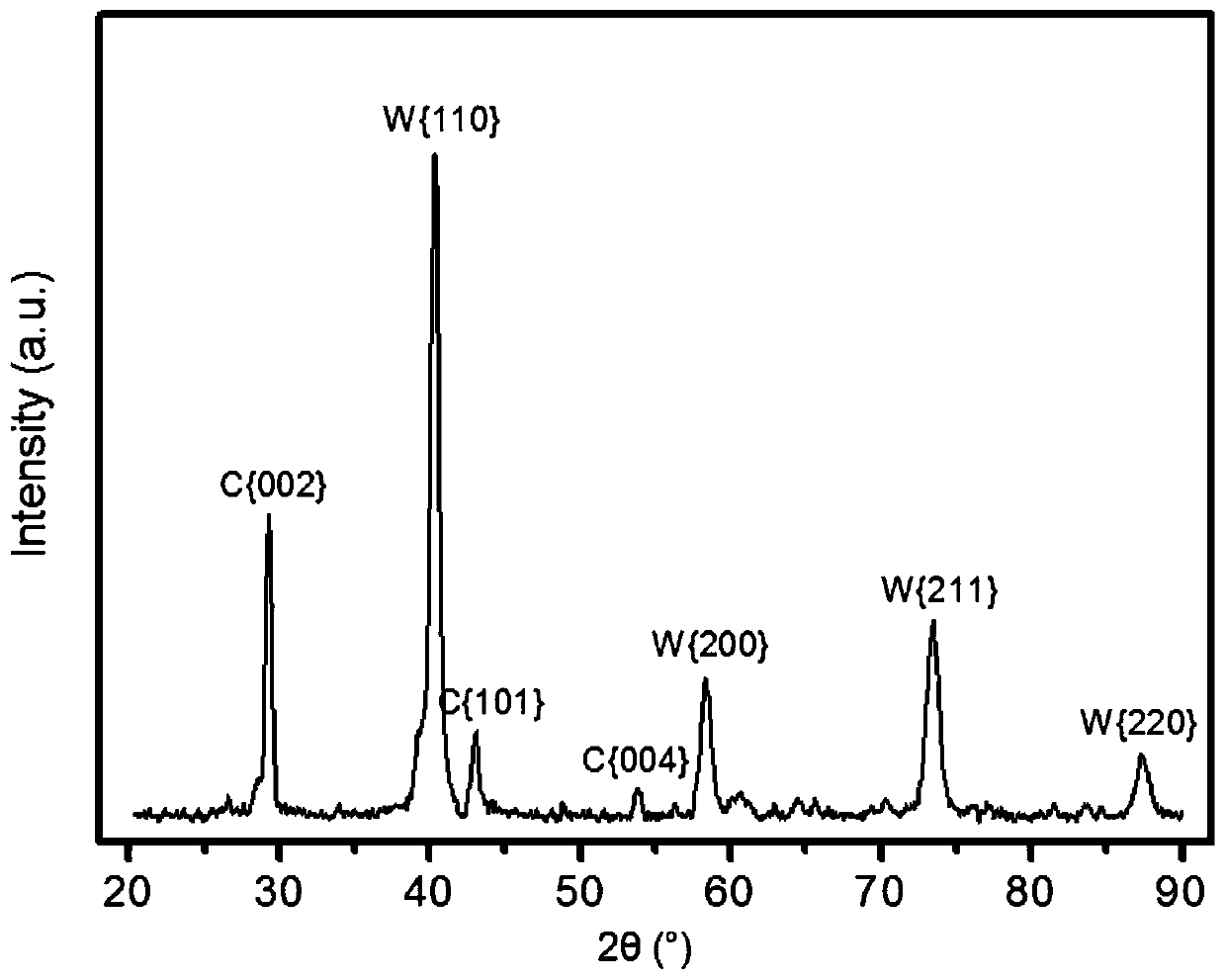

Preparation method for carbon fiber powder reinforced tungsten-based composite material

The invention discloses a preparation method for a carbon fiber powder reinforced tungsten-based composite material. The preparation method is achieved in the way that tungsten powder and carbon fiberpowder pretreated through rhenium plating are taken as raw materials to undergo raw material treatment, laser sintering, sample post-treatment and other steps correspondingly. According to the preparation method, the preparation process is simple, energy saving and emission reduction are achieved, the effect of being environment-friendly is achieved, in the case of the prepared composite material, the crystallinity is good, the density is high, the average density is 17.32 g / cm<3>, the average relative density is 98.97%, the product hardness is high, the average hardness can reach up to 340.9HV0.2, the toughness is good, the minimum fracture toughness is 6.5 MPa.m<1 / 2>, no degreasing process is adopted, so that the deformation problem caused by the complex degreasing process is avoided,in addition, the rhenium on the surface of the carbon fiber powder successfully blocks direct contact between the carbon and the tungsten, and the rhenium has excellent wettability to the tungsten, sothat a composite material interface transition layer is formed, the interface problem in the preparation process is solved, the preparation procedure of the product prepared through the method is greatly shortened compared with a traditional vertical fusion sintering method, and the preparation method can be developed into a 3D printing technology downstream to realize the direct production of the terminal product.

Owner:重庆金锐新材料技术研究院有限公司

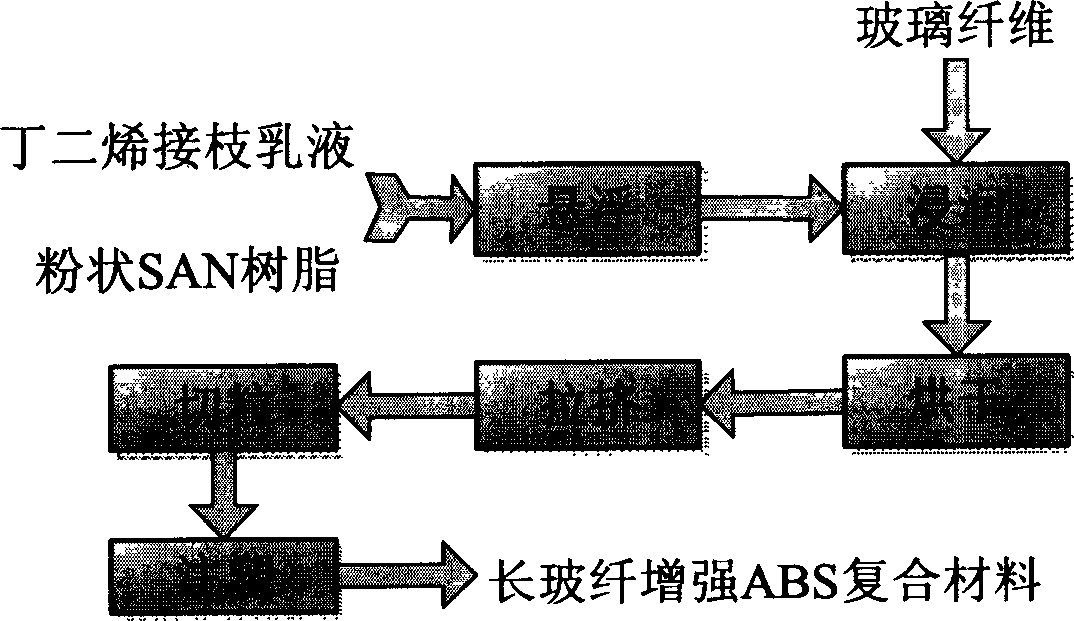

Method for preparing long fiber reinforced ABS composite material

The present method of long glass fibre reinforced ABS composite material uses intermedium butadiene graft emulsion of ABS and SAN resin powder body as raw material and adopts the following steps: adding ABS antioxidant 1010, stirring to prepare suspension; making the continuous glass fibre whose surface is streated by coupling agent be passed through the suspension imbibition tank under the action of traction force; then making said continuous glass fibre be passed through an open drying oven, drying, passed through a closed melting pipeline heating and melting, then extrusion-forming by means of die, granulating to obtain composite material chips; drying chips, injection moulding so as to obtain the invented product.

Owner:DONGHUA UNIV

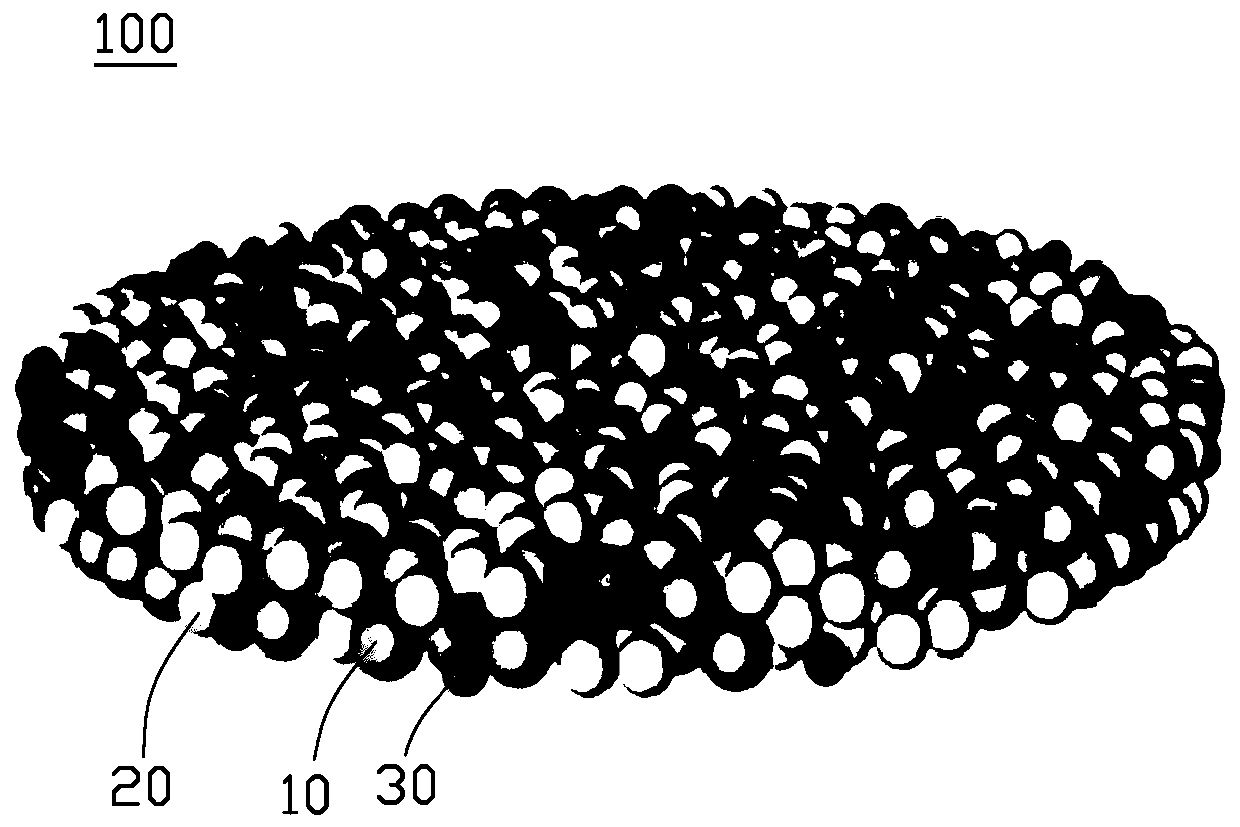

Positive electrode material, preparation method thereof and battery

InactiveCN110828797AImprove ionic conductivityIncrease gram capacitySecondary cellsPositive electrodesAll solid stateElectrical battery

The invention relates to a positive electrode material, a preparation method thereof and a battery. The positive electrode material is of a core-shell structure with a coating layer on the surface; the core-shell structure comprises an inner core and a shell layer coating the surface of the inner core, the inner core is made of nickel cobalt lithium manganate, the shell layer is made of lithium cobalt oxide, and the coating layer is made of lithium niobate and / or lithium titanate. In the positive electrode material, the coating layer endows the material with excellent ionic conductivity, goodinterfacial compatibility with sulfide solid electrolyte can be achieved, and the interface problem is solved; the core material can provide high gram volume, and the shell layer can endow the material with excellent rate capability, so that the positive electrode material has excellent electrochemical performance. When the positive electrode material is applied to an all-solid-state lithium ion battery, the specific discharge capacity, the cycle performance and the rate capability of the battery can be effectively improved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

Poly ethylene (PE) combined pipe

A poly ethylene (PE) combined pipe is formed by combining a high-density poly ethylene (HDPE) core pipe, a stainless steel mesh layer, a PE combination layer and a modified PE layer, wherein the HDPE core pipe is located in an innermost layer. The stainless steel mesh layer is wrapped outside the HDPE core pipe, the PE combination layer is wrapped outside the stainless steel mesh layer, and the modified PE layer is wrapped outside the PE combination layer. The PE combined pipe has the advantages of being high in applicability and combination strength, non-toxic, free of stimulation, resistant to corrosion, difficult to rust and low in cost and the like. Modified PE pipes are chosen for the modified PE layer, the modified PE layer is resistant to corrosion, long in service life and capable of being resistant to corrosion of various corrosive media such as acid, alkali, salt and organic solvents, corrosion damage caused by electrocorrosion generated in materials such as steel pipes is avoided, and the service life of the modified PE layer can be 60-70 years. The stainless steel mesh layer can improve compressive strength of an HDPE combined pipe, and accidents of the HDPE compound pipe such as fracture and water leakage and the like cannot occur easily.

Owner:郭翠芳

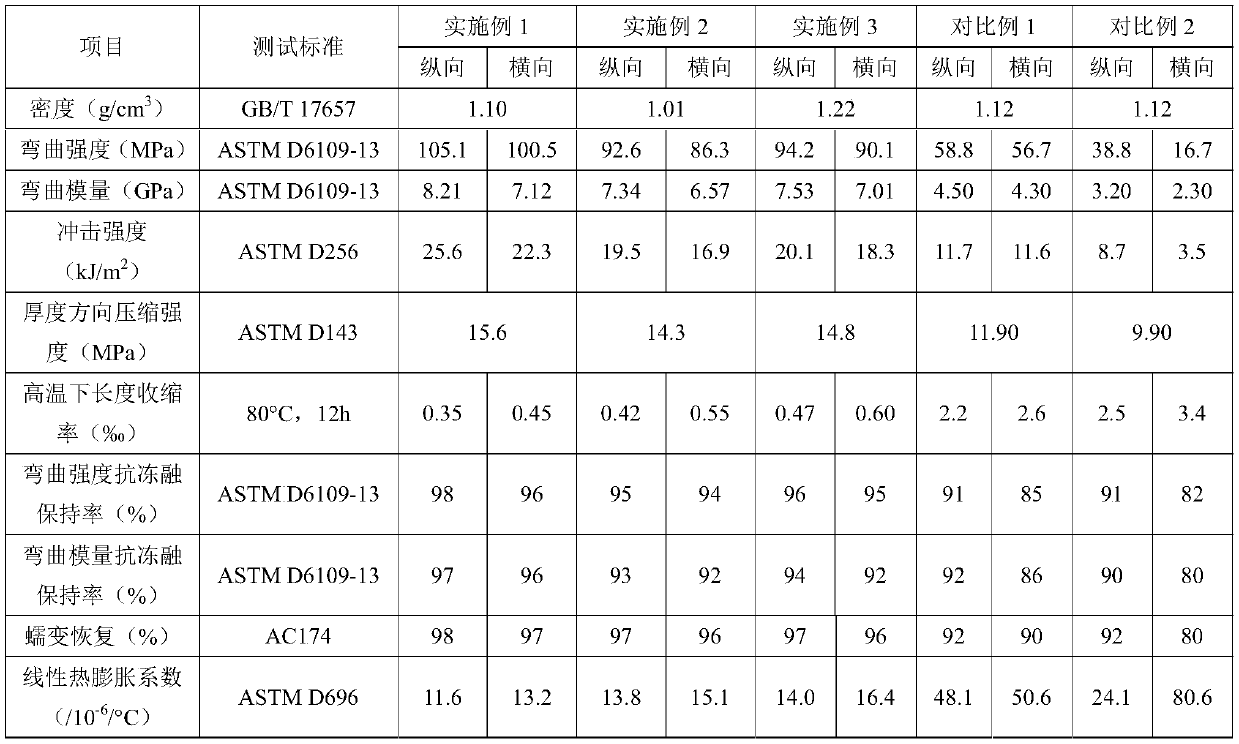

Continuous fiber cloth three-dimensional reinforced wood-plastic composite material as well as production method and equipment thereof

ActiveCN111421926AReduce defectsStrong controllability of curing degreeLamination ancillary operationsSynthetic resin layered productsFiberWood-plastic composite

The invention discloses a continuous fiber cloth three-dimensional reinforced wood-plastic composite material and a production method and equipment thereof. The reinforced wood-plastic composite material comprises a wood-plastic core layer; a wood-plastic surface layer is arranged outside the wood-plastic core layer, and thermosetting resin impregnated fiber cloth is arranged on at least one sidebetween the wood-plastic core layer and the wood-plastic surface layer. Experimental data show that the transverse / longitudinal bending property, the transverse / longitudinal tensile property, the transverse / longitudinal impact property, the transverse / longitudinal creep property, the compression property in the thickness direction, the dimensional stability of boiling at 100 DEG C and the surfacehardness of the reinforced wood-plastic composite material in some embodiments of the invention are remarkably improved.

Owner:SOUTH CHINA AGRI UNIV

Galvanizing carbon fiber foamed light metal and preparation method thereof

The invention provides a galvanizing carbon fiber foamed light metal and a preparation method thereof, and relates to foamed light metal technical field. The foamed light metal is composed by galvanizing carbon fiber and light metal. The preparation method comprises the following steps: (1) electroplating carbon fiber in a solution formed by zinc chloride, ammonium chloride, boric acid and dextrin; (2) adding a certain amount of galvanizing short fiber and carboxy methyl amylum ester into saturated salt water and followed by stirring uniformly, and adding a certain amount of salt particle to mix the mixture uniformly and followed by compaction; (3) heating the above mixture and followed by a heat preservation treatment to form a preform; (4) putting the preform into a mould, and filling salt particle to the full around the preform for compaction; (5) heating the preform to a temperature of 300-350 DEG C and followed by a heat preservation treatment, and pouring an overheated light metal solution into the mould to fill gap of the salt particle; (6) washing the salt particle away with water after cooling and solidification to obtain the galvanizing carbon fiber foamed light metal. The galvanizing carbon fiber foamed light metal has the advantages of high strength, high modulus and the like, and has wide and practical application.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

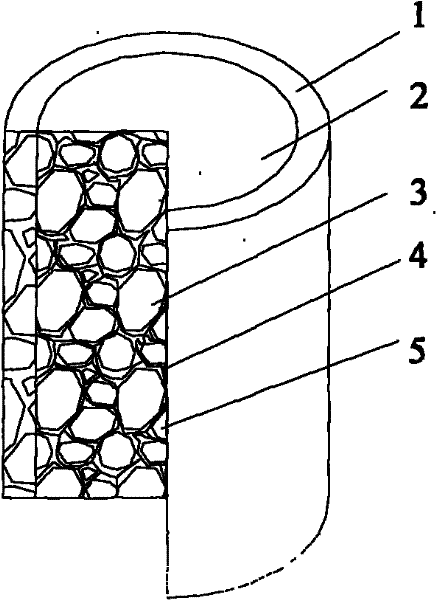

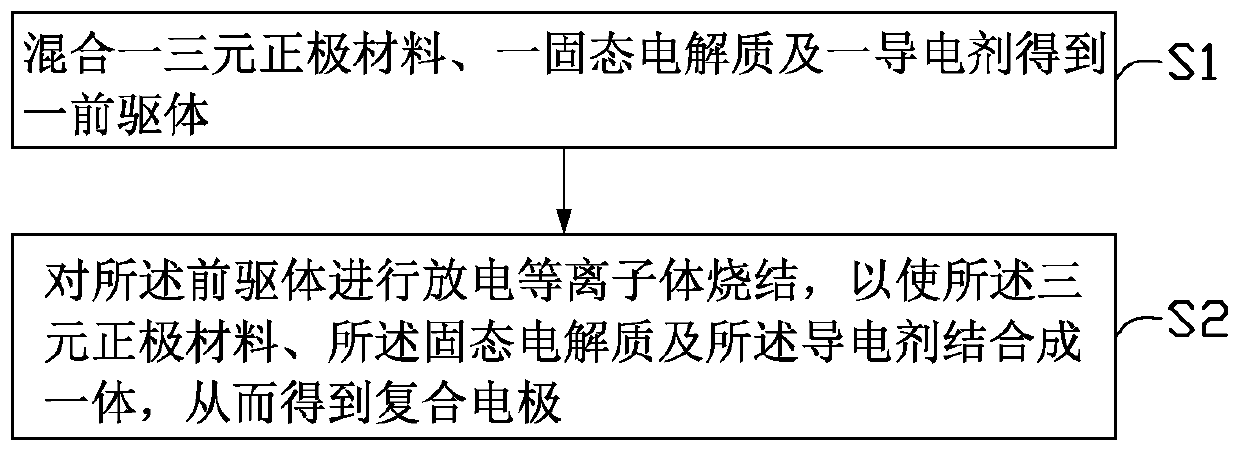

Preparation method of composite electrode, composite electrode and lithium ion battery

InactiveCN110224120AShort preparation timeFix interface issuesCell electrodesSecondary cellsPressureless sinteringLithium electrode

The invention provides a preparation method of a composite electrode. The preparation method comprises the following steps: mixing a ternary positive electrode material, a solid electrolyte and a conductive agent to obtain a precursor; carrying out discharge plasma sintering on the precursor, so that the ternary positive electrode material, the solid electrolyte and the conductive agent are combined into a whole to obtain a composite electrode. The invention further provides the composite electrode and a lithium ion battery. According to the preparation method of the composite electrode provided by the invention, through discharge plasma sintering treatment, the ternary positive electrode material, the solid electrolyte and the conductive agent are tightly combined together in the case that own structures of the ternary positive electrode material, the solid electrolyte and the conductive agent are not damaged, and meanwhile, the interface problem between the electrode and the solid electrolyte in the lithium ion battery is solved; meanwhile, compared with the traditional hot pressing method and a pressureless sintering method, in the preparation method disclosed by the invention,sintering and hot pressing are carried out simultaneously, thereby greatly shortening the preparation time.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

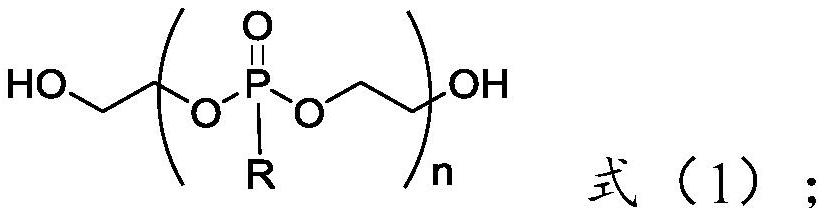

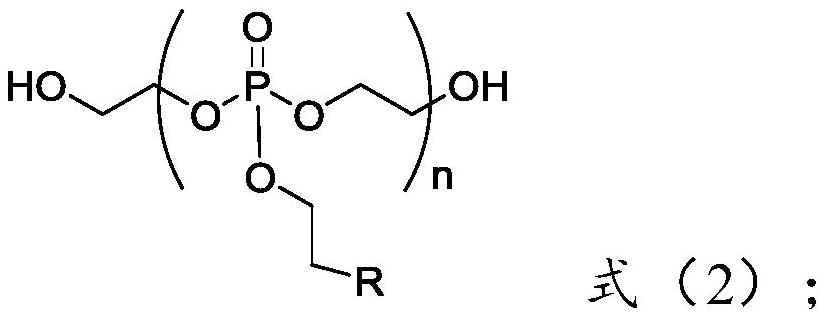

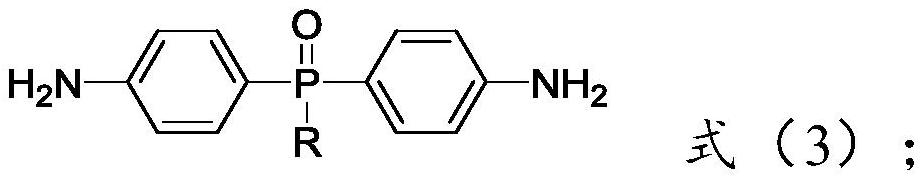

High-flame-retardant waterborne polyurethane and preparation method thereof

The invention provides waterborne polyurethane and a preparation method thereof. The preparation method comprises the following steps: letting phosphorus-free polyol react with specific phosphorus-containing polyol as shown in a formula (1), a phosphorus-containing stabilizer as shown in a formula (2) and polyisocyanate to form a prepolymer, emulsifying, and reacting with a phosphorus-containing chain extender to form the waterborne polyurethane. Phosphorus-containing groups are introduced into a soft segment of a polyurethane molecular chain by adopting phosphorus-containing polyol shown as the formula (1) to form a part of a waterborne polyurethane structure unit, so that the waterborne polyurethane structure unit has flame retardance under the condition that a flame retardant is not added; by adopting the phosphorus-containing stabilizer as shown in the formula (2), emulsification of phosphorus-containing waterborne polyurethane can be promoted, and the problem that emulsion is unstable after chain extension is solved, so that the problems that when a phosphorus-containing group is introduced into a polyurethane molecular structure, emulsification is difficult, and a waterbornedispersion liquid is difficult to form are solved. Moreover, phosphine-containing groups are introduced into the soft segment, the stabilizer and the chain extender of the waterborne polyurethane, sothat the flame retardance is greatly improved; and meanwhile, the binding power of the waterborne polyurethane is also enhanced by introducing a specific phosphorus-containing structure.

Owner:SHANGHAI DIMU NEW MATERIAL TECH

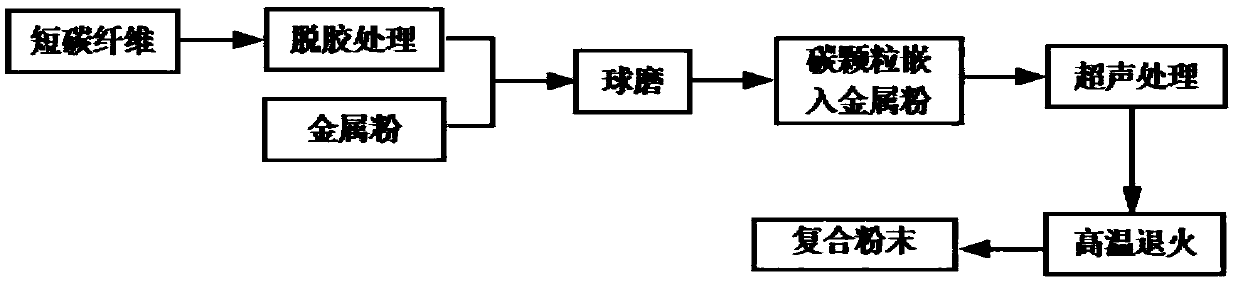

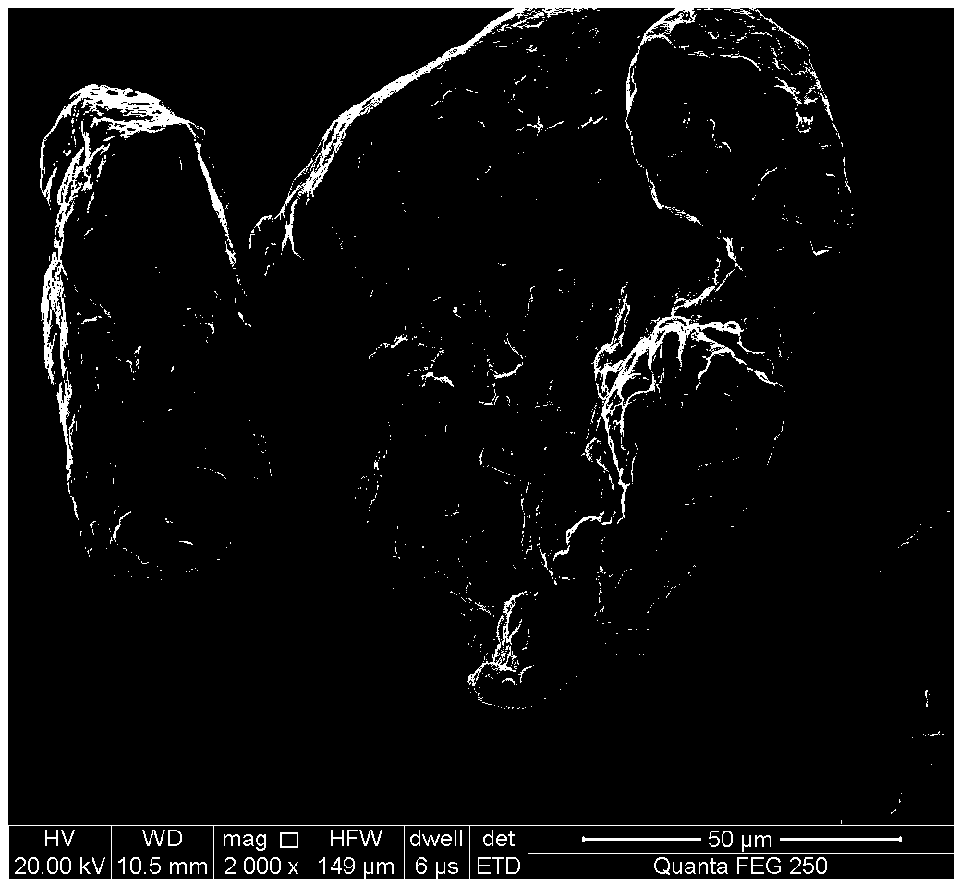

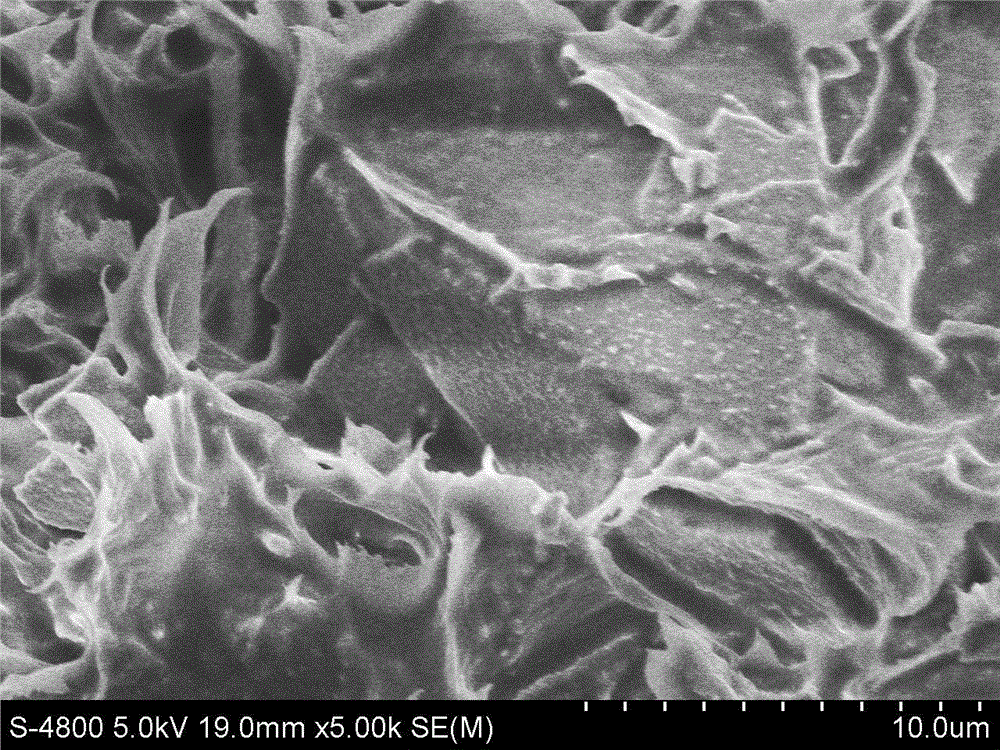

Composite powder of metal-metal carbide coated carbon particle and preparation method thereof

ActiveCN109570493AImprove heat resistanceEvenly embeddedPhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to composite powder of a metal-metal carbide coated carbon particle and a preparation method thereof, and belongs to the technical field of metal powder. The metal-metal carbidecoated carbon particle is composed of a metal layer, a metal carbide layer and a carbon particle, wherein the metal carbide layer is coated on the surface of the carbon particle, and the metal layer is coated on the surface of the metal carbide layer; according to the composite powder, superfine carbon particles and matrix metal powder are used as raw materials, and mechanical force is applied, sothat the superfine carbon particles penetrate through and / or are inlaid into the matrix metal powder, and then in-situ carburization is performed so as to obtain the metal carbide layer. The preparation method comprises the steps of performing mechanical milling on degummed short carbon fiber and the metal powder first so as to obtain a large quantity of superfine carbon particles which are uniformly inlaid into the metal powder, then separating and annealing at high temperature, so that solid-phase reaction occurs between the carbon particles and surrounding metal, and the metal-carbon particle composite powder of which metal carbide is uniformly coated on the surfaces of the carbon particles is obtained.

Owner:CENT SOUTH UNIV

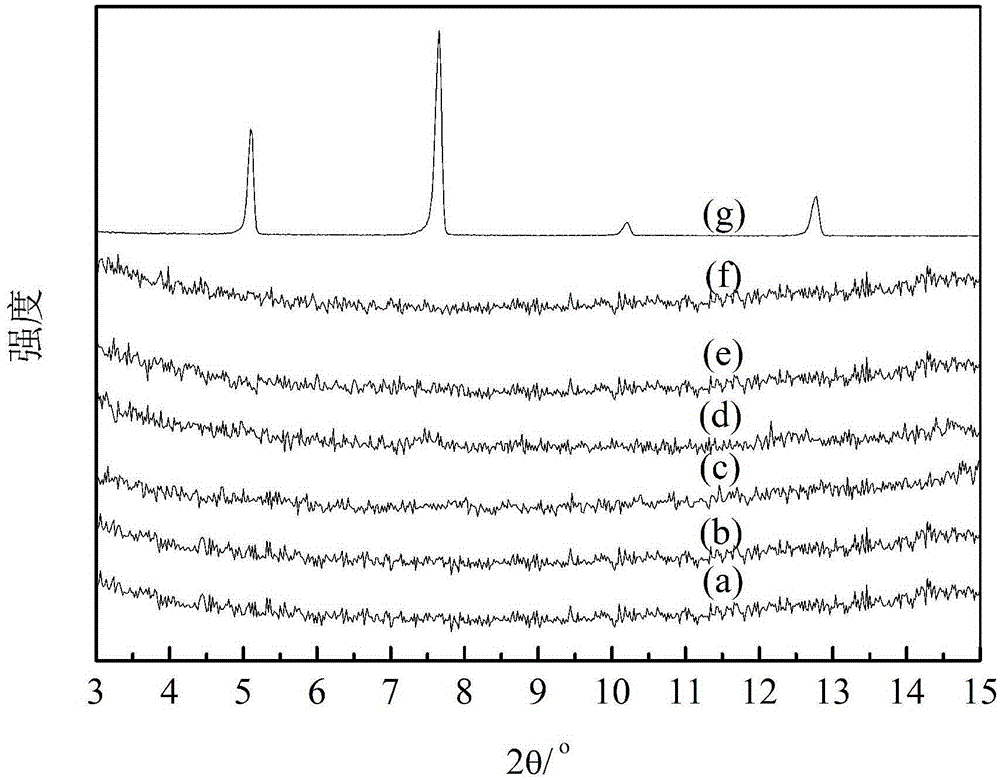

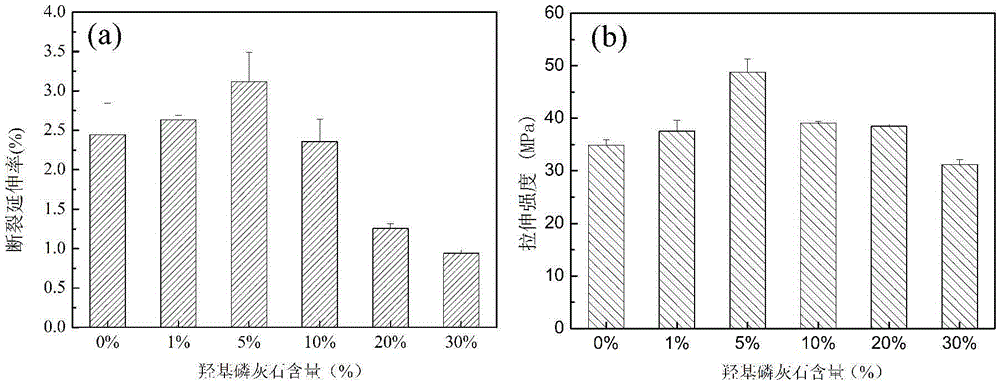

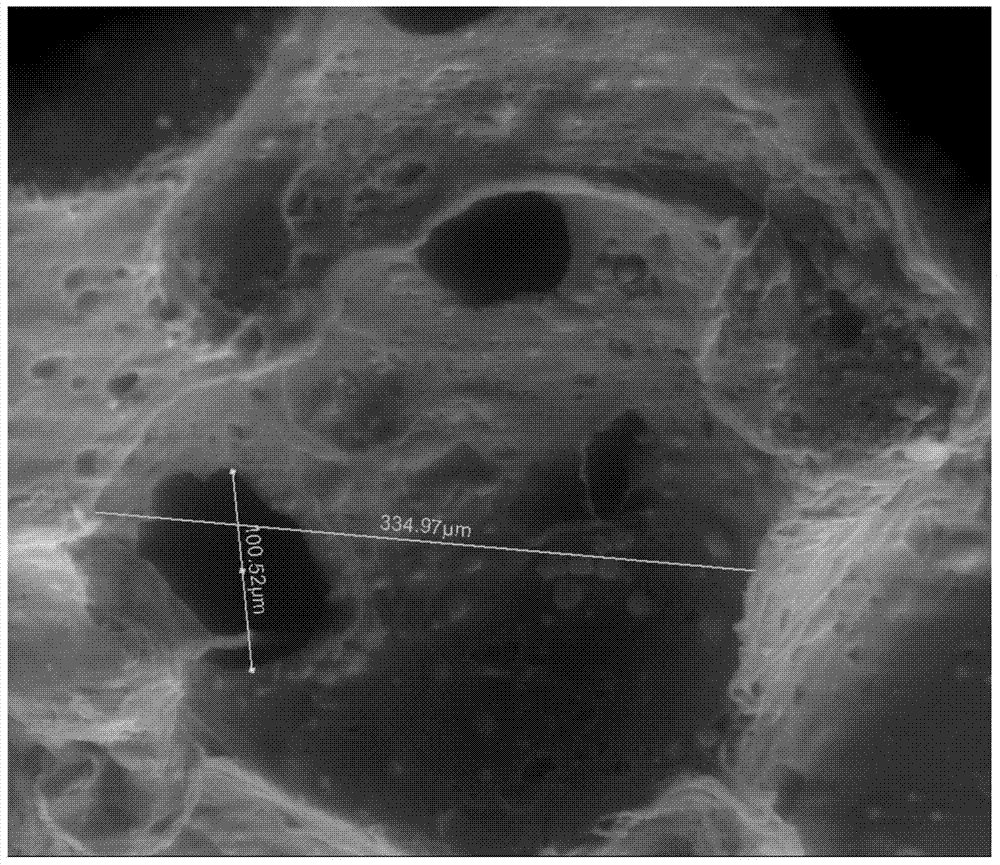

Sheet hydroxyapatite/polylactic acid nanometer composite prepared through in-situ intercalation method

InactiveCN105295012AAchieve strengthAchieve resilienceMaterial nanotechnologyPhosphorus compoundsNano compositesApatite

The invention provides a new method for preparing a sheet nanometer hydroxyapatite / polylactic acid composite through an in-situ compound intercalation method for solving the problems that a traditional blending method is complex in preparation step, poor in nanoparticle dispersion, contradictory in strength and toughness and the like. The method includes the steps of preparing long-range orderly nanometer sheet hydroxyapatite with lauric acid as template agent, conducting ring opening polymerization on lactide molecules between layers of hydroxyapatite to form polylactic acid through the in-situ polymerization intercalation method with lactide monomers as the raw material, and forming the organic and inorganic nanometer composite of a nacre-like structure. Breakthrough is achieved on the aspects of strength and toughness of the composite at the same time, the tensile strength of the composite with addition amount of 5% is increased by 40% compared with that of pure polylactic acid, and the elongation at break is increased by 30%. The preparation process is simple, surface treatment does not need to be conducted on hydroxyapatite, no substances with biological toxicity are introduced in the whole process, and biological compatibility is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Organic amine surface-modified metal sulfide material, manufacture method and applications thereof

InactiveCN104212202AImprove performanceFix interface issuesPhysical/chemical process catalystsLuminescent compositionsChemical synthesisChemical reaction

The invention provides an organic amine surface-modified metal sulfide material, which is composed of a metal sulfide material and an organic amine shell, wherein the organic amine shell is covered on the metal sulfide material. The metal sulfide material and the organic amine shell are bound together through strong chemical bonds, so the chemical and physical properties of the provided material are very stable. Because the metal sulfide material and the organic amine shell are strongly bound together, the shell will not fall off the metal sulfide material even under various chemical reactions or after a plurality of circulation usages. The invention also provides a method for carrying out organic amine surface modification on the metal sulfide material. The modification method comprises the following steps: mixing the metal sulfide material and an organic compound / polymer containing an amino functional group in an organic phase, and then heating the system to carry out chemical synthesis. The invention further provides the applications of the provided metal sulfide material, which is mainly used as a semiconductor luminescent material, a photo-electric and electro-optical conversion material, a photoelectric catalysis material, a photo-thermal material, a bio-labeling material, a coloring material, and the like.

Owner:BEIJING GIGNANO BIOINTERFACE

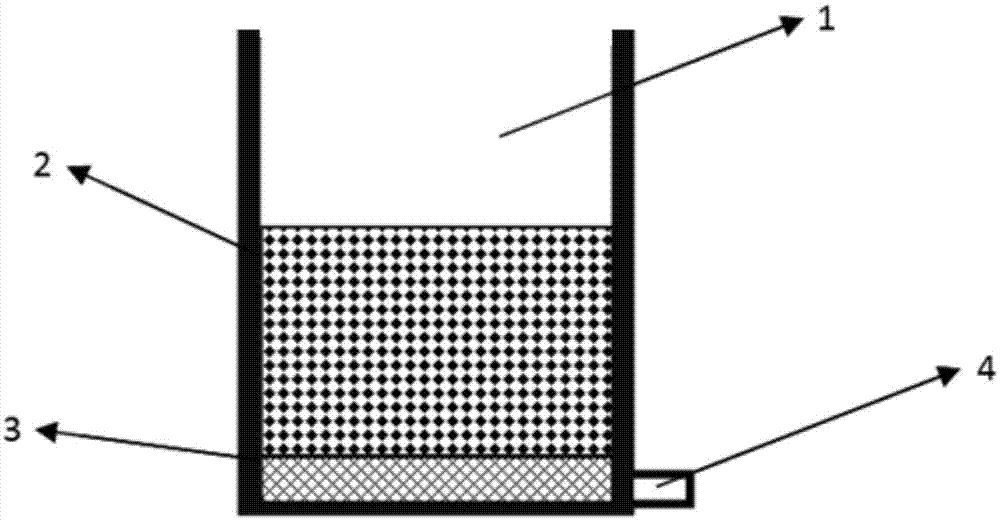

Modified polyvinyl alcohol hydrogel material, special die, preparation method and application

InactiveCN104708736AImprove biological activityImprove mechanical propertiesProsthesisStress concentrationEngineering plastic

The invention discloses a modified polyvinyl alcohol hydrogel material, a special die, a preparation method and application. The preparation method comprises the following steps: (1) preparing polyvinyl alcohol / bioactive calcium-phosphorus powder blended suspension I and polyvinyl alcohol / engineering plastic blended suspension II; (2) injecting the suspension I into the special die, vacuumizing at the gas outlet of the die until a pore-forming agent is right impregnated by the suspension I, adding the suspension II, and pressurizing the die to obtain a target material precursor I; (3) performing freezing treatment on the precursor I, performing unfreezing treatment at room temperature, and radiating with gamma rays to further form a target material precursor II; (4) dialyzing and washing the precursor II in de-ionized water for multiple times to obtain the target material. The obtained material has high biocompatibility and bioactivity, and can be applied to cartilage repair and replacement, the problem that an interface exists between a compacted layer and a porous layer is solved, and the problems of stress concentration and the like in a using process are solved.

Owner:SOUTH CHINA UNIV OF TECH

User click data-based webpage analysis method

ActiveCN101777080BFix interface issuesSpecial data processing applicationsAnalysis dataData harvesting

The invention discloses a user click data-based webpage analysis method, which comprises the following steps: establishing a coordinate system on a webpage; collecting coordinates of user click data through Javascript technology; creating an ID for the content of the current webpage; when the content is changed, dynamically updating the current ID, and combining a coordinate of the click data with a corresponding ID number to form click data so as to adapt to a format of a background OLAP analysis structure, and sending the click data to a data collection server; storing the click data in a database, and further integrating the click data with associated data collected by the system; and finally forming a thermodynamic chart on the webpage through the rich media technology and displaying the thermodynamic chart to the user. The invention provides a feasible analysis method for dynamically changed webpages, has higher information feedback capacity, can provide more detailed analysis data for online analysts aiming at the webpages with different content, and provides further reference support for the optimization of the wepages.

Owner:BEIJING GRIDSUM TECH CO LTD

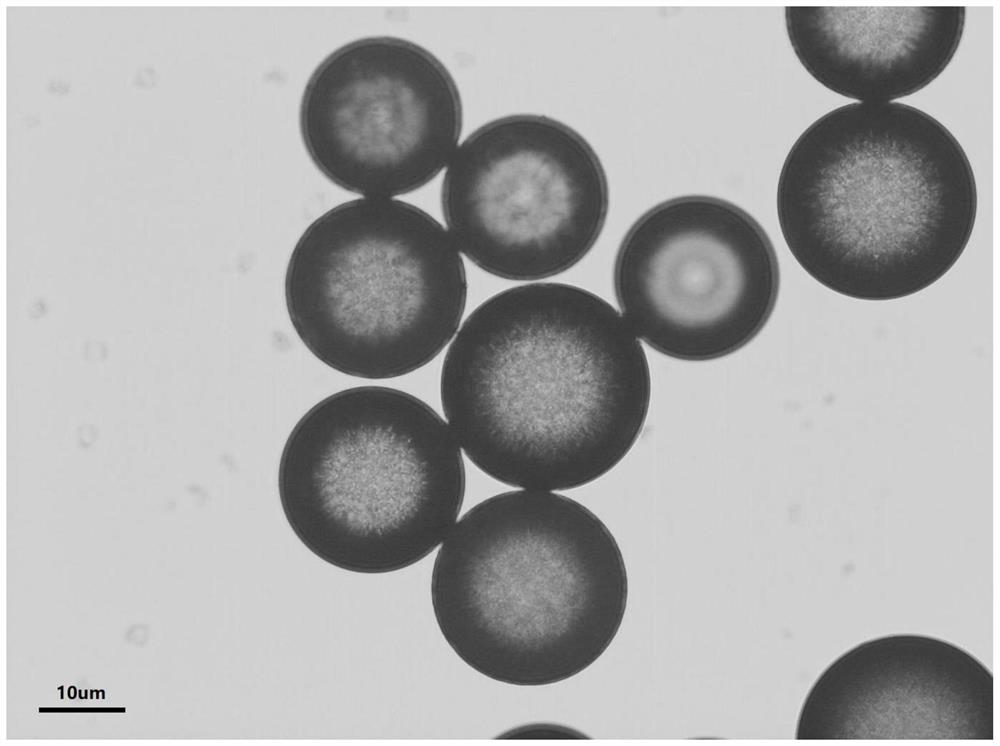

Microcapsule fire extinguishing agent and preparation method thereof

ActiveCN112657114AGood flame retardant performanceExcellent external temperature thermal response functionMicroballoon preparationFire extinguisherIn situ polymerizationPolymer chemistry

The invention provides a microcapsule fire extinguishing agent and a preparation method thereof. The microcapsule fire extinguishing agent comprises a flame-retardant shell composed of a low-melting-point copolymer and a cooling inner core containing a cooling material, wherein the flame-retardant shell coats the cooling inner core to form microcapsule particles with a core-shell structure, the low-melting-point copolymer is formed by copolymerizing a low-melting-point high-molecular polymer monomer and a flame retardant, the flame-retardant shell melts and explodes automatically when the external environment reaches the preset starting temperature, and the cooling inner core in the flame-retardant shell is released. The microcapsule fire extinguishing agent provided by the invention adopts an in-situ polymerization preparation method, and the microcapsule fire extinguishing agent with different starting temperatures is prepared by regulating and controlling the reaction parameters such as the variety of low-melting-point high-molecular polymer monomers, the mass ratio of the low-melting-point high-molecular polymer monomers to the cooling material, the copolymerization reaction time and pressure and the like, so that the microcapsule fire extinguishing agent is suitable for different scene requirements. The microcapsule fire extinguishing agent provided by the invention has targeting property, also has dual effects of cooling and fire extinguishing, and has huge application value.

Owner:HUAZHONG UNIV OF SCI & TECH

Lost foam casting method of three-dimensional network ceramic-iron-based composite material

ActiveCN107398544AContinuation of electrical and thermal conductivityStable friction performanceFoundry mouldsFoundry coresIntermediate frequencyChemical plating

The invention discloses a lost foam casting method of a three-dimensional network ceramic-iron-based composite material. The method comprises the steps of performing surface treatment and chemical plating on three-dimensional network ceramic, manufacturing a model cluster, brushing fire-resistant coating on the model cluster and drying the model cluster, performing modeling, burying sand, performing vibrating, smelting a metal matrix, sucking a sand box to gain negative pressure, performing spheroidization and inoculation on an iron matrix, performing casting, opening the sand box and cleaning sand. The main components of foam ceramic are SiC and Al2O3. Smelting of the metal is carried out in an intermediate frequency furnace. According to the lost foam casting method of the three-dimensional network ceramic-iron-based composite material, compared with an existing preparation method, the method is simpler in operation, short in production technology and lower in technology cost; and the method is suitable for preparation of castings with various sizes, and castings of different ceramic reinforcing parts, with different ceramic contents and different shape requirements can be prepared.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com