Fiber mesh tape-wound and reinforced composite pipe, preparation process and device

A fiber mesh, reinforced composite technology, applied in mechanical equipment, pipes, rigid pipes, etc., can solve the problems of unstable performance in long-term use, poor interface bonding of filament winding reinforced composite pipes, etc., to reduce the number of production workers, The effect of improving mechanical properties and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

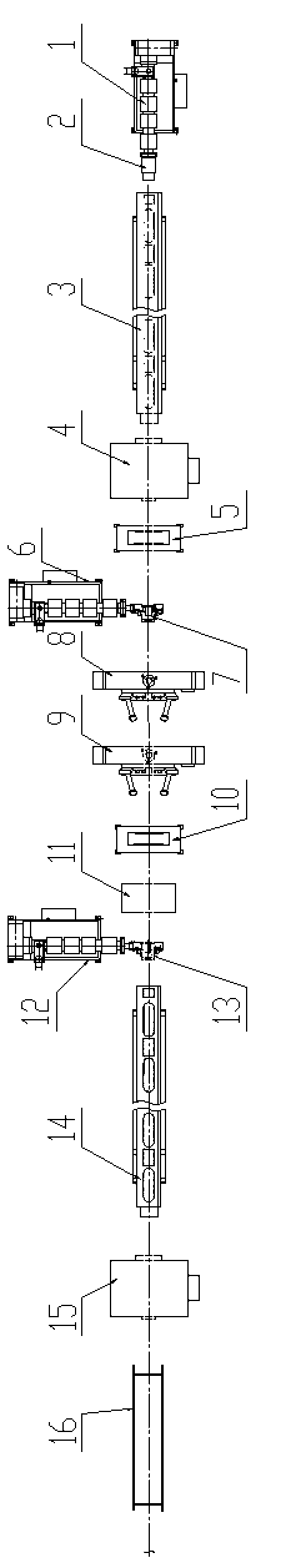

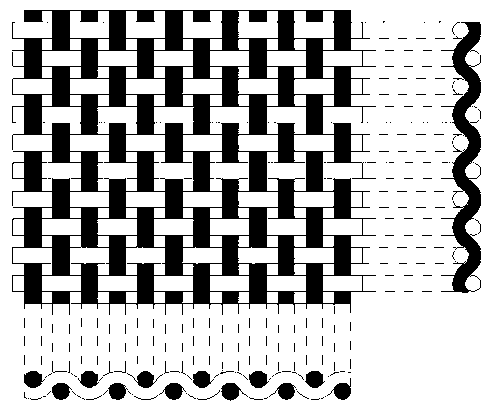

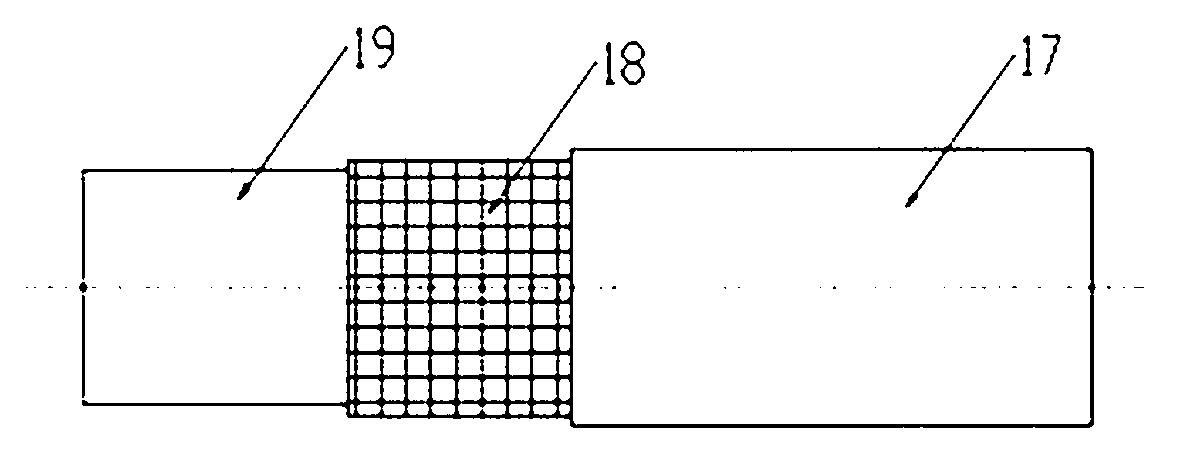

[0030] Example 1: Aramid fiber mesh belt winding reinforced polyethylene composite pipe

[0031] 95 parts of polyethylene (PE80) and 5 parts of black polyethylene masterbatch are mixed and dried, then added to a single-screw extruder, heated, sheared and plasticized, and then extruded. The extrusion temperature is 180-200°C. The extruded resin is pulled into the pre-vacuum spray sizing box to form a core pipe with the help of the traction tube, and the temperature of the circulating spray cooling water is 14-18°C. The core pipe passes through the front heating box, and the heating temperature is 220-240°C to melt the surface of the pipe, and then it passes through the bonding resin to coat the die head, and the bonding resin extrusion temperature is 200-220°C. The first and second winding machines wind the glued pipe successively, the speed range of the winding machines is 2-40rpm, and the winding tension is 150-600N. The wound pipe passes through the post-heating box, the he...

Embodiment 2

[0032] Example 2: Fiberglass grid tape winding reinforced polypropylene composite pipe

[0033]Mix and dry 96 parts of random copolymerized polypropylene (PP-R) and 4 parts of green masterbatch, add them to a single-screw extruder, heat, shear and plasticize, and then extrude. The extrusion temperature is 210-230°C. The extruded resin is pulled into the pre-vacuum spray sizing box to form a core pipe with the help of the traction tube, and the temperature of the circulating spray cooling water is 14-18°C. The core pipe passes through the front heating box, and the heating temperature is 230-240°C to melt the surface of the pipe, and then it passes through the bonding resin to coat the die head, and the bonding resin extrusion temperature is 200-220°C. The first and second winding machines successively wind the glued pipes, the speed range of the winding machines is 2-40rpm, and the winding tension is 150-400N. The wound pipe passes through the post-heating box, the heating te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com