Full-solid-state lithium battery negative electrode material, preparation method and all-solid-state lithium battery

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems that the modification method cannot be effectively controlled, and the performance of the battery is affected, so as to achieve improved electrochemical performance, excellent matching, and good performance. The effect of conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation step of described titanium dioxide white powder comprises:

[0040] S1: Evenly mix butyl titanate and absolute ethanol at a volume ratio of 1:2-3;

[0041] S2: adding deionized water dropwise to the mixed solution to prepare a gel;

[0042] S3: After aging for a period of time, the gel is dried in an oven, dried and ground to obtain a white titanium dioxide powder.

[0043] Preferably, the volume ratio of the deionized water to the mixed solution is 0.1-0.6:1. If the amount of deionized water added is too small, it cannot ensure that the butyl titanate in the mixed solution cannot be completely hydrolyzed, which will affect the production of TiO 2 quality. If too much deionized water is added, the gel cannot be formed.

[0044] Preferably, the aging time in the step S3 is 20-36h. The aging time determines the progress of the reaction and the particle size of the reaction product. If the time is too short, the reaction cannot be completely carried ou...

Embodiment 1

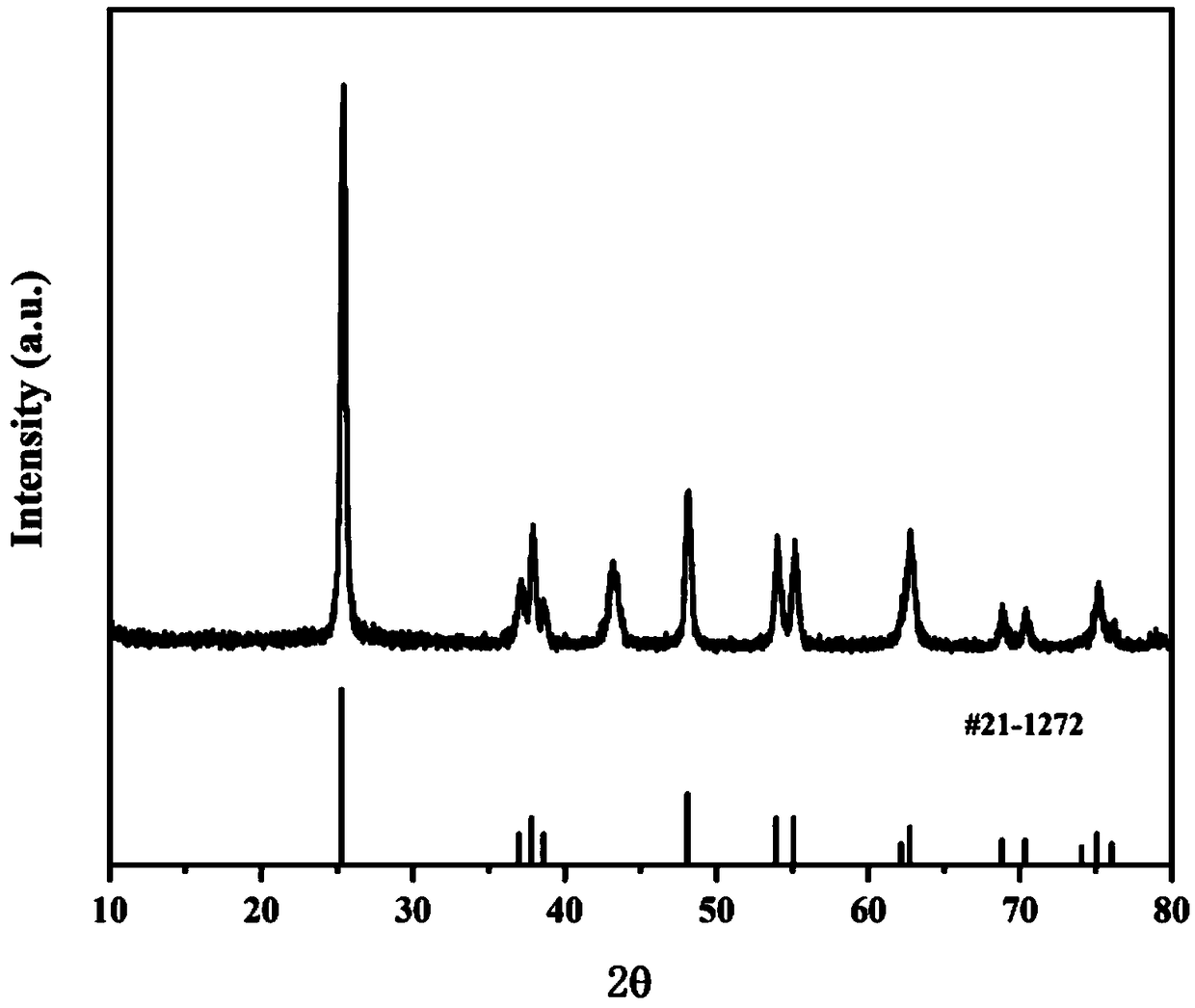

[0051] Choose LiCoO 2 As a positive electrode material coated into a pole piece, garnet-type Li 7 La 3 Zr 2 o 12 Pressed into 13mm sheets as electrolyte. Mix butyl titanate and absolute ethanol uniformly at a ratio of 1:2 to obtain 300ml of a mixed solution, and add 90ml of deionized water dropwise to the mixed solution to prepare a gel. After aging for 30 hours, it was dried and ground at 90°C to obtain a white powder. The resulting white powder contained 2% H 2 Calcined in Ar mixed gas for 20s, the final black product was obtained. figure 1 For the XRD pattern of the prepared product, as shown in the figure, the prepared material is titanium dioxide. figure 2 For the high-resolution TEM image of the prepared product, as shown in the figure, the prepared material has an obvious layered core-shell structure, in which TiO 2 The core size is 300nm, oxygen-deficient TiO 2 The shell thickness is 30 nm.

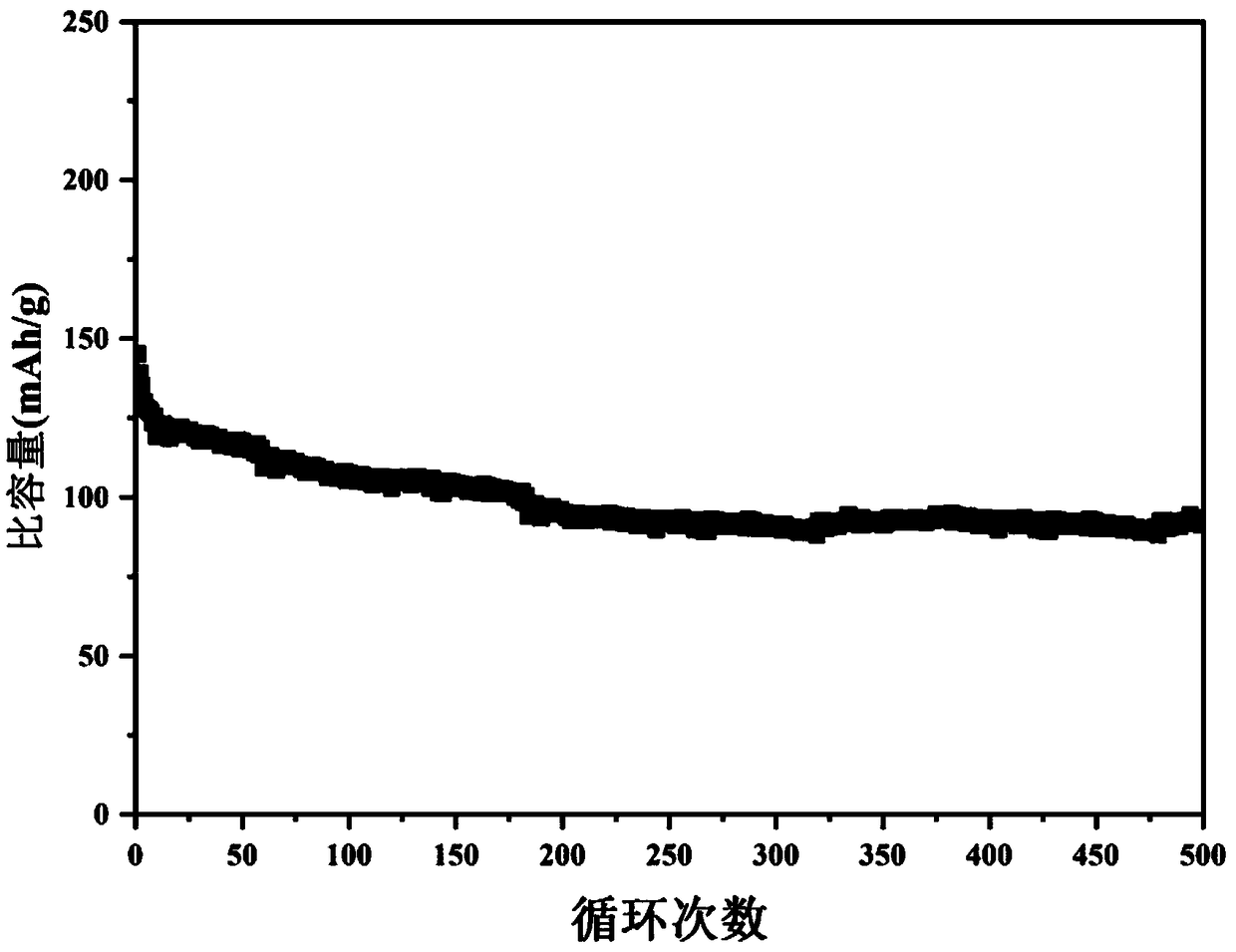

[0052] The material prepared in this example was coated into a pol...

Embodiment 2

[0054] Choose LiFeO 4 As the positive electrode material coated into a pole sheet, Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 Pressed into 13mm sheets as electrolyte. Mix butyl titanate and absolute ethanol uniformly at a ratio of 1:3 to obtain 200ml of a mixed solution, and add 100ml of deionized water dropwise to the mixed solution to prepare a gel. After aging for 24 hours, it was dried and ground at 80°C to obtain a white powder. The resulting white powder contained 3% H 2 Calcined in Ar mixed gas for 10s, the final black product is obtained, in which TiO 2 The core size is 500nm, and oxygen-deficient TiO 2 The shell thickness is 70 nm.

[0055] After the materials prepared in this example were coated into pole pieces, they were assembled into coin cells in the order of positive electrode-electrolyte-negative electrode for testing. When performing constant current charge and discharge at 5C rate of the positive electrode material at 70°C, the specific capacity can still be m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com