Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Evenly embedded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

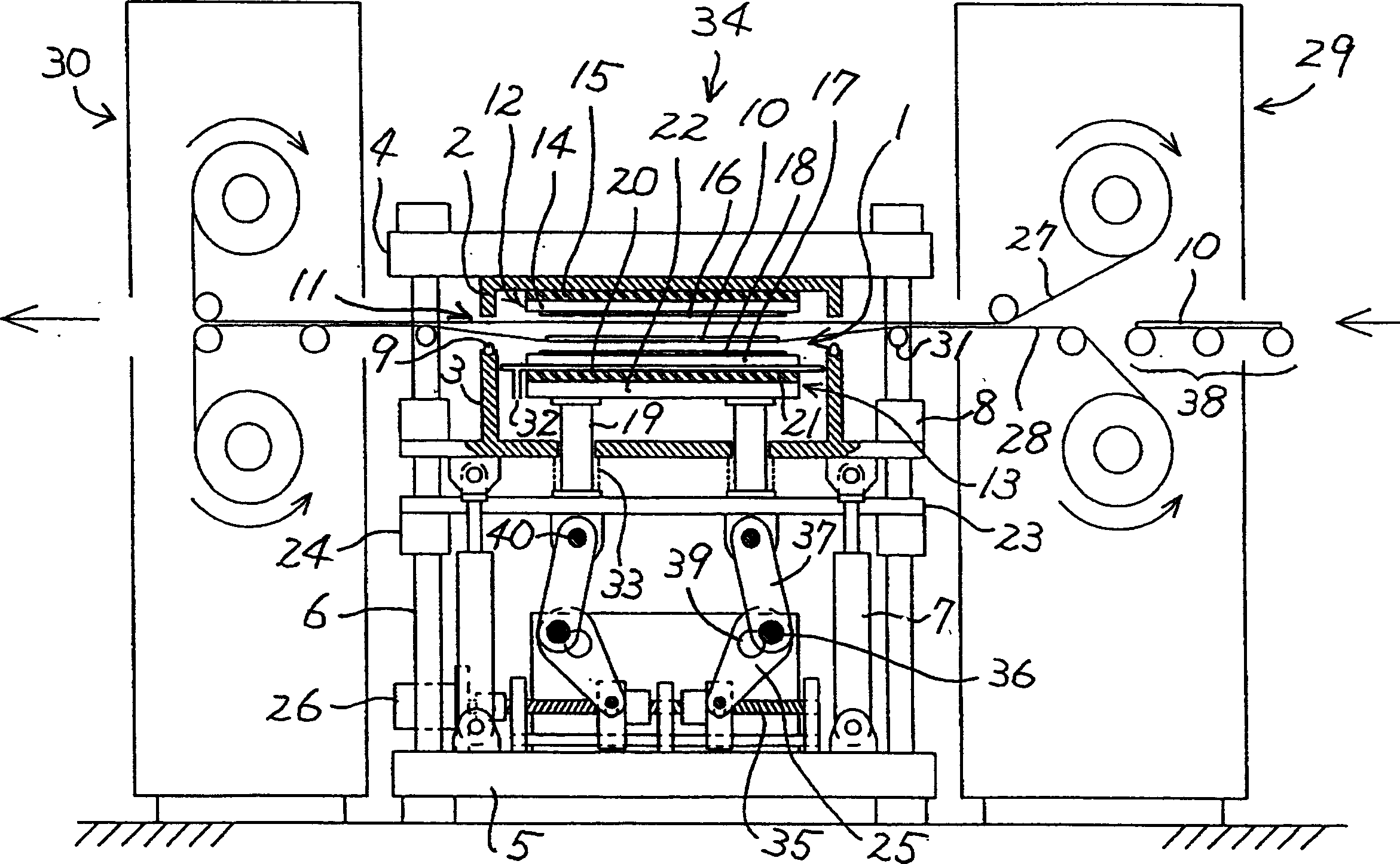

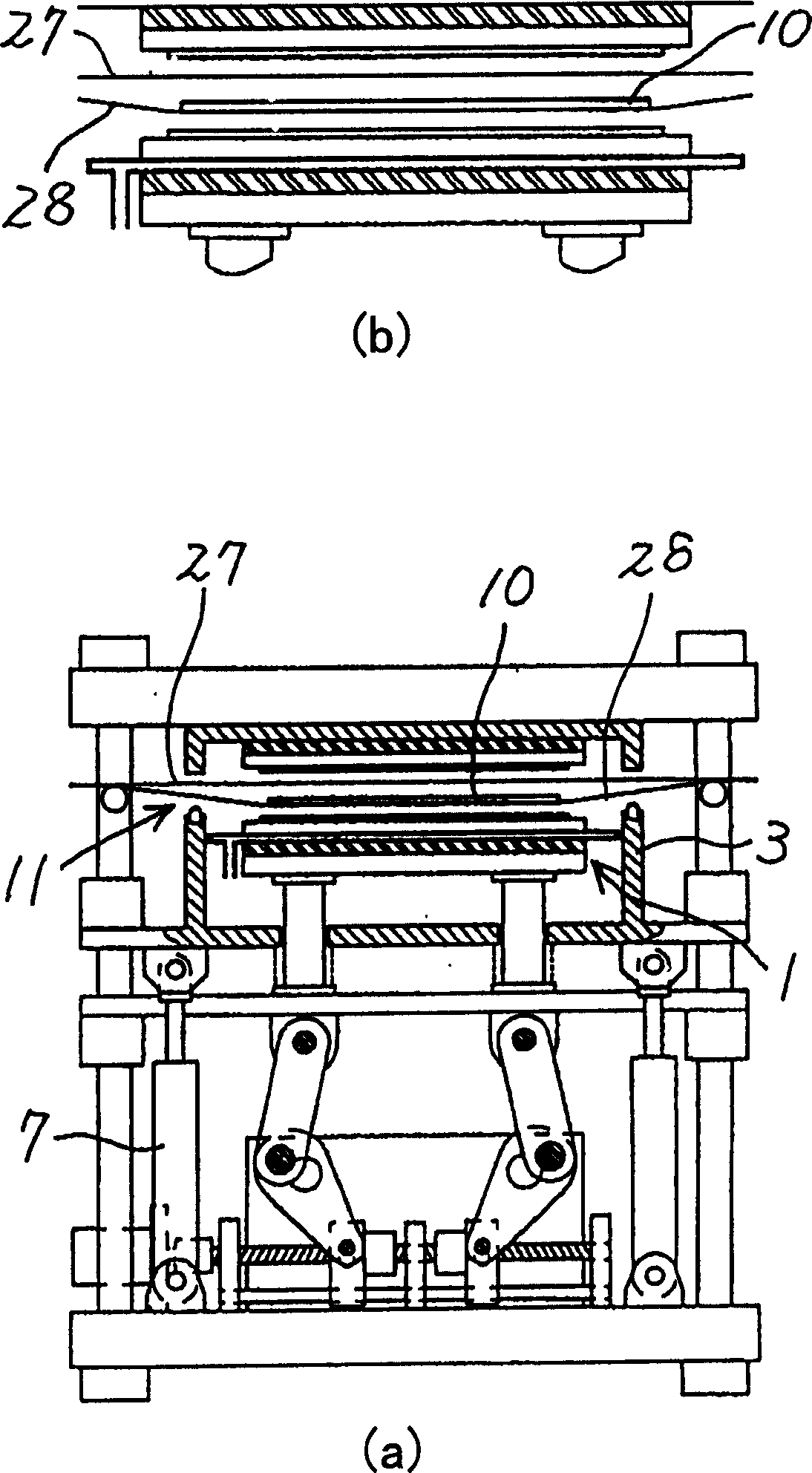

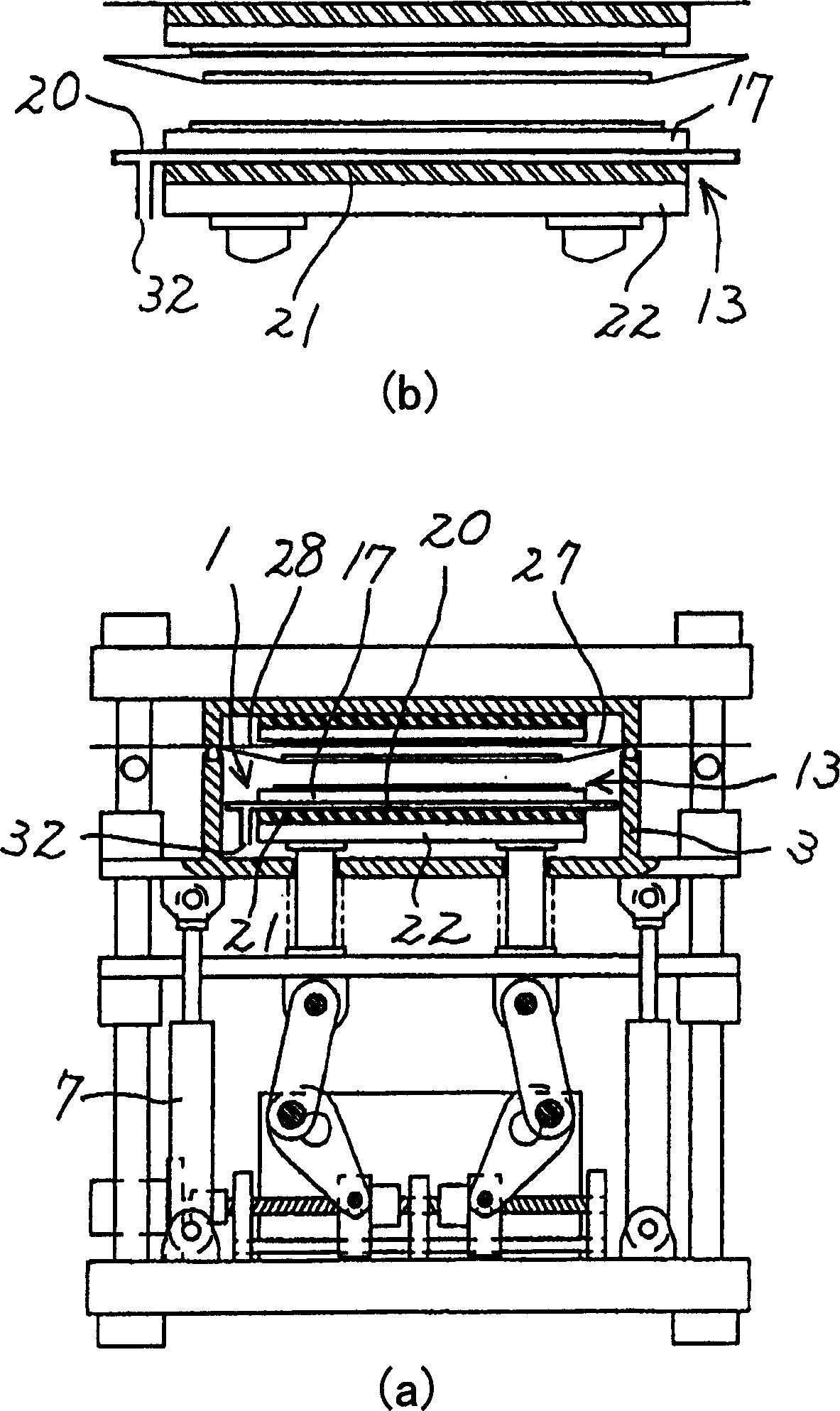

Pressure device and method

InactiveCN1498062AEvenly embeddedLayered productsNon-metallic protective coating applicationEngineeringVacuum chamber

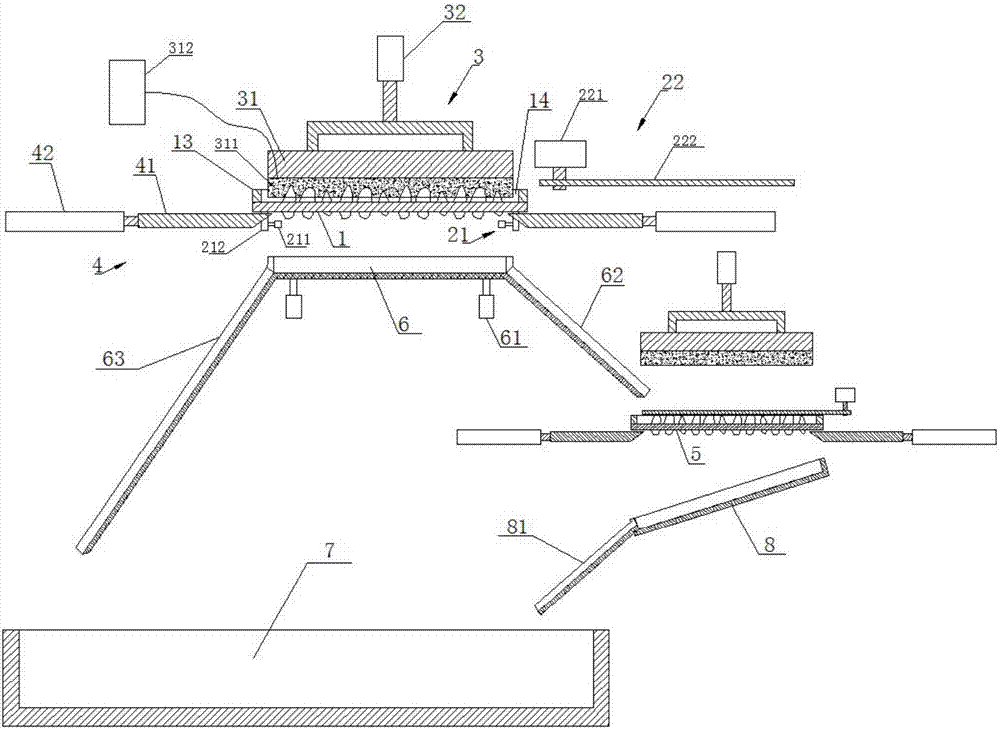

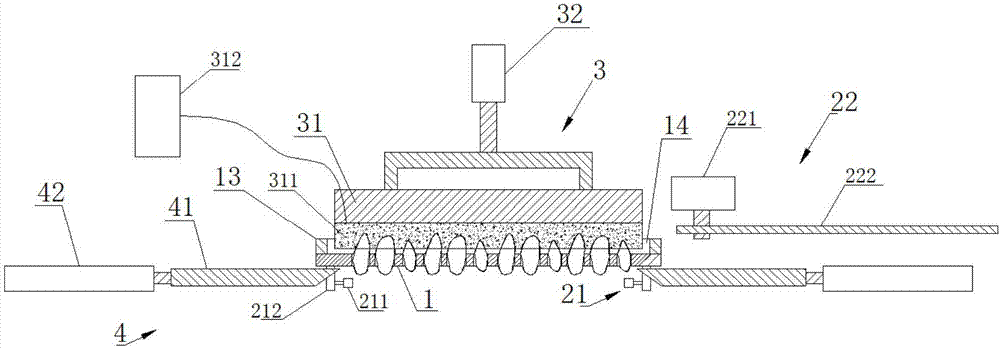

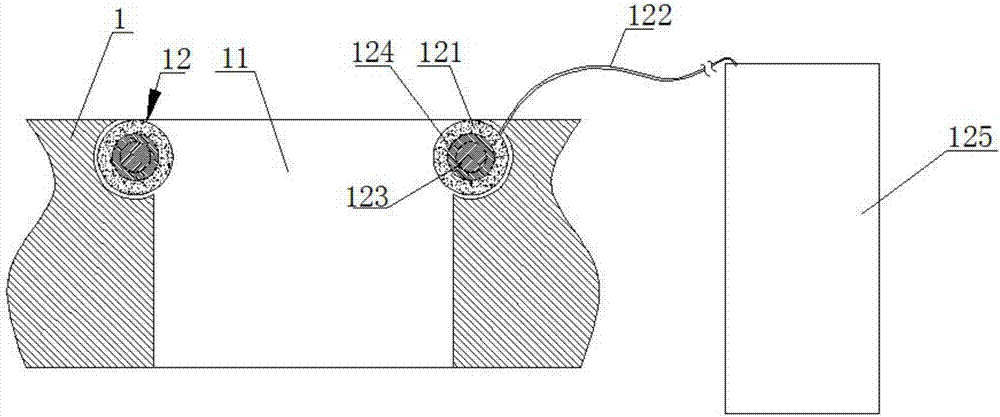

A pressing apparatus for flattening a material of a film state on a substrate and a pressing method thereof are provided to bury easily the material of the film state by using a pressing block and an additional driver. A pressing apparatus includes a vacuum pressing unit, a vacuum chamber, a substrate carrier unit, top and bottom pressing blocks, and a first driver. The vacuum chamber(1) is installed at the vacuum pressing unit and includes top and bottom housing members(2,3) for forming a decompressing state and an opening(11) for substrate exit. The substrate carrier unit carries a substrate(10) from or into the vacuum chamber through the opening and includes a couple of film belts(27,28). The top and the bottom pressing blocks(12,13) are arranged in the inside of the vacuum chamber in order to pinch, heat, and press the substrate. The first driver is used for approaching the top and the bottom pressing blocks to each other or separating the top pressing block from the bottom pressing block. The first driver includes a predetermined instrument for forming a reinforced structure to support the repulsive force against the pressure applied to the substrate.

Owner:SANEI GIKEN

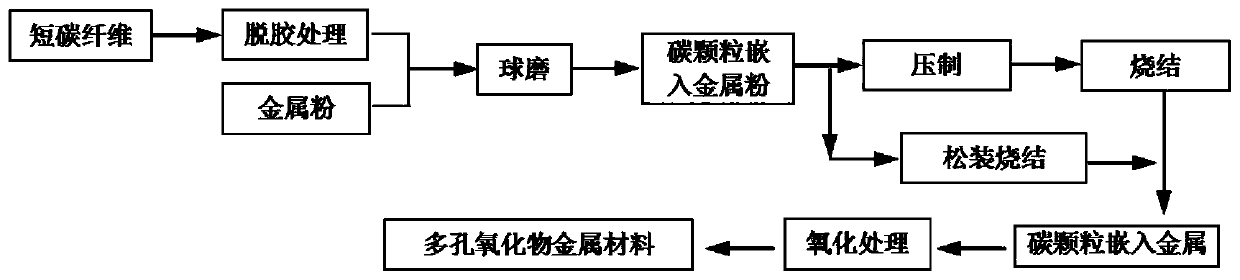

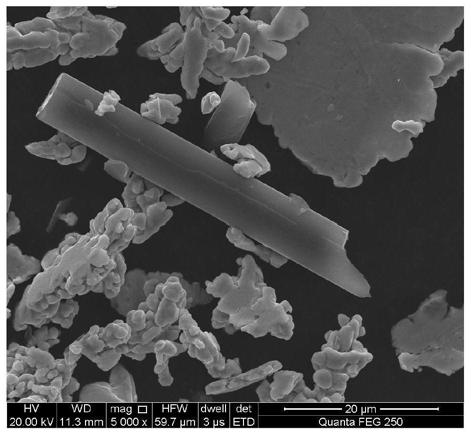

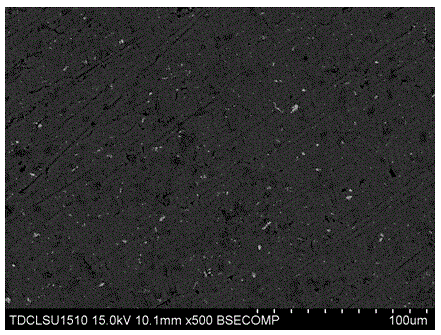

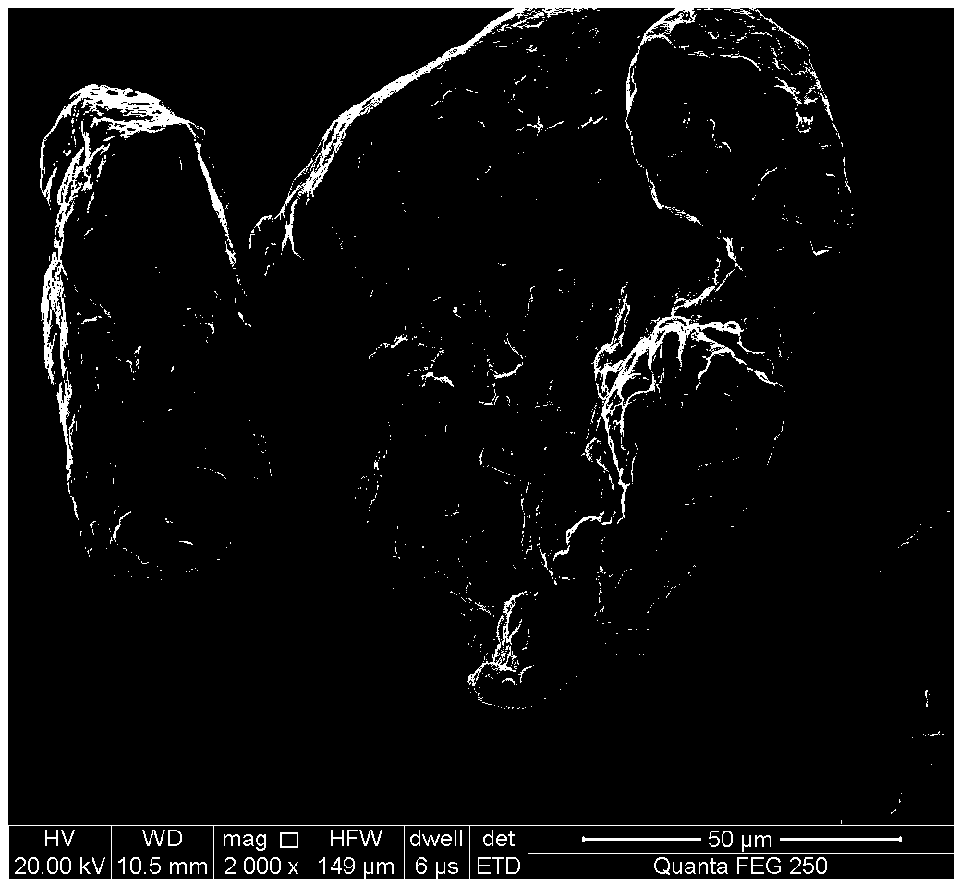

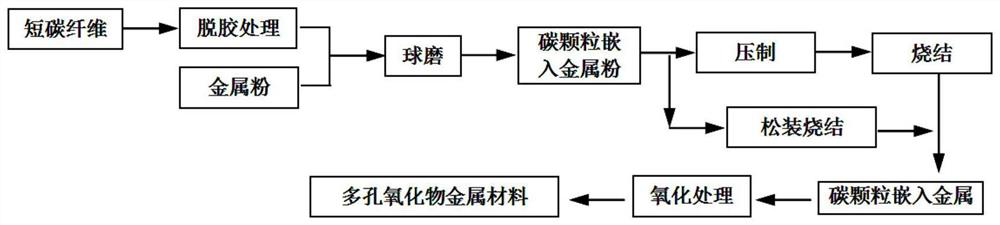

Preparation method of porous metal oxide

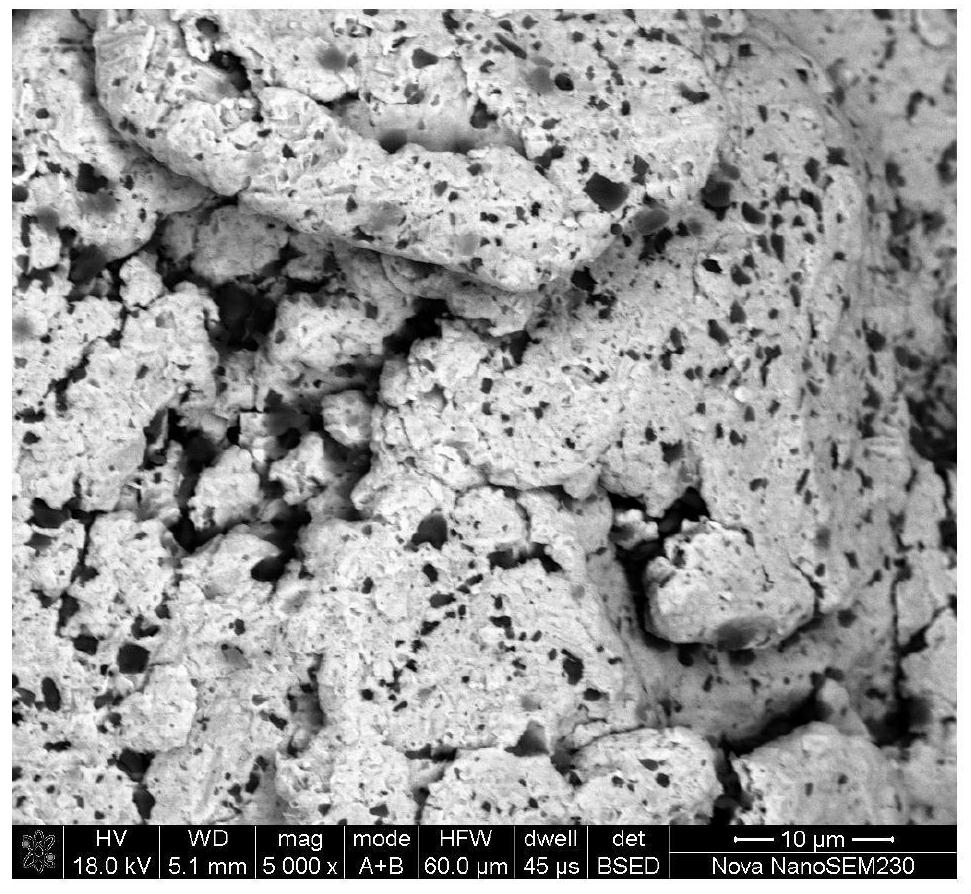

The invention relates to a preparation method of a porous metal oxide, and belongs to the crossing field of metal powder technology and metal material surface treatment. The preparation method comprises the following steps: firstly degumming short carbon fibers, then performing a suitable ball milling process on the degummed short carbon fibers and a metal powder to obtain a metal powder embeddedwith ultrafine carbon particles, performing sintering after press-forming in a protective atmosphere or vacuum, or directly performing loose sintering, finally performing short-time annealing treatment in oxygen-containing air to remove the carbon particles in the metal powder and partially oxidize the surface of metal particles to obtain the porous metal whose surface is partially oxidized. The porous metal oxide prepared by the method exhibits good oil storage, hydrogen storage, paraffin wax storage, lithium storage performances, and catalytic performance, and the porous metal oxide has simple preparation process and low cost.

Owner:CENT SOUTH UNIV

Preparation method of hollow graphite material and hollow graphite material prepared by same

The invention relates to a preparation method of a hollow graphite material and a hollow graphite material prepared by the same. The preparation method comprises the following steps: adding the grinding balls, a ball milling medium and graphite powder into a ball milling tank at a mass ratio of (2-30):(1-10):1; performing ball milling for 5-60 hours on ball milling equipment at a speed of 100-800r / min; and removing the ball milling medium and drying. The hollow graphite material prepared by the method has the characteristics of high specific surface area, high porosity and lamellar form and can increase the embedded quantity of the embedded atoms and guarantee the embedding uniformity; by adopting the mechanically modified ball milling technology, the method is simple to operate and facilitates large-scale production.

Owner:BTR NEW MATERIAL GRP CO LTD +1

Method for synthesizing Al-Cu alloy in situ by powder metallurgy

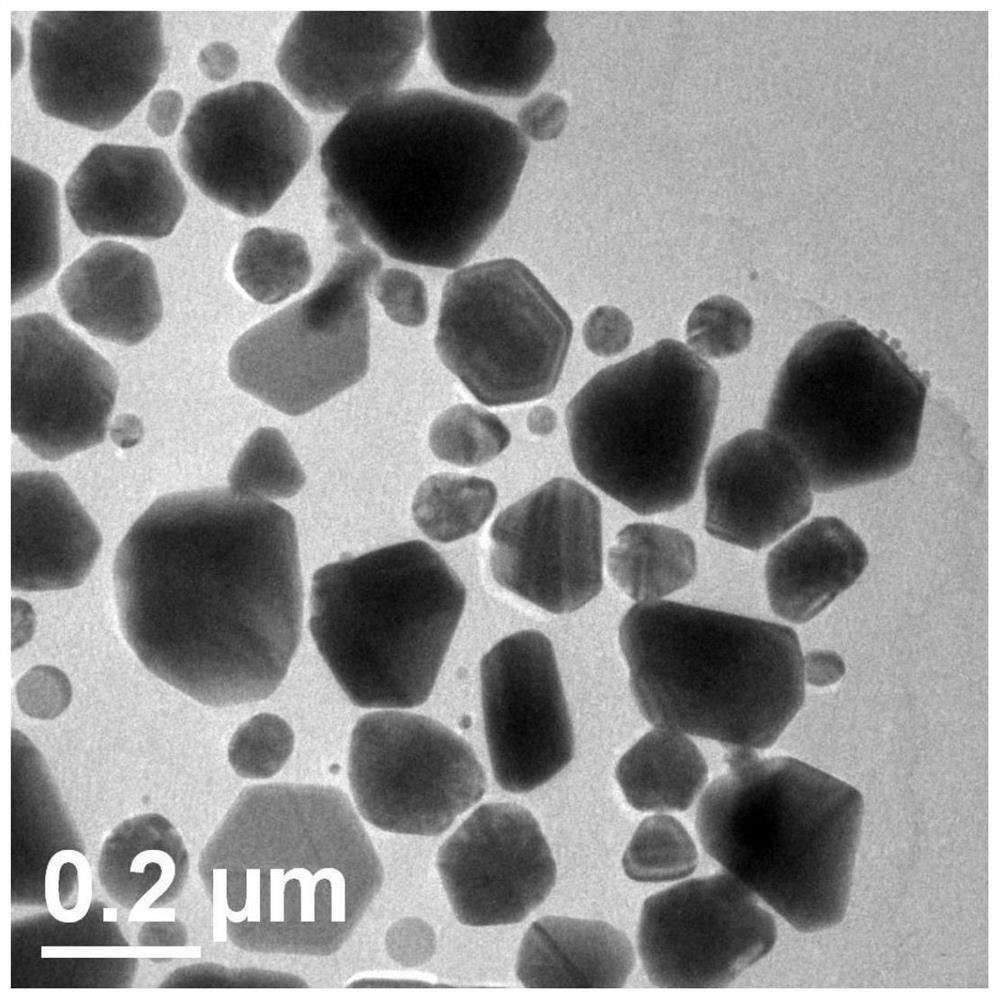

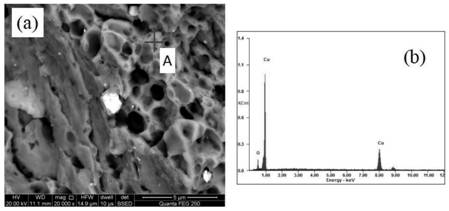

The invention discloses a method for synthesizing Al-Cu alloy in situ by powder metallurgy. The method comprises the following steps: firstly, obtaining a microscopic structure that copper nanoparticles are uniformly deposited on aluminum powder by an impregnation method, performing ball-milling for a relatively short time, uniformly dispersing copper and embedding dispersed copper into the aluminum powder; secondly, densifying the powder by a cold-pressing sintering or vacuum hot-pressing method to obtain a block material; finally, performing hot extrusion forming to obtain the Al-Cu alloy material. The method has the advantages that the Al-Cu alloy material is prepared by the method, and the mechanical property of the alloy material is superior to that of other powder metallurgy aluminum alloy material. Meanwhile, the method also can be popularized and applied to other metal powder so as to prepare different matrix alloy materials. Therefore, the method has a wide industrial application prospect.

Owner:TIANJIN UNIV

Preparation method of layered nickel cobalt lithium manganate cathode material

InactiveCN105789614AEvenly embeddedImprove electrochemical performanceSecondary cellsPositive electrodesManganateMixed materials

The invention relates to a nickel cobalt lithium manganate cathode material, in particular to a preparation method of a layered nickel cobalt lithium manganate cathode material. The preparation method comprises the following steps: feeding a mixture of solid-state Mn(NO3)2, CoCO3, Ni(NO3)2.6H2O and Li2CO3 into an inner cavity of a rotating drum according to a stoichiometric ratio; throwing out the mixture from the inner cavity by using the rotating drum under the action of centrifugal force, and feeding the mixture into the inner cavity of the drum again to obtain a uniform mixture; adding a dispersant to the uniform mixture for ball milling; placing ball-milled slurry in a drying oven for drying to obtain a precursor; presintering the precursor in a resistance furnace; grinding the presintered precursor, and placing the ground materials in a rotary roaster for roasting. According to the preparation method of the invention, the centrifugal force and a fan are used to enable the mixed materials to achieve irregular circulating motion, so as to achieve the purpose of mixing the materials uniformly without dead corner; the nickel cobalt lithium manganate cathode material with excellent electrochemical properties is obtained through presintering and roasting.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

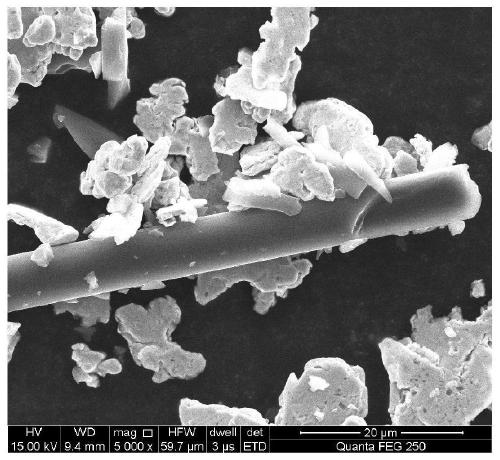

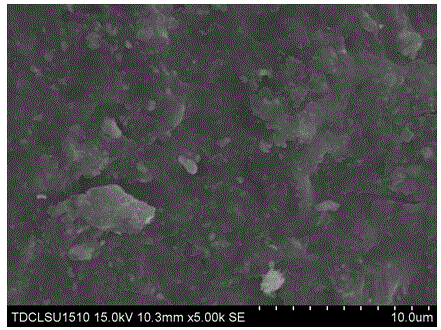

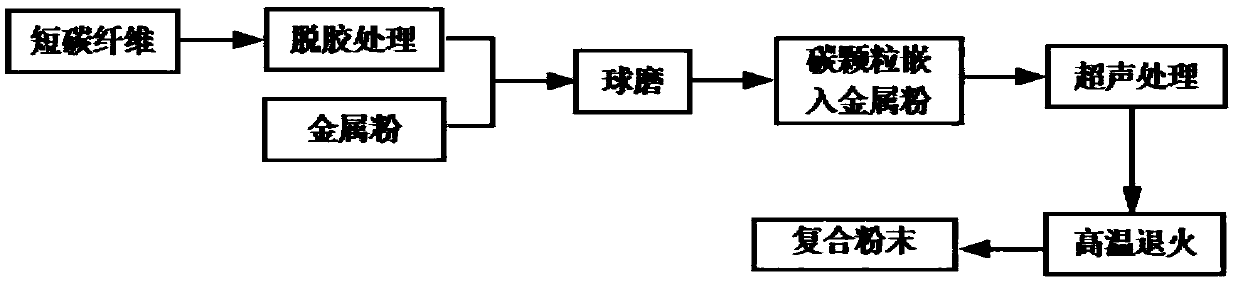

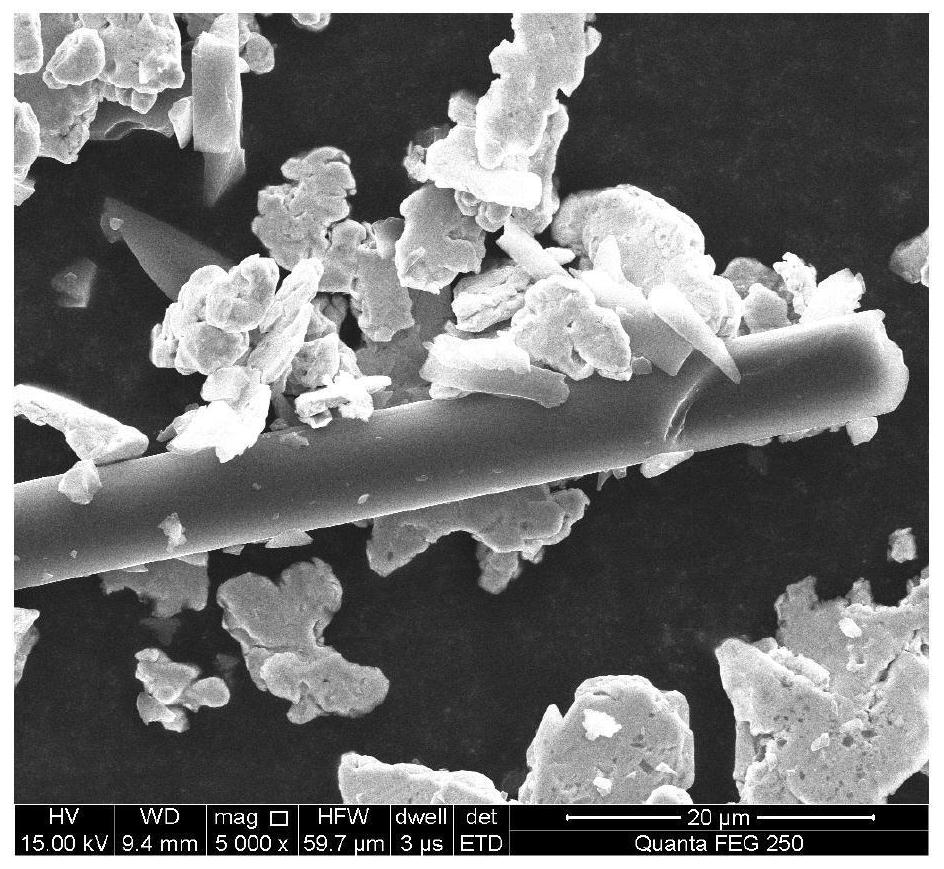

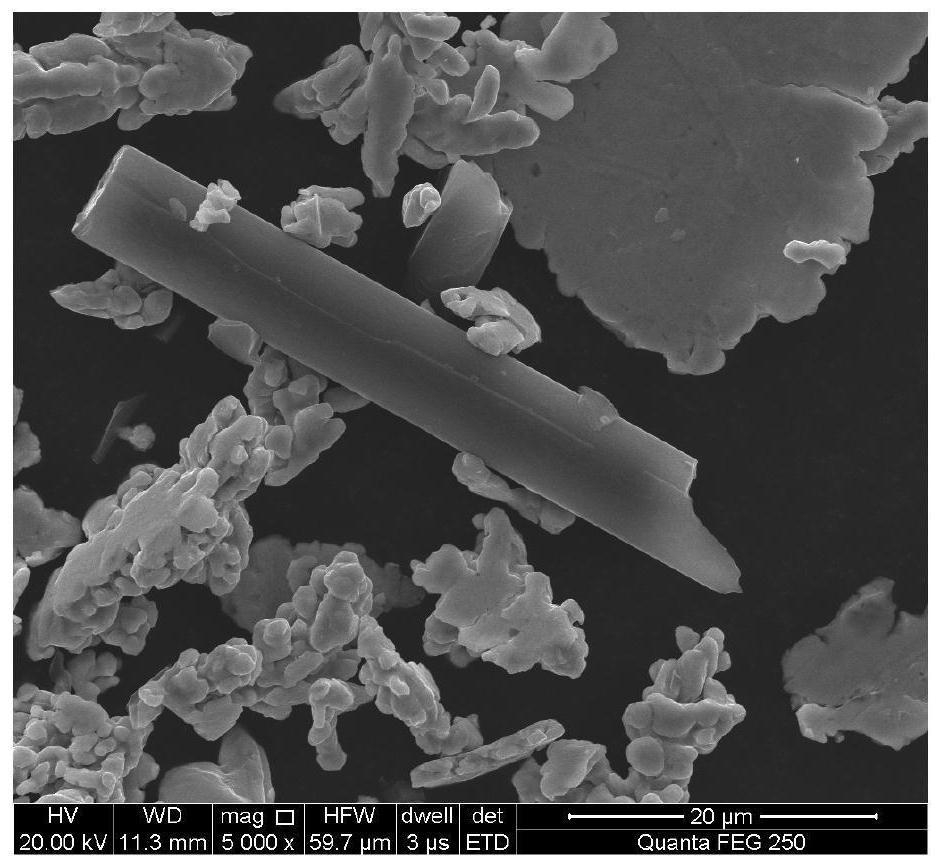

Composite powder of metal-metal carbide coated carbon particle and preparation method thereof

ActiveCN109570493AImprove heat resistanceEvenly embeddedPhysical treatmentCarbon fibresFiberCarbon fibers

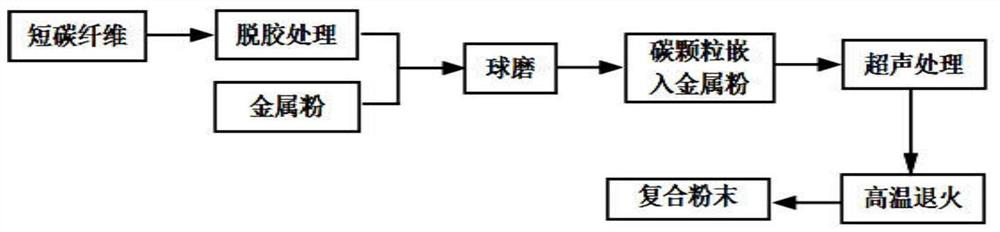

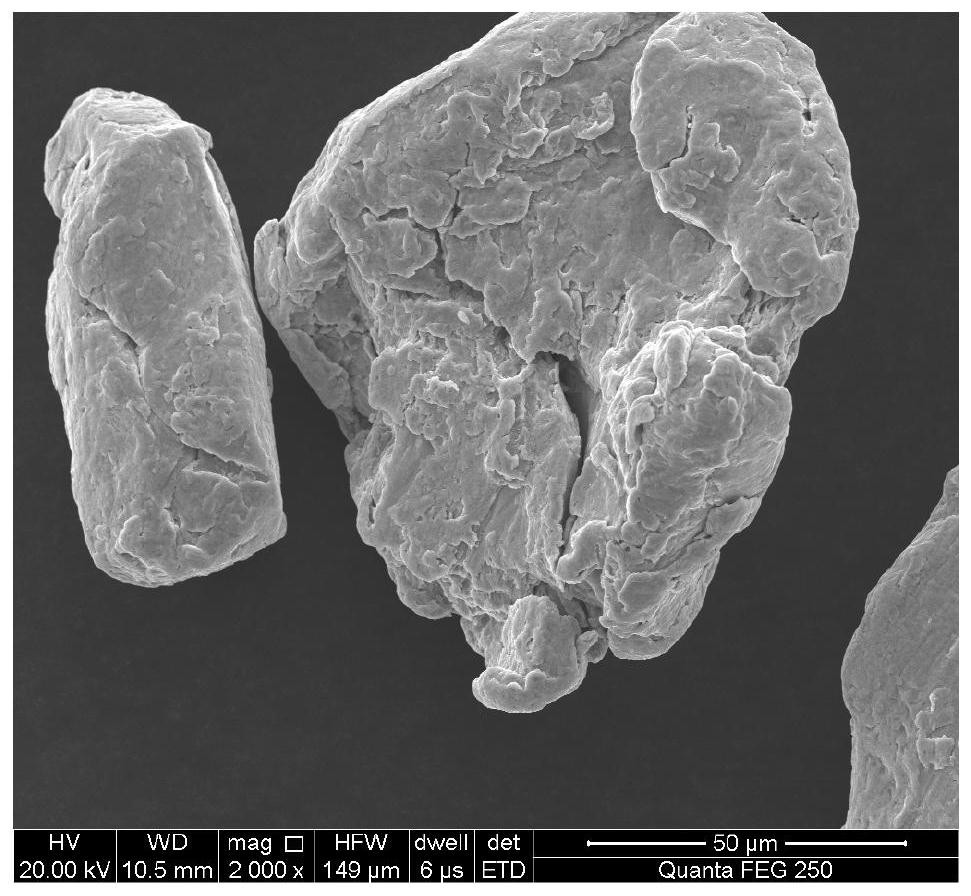

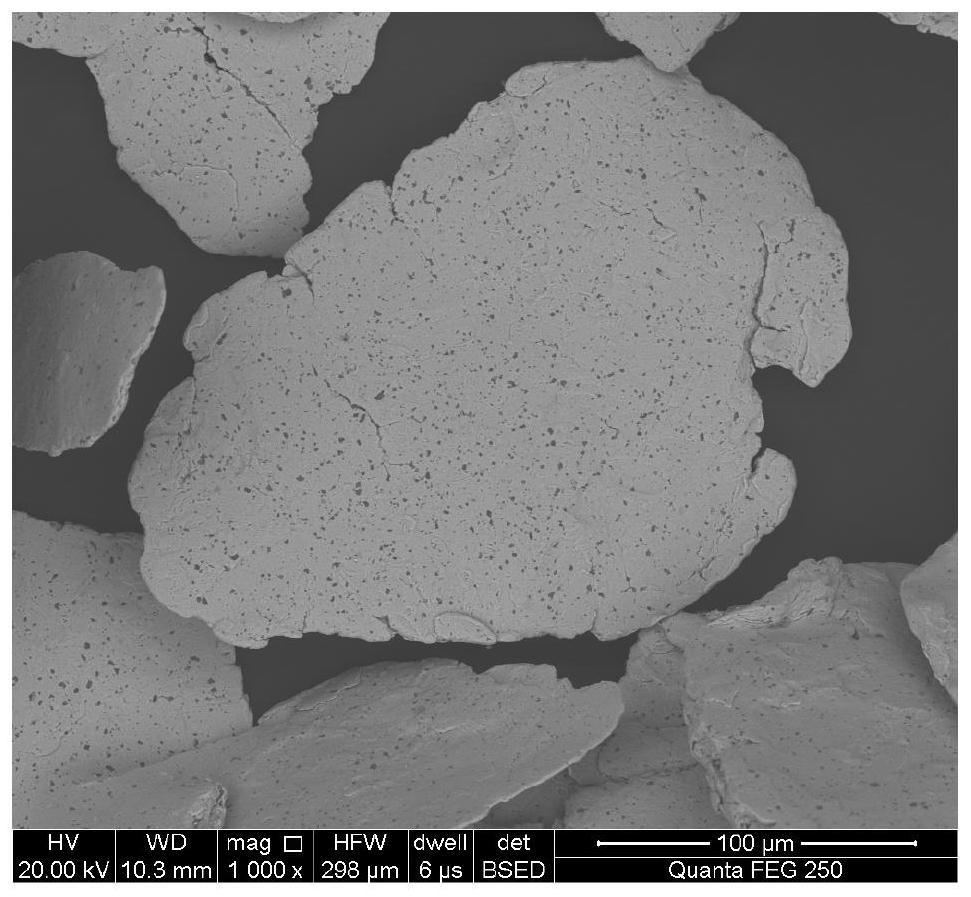

The invention relates to composite powder of a metal-metal carbide coated carbon particle and a preparation method thereof, and belongs to the technical field of metal powder. The metal-metal carbidecoated carbon particle is composed of a metal layer, a metal carbide layer and a carbon particle, wherein the metal carbide layer is coated on the surface of the carbon particle, and the metal layer is coated on the surface of the metal carbide layer; according to the composite powder, superfine carbon particles and matrix metal powder are used as raw materials, and mechanical force is applied, sothat the superfine carbon particles penetrate through and / or are inlaid into the matrix metal powder, and then in-situ carburization is performed so as to obtain the metal carbide layer. The preparation method comprises the steps of performing mechanical milling on degummed short carbon fiber and the metal powder first so as to obtain a large quantity of superfine carbon particles which are uniformly inlaid into the metal powder, then separating and annealing at high temperature, so that solid-phase reaction occurs between the carbon particles and surrounding metal, and the metal-carbon particle composite powder of which metal carbide is uniformly coated on the surfaces of the carbon particles is obtained.

Owner:CENT SOUTH UNIV

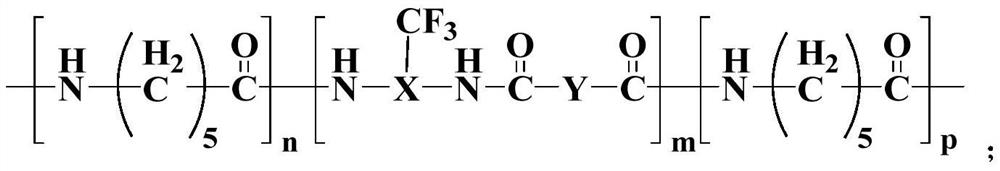

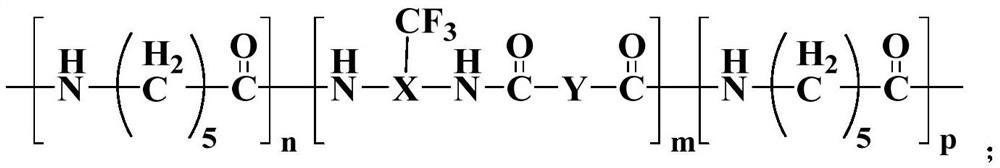

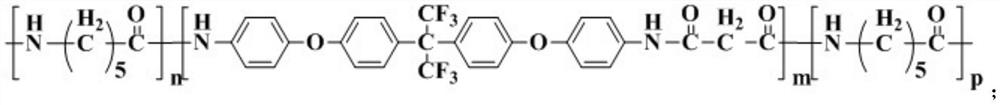

Fluorine-containing water-resistant polyamide 6 and preparation method thereof

The invention relates to fluorine-containing water-resistant polyamide 6 and a preparation method thereof, and the method comprises the following steps: adding a fluorine-containing chain extender into a prepolymer of polyamide 6, and carrying out polymerization reaction to prepare the fluorine-containing water-resistant polyamide 6. The structural formula of the fluorine-containing chain extender is shown in the specification, wherein X is a group containing a benzene ring, an ether bond, tertiary-butyl carbon and sulfuryl, Y is methylene containing 1-9 carbon atoms, and m is 10-50. The addition amount of the fluorine-containing chain extender is 10-50wt% of the feeding mass of caprolactam. The structural formula of the prepared fluorine-containing water-resistant polyamide 6 is shown in the specification, wherein the ratio of m to n to p is (10-50):(95-250):(150-250). According to the method disclosed by the invention, the interface compatibility between polyamide and a fluorine-containing polymer and the like is better improved by forming a fluorine-containing block copolymer through a polymerization reaction, and the prepared fluorine-containing water-resistant polyamide 6 is good in mechanical property and stress creep resistance caused by water absorption.

Owner:JIAXING UNIV

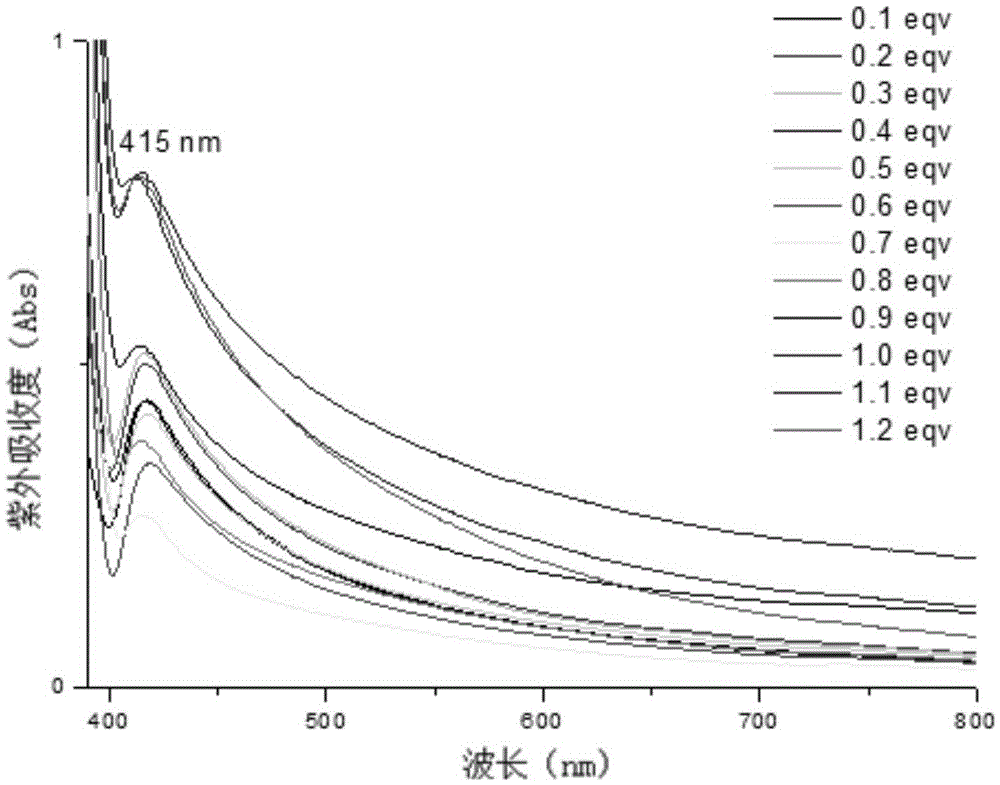

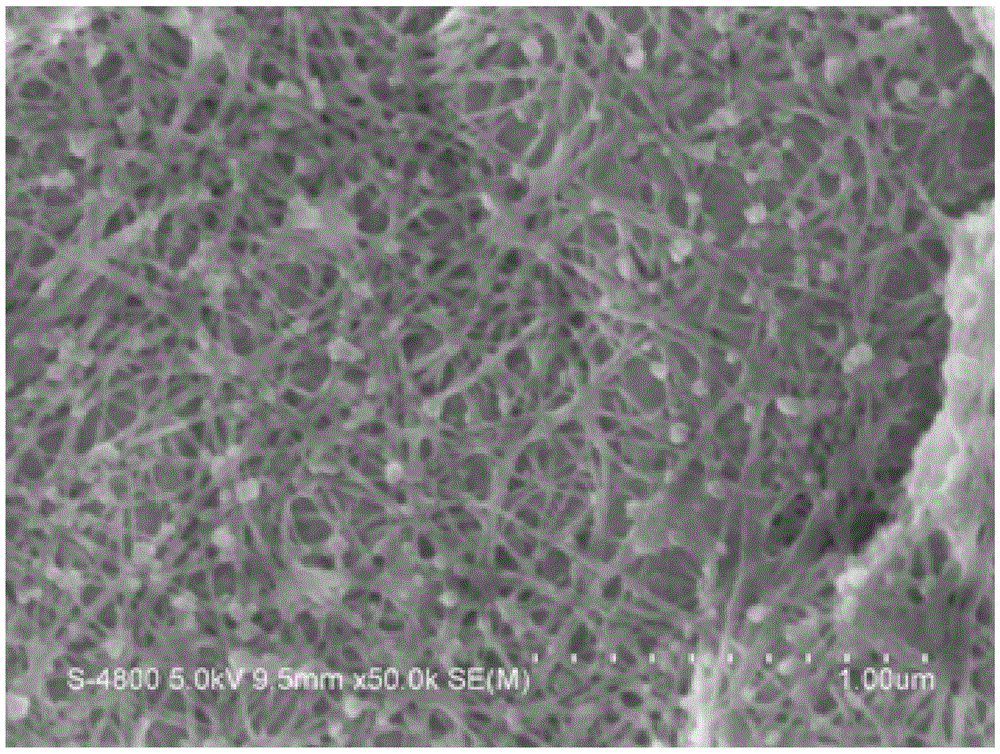

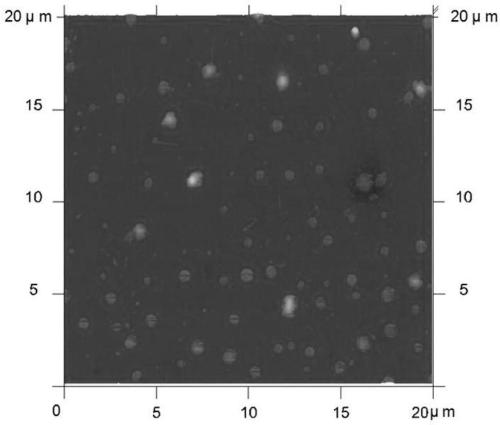

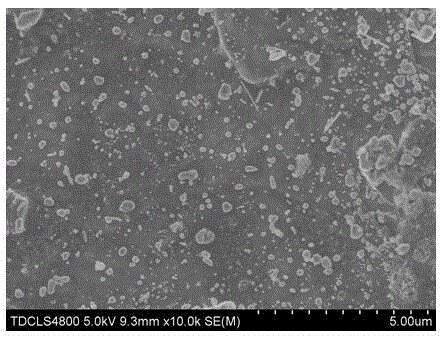

Gel material on basis of silver nano-particles, method for preparing gel material and application thereof

InactiveCN105664934ANarrow particle size distributionEvenly embeddedOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsNitro compoundCatalytic effect

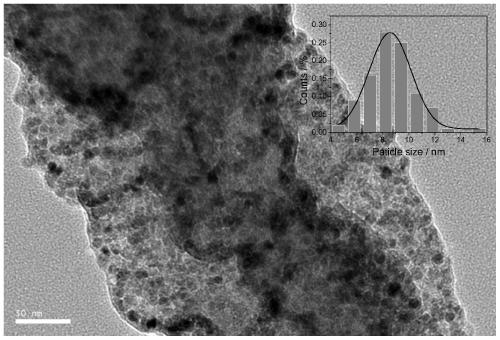

The invention discloses a gel material on the basis of silver nano-particles, a method for preparing the gel material and application thereof.The method includes mixing 2-amino-5-mercapto-1, 3, 4 thiadiazole and silver nitrate with each other under the condition of existence of dimethylformamide and water to obtain the gel material on the basis of the silver nano-particles.According to the technical scheme, the gel material, the method and the application have the advantages that the 2-amino-5-mercapto-1, 3, 4 thiadiazole and the silver nitrate are mixed with each other under the condition of existence of the dimethylformamide and the water, so that the silver nano-particles in the gel material prepared by the aid of the method are narrow in particle size distribution and can be uniformly embedded in metal organic gel fiber networks; excellent catalytic effects can be realized by the gel material on the basis of the silver nano-particles when aromatic nitro compounds are reduced, the reduction yield can be greatly increased, and the reduction time can be shortened.

Owner:ANHUI NORMAL UNIV

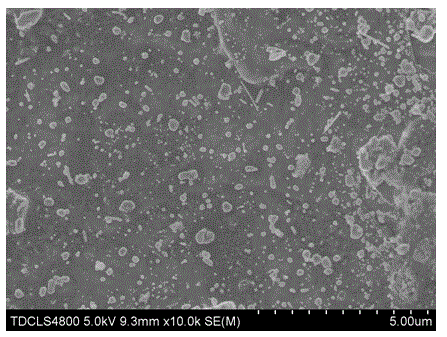

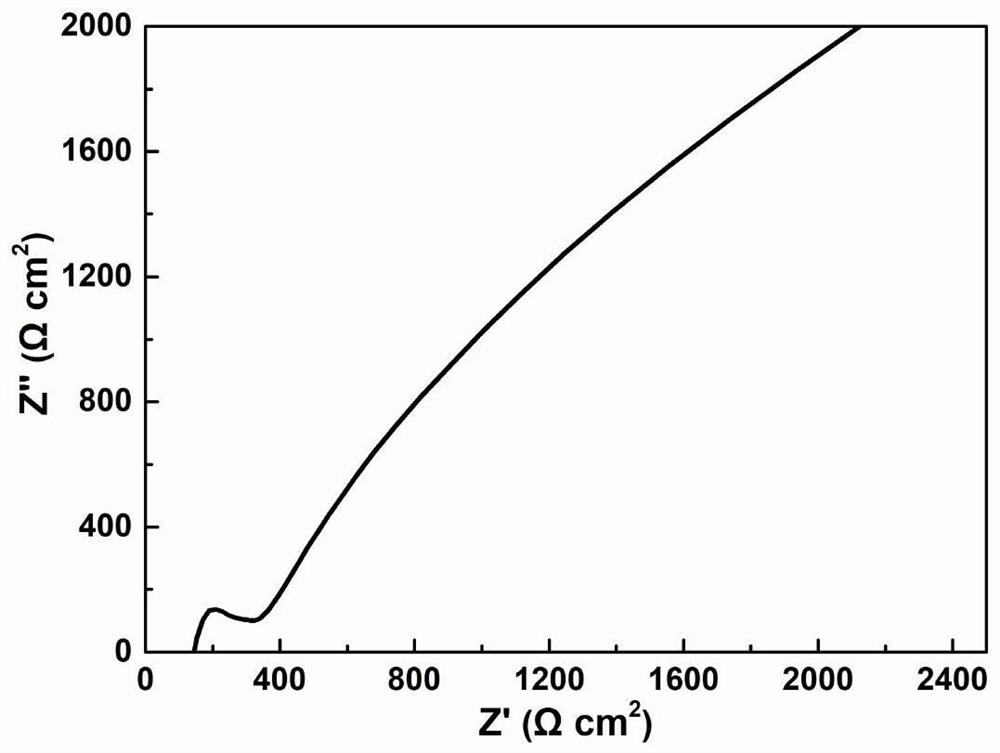

Preparation method of difunctional electrocatalyst

The invention provides a preparation method of a difunctional electrocatalyst. The preparation method comprises the following steps: mixing FeCl3.9H2O, CoCl2.6H2O and NiCl2.6H2O with black polypyrrole powder, freeze-drying, and annealing at 800 DEG C to obtain the difunctional electrocatalyst. The catalyst prepared by the method is used in an OER / ORR reaction, has excellent catalytic performance, is simple in preparation process, has low requirements on equipment and process conditions, and is beneficial to popularization and application. The air positive electrode provided by the invention is applied to the zinc-air battery, and has excellent charge-discharge performance and cycling stability.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

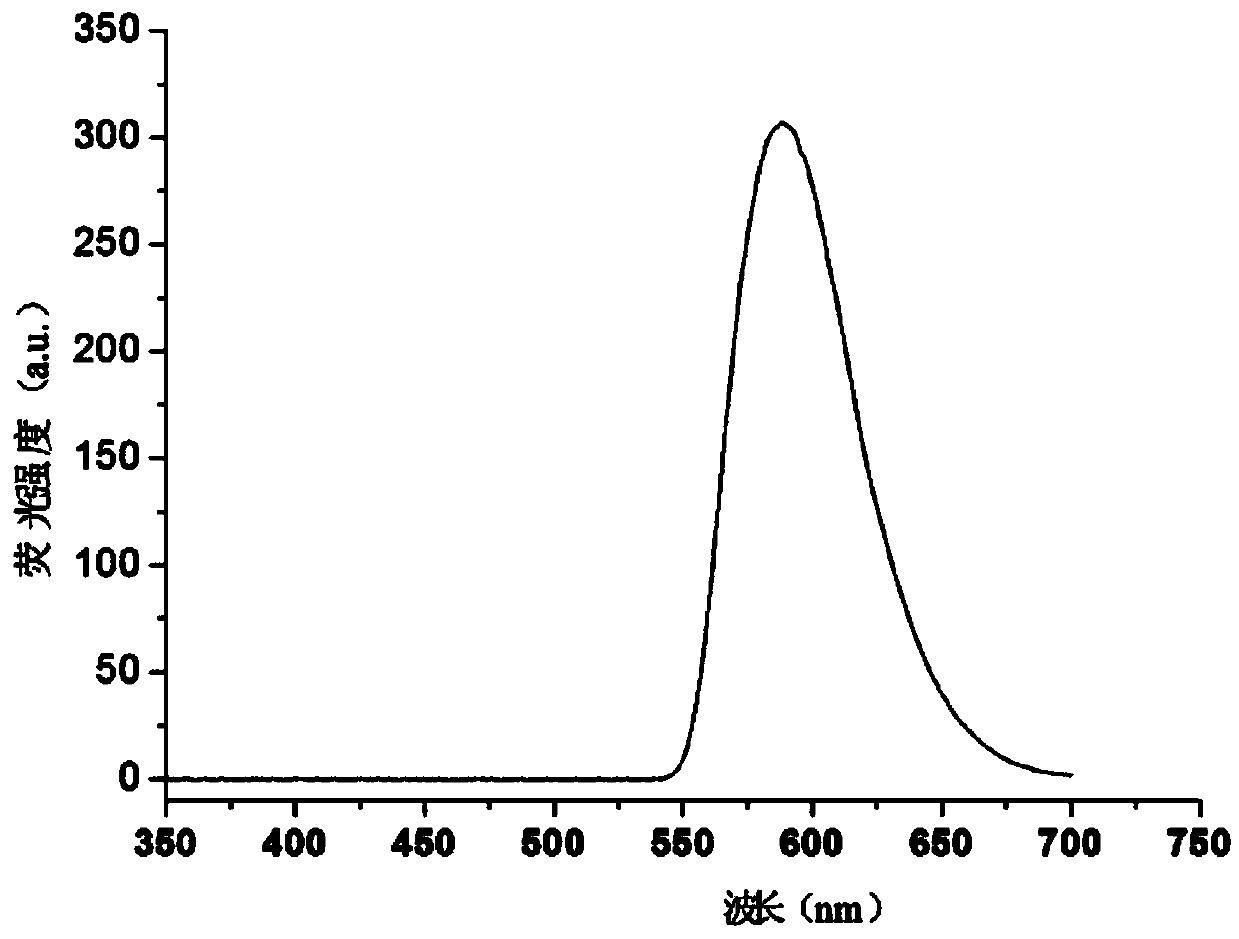

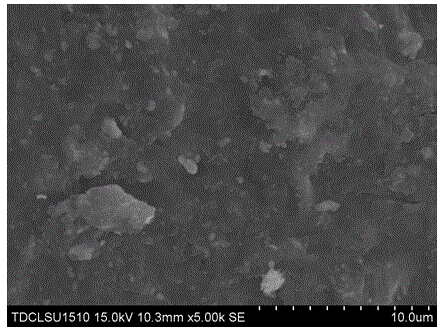

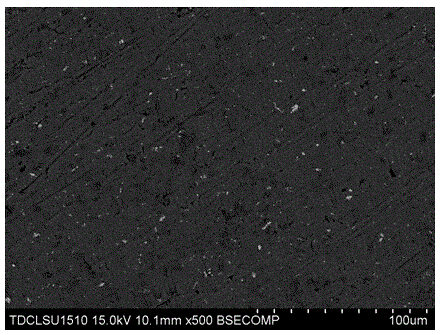

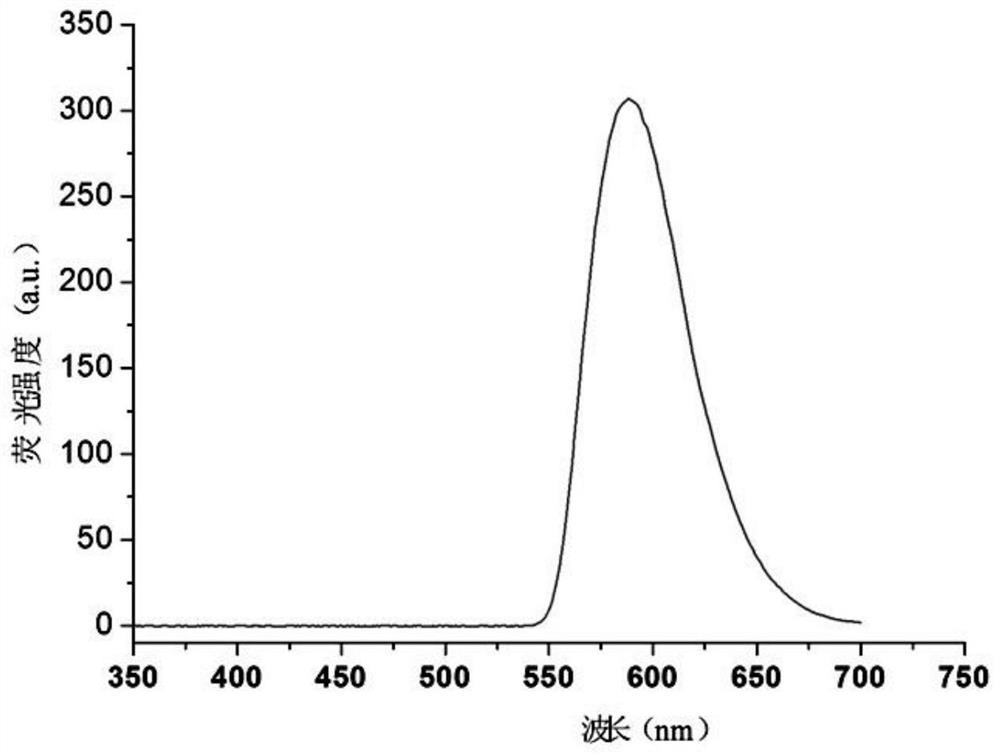

Preparation method of manganese doped zinc sulfide quantum dot embedded fluorescent composite membrane

ActiveCN109652057AEvenly embeddedEasy to prepareMaterial nanotechnologyNanoopticsCross-linkWater baths

The invention discloses a preparation method of a manganese doped zinc sulfide quantum dot embedded fluorescent composite membrane. The method includes the steps of: dissolving manganese doped zinc sulfide fluorescent quantum dots, film-forming monomers, a cross-linking agent and an initiator in a solvent in order, and conducting ultrasonic dispersion and stirring to obtain a casting solution; atroom temperature, spreading the casting solution evenly on a matrix material, performing covering with polymethyl methacrylate, conducting heating in water bath under pressure to initiate polymerization; and then placing the obtained membrane into a hydrofluoric acid solution for etching to remove the matrix material, thus obtaining the fluorescent quantum dot embedded composite membrane. The method provided by the invention has the characteristics of simple synthesis, strong fluorescence performance, low biotoxicity and reusability. The prepared embedded composite membrane has the advantagesof good transparency, stable fluorescence, high mechanical strength and good self-cleaning ability, and has enormous application potential in optical sensing, biochemical analysis, water pollution, food analysis and environmental protection.

Owner:合肥九州龙腾科技成果转化有限公司

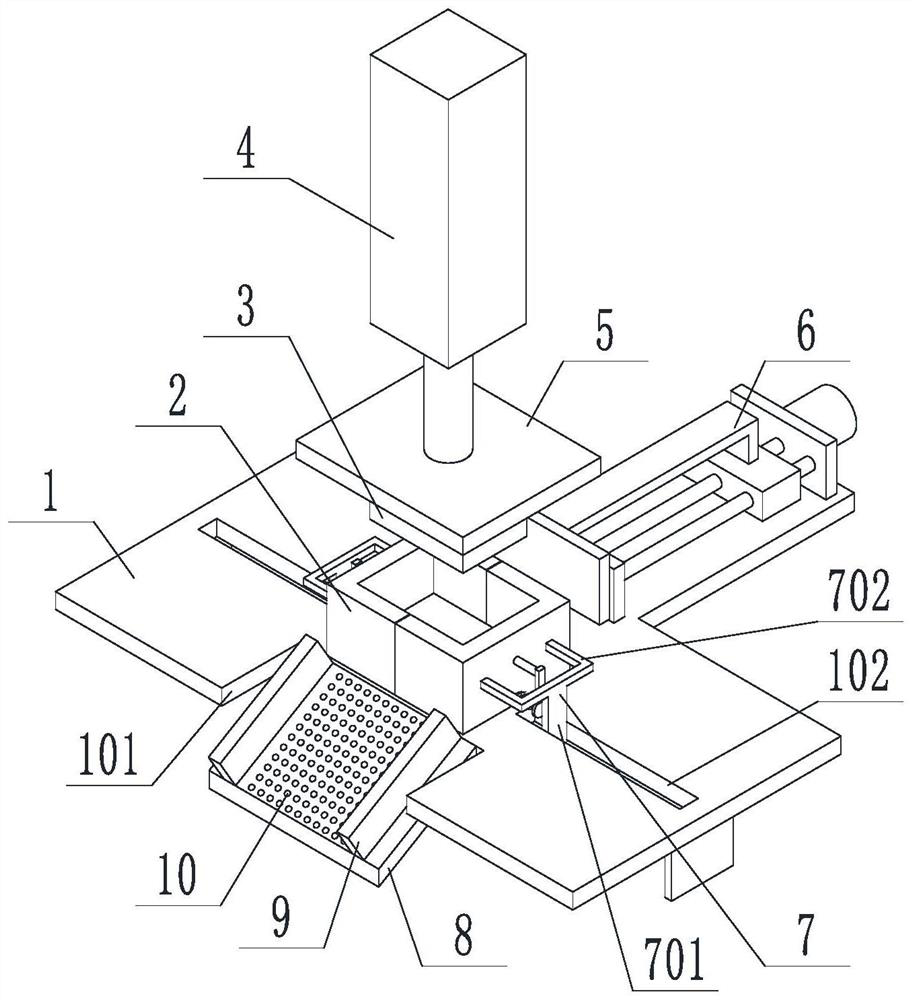

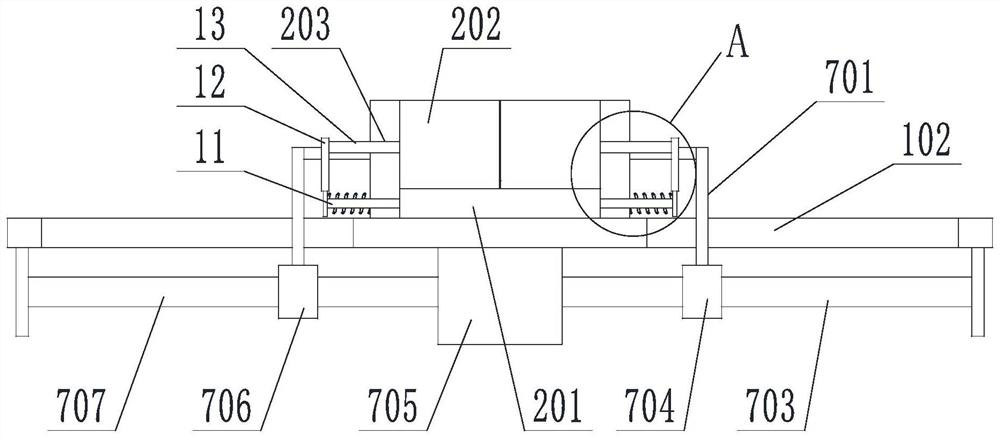

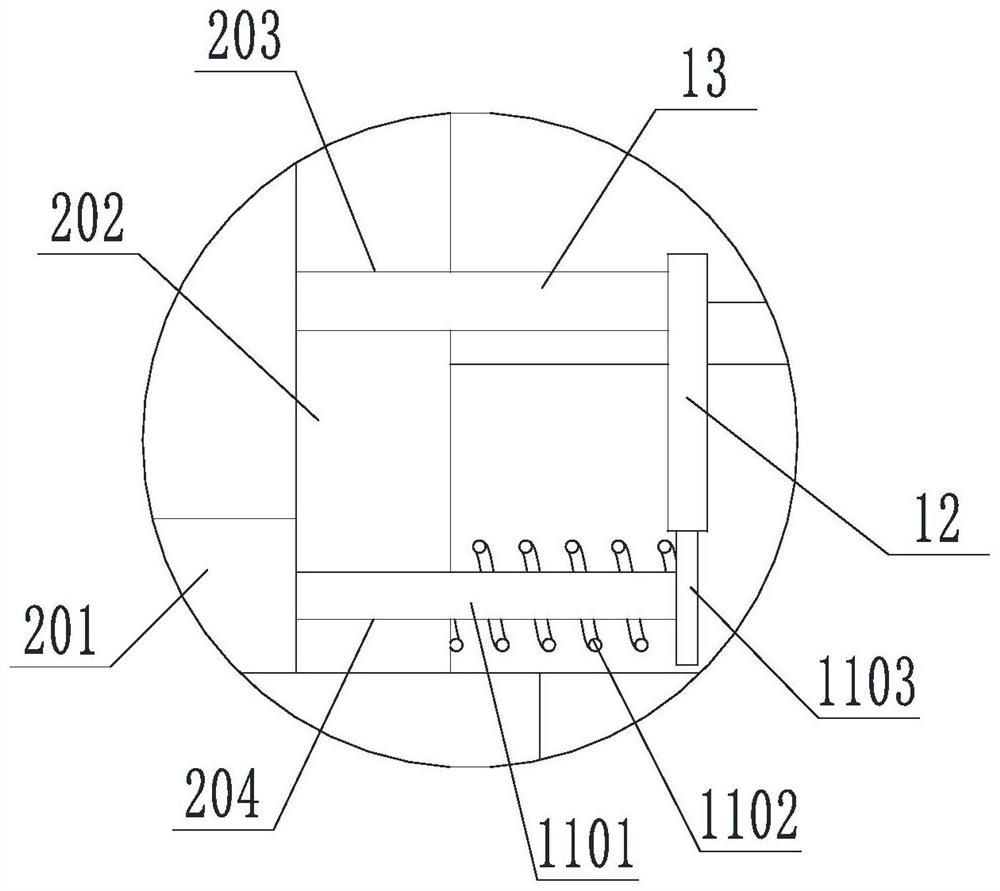

Environment-friendly demolding equipment for heating and heat-preserving lunch box

The environment-friendly demolding equipment comprises a workbench and a lifting electric cylinder located above the workbench, a lower mold is arranged on the surface of the workbench and comprises a bottom plate and a side frame located on the bottom plate, the side frame is composed of two U-shaped plates, and the two U-shaped plates are horizontally in butt joint to form a mold cavity; the two U-shaped plates are horizontally butted and matched with the bottom plate to form a complete lower die; a driving assembly is arranged on the surface of the worktable; a pushing assembly is arranged on the surface of the workbench, and the working direction of the pushing assembly is perpendicular to the working direction of the driving assembly. The output end of the lifting electric cylinder is vertically downward and connected with a lifting plate, and an upper die matched with the die cavity of the lower die is arranged on the bottom face of the lifting plate. The side frame is driven to move through the driving assembly, automatic splitting of the lower mold is achieved, rapid demolding is achieved, and the production efficiency can be improved; and separation of the product and the bottom plate is achieved through the pushing assembly, automatic discharging is achieved, and the production efficiency can be improved.

Owner:德清福蓝得新材料科技有限公司

Preparation method for cobalt-nickel-manganese-lithium battery positive electrode material

The invention relates to cobalt-nickel-manganese-lithium positive electrode material, and specifically to a preparation method for a cobalt-nickel-manganese-lithium battery positive electrode material. The preparation method comprises the steps of mixing solid Mn(NO<3>)<2>, CoCO<3> and Ni(NO<3>)<2>.6H<2>O based on chemometry, and performing ball milling on the mixture to obtain mixed particles; mixing the mixed particles with solid Li<2>CO<3>, and putting the mixture into an inner cavity of a rotary roller to throw out; then putting the thrown-out mixture into the inner cavity of the roller again to obtain a uniformly-mixed mixture; adding a dispersing agent and performing mechanical activation; then drying to obtain a precursor; performing pre-sintering on the precursor; then performing grinding after pre-sintering and then performing baking on the precursor to obtain the cobalt-nickel-manganese-lithium battery positive electrode material. According to the preparation method, a ternary material is subjected to ball milling by a ball milling machine initially, so that uniform particle size of the material is realized; irregular circulation movement of the mixed material is realized by centrifugal force and a fan, so that the purpose of uniformly mixing materials without dead corners is fulfilled; and then the cobalt-nickel-manganese-lithium battery positive electrode material with an excellent electrochemical performance is obtained by carrying out pre-sintering and baking.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

Preparation method for lithium nickel manganese cobalt positive electrode material

InactiveCN105870413AEvenly embeddedImprove electrochemical performanceCell electrodesSecondary cellsSolid-stateNickel

The invention relates to a lithium nickel manganese cobalt positive electrode material, in particular to a preparation method of the lithium nickel manganese cobalt positive electrode material. The preparation method comprises the following steps of throwing a mixture of solid-state Mn(NO<3>)<2>, CoCO<3>, Ni(NO<3>)<2>.6H<2>O and Li<2>CO<3> into an inner cavity of a rotating roller according to stiochiometric ratio; throwing the mixture out of the inner cavity by the rotating roller under the effect of a centrifugal force, and throwing the mixture into the inner cavity of the roller again; circulating the steps to obtain the uniformly-mixed mixture; adding a dispersing agent into the above uniformly-mixed mixture for ball milling; placing the paste after ball milling in a drying box for drying to obtain a precursor; pre-sintering the precursor; and grinding the precursor after pre-sintering, and roasting the precursor to obtain the lithium nickel manganese cobalt positive electrode material. Irregular circulation movement of the mixture material is achieved by the centrifugal force and a fan, so that the purposes of uniformity and no dead angle of the mixed material are achieved, and then the lithium nickel manganese cobalt positive electrode material with excellent electrochemical performance is obtained by pre-sintering and roasting.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

Preparation method and application of nonmetal doped stainless steel mesh composite material

ActiveCN110090656AHigh temperature resistantHas acid and alkali resistancePhysical/chemical process catalystsWater contaminantsLithium chlorideTube furnace

The invention discloses a preparation method and application of a nonmetallic doped stainless steel mesh composite material, and the preparation method comprises the following steps of: firstly, performing surface activation treatment on a cleaned stainless steel mesh by adopting a mixed solution of lithium chloride and phosphoric acid; and transferring the activated stainless steel mesh and an inorganic nonmetal source to a tubular furnace for calcination and pyrolysis to obtain the target product. The composite material can be used as a catalyst to construct an organic pollutant catalytic reaction device to degrade organic pollutants, the catalytic degradation rate reaches 100%, and the removal rate of total organic carbon reaches more than 99%.

Owner:HEFEI UNIV OF TECH

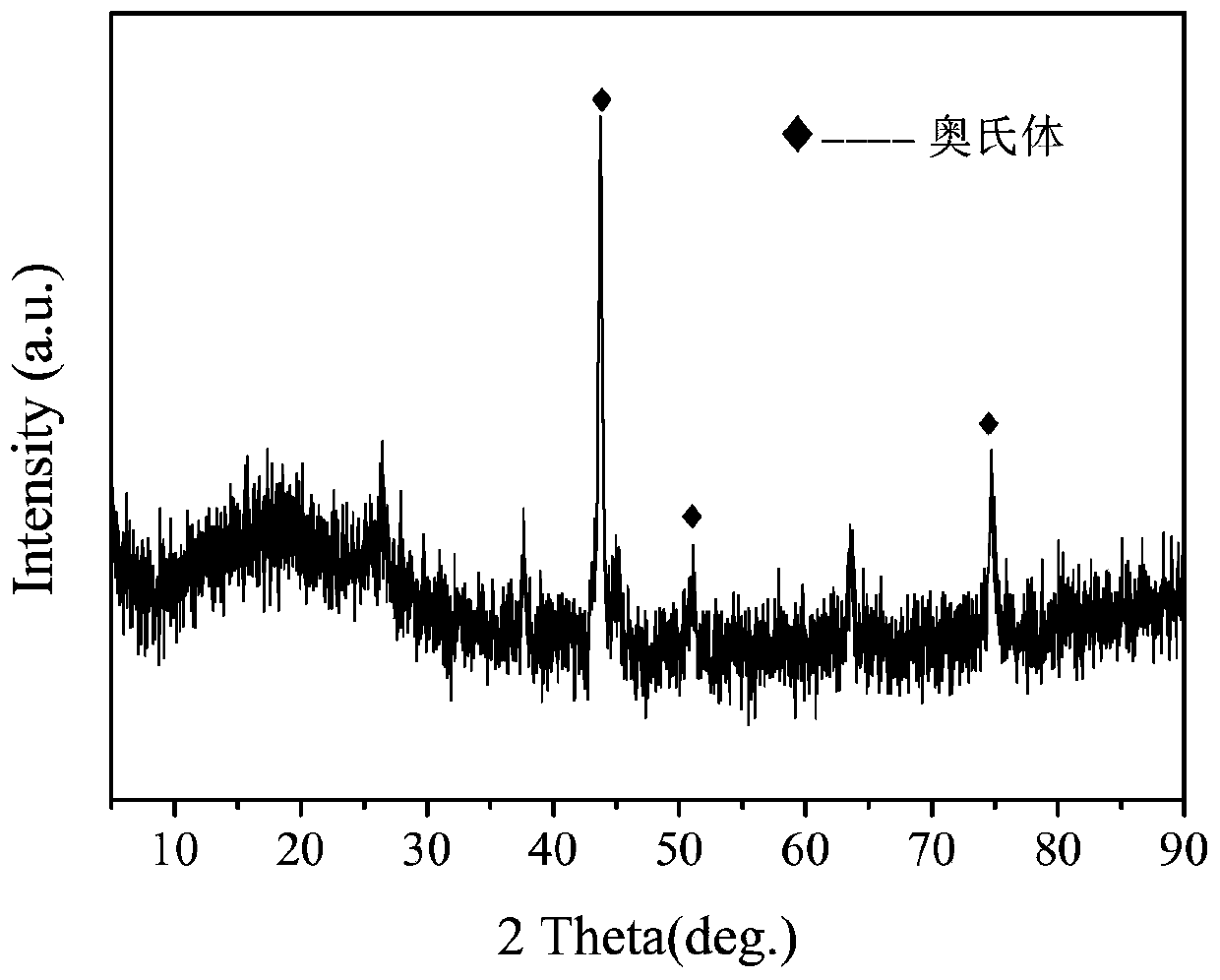

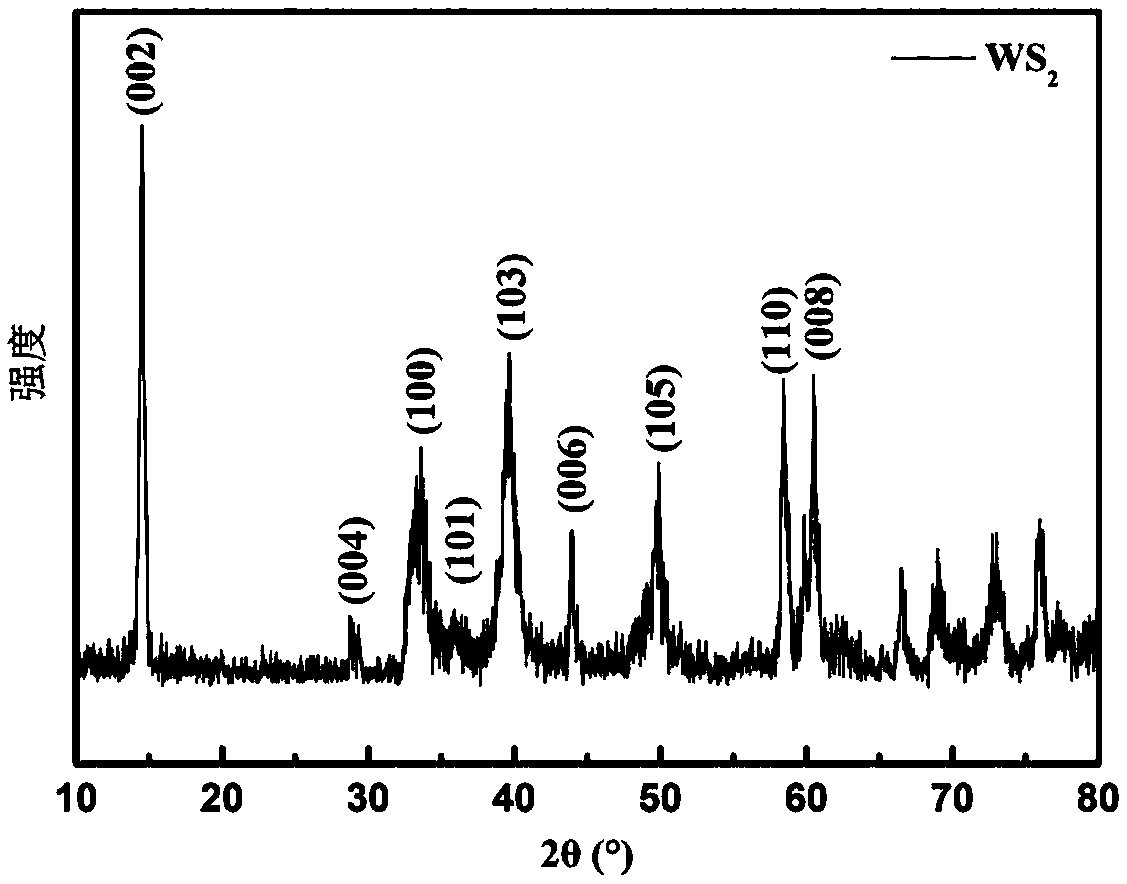

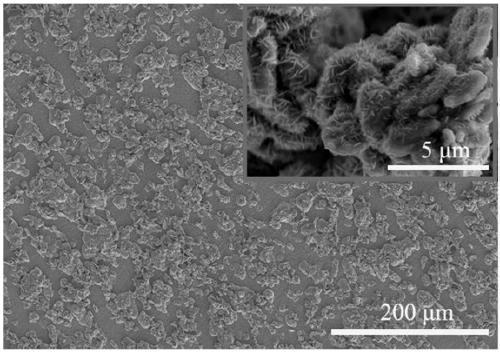

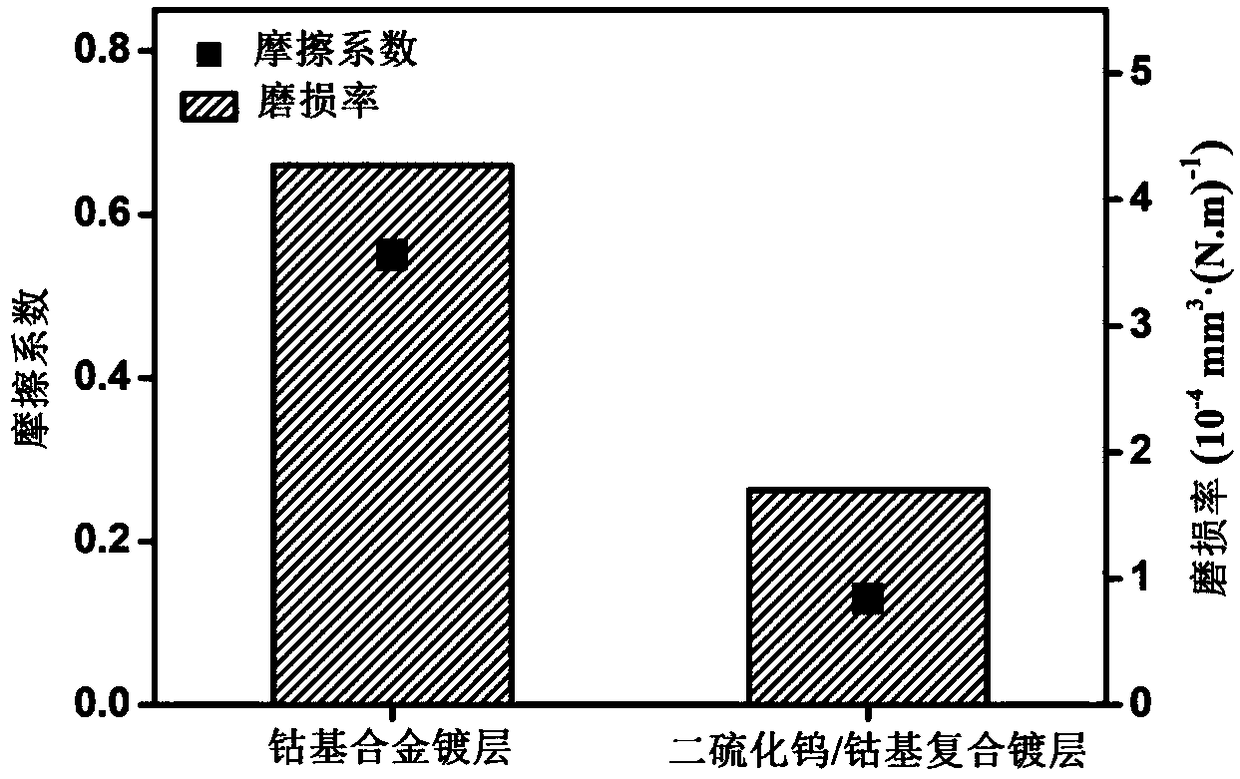

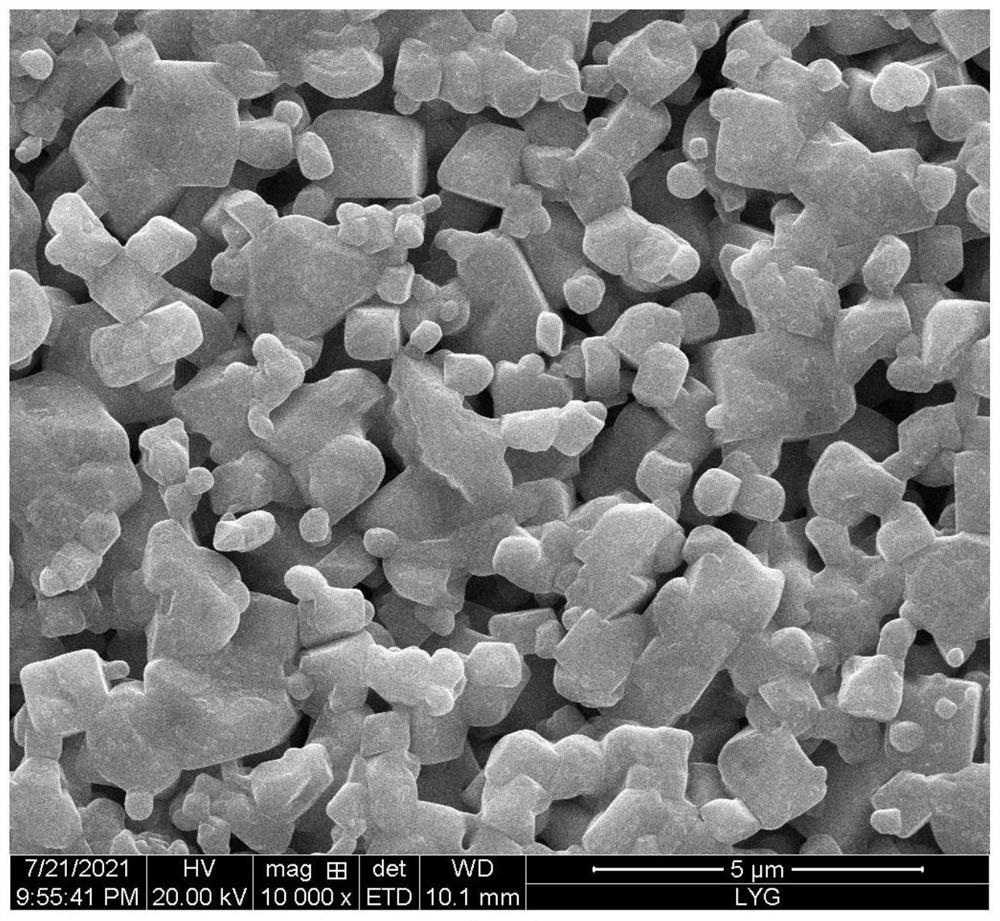

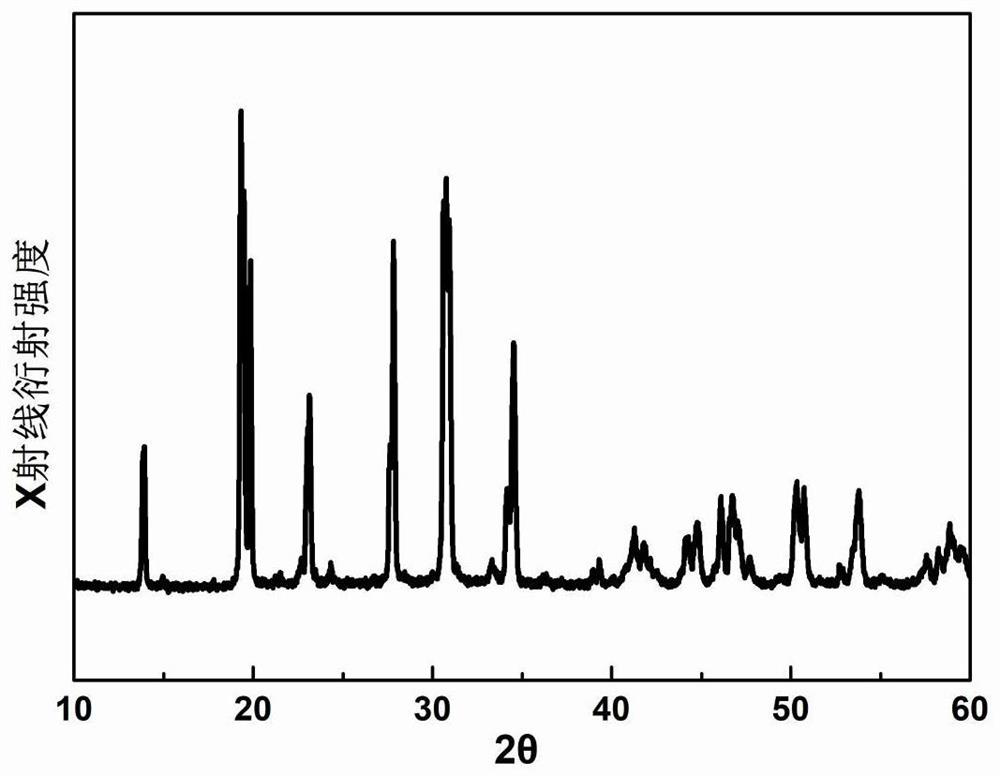

Tungsten disulfide/cobalt disulfide based composite coating and preparation method and application thereof

InactiveCN109137014AEvenly embeddedEmbedded firmlyCellsElectrolytic coatingsFriction reductionNickel salt

The invention belongs to the technical field of surface functional film materials, and discloses a tungsten disulfide / cobalt disulfide based composite coating and a preparation method and applicationthereof. Cobalt, nickel or cobalt-nickel alloy is used as an anode, a to-be-plated workpiece is used as a cathode, and after the anode and the cathode are soaked in a composite electroplating solutionand are ultrasonically vibrated, electrolytic deposition is carried out on the to-be-plated workpiece by pulse current to obtain the tungsten disulfide / cobalt disulfide based composite coating; and the composite electroplating solution comprises the following components under the condition that the total volume of deionized water and various substances is 1L: 30-100 g / L of cobalt salt, 30-100 g / Lof nickel salt, 10-50 g / L of boric acid, 10-50 g / L of a complexing agent, 0.05-0.3 g / L of a surfactant and 6-16 g / L of tungsten disulfide. The preparation method is simple, and the composite coatinghas high hardness, excellent wear resistance and friction reduction property and corrosion resistance. The composite coating is applied to a functional protection layer of a mechanical part which requires low friction coefficient, wear resistance and corrosion resistance, the overall performance of the mechanical part can be improved effectively, and the service life of the mechanical part is prolonged.

Owner:GUANGDONG UNIV OF TECH

Preparation method and application of solid electrolyte

ActiveCN114188601AEvenly embeddedUniform deintercalationSolid electrolytesSecondary cellsSolid state electrolyteSodium metasilicate

The invention relates to the technical field of solid electrolyte, in particular to a preparation method and application of solid electrolyte. The invention provides a preparation method of a solid-state electrolytic tank, which comprises the following steps: mixing a sodium-containing salt, a phosphorus-containing salt, a zirconium oxide and a silicon oxide for the first time, and calcining to obtain a sodium zirconium silicophosphate precursor; and mixing the sodium zirconium silicophosphate precursor, a binder and sodium metasilicate for the second time, and sequentially carrying out tabletting and liquid-phase sintering to obtain the solid electrolyte. The solid electrolyte prepared by the preparation method has a relatively wide electrochemical window.

Owner:YUNNAN UNIV

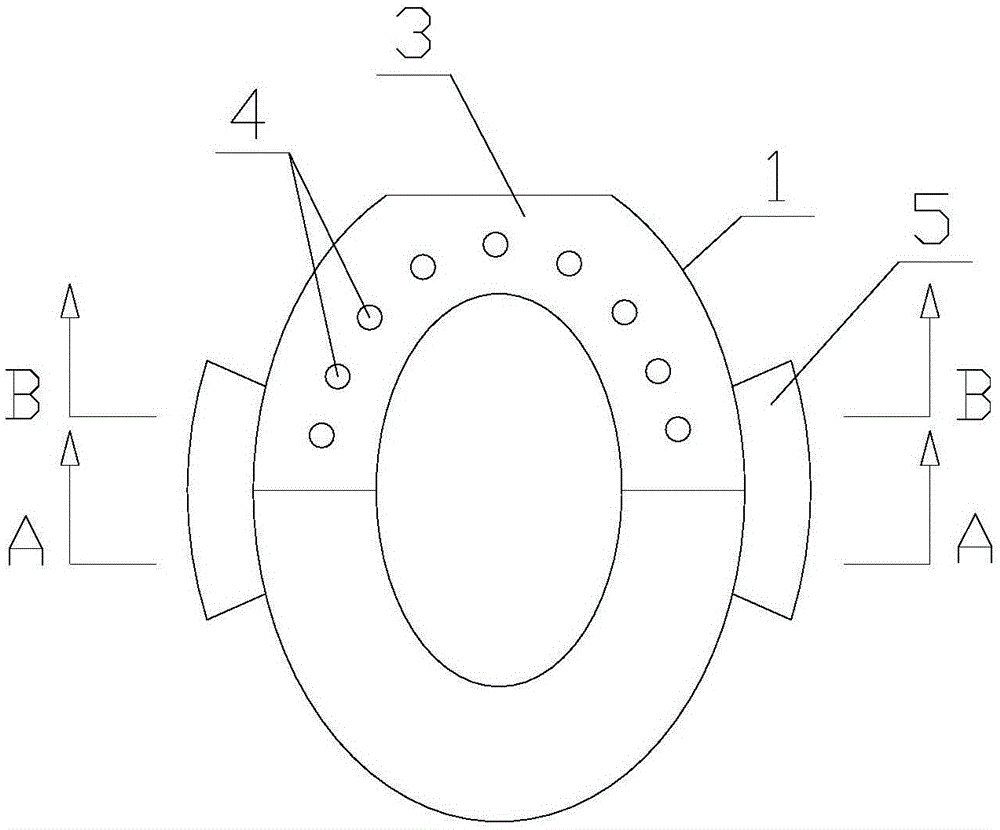

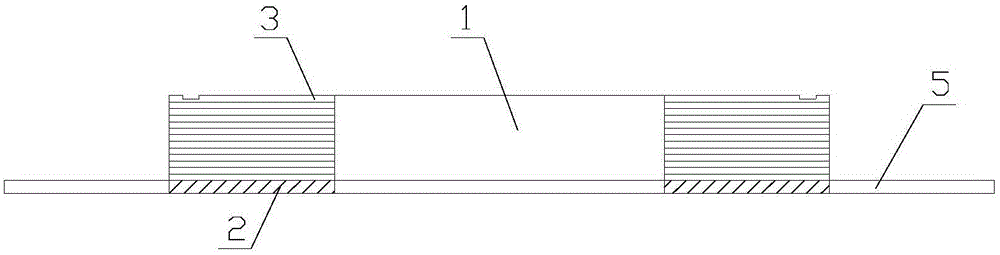

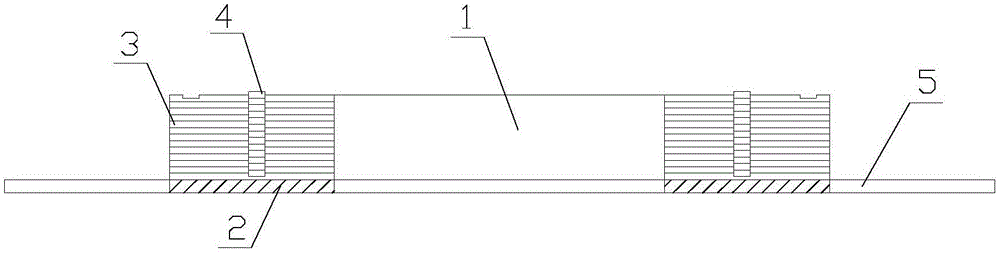

Allergy-preventing flavored immediately-tearing type closestool packing paper

The invention relates to allergy-preventing flavored immediately-tearing type closestool packing paper which comprises a closestool cushion body and two wrapping belts, wherein a waterproof bottom layer on the bottom and a plurality of pieces of cushioning paper wrap the closestool cushion body, the cushioning paper is sequentially laid on the waterproof bottom layer; the wrapping belts are symmetrically mounted on the two sides of the waterproof bottom layer; a fragrance structure is arranged on the half part, not contacting the human body, of each piece of cushioning paper. The allergy-preventing flavored immediately-tearing type closestool packing paper can be rapidly replaced, the material is environmentally friendly, the use is convenient, the fragrance is obtained, and the demands of users with allergic constitution are also adapted.

Owner:桂林市独秀纸品有限公司

A kind of preparation method of porous metal oxide

The invention relates to a preparation method of a porous metal oxide, which belongs to the intersection field of metal powder technology and metal material surface treatment. The preparation method is as follows: degumming the short carbon fibers first, then passing the degummed short carbon fibers and metal powder through a proper ball milling process to obtain metal powder embedded with ultrafine carbon particles, and then sintering in a protective atmosphere or vacuum after pressing. Or direct loose-pack sintering, and finally perform short-term annealing in oxygen-containing air. While removing carbon particles in the metal powder, the surface of the metal particles is partially oxidized to obtain a porous metal with a partially oxidized surface. The porous metal oxide prepared by the invention exhibits good properties of oil storage, hydrogen storage, paraffin wax storage, lithium storage, and catalytic performance, and the preparation process is simple and the cost is low.

Owner:CENT SOUTH UNIV

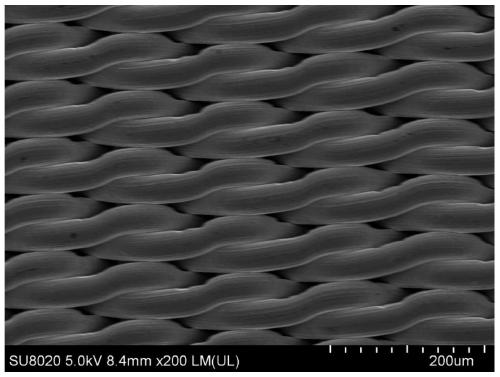

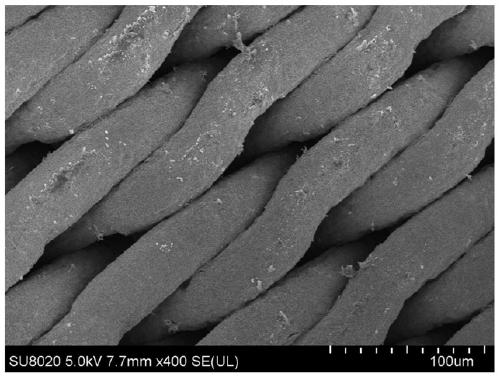

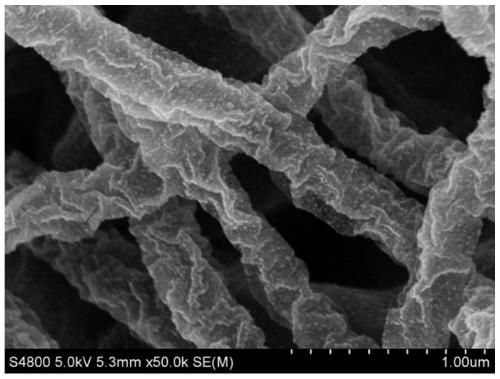

S-doped surface-wrinkled carbon fiber loaded Co and MnO nanoparticles and preparation method and application thereof

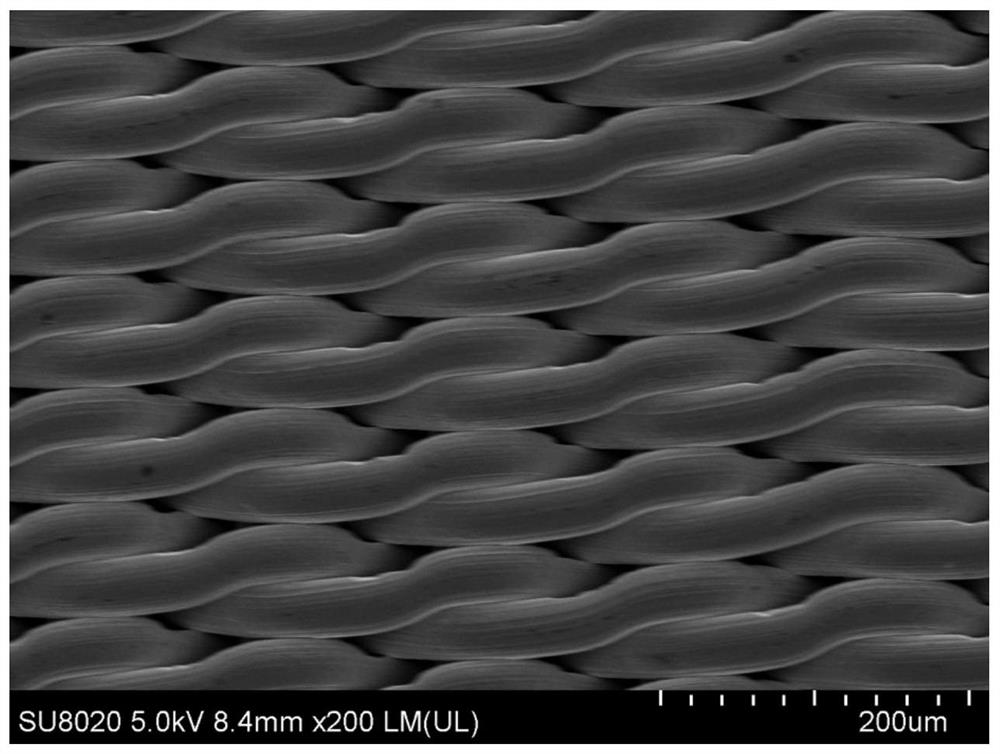

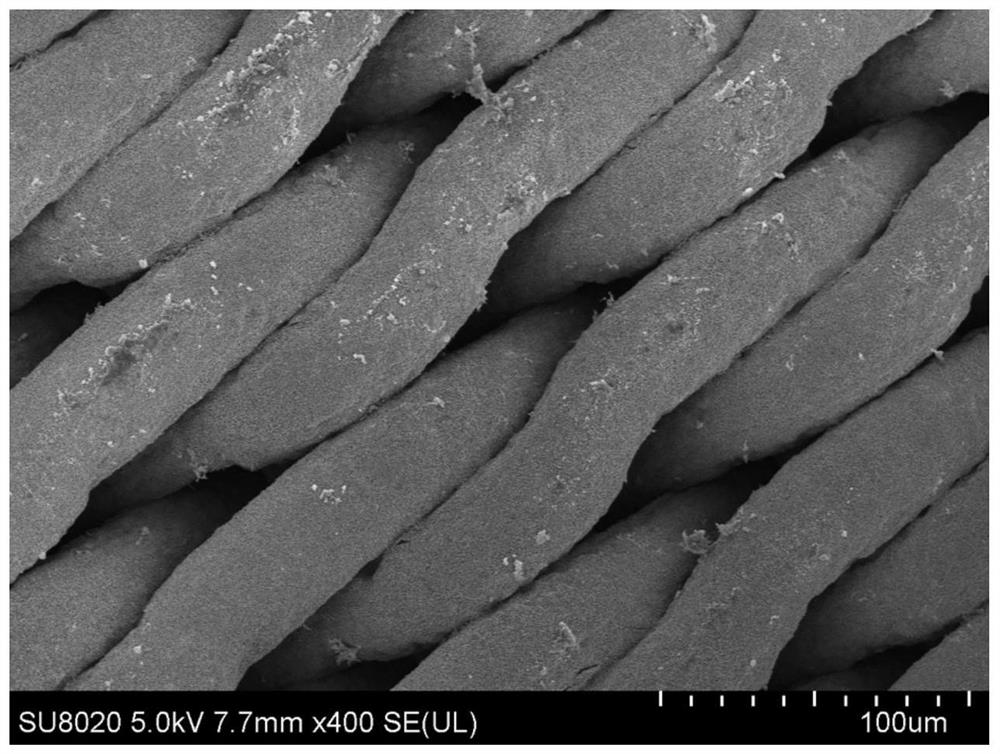

ActiveCN111575836AImprove electrocatalytic activityImprove stabilityCell electrodesElectro-spinningMANGANESE ACETATEFiber

The invention provides S-doped surface-wrinkled carbon fiber loaded Co and MnO nanoparticles and a preparation method and application thereof. The preparation method comprises the following steps thatpolyvinylpyrrolidone is added into a mixed solvent of DMF and ethanol, cobalt nitrate, manganese acetate and thiourea (N2H4CS) are added after the polyvinylpyrrolidone is dissolved, after the mixtureis mixed to be uniform, and polymer fibers are obtained through electrostatic spinning; low-temperature pre-oxidation is carried out on the polymer fibers to obtain a precursor; and high-temperaturecalcination is carried out on the precursor to obtain the S-doped surface-wrinkled carbon fiber loaded Co and MnO nanoparticles. According to the S-doped surface-wrinkled carbon fiber loaded Co and MnO nanoparticles and the preparation method and application thereof, an S-doped surface-wrinkled carbon fiber loaded Co and MnO nanoparticle catalyst prepared by the invention has similar oxygen reduction electrocatalytic performance and better stability, is a zinc-air battery catalyst with great potential, and has a wide application prospect in the future energy industry.

Owner:NANJING NORMAL UNIVERSITY

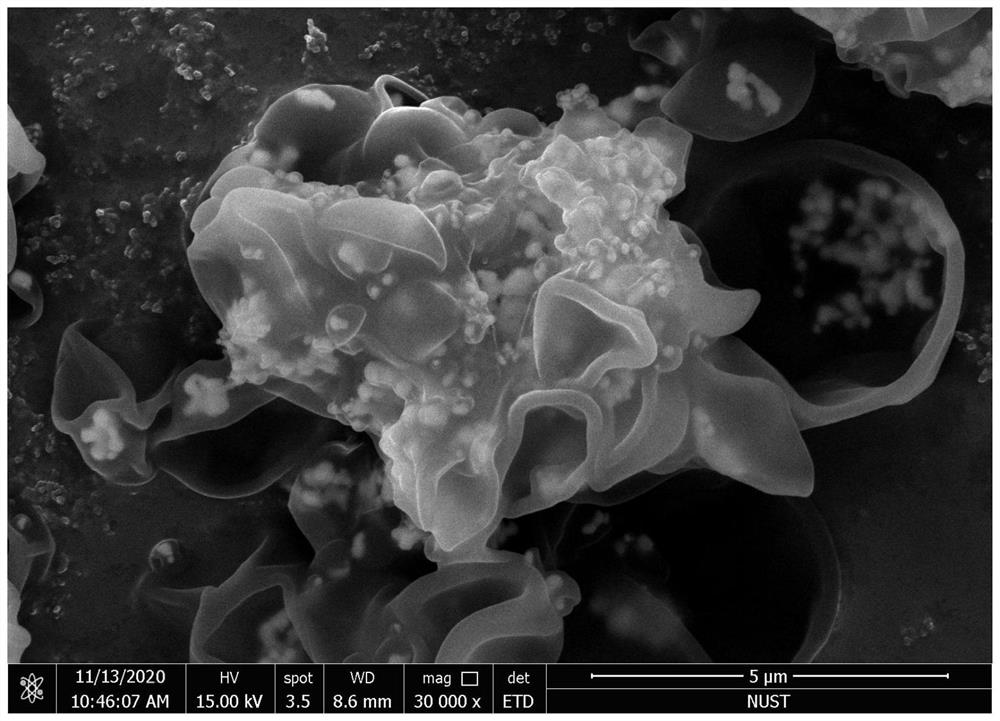

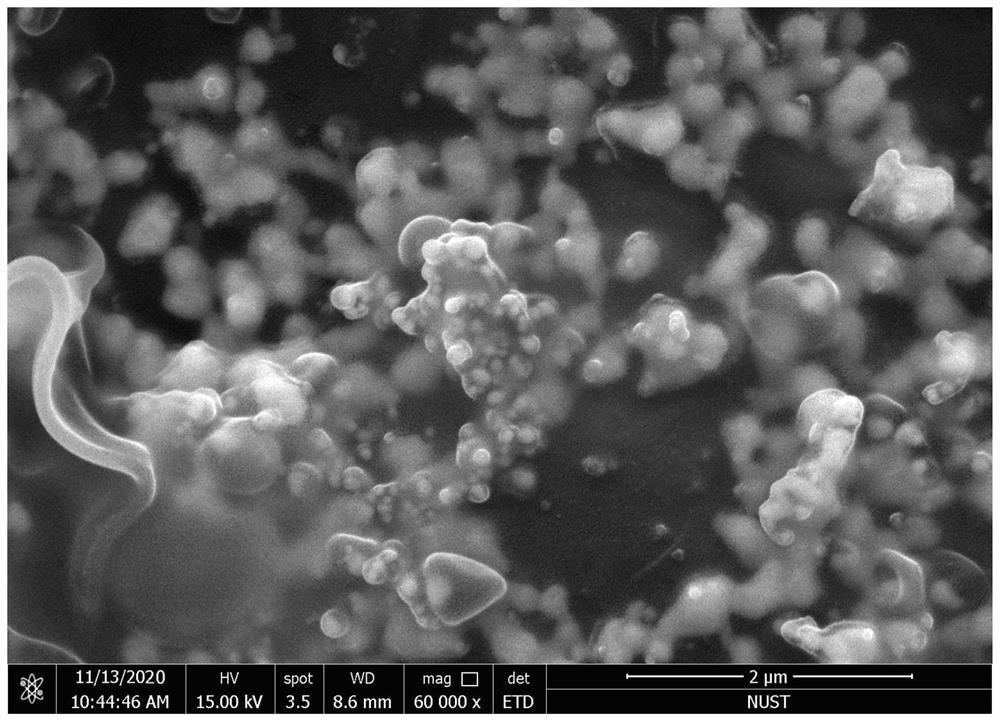

Tremella-shaped carbon-coated nano-silver material as well as preparation method and application thereof

PendingCN114471547AUnique shapeLow densityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsTremellaHydrothermal reaction

The invention discloses a tremella-shaped carbon-coated nano-silver material and a preparation method and application thereof.The preparation method comprises the steps that under the dark condition, a silver nitrate solution with the concentration being 0.01 mol / L is added into a sucrose solution with the concentration being 0.1-0.5 mol / L, 3-5 mL of trioctylamine is dropwise added into the mixed solution, ultrasonic dispersion is conducted, and a milk white solution is formed; wherein the molar ratio of the cane sugar to the silver nitrate is (50-100): 1; and carrying out hydrothermal reaction on the milk white solution at 150-180 DEG C for 18 hours, and cooling to room temperature after drying to obtain the tremella-shaped carbon-coated nano-silver material. The tremella-shaped carbon-coated nano-silver material has the characteristics of low density, high void ratio, large specific surface area, uniform embedding of silver nanoparticles and the like, and has excellent application performance in the field of catalyzing selective oxidation of propylene to generate epoxypropane.

Owner:XIJING UNIV

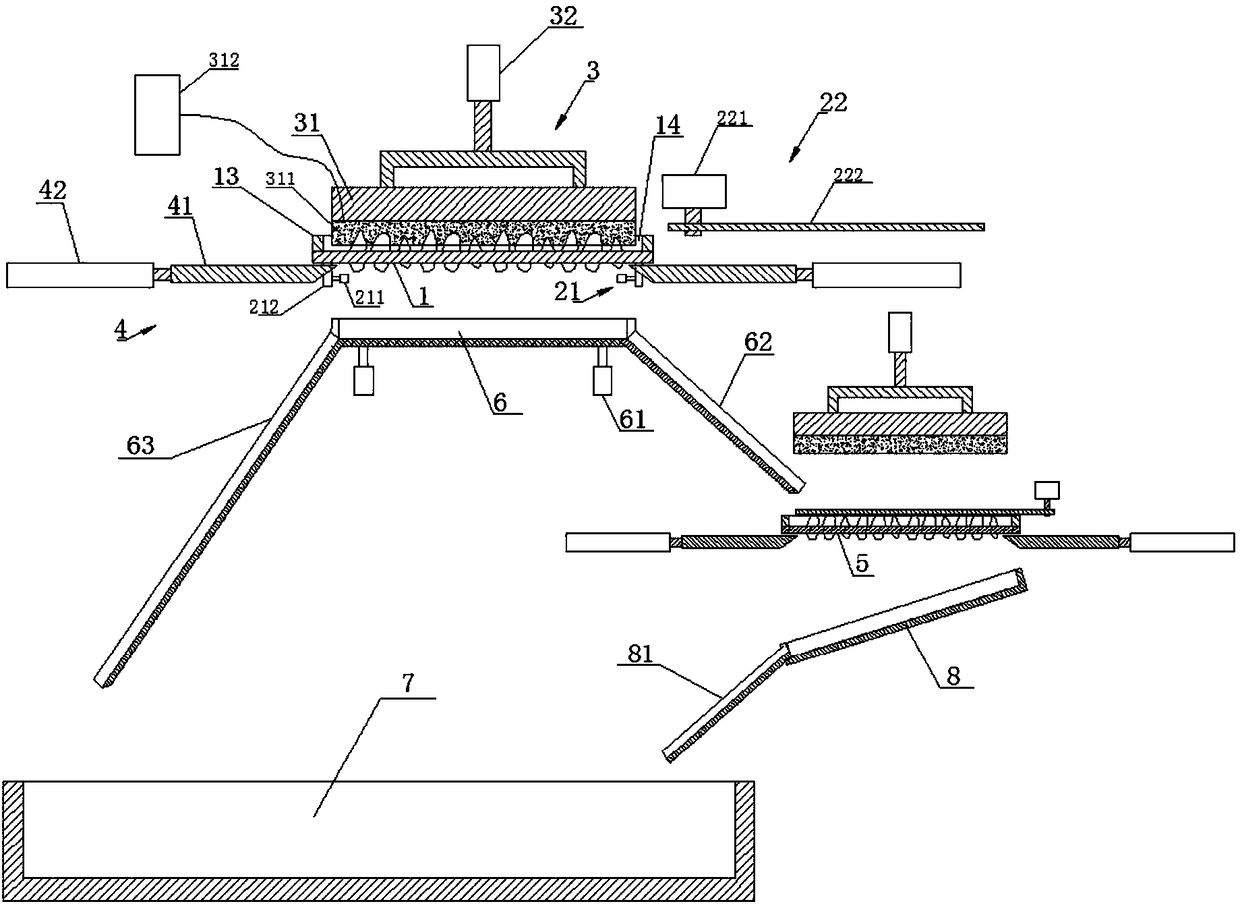

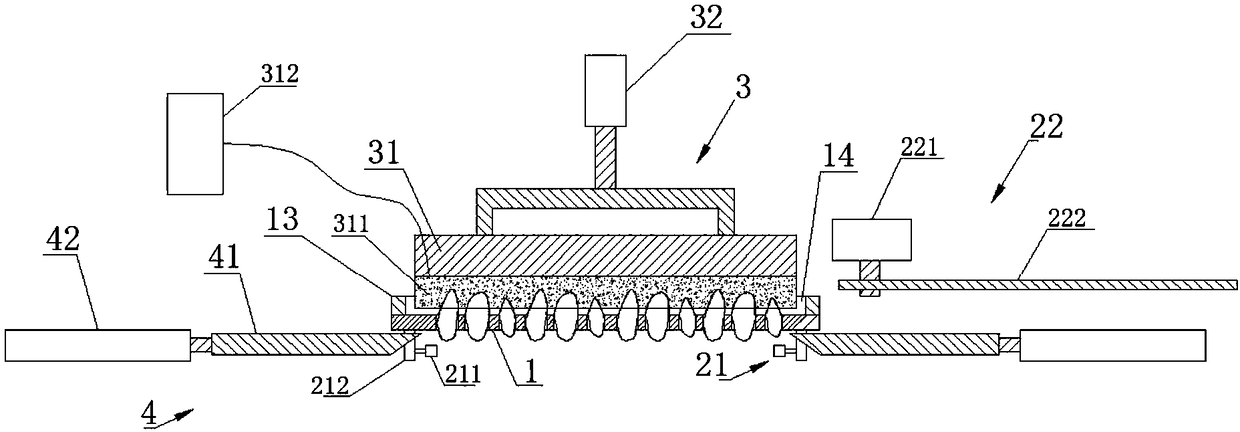

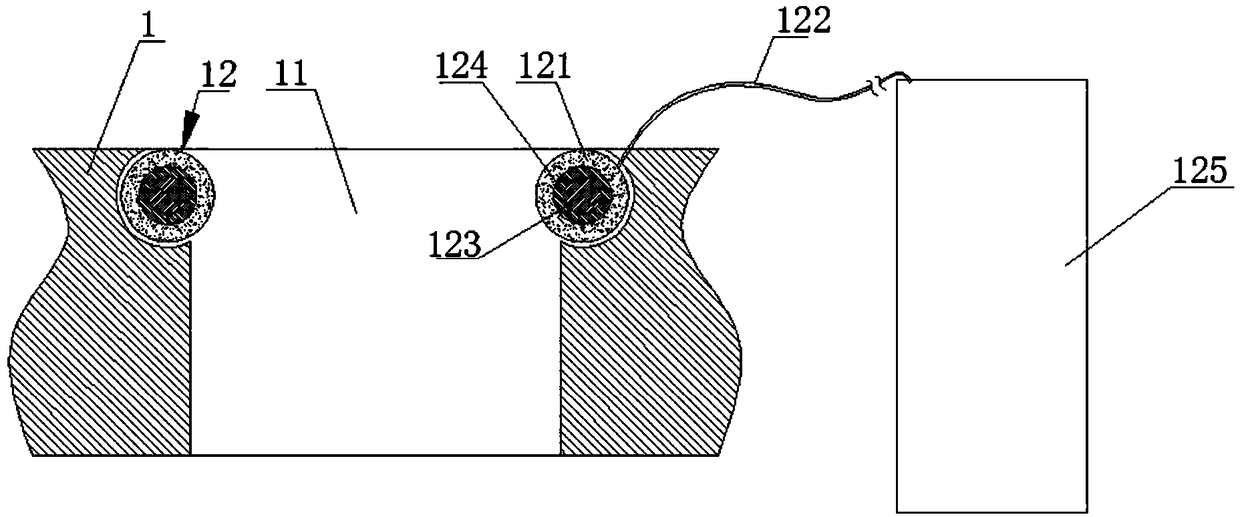

Halving device for cobblestones

ActiveCN106994747AReduce pollutionReduce processing costsWorking accessoriesStone-like material working toolsEngineeringMachining process

The invention relates to a halving device for cobblestones. The device comprises a first halving mechanism group; the first halving mechanism group comprises a first rigid mesh plate, a cobblestone pressing mechanism and a cobblestones folding mechanism; the first rigid mesh plate is arranged horizontally; the cobblestone pressing mechanism comprises an upper pressing plate arranged above the first rigid mesh plate and a first hydraulic device for driving the upper pressing plate to move vertically; the cobblestones folding mechanism comprises a cobblestones folding plate arranged below the first rigid mesh plate and a second hydraulic device for driving the cobblestones folding plate to move horizontally; and a corrosion ring is arranged at the upper part of each mesh of the first rigid mesh plate along the circumference and comprises a circular chitosan gelatin sponge, a capillary for communicating the chitosan gelatin sponge with a strong alkaline solution storage tank as well as an electrostriction ring penetrates through the middle of the chitosan gelatin sponge along the circumference of the chitosan gelatin sponge. With the device, the cobblestones can be halved effectively, the machining cost is low, the machining process is table, little dust pollution exists, and the automation degree is high.

Owner:福州高科新技术开发有限公司

A kind of porous metal oxide particle and preparation method thereof

ActiveCN109573952BEasy reunionAchieve ultra-fineOxygen/ozone/oxide/hydroxideIron oxides/hydroxidesFiberCarbon fibers

The invention relates to a porous metal oxide particle and a preparation method thereof and belongs to the technical field of metal powder. The preparation method of the porous metal oxide particle comprises degumming short carbon fiber, performing an appropriate ball-milling process on the degummed short carbon fiber and metal powder to obtain ultrafine carbon particle embedded metal powder; performing annealing treatment in an oxidizing atmosphere to obtain surface oxidation controllable porous metal powder. The prepared porous metal oxide particle is high in oil storage, hydrogen storage, paraffin storage and lithium storage performance as well as catalytic performance; meanwhile, the preparation method of the porous metal oxide particle is simple in process and low in cost.

Owner:CENT SOUTH UNIV

A device for breaking pebbles into half

ActiveCN106994747BReduce pollutionReduce processing costsWorking accessoriesStone-like material working toolsGelatin spongeEngineering

The invention relates to a halving device for cobblestones. The device comprises a first halving mechanism group; the first halving mechanism group comprises a first rigid mesh plate, a cobblestone pressing mechanism and a cobblestones folding mechanism; the first rigid mesh plate is arranged horizontally; the cobblestone pressing mechanism comprises an upper pressing plate arranged above the first rigid mesh plate and a first hydraulic device for driving the upper pressing plate to move vertically; the cobblestones folding mechanism comprises a cobblestones folding plate arranged below the first rigid mesh plate and a second hydraulic device for driving the cobblestones folding plate to move horizontally; and a corrosion ring is arranged at the upper part of each mesh of the first rigid mesh plate along the circumference and comprises a circular chitosan gelatin sponge, a capillary for communicating the chitosan gelatin sponge with a strong alkaline solution storage tank as well as an electrostriction ring penetrates through the middle of the chitosan gelatin sponge along the circumference of the chitosan gelatin sponge. With the device, the cobblestones can be halved effectively, the machining cost is low, the machining process is table, little dust pollution exists, and the automation degree is high.

Owner:福州高科新技术开发有限公司

Composite powder of metal-metal carbide coated carbon particles and preparation method thereof

ActiveCN109570493BImprove heat resistanceEvenly embeddedPhysical treatmentCarbon fibresFiberCarbon fibers

The invention relates to a metal-metal carbide-coated carbon particle composite powder and a preparation method thereof, belonging to the technical field of metal powder. The metal-metal carbide coated carbon particles include a metal layer, a metal carbide layer, and carbon particles; the metal carbide layer is coated on the surface of the carbon particles; the metal layer is coated on the surface of the metal carbide layer; The composite powder uses ultra-fine carbon particles and matrix metal powder as raw materials, and through mechanical force, the ultra-fine carbon particles penetrate and / or embed in the matrix metal powder; and then obtain a metal carbide layer by in-situ carbonization. The preparation method is as follows: : Firstly, through mechanical ball milling of degummed short carbon fibers and metal powder, a large number of ultra-fine carbon particles are evenly embedded in metal powder, and then separated and annealed at high temperature to make the carbon particles react with the surrounding metal in a solid state, and obtain a uniform coating on the surface of the carbon particles. Metal-carbon particle composite powders coated with metal carbides.

Owner:CENT SOUTH UNIV

Active element uniformly-doped thin film electrode and preparation method thereof

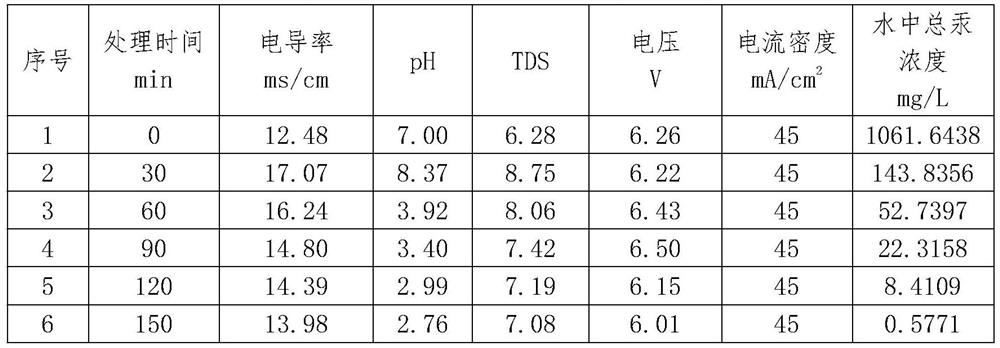

ActiveCN112607831AEvenly embeddedExtended service lifeWater contaminantsWater/sewage treatmentRheniumThin film electrode

The invention provides an active element uniformly-doped thin film electrode and a manufacturing method thereof. The active element uniformly-doped thin film electrode comprises a substrate and a surface composite powder thin film of the substrate, the surface composite powder film is uniformly doped with active elements and carbon-based material micro powder, and the active elements comprise noble metal particles, an organic diboron compound and rhenium particles; the mass fraction of noble metal particles in the surface composite powder film is 0.1%-30%, the mass fraction of rhenium particles is 0.1%-10%, the mass fraction of an organic diboron compound is 0.1%-15%, and the balance is carbon-based material micro powder; and the substrate is an inert metal plate. The active elements such as noble metal elements and boron elements are uniformly dispersed in a film of the carbon-based electrode, the electro-catalytic performance of a traditional doped carbon-based film electrode is improved by controlling the components of the composite powder, and the composite electrode with high electro-catalytic performance is prepared; meanwhile, due to the addition of noble metal elements, the degradation effect on toxic and refractory organic matters is guaranteed, and the removal effect on heavy metal sewage containing mercury and the like is enhanced.

Owner:江苏羟源环能科技有限公司

Method for preparing silicon-carbon negative electrode of lithium battery through mechanical compounding without firing

InactiveCN112420992AImprove composite effectImprove wettabilityElectrode carriers/collectorsNegative electrodesElectrolytic agentActive agent

The invention provides a method for preparing a silicon-carbon negative electrode of a lithium battery through mechanical compounding without firing and a product thereof. The method comprises the following steps: ball-milling silicon powder and carbon powder; then subjecting the treated silicon powder and carbon powder to mixing and ball-milling with raw materials such as SBR styrene-butadiene latex, silicate minerals and a conductive filler to form a slurry mixture; mixing the slurry mixture with a surfactant to form composite slurry coated with silicon-carbon mixed powder; sufficiently impregnating the obtained composite slurry with conductive foamed plastic; and finally, curing the composite slurry at room temperature to form a carrier-loaded silicon / carbon negative pole piece with a foam structure. The method can realize curing at normal temperature; preparation process is simple; a physical confinement can be formed for the silicon-carbon negative electrode material; and the compounding capacity of silicon / carbon powder is improved. In addition, a certain amount of the styrene-butadiene latex is doped into the composite slurry, so an active material and a conductive agent canbe uniformly embedded into the foamed plastic, and a conductive channel is fully and effectively formed; and the specific surface area of the negative electrode material is large, an electrolyte andthe negative electrode material can be fully infiltrated, and the cycle performance of the battery is effectively improved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

A kind of preparation method and application of non-metal doped stainless steel mesh composite material

ActiveCN110090656BHigh temperature resistantHas acid and alkali resistancePhysical/chemical process catalystsWater contaminantsO-Phosphoric AcidLithium chloride

Owner:HEFEI UNIV OF TECH

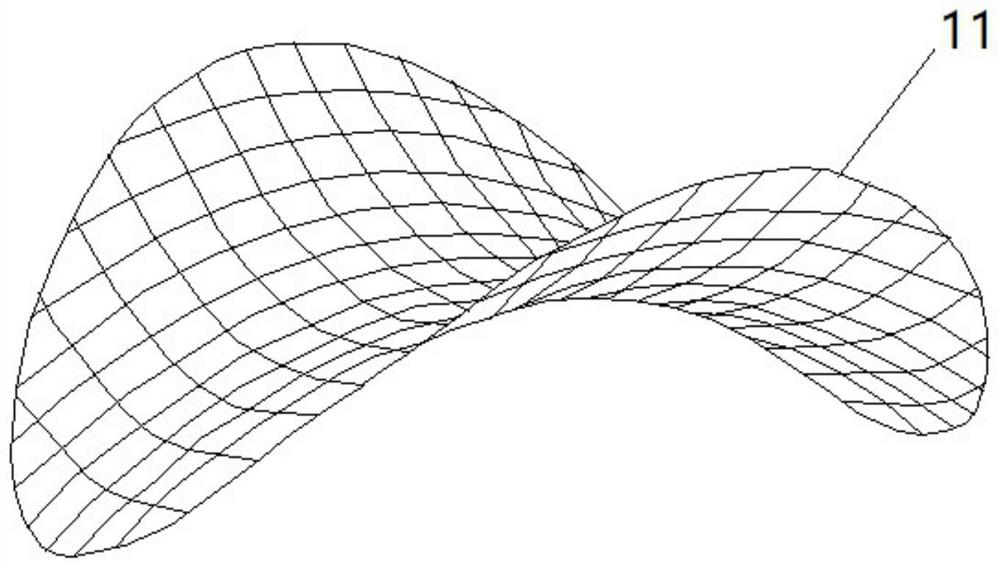

Plastic sheet embedded particle composite electrode and preparation method thereof

InactiveCN113896296APrevent crushingNot easy to fall offWater/sewage treatmentSustainable biological treatmentComposite electrodePlastic materials

The invention discloses a plastic sheet embedded particle composite electrode and a preparation method thereof. The plastic sheet embedded particle composite electrode is used for suspending in a reactor of a three-dimensional electrode, and comprises a plastic sheet playing a mounting and supporting role, wherein the plastic sheet is prepared from a plastic material and is a spatial curved surface sheet with a spatial curved surface, scattered and granular particles are embedded in the surface of the plastic sheet, the particles are used for mass transfer after being in contact with wastewater in a reactor, and the particles are connected with the plastic sheet to form a composite particle electrode. According to the plastic sheet embedded particle composite electrode, the plastic sheet is made of the plastic material, the resistance is high, the supporting effect of the plastic sheet on the particles is beneficial for preventing the particles embedded in the particles from being smashed due to pressure friction, and the particles are stably embedded in the plastic sheet; and the particles are mutually dispersed and insulated, so that each particle can fully exert the efficiency of the microbattery, the short-circuit current is greatly reduced, the current efficiency is improved, and the mass transfer and wastewater treatment effects are improved.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

A kind of method of powder metallurgy in-situ synthesis al-cu alloy

The invention discloses a method for synthesizing Al-Cu alloy in situ by powder metallurgy. The method comprises the following steps: firstly, obtaining a microscopic structure that copper nanoparticles are uniformly deposited on aluminum powder by an impregnation method, performing ball-milling for a relatively short time, uniformly dispersing copper and embedding dispersed copper into the aluminum powder; secondly, densifying the powder by a cold-pressing sintering or vacuum hot-pressing method to obtain a block material; finally, performing hot extrusion forming to obtain the Al-Cu alloy material. The method has the advantages that the Al-Cu alloy material is prepared by the method, and the mechanical property of the alloy material is superior to that of other powder metallurgy aluminum alloy material. Meanwhile, the method also can be popularized and applied to other metal powder so as to prepare different matrix alloy materials. Therefore, the method has a wide industrial application prospect.

Owner:TIANJIN UNIV

A preparation method of manganese-doped zinc sulfide quantum dot embedded fluorescent composite film

ActiveCN109652057BEvenly embeddedEasy to prepareMaterial nanotechnologyNanoopticsFluorescencePolymethyl methacrylate

The invention relates to a method for preparing a manganese-doped zinc sulfide quantum dot embedded fluorescent composite film, which comprises the following steps: sequentially combining manganese-doped zinc sulfide fluorescent quantum dots, a film-forming monomer, a cross-linking agent and an initiator Dissolved in a solvent, ultrasonically dispersed and stirred to make a casting solution; at room temperature, the casting solution is evenly spread on the matrix material, covered with polymethyl methacrylate, and heated in a water bath under pressure to initiate polymerization; polymerization Afterwards, the membrane is placed in a hydrofluoric acid solution to etch and remove the matrix material to obtain a fluorescent quantum dot embedded composite membrane. The method of the present invention is easy to synthesize, has strong fluorescent performance, low biological toxicity and can be reused. The embedded composite film has the advantages of good transparency, stable fluorescence, high mechanical strength and good self-cleaning ability, and can be used in optical sensing, biochemical It has great application potential in food analysis, water pollution, food analysis and environmental protection.

Owner:合肥九州龙腾科技成果转化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com