Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Achieve ultra-fine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of Al-Cu-Mg-Ag ultrafine crystal heat-resistant aluminum alloy

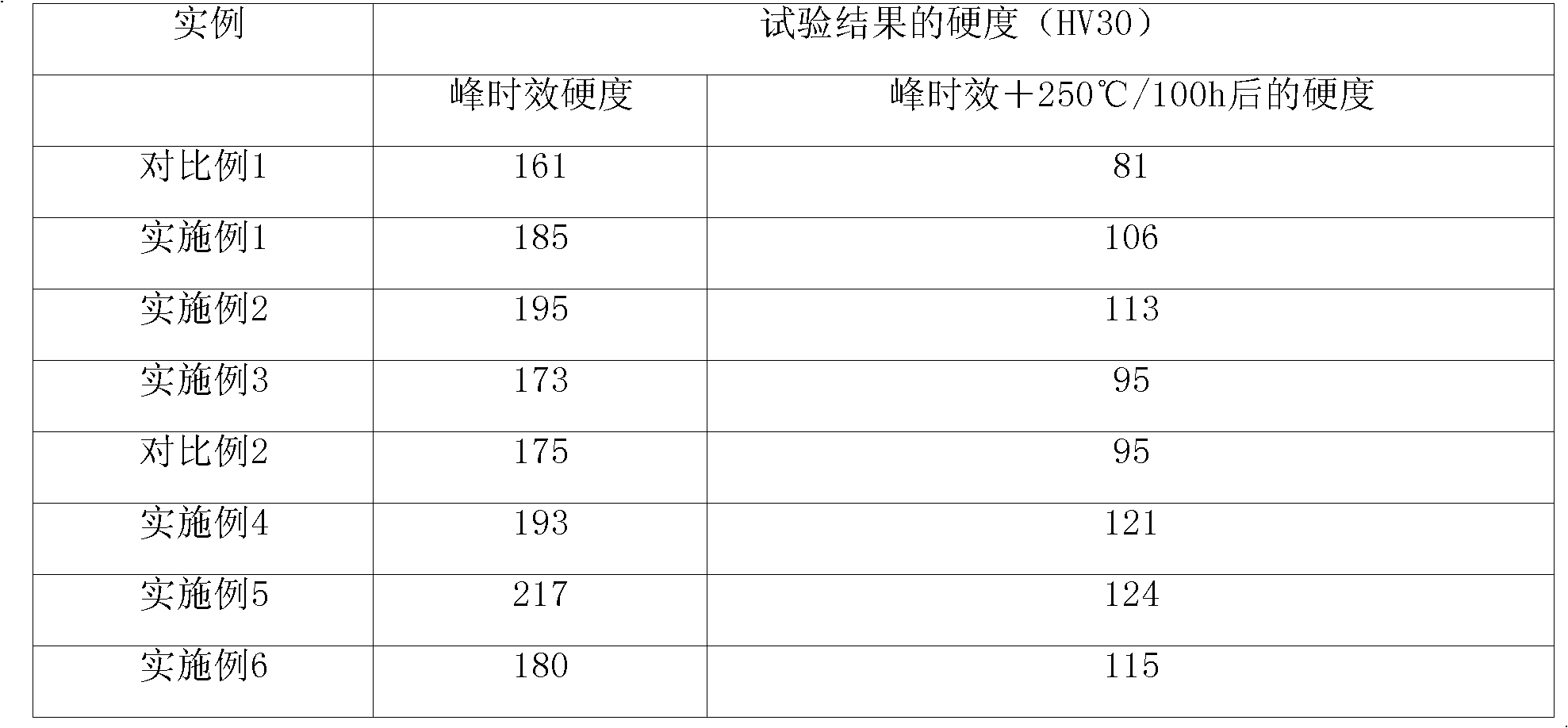

The invention provides a preparation method of an Al-Cu-Mg-Ag ultrafine crystal heat-resistant aluminum alloy, comprising the following steps: hot extrusion, solid solution hardening, equal channel angular pressing and ageing treatment, thus finally improving the heat resistance of Al-Cu-Mg-Ag alloy. The specific steps are as follows: homogenizing annealing of the as-cast aluminum alloy, hot extrusion with the extrusion ratio of 8-15, multi-pass equal channel angular heat extruding deformation at the temperature of 350-430 DEG C, solution treatment, hardening in water at a room temperature, and then ageing treatment at the temperature of 150-210 DEG C; or solution treatment of the alloy in a hot extrusion state, hardening in water at the room temperature, multi-pass equal channel angular heat extruding deformation at the room temperature and then ageing treatment. The process method of the invention can improve the heat resistance of the Al-Cu-Mg-Ag alloy and enlarge the application range of the aluminum alloy on the basis of the existing alloy. The preparation method of the invention has simple process and convenient operation, and can effectively refine crystal particles of the Al-Cu-Mg-Ag alloy, improve the density of a precipitated and strengthened phase, enhance the overall strength and the high-temperature heat resistance of the Al-Cu-Mg-Ag alloy, and achieve industrialized production and application.

Owner:CENT SOUTH UNIV

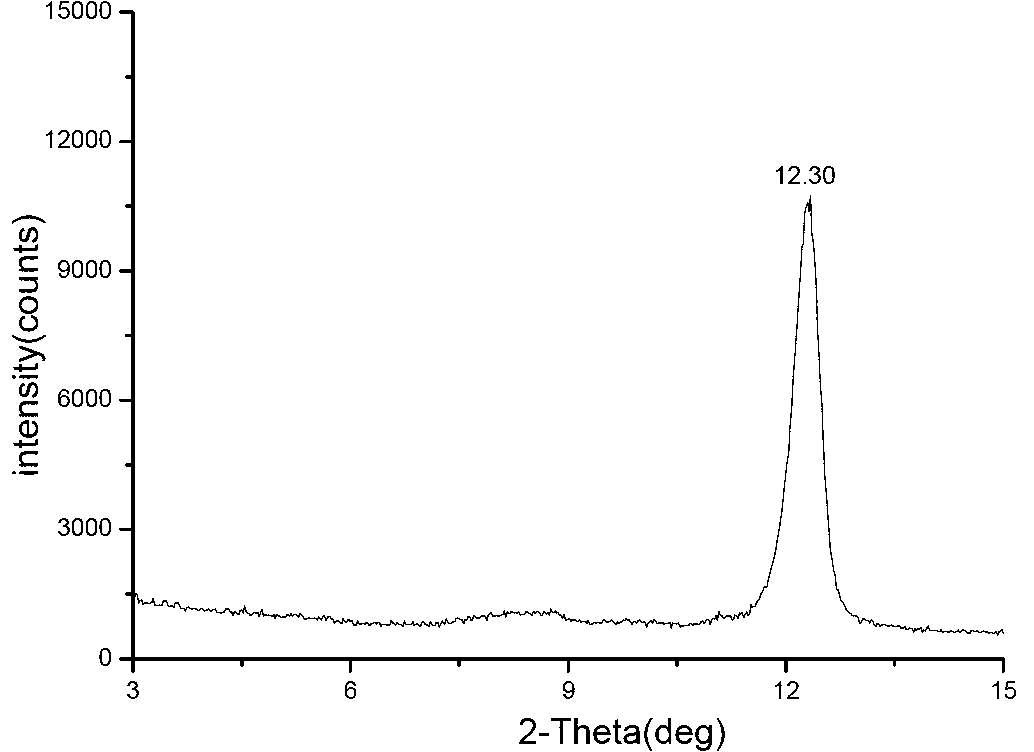

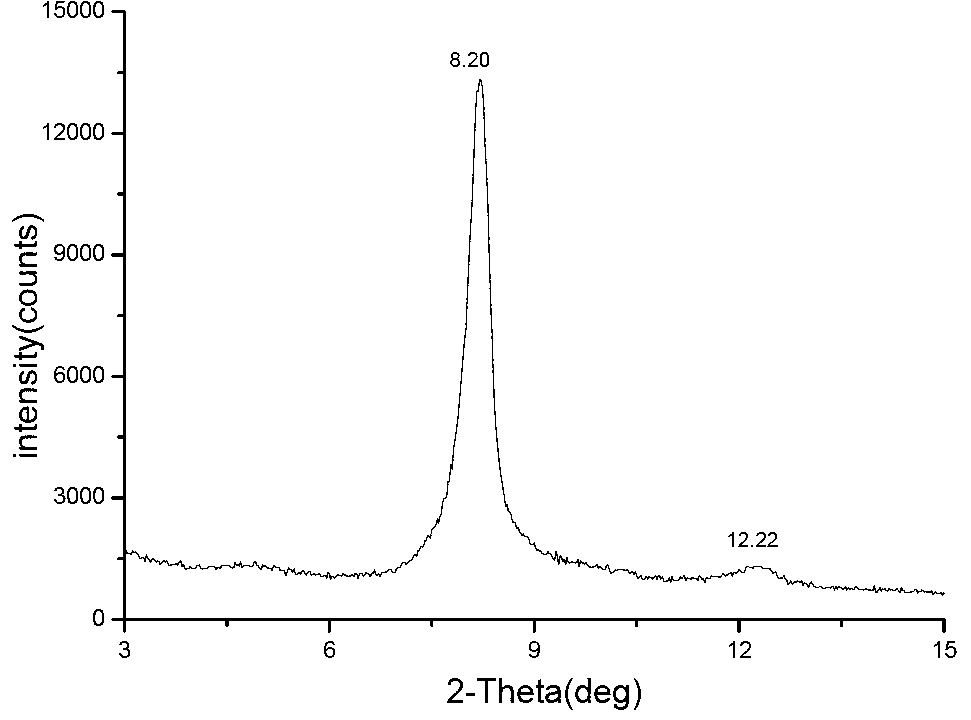

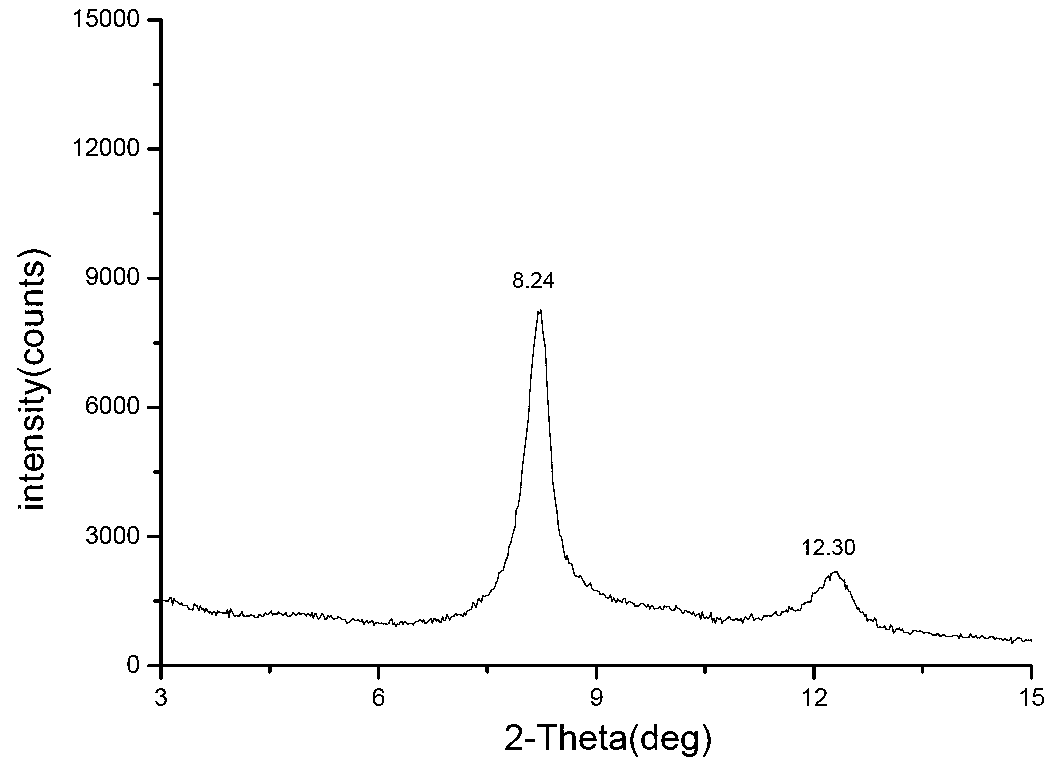

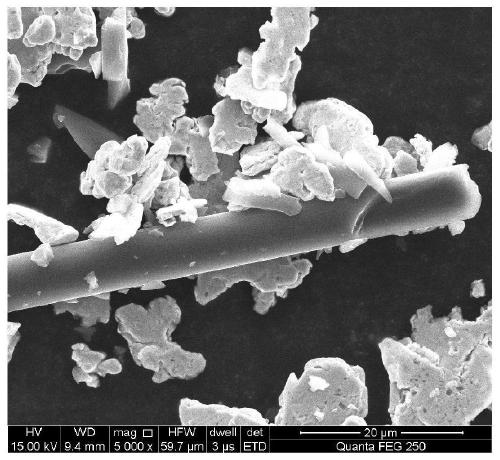

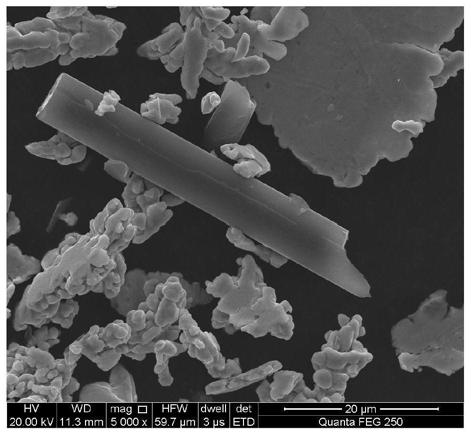

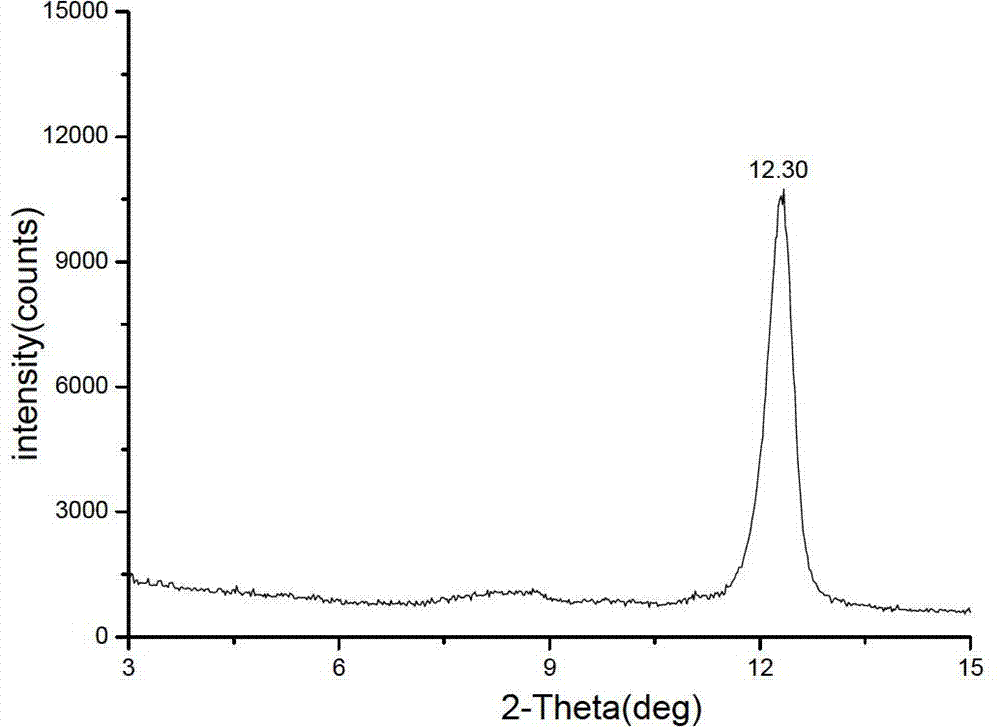

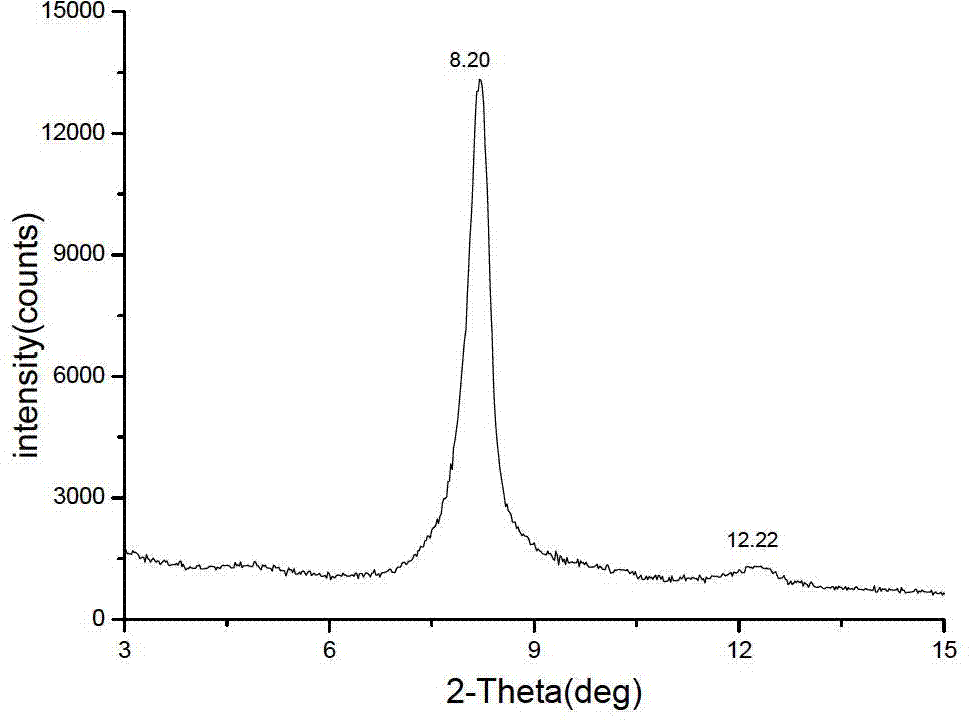

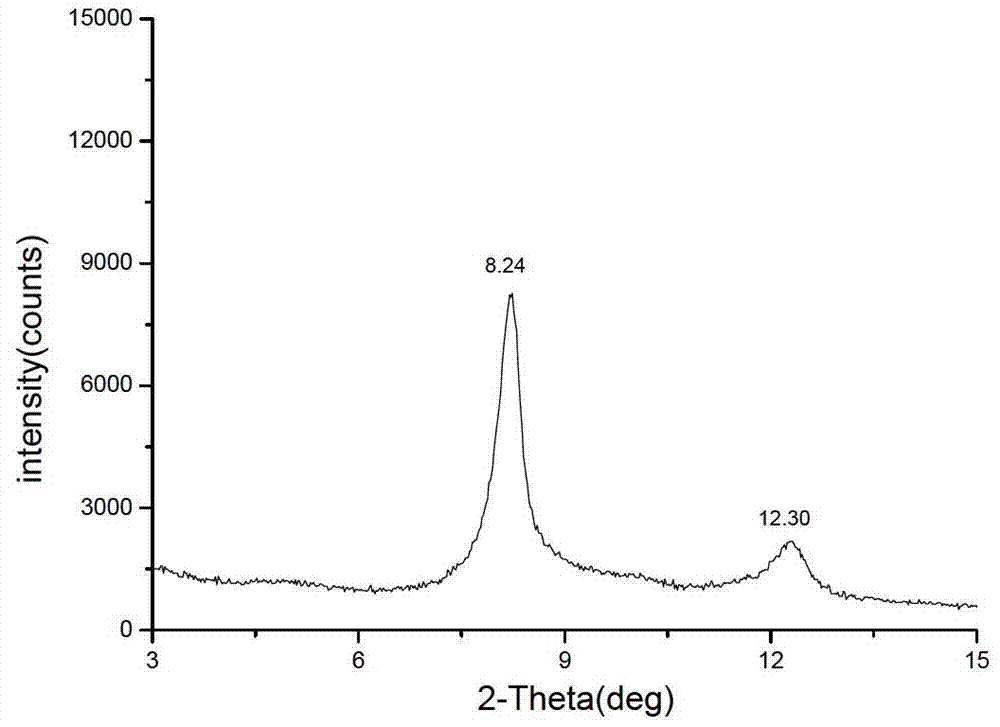

Preparation method of superfine modified kaolin

The invention relates to a preparation method of superfine modified kaolin, which is characterized in that the preparation method comprises the following steps that (1), kaolin powder and carbamide are uniformly mixed in an open container, and fully absorb moisture in air to form a mixture; (2), the mixture is heated, and reacts at 70-120 DEG C; a kaolin-carbamide intercalation compound is prepared; an intercalation rate is 80%-98%; (3), the compound is placed into a ball mill; a certain amount of dispersing agent and water is added; wet grinding is conducted; the content of ground kaolin with a particle size less than 2 micrometers is above 90%; a kaolin mud cake is obtained through suction filtration and dehydration; (4) a certain amount of silane coupling agent and water is added into the kaolin mud cake, and stirred at 50-80 DEG C; a coupling reaction happens; the modification is achieved; and (5) the modified kaolin is dried, and the finished superfine modified kaolin is prepared. According to the preparation method, the intercalation rate is high; the influence on a crystal structure of the kaolin is small; a peeling effect is good; and the prepared superfine modified kaolin is particularly applicable to rubber and plastic materials and oil paint.

Owner:中国高岭土有限公司

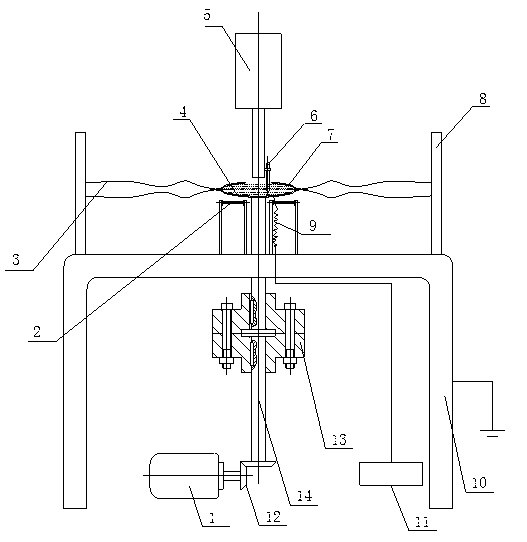

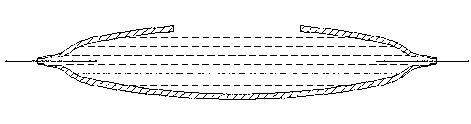

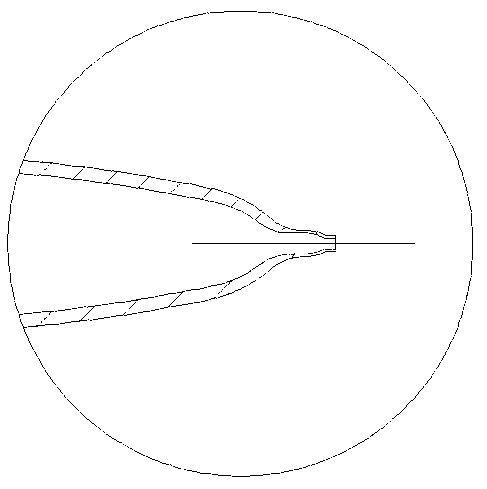

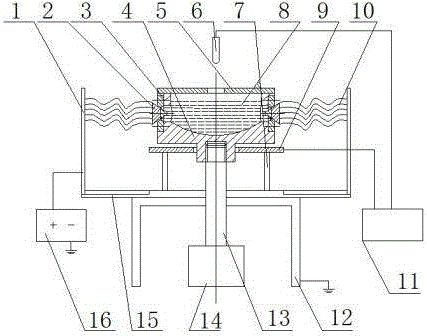

Centrifugal electrostatic spinning device

The invention discloses a centrifugal electrostatic spinning device. The centrifugal electrostatic spinning device mainly comprises a high voltage electrostatic generator, a spinning component, a feeding component, a temperature measurement component and a receiving component, wherein the high voltage electrostatic generator is connected with the spinning component through a spring. The spinning component is composed of a motor, a drive device, a coupling, a rotating shaft and a liquid storage groove, and heated in an infrared mode. The feeding component is a small extruder and mainly provides polymer liquid for the liquid storage groove. The temperature measurement component is a thermocouple which is directly inserted into the liquid storage groove. The receiving component is a receiving net arranged on the periphery of the spinning component. The centrifugal electrostatic spinning device has the advantages that ultrafine of electrostatic spinning polyester fibers by a combined action of centrifugal force and electrostatic force is utilized, efficiency of electrostatic spinning is greatly improved, and mass production of the electrostatic spinning is promoted to achieve.

Owner:BEIJING UNIV OF CHEM TECH

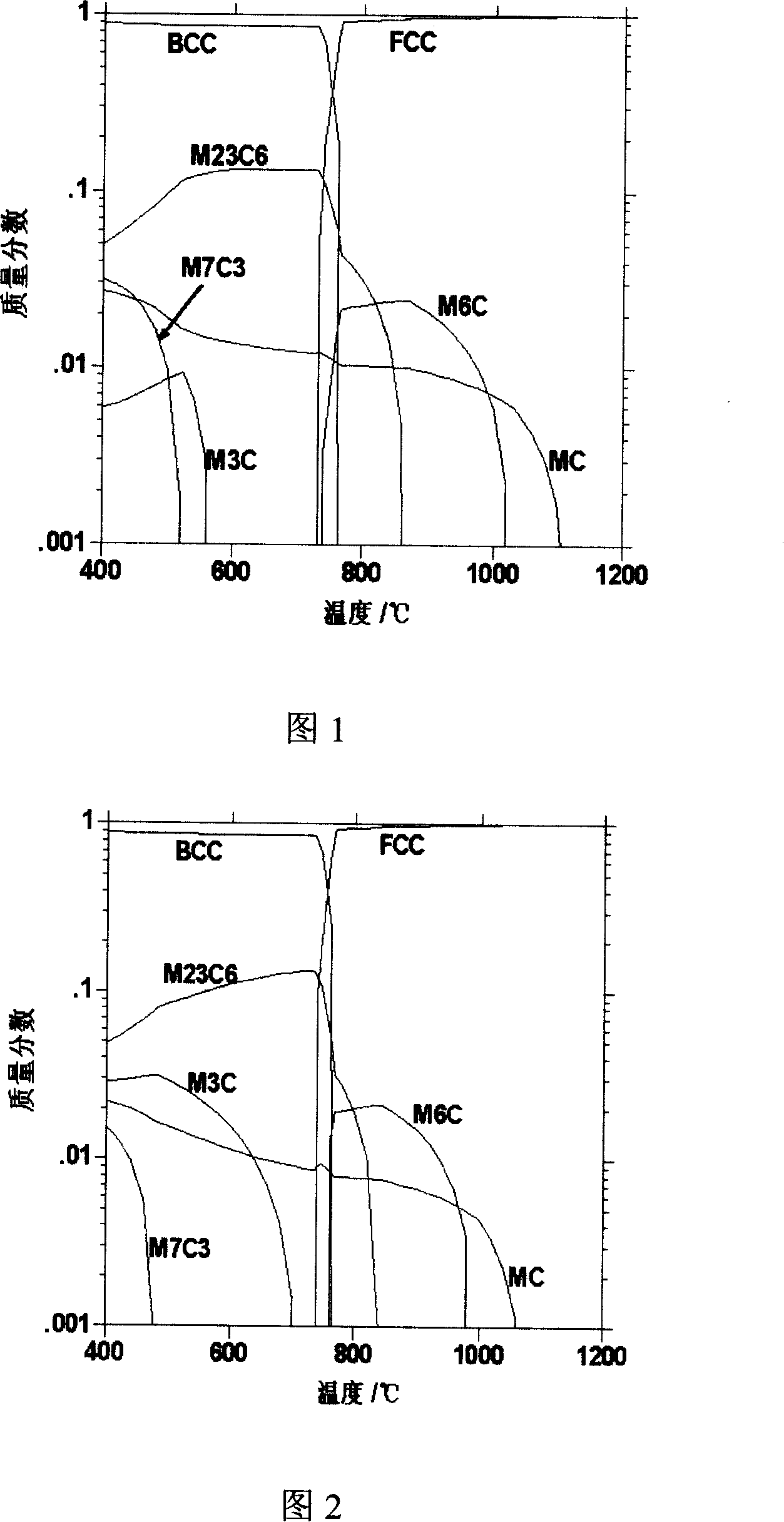

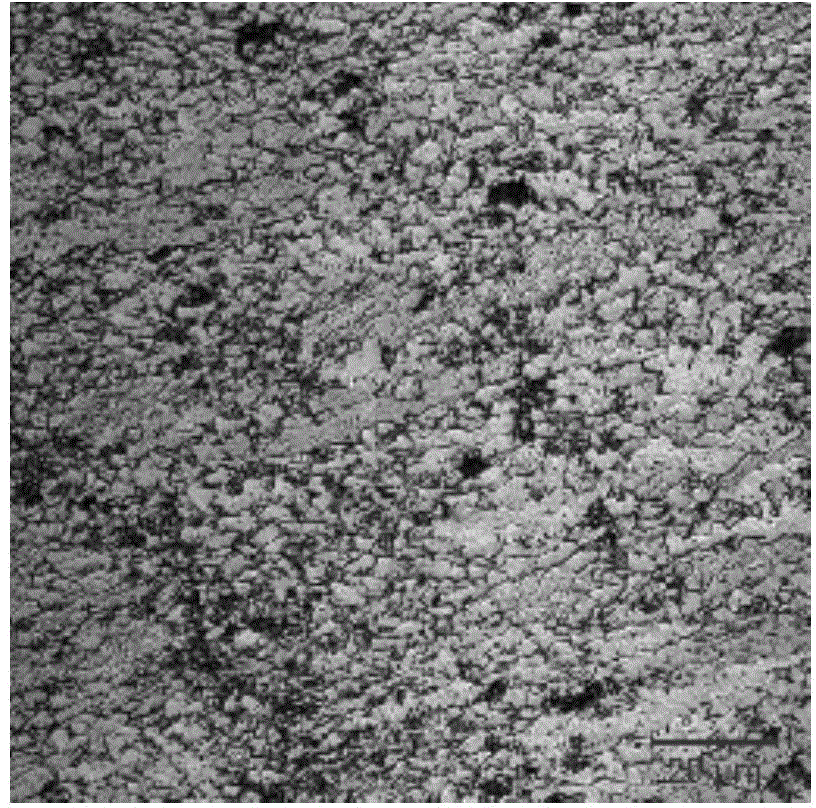

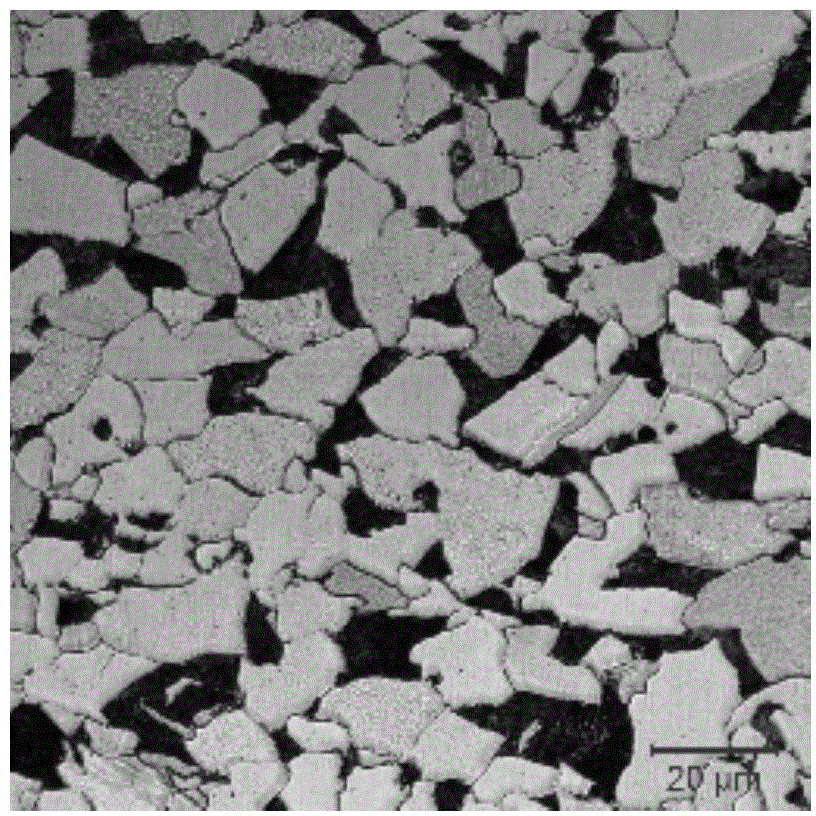

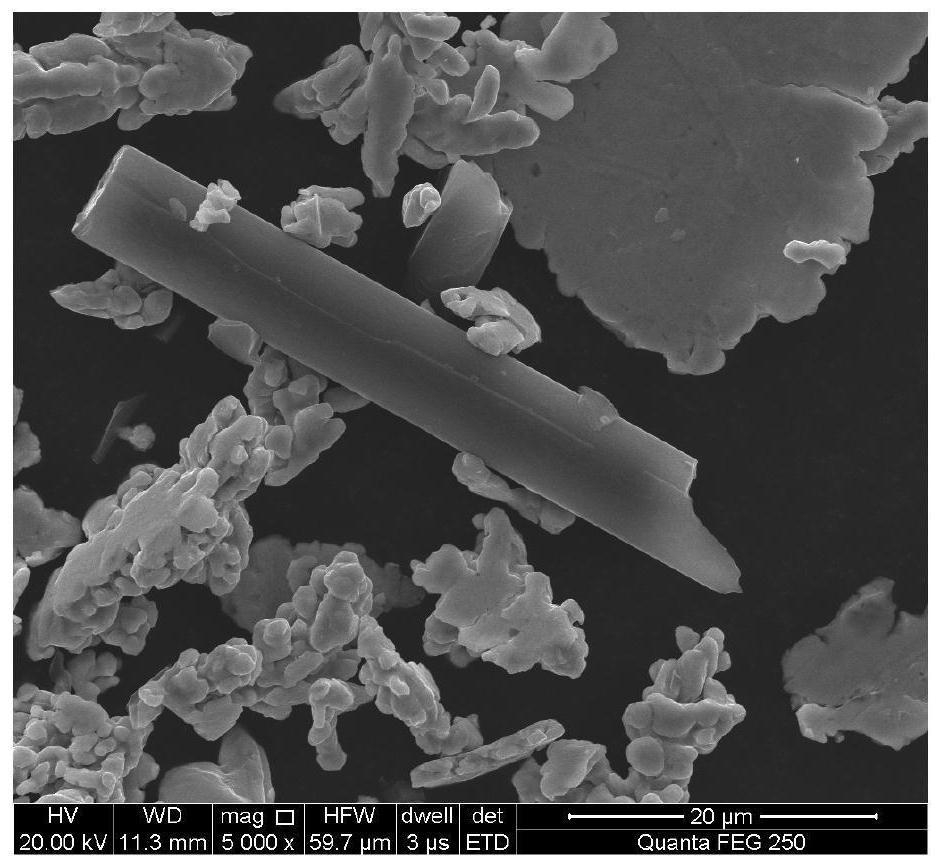

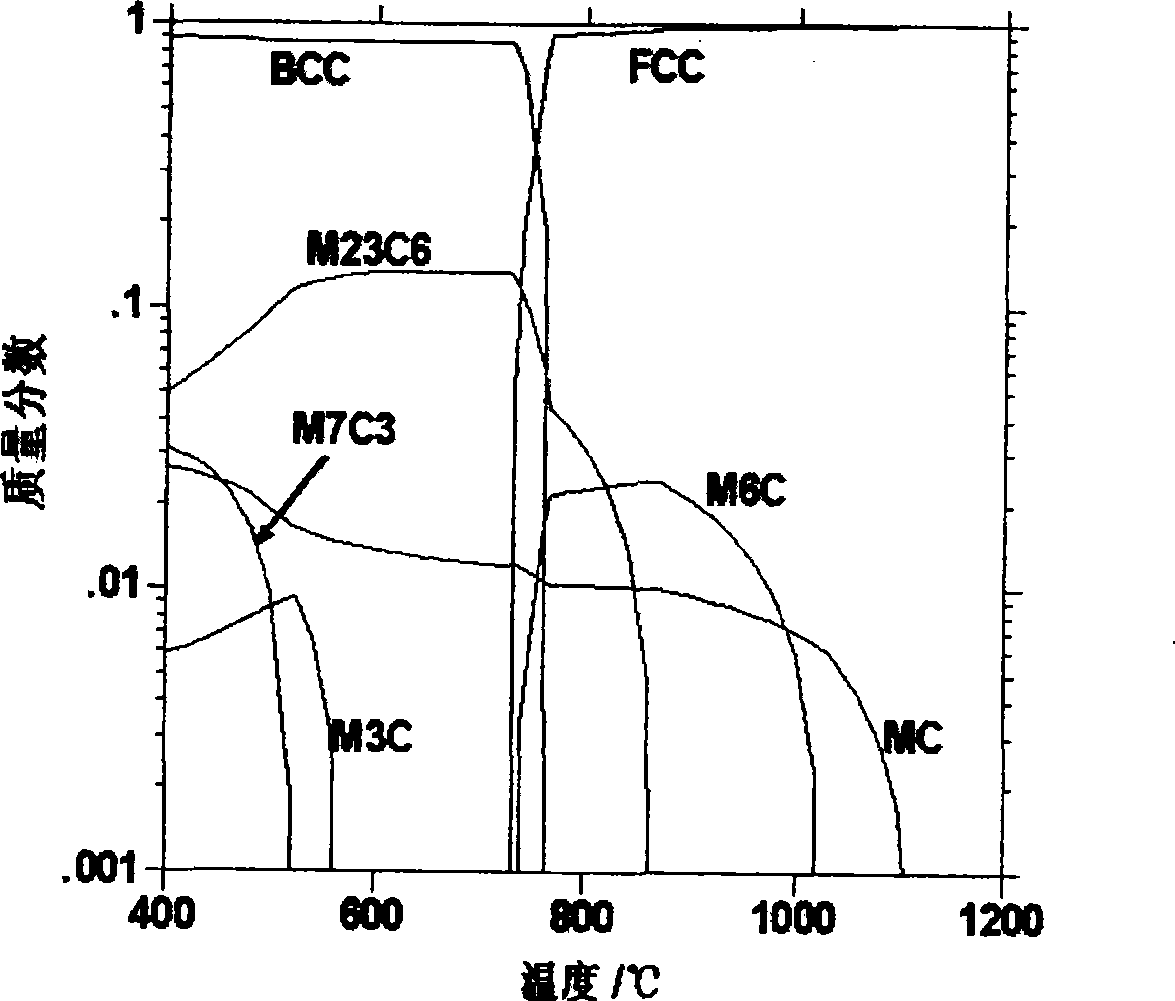

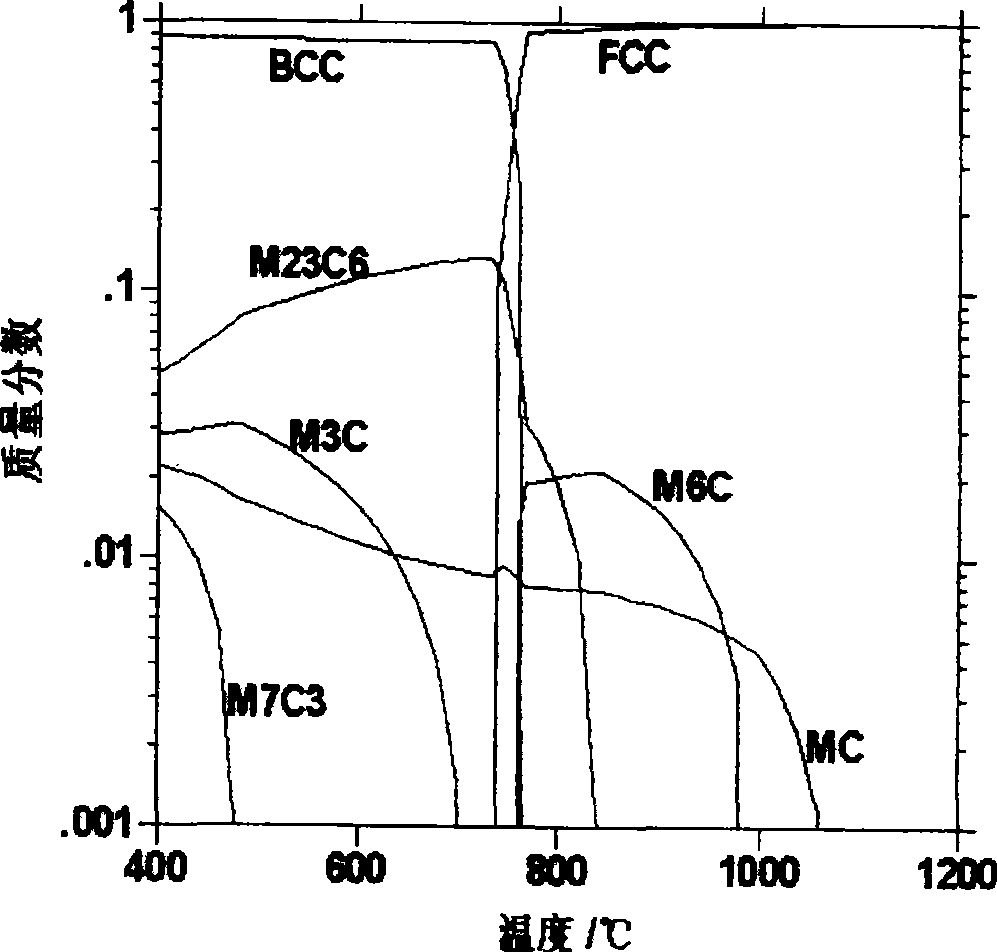

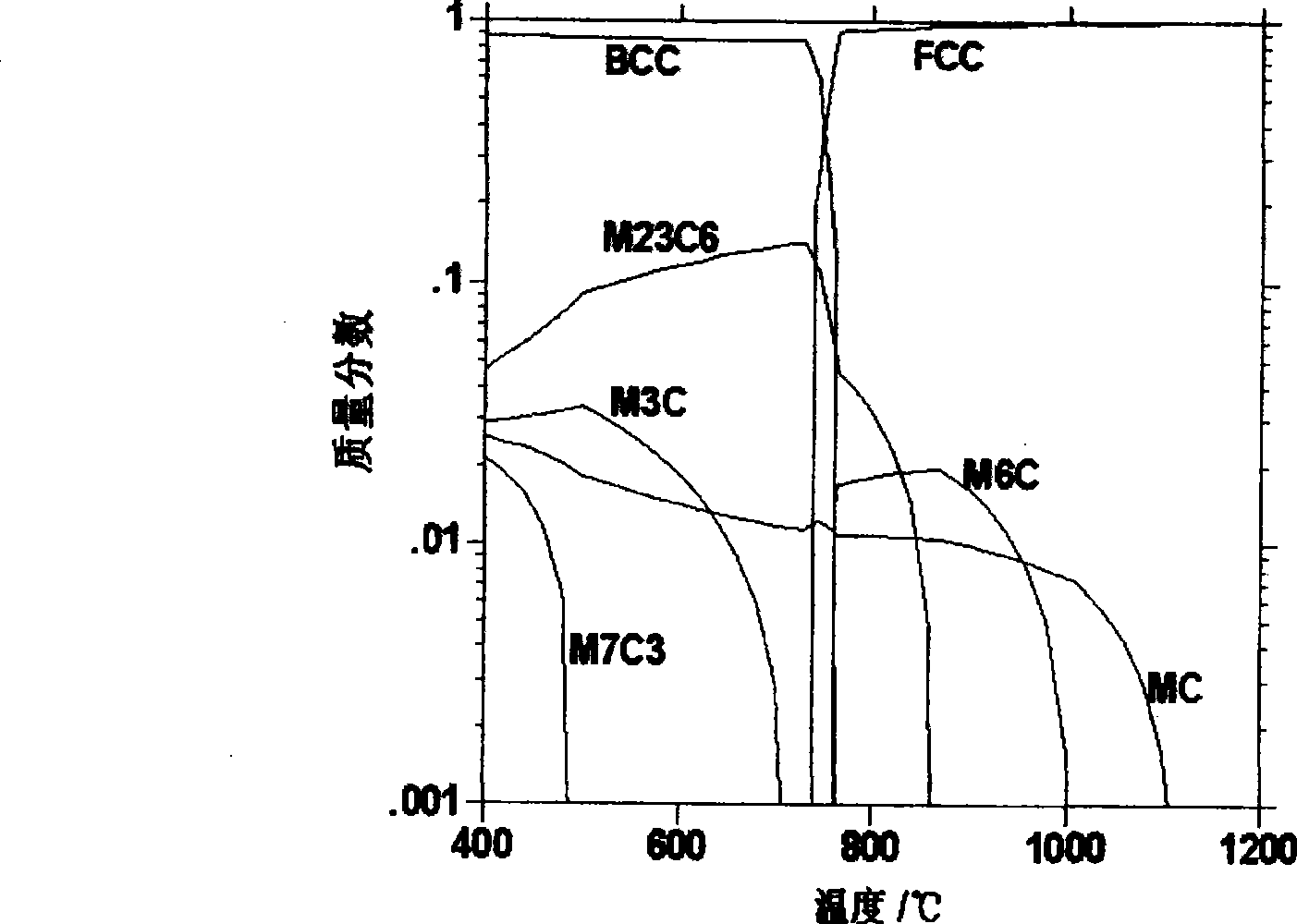

Alloy tool steel in multi-type super-fine carbonates

InactiveCN101070580AHigh hardnessImprove wear resistanceHeat treatment process controlHigh carbonQuenching

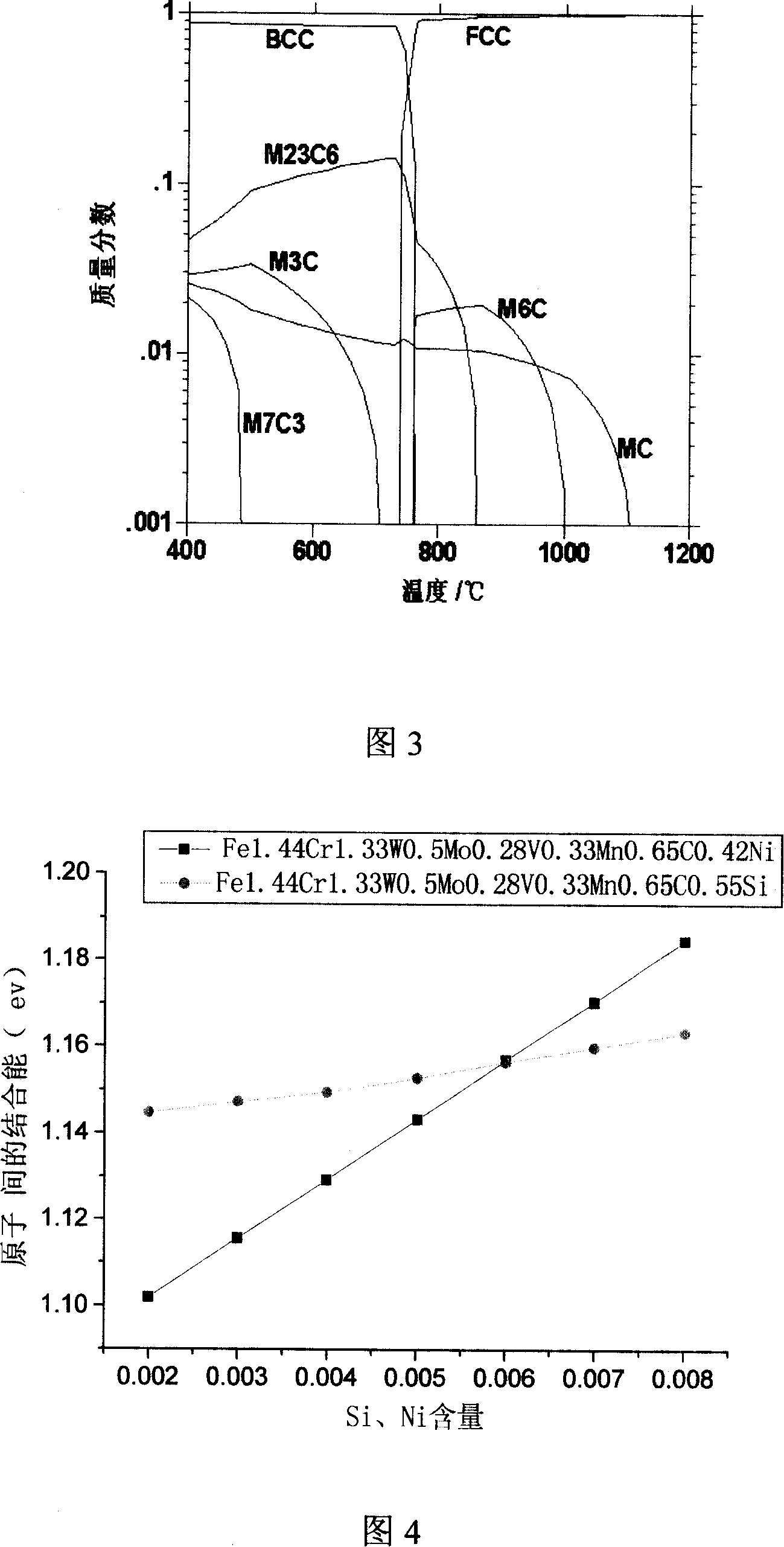

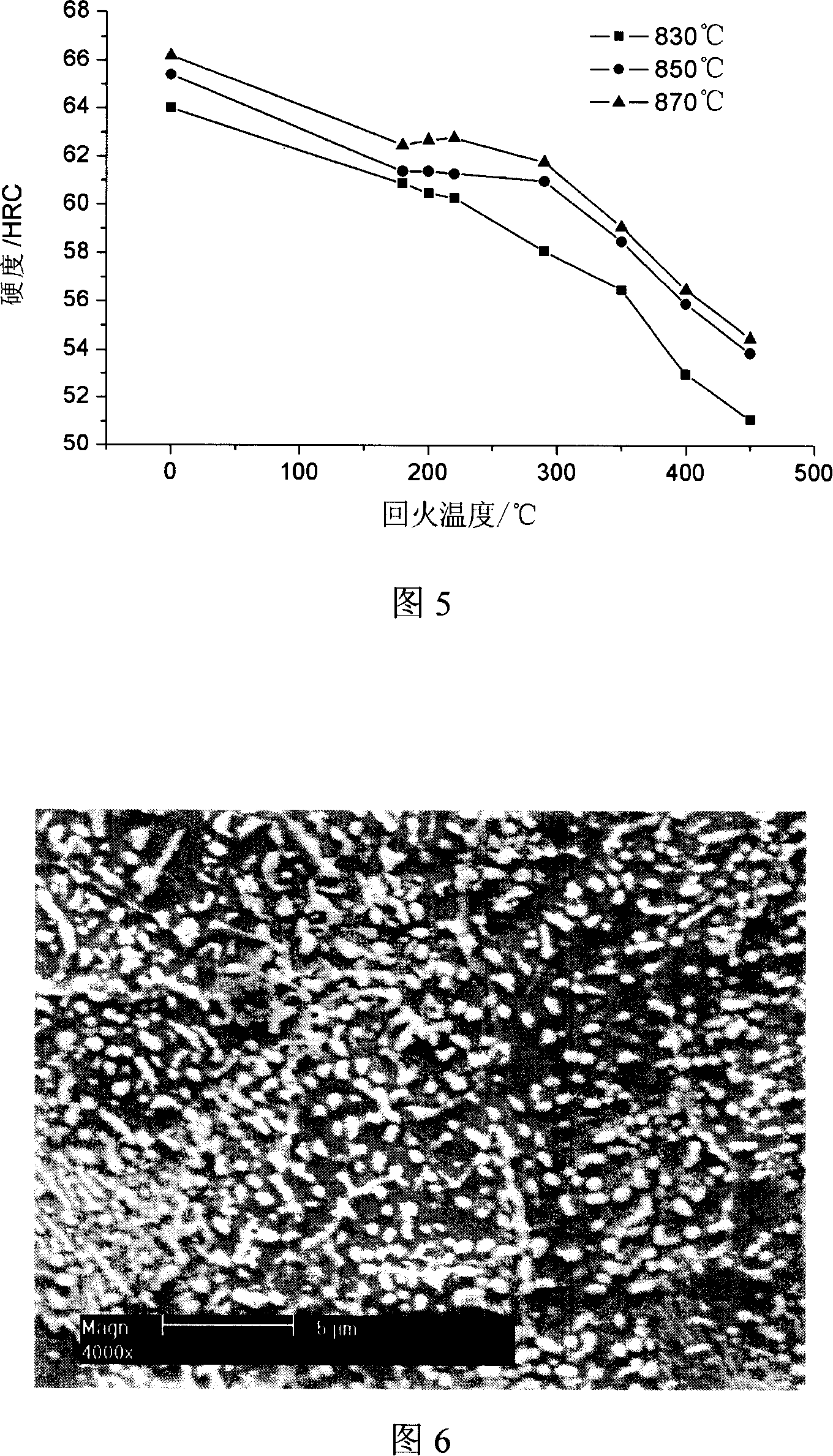

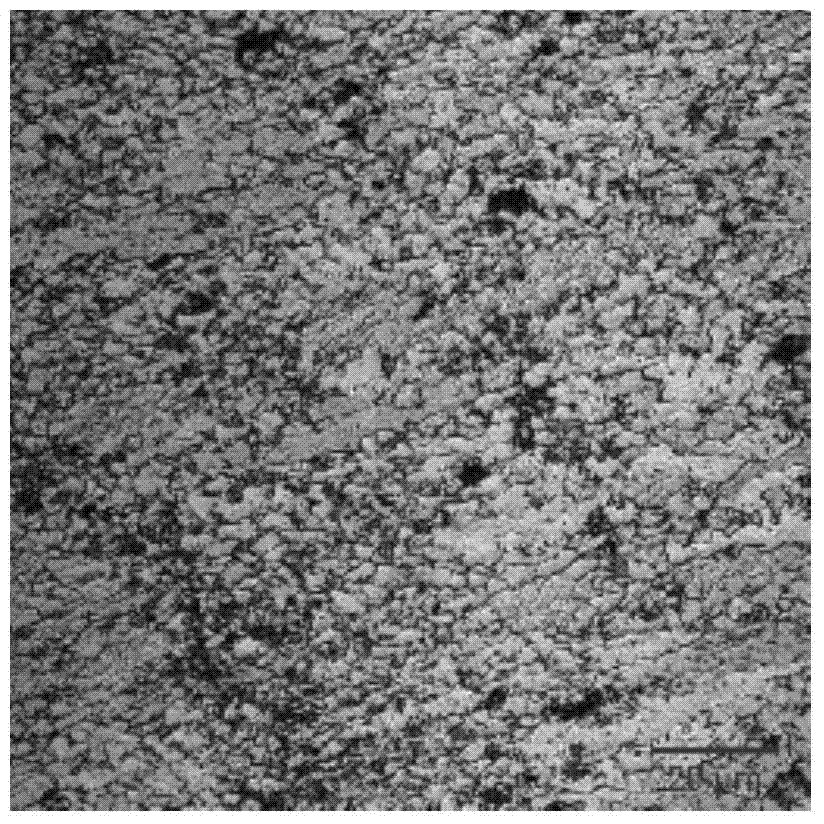

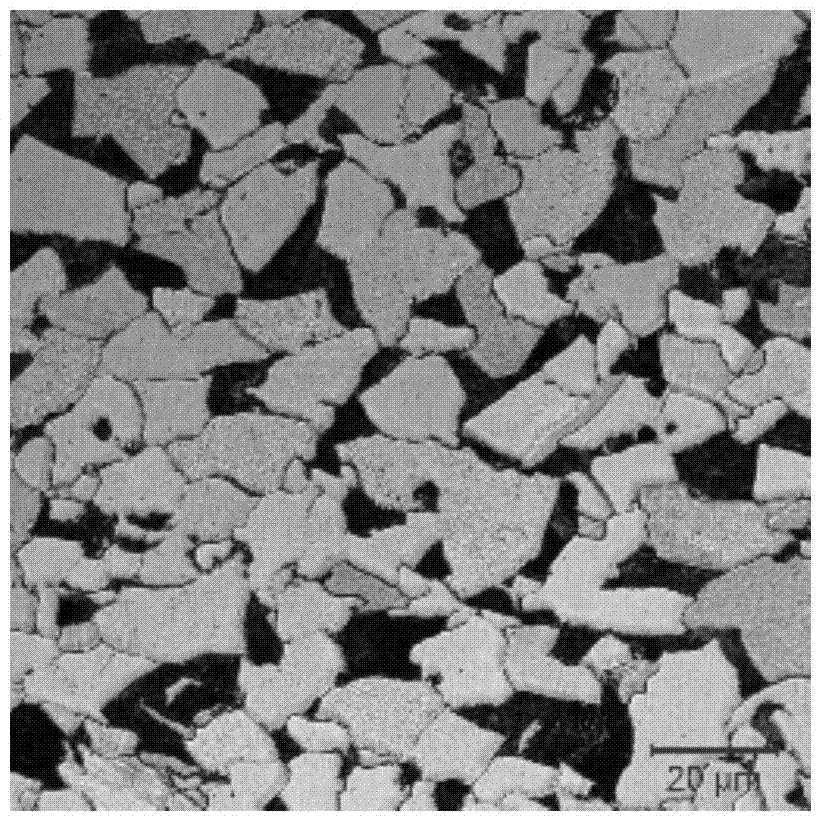

This invention relates to alloying and heat treatment craft of tool die steel, it belongs to one kind of DM8B-2 multi-types superfine carbide high carbon alloy tool steel. Using alloy design method which voluntarily developing, do the phase equilibrium thermo dynamics, electronic / atom level binding energy computation,quenching and the tempered hardness computation as well as to synthesis appraisal its toughness and sintensity. Its ingredient characteristic is appropriate C quantity and Cr / (W+Mo) ratio, reasonable Si, Mn as well as few Ni; Its microstructure characteristic has the superfine carbide, annealing carbide size is between 0.05-0.8mum, when quenching, the undissolved carbide size should not to be smaller than 0.5mum. after quenching to add 200degree C-300degree C, tempering may enable the tempering hardness to achieve 61-64HRC by using carbide precipitation hardening. It has high yield strength and the impact toughness.In the thin edge cutting tool, cutting die and weightily attacking die areas, it has widespread application prospect.

Owner:DALIAN MARITIME UNIVERSITY

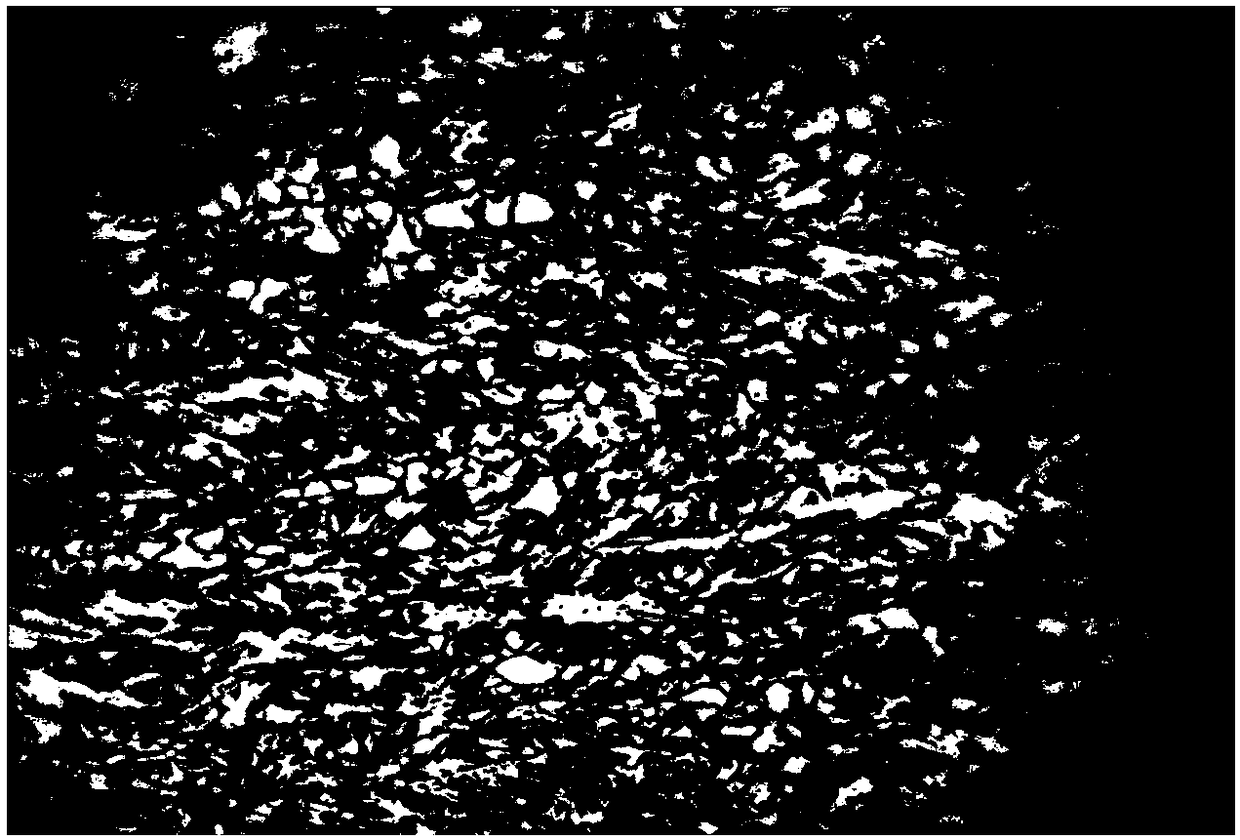

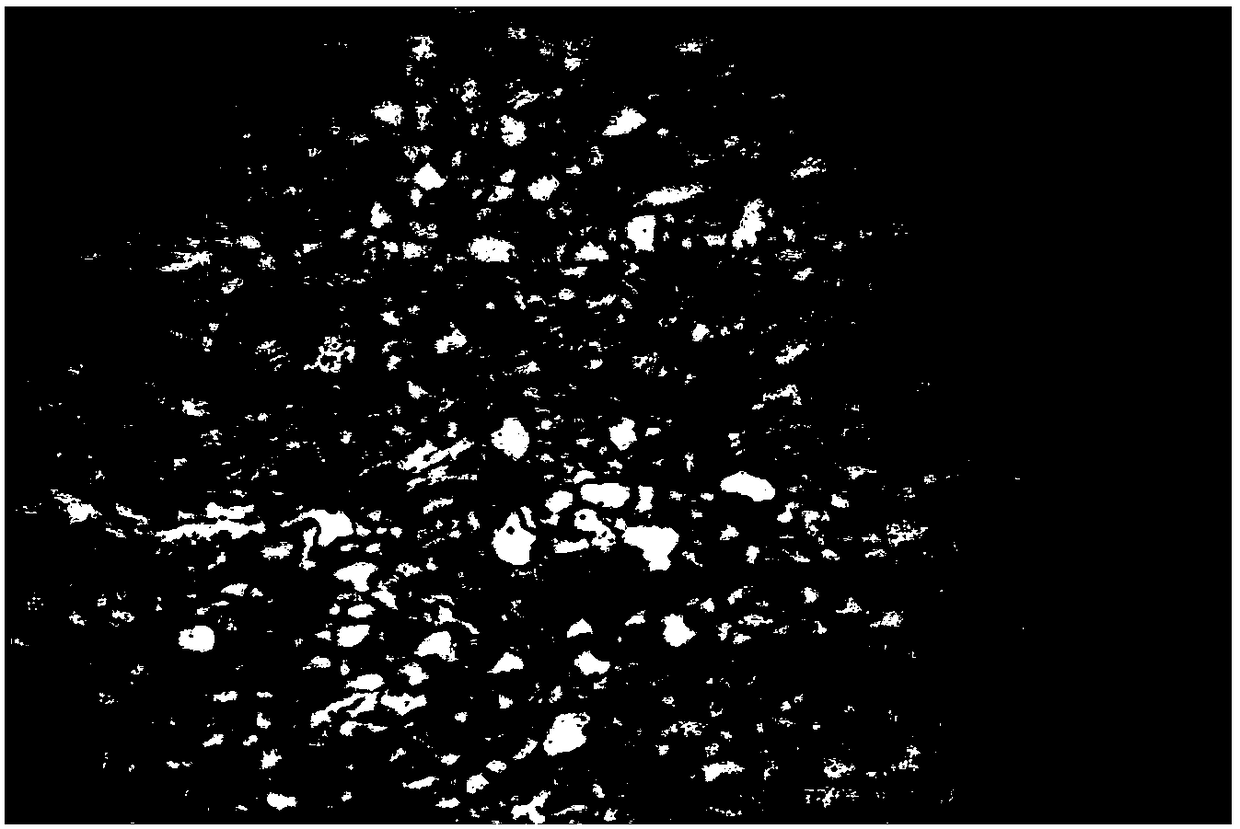

Method for producing ultra-fine grains on surface layer of thick/ultra-thick low-alloy steel plate

ActiveCN103572023AGood surface toughness at low temperatureGood application prospectSteel platesAlloy steel

The invention relates to a method for manufacturing a low-alloy steel plate, and particularly discloses a method for producing ultra-fine grains on the surface layer of a thick / ultra-thick low-alloy steel plate. The method specifically comprises the following steps of 1, uniformly heating a plate blank for 30 to 60 minutes, and taking the plate blank out of a furnace; 2, reducing the temperature of the surface layer of an intermediate blank to 350 to 550 DEG C at speed of more than or equal to 10 DEG C per second, and waiting for temperature rise; 3, when the temperature of the surface layer of the intermediate blank returns to 850 to 960 DEG C, and performing multi-pass rolling, wherein the temperature of the surface layer of the plate blank is reduced to be lower than Ar1 at speed of 10 to 80 DEG C per second between every two rolling passes, the rolling of the next pass is started after the temperature rise, and the final rolling temperature is 780 to 850 DEG C; 4, cooling the plate blank after the plate blank is rolled, namely quickly cooling the blank plate at speed of 1 to 20 DEG C per second, air-cooling the blank plate to 250 to 400 DEG C after the temperature rise, and performing stack cooling. According to the method, energy accumulatively stored on the middle part of the thick steel plate is fully used for performing controlled rolling and controlled cooling for multiple times to refine austenite grains on the surface layer on the premise of no remarkable increase of load of a conventional rolling mill.

Owner:NANJING IRON & STEEL CO LTD

Microwave sintering method for hard alloy

The invention relates to a microwave sintering method for hard alloy. The microwave sintering method comprises the three stages of degreasing, oxidation-reduction and final densification. The microwave sintering method has the advantages that fine tungsten carbide particles cannot become larger or are not prone to becoming larger, namely, ultra refinement can be achieved, and strength and toughness of the hard alloy are facilitated; there is no enough time to remotely diffuse cobalt in an alloy matrix, namely, there is no enough time to diffuse the high-content cobalt in the core of the matrix into a surface layer, and therefore the gradient feature of the hard alloy is well kept; due to the plasma heating effect of microwave sintering, a junction surface cannot crack, a good transition layer is formed between the core and the surface layer, and the core and the surface layer are combined very firmly; the alloy obtained through microwave sintering is high in density and low in porosity.

Owner:冯冬维

Method for producing ultra-fine grains on surface layer of thick/ultra-thick low-alloy steel plate

ActiveCN103572023BAchieve ultra-fineGood surface toughness at low temperatureThick platePhysical chemistry

The present invention involves a manufacturing method of a low -alloy steel plate. Specifically, it is a manufacturing method for the super fine crystal of low -alloy steel thick plates / extra thick plates; as follows: 1. Uniform heating plate blank 30-60min is released;2. Reduce the surface temperature of the middle blank at ≥10 ℃ / s to 350-550 ° C, wait for the return of red; 3. When the temperature of the surface layer of the middle blank is red to 850-960 ° C, multiple secondary rolling is performed.During the secondary track, the surface temperature of the board is quickly reduced to below AR1 at 10 ~ 80 ° C / s. After waiting for the return to red, the next rolling temperature is 780 ~ 850 ° C;20 ° C / s Fast cooling board blank, wait for the return of red to 250-400 ° C after returning to red, and stack cold; this method does not significantly increase the existing rolling load, make full use of the accumulated storage energy in the middle of the thick steel plate, control multiple times many times, and repeatedly control it.Cold the rolling and control the surface of the surface of the surface of the surface.

Owner:NANJING IRON & STEEL CO LTD

Method for producing superfine talcum powder by adopting mixed grinding technology

InactiveCN101870828AImprove mechanical propertiesImprove performancePigment physical treatmentIonHigh intensity

The invention relates to a method for producing superfine talcum powder by adopting a mixed grinding technology, which belongs to the technical field of the preparation of superfine powder. The method comprises the following concrete steps of: (1) adding a high-strength grinding medium into a grinding container of a sand grinder, wherein the filling ratio of the medium is 40 to 80 percent (by volume percent); and then, adding the raw material of talcum powder with the ball-material mass ratio of 10 to 35 and then grinding for a period of time at a certain speed by a dry method; (2) preparing deionized water or water dispersing liquid formed by mixing deionized water and an auxiliary agent; (3) adding the deionized water or the water dispersing liquid containing the auxiliary agent into the grinding container and then grinding for a period of time at a certain speed by a wet method, wherein the mass percentage concentration of slurry is 20 to 50 percent; and (4) carrying out filtration, spray drying and airflow pulverization on the slurry of the ground powder so as to prepare a superfine talcum powder product with different particle size distribution. The superfine talcum powder produced by the invention decreases the particle size, also keeps the laminated structure of talcum more integrally and provides a favorable basis for the application of the talcum powder.

Owner:SHANGHAI UNIV

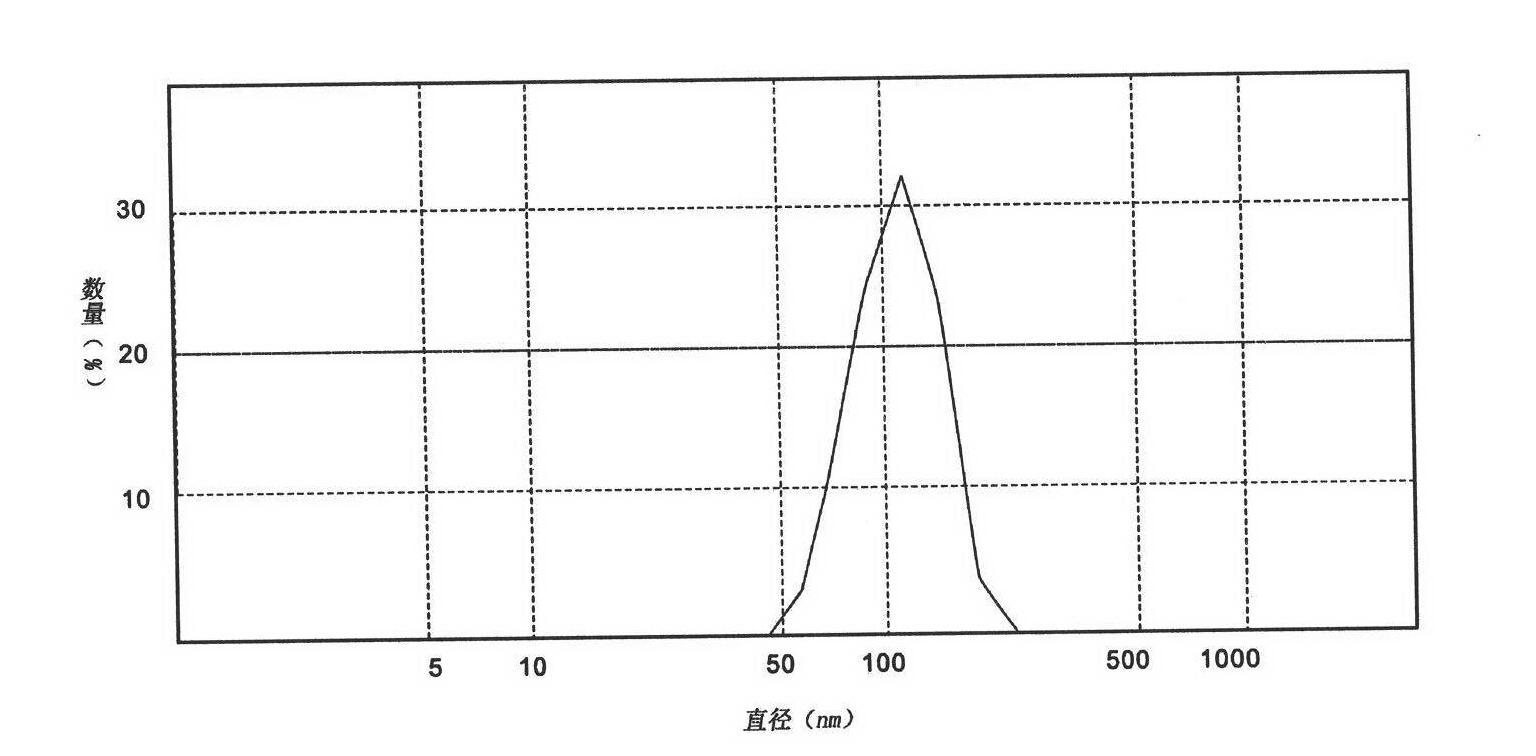

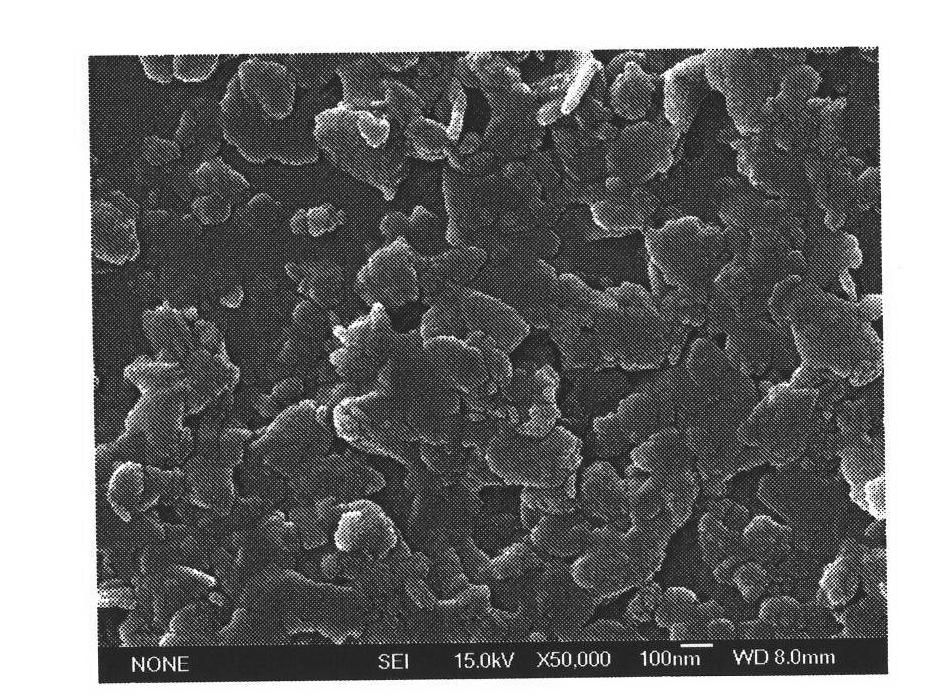

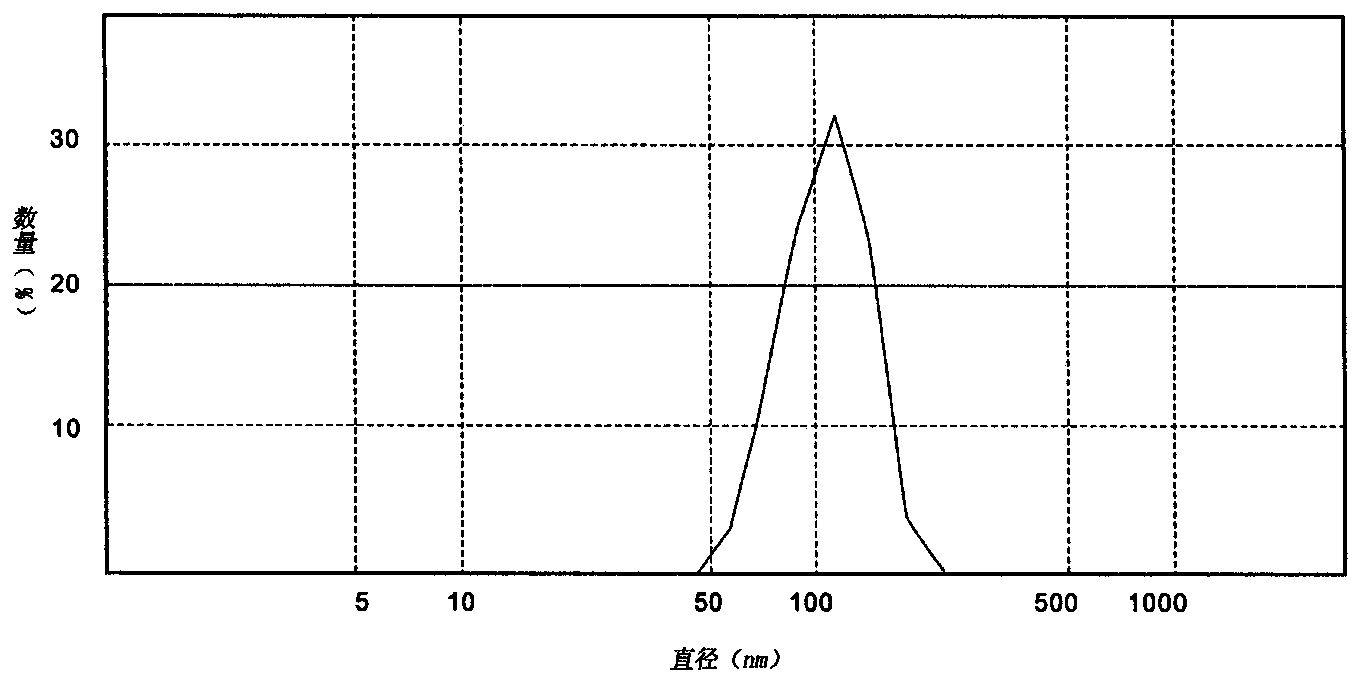

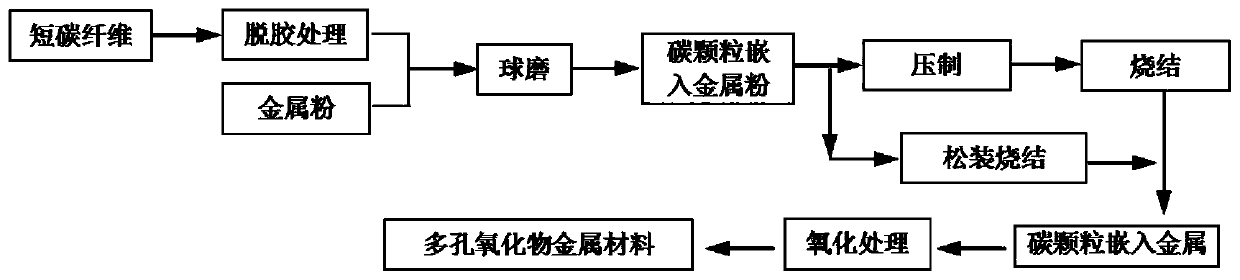

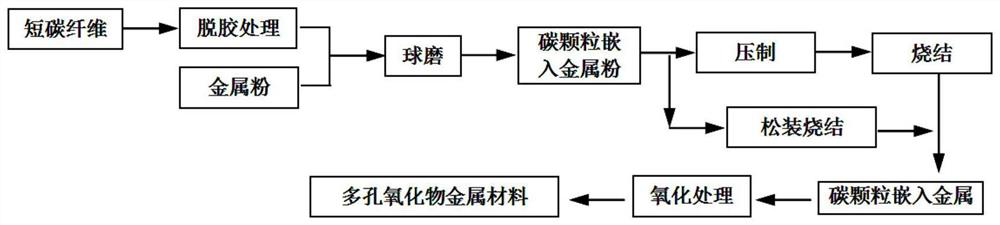

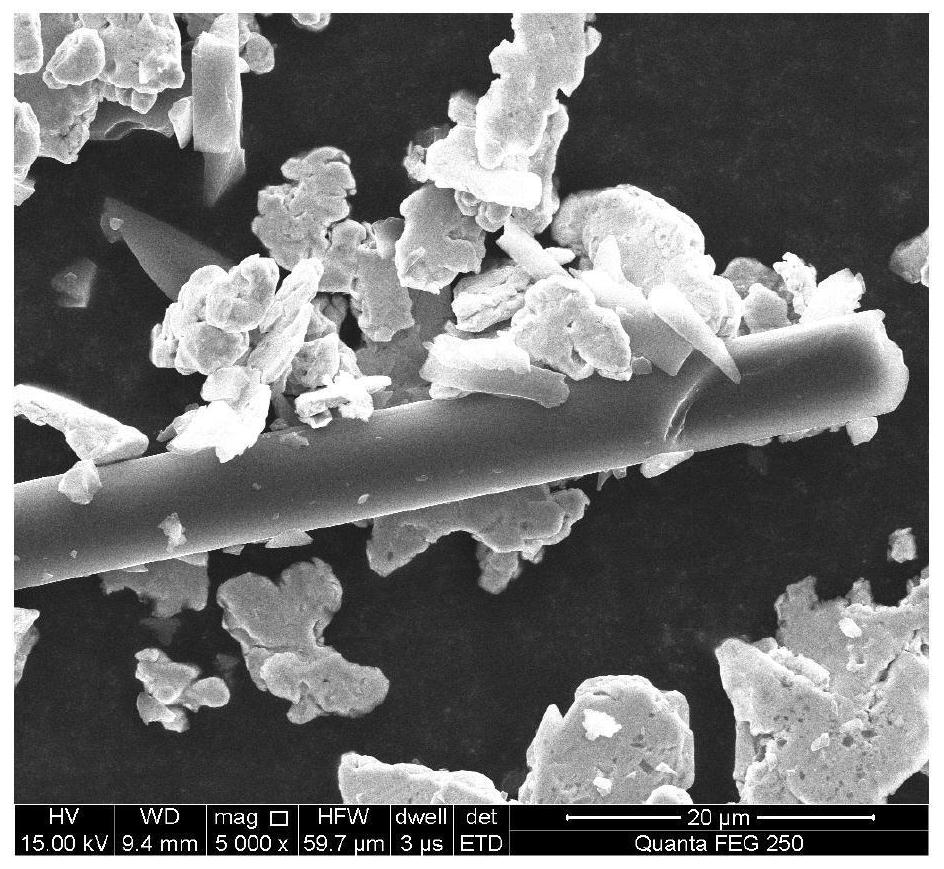

Preparation method of porous metal oxide

The invention relates to a preparation method of a porous metal oxide, and belongs to the crossing field of metal powder technology and metal material surface treatment. The preparation method comprises the following steps: firstly degumming short carbon fibers, then performing a suitable ball milling process on the degummed short carbon fibers and a metal powder to obtain a metal powder embeddedwith ultrafine carbon particles, performing sintering after press-forming in a protective atmosphere or vacuum, or directly performing loose sintering, finally performing short-time annealing treatment in oxygen-containing air to remove the carbon particles in the metal powder and partially oxidize the surface of metal particles to obtain the porous metal whose surface is partially oxidized. The porous metal oxide prepared by the method exhibits good oil storage, hydrogen storage, paraffin wax storage, lithium storage performances, and catalytic performance, and the porous metal oxide has simple preparation process and low cost.

Owner:CENT SOUTH UNIV

Isothermal processing technology of large-specification sheet of high-strength magnesium alloy

The invention discloses an isothermal processing of a large-specification sheet of a high-strength magnesium alloy, and relates to the technical field of the production and processing technology of nonferrous metals. The technology comprises the following steps: removing surface scales and surface wrinkles and chamfers of magnesium alloy cast ingots, and sequentially carrying out homogenizing annealing, isothermal constraint upsetting, hot piercing and isothermal backward extrusion, splitting and isothermal flattening, modulation isothermal rolling, heat treatment and polishing treatment. The technology makes the magnesium alloy sheet have a high strength, and can realize the shaping of large-specification high-strength magnesium alloy sheets.

Owner:江苏诚德钢管股份有限公司

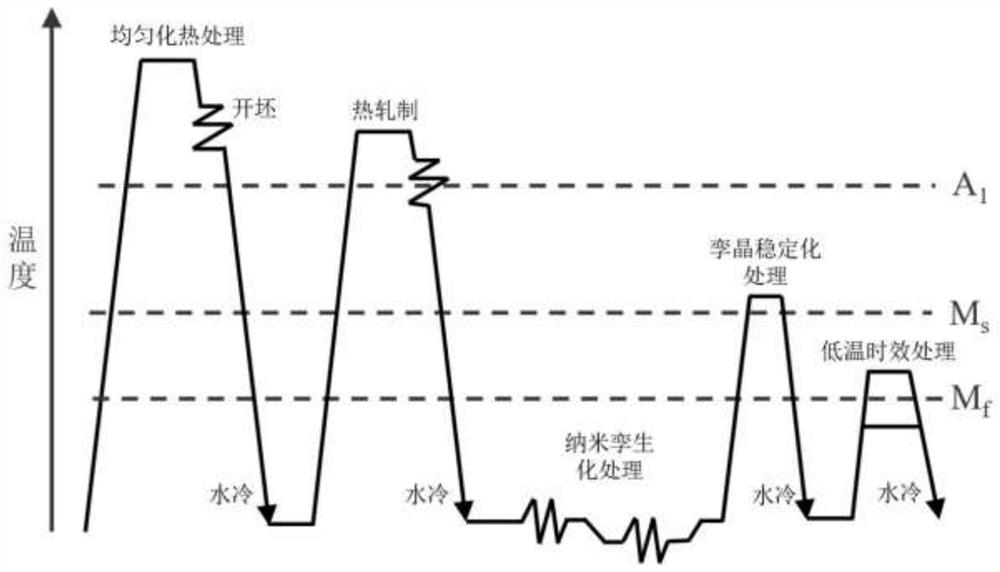

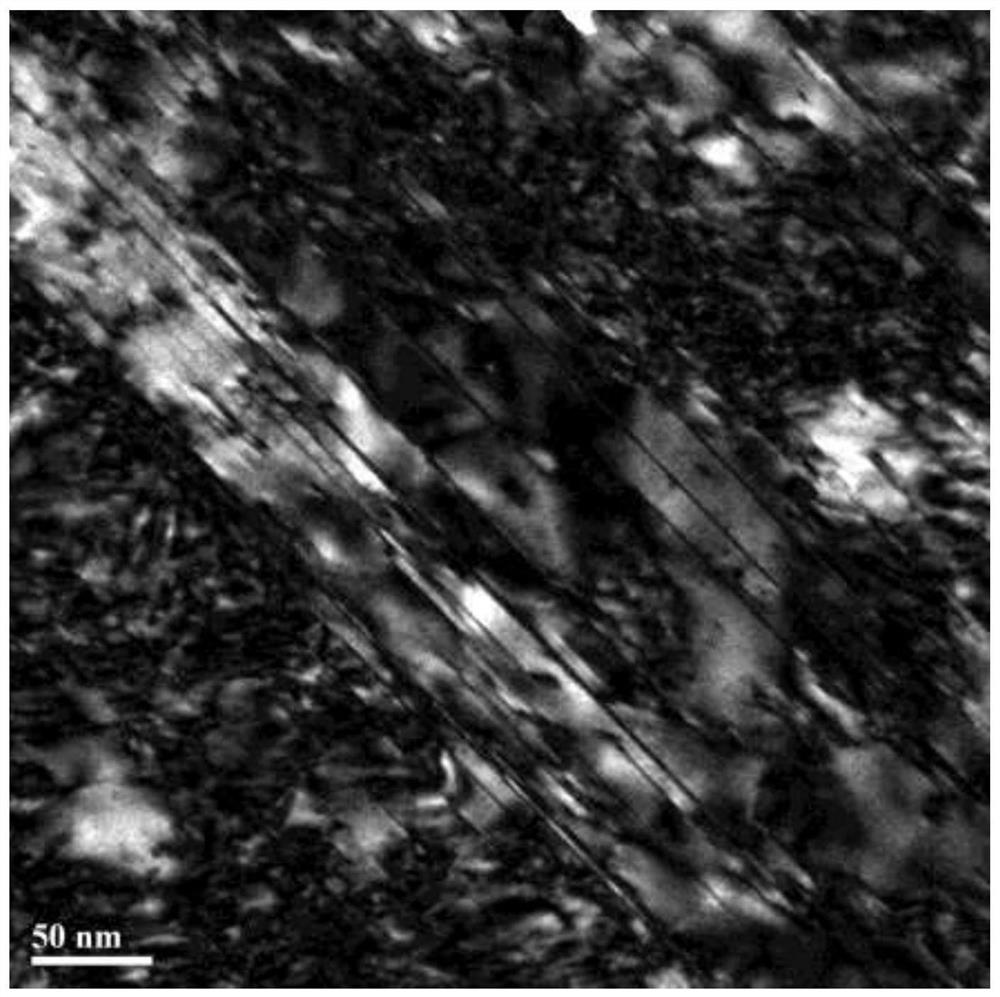

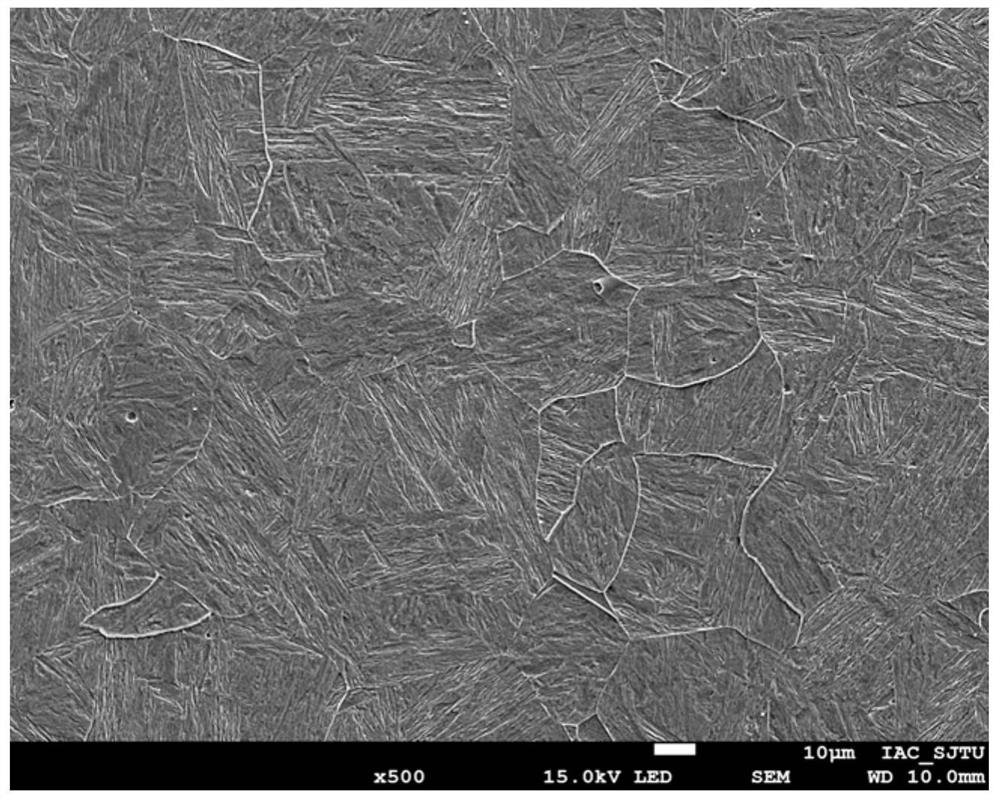

High-strength and high-toughness wear-resistant steel and preparation method for nano twin crystal reinforcement and toughening of high-strength and high-toughness wear-resistant steel

ActiveCN113388787AGood value for moneyImprove mechanical propertiesRoll force/gap control deviceTemperature control devicePressure castingIndustrial equipment

The invention relates to high-strength and high-toughness wear-resistant steel and a preparation method for nano twin crystal reinforcement and toughening of high-strength and high-toughness wear-resistant steel. The steel comprises the components in percent by mass: 0.35%-0.85% of C, 15.2%-24.8% of Mn, 0.1%-0.5% of Si, smaller than or equal to 1.0% of Al, smaller than or equal to 0.005% of S, smaller than or equal to 0.01% of P, 0.5%-1.5% of Nb, 0.2%-0.8% of Ti, 0.2%-0.75% of V, 0.005%-0.05% of N, 0.02%-0.1% of rare earth RE and the balance Fe and inevitable impurities. The stacking fault energy of an alloy is 24-30 kJ / m <2>, and the mass percent of the addition amount of Ti, Nb and V is 2: 1: 1. The preparation process comprises the steps of alloy smelting and negative pressure casting, homogenization heat treatment and cogging, hot rolling, nanometer twinning treatment, nanometer twinning stabilization and low-temperature aging treatment. According to the invention, fine structure regulation and control are carried out based on means of deformation and heat treatment by means of low fault energy and microalloying component optimization matching design, so that good structure matching is realized, and the alloy has high strength, high toughness and high wear resistance. The wear-resistant steel is excellent in comprehensive mechanical property, low in alloy cost, simple in preparation process, low in production and manufacturing cost and easy to put into industrial production and large-scale industrial equipment.

Owner:上交(徐州)新材料研究院有限公司

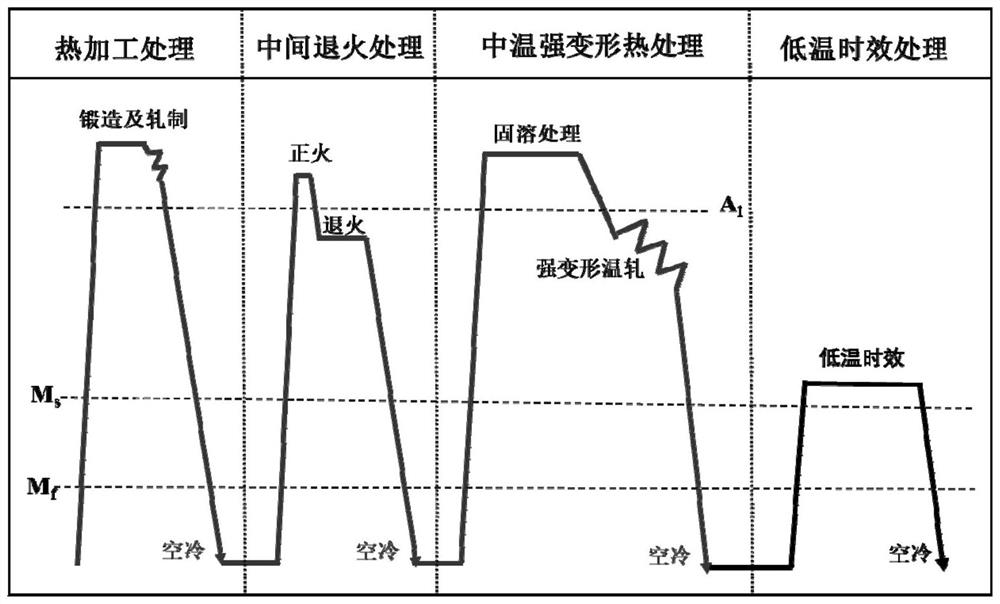

Air-cooled hardened steel plate with ultra-high strength, high toughness and ultra-fine structure and preparation process of air-cooled hardened steel plate

ActiveCN112063921AImprove plasticity and toughnessFacilitates microscopic stress-strain distributionFurnace typesHeat treatment furnacesSteel platesOxidation resistant

The invention relates to an air-cooled hardened steel plate with ultra-high strength, high toughness and an ultra-fine structure and a preparation process of the air-cooled hardened steel plate. The air-cooled hardened steel plate comprises the following components in percentage by mass: less than or equal to 0.08% of C, 0.1-0.35% of Si, 0.2-0.8% of Mn, 10-15% of Cr, 2.0-3.0% of W, 2.0-3.0% of Co,0.1-0.3% of V, 0.025-0.08% of Nb, 0.03-0.06% of N, 0.05-0.1% of Ta, 0.02-0.06% of Nd, less than or equal to 0.0005% of B and the balance of Fe and inevitable impurities. The preparation process comprises the steps of smelting, hot working treatment, secondary intermediate annealing treatment, medium-temperature strong deformation heat treatment and low-temperature aging treatment. Structural regulation and control are conducted through conventional equipment and production process, the martensite structure can be refined to the nanoscale, furthermore, a large number of nano-particles are separated out and distributed in a matrix in a dispersed mode, and the comprehensive performance of the low-carbon martensite steel plate is remarkably improved. Compared with the prior art, the preparedmaterial has ultrahigh strength, high toughness, good corrosion resistance, oxidation resistance, heat resistance and low-temperature performance. The preparation process is simple, industrial large-scale production is facilitated, production cost is low, production efficiency is high, and the product application range is wide.

Owner:SHANGHAI JIAO TONG UNIV

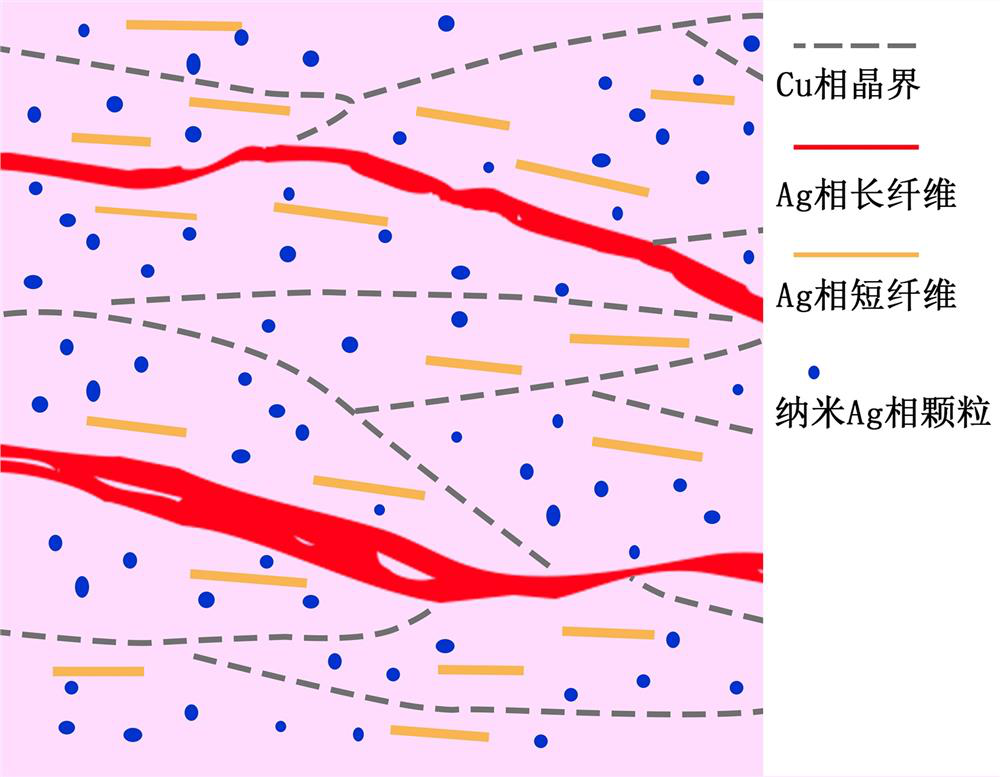

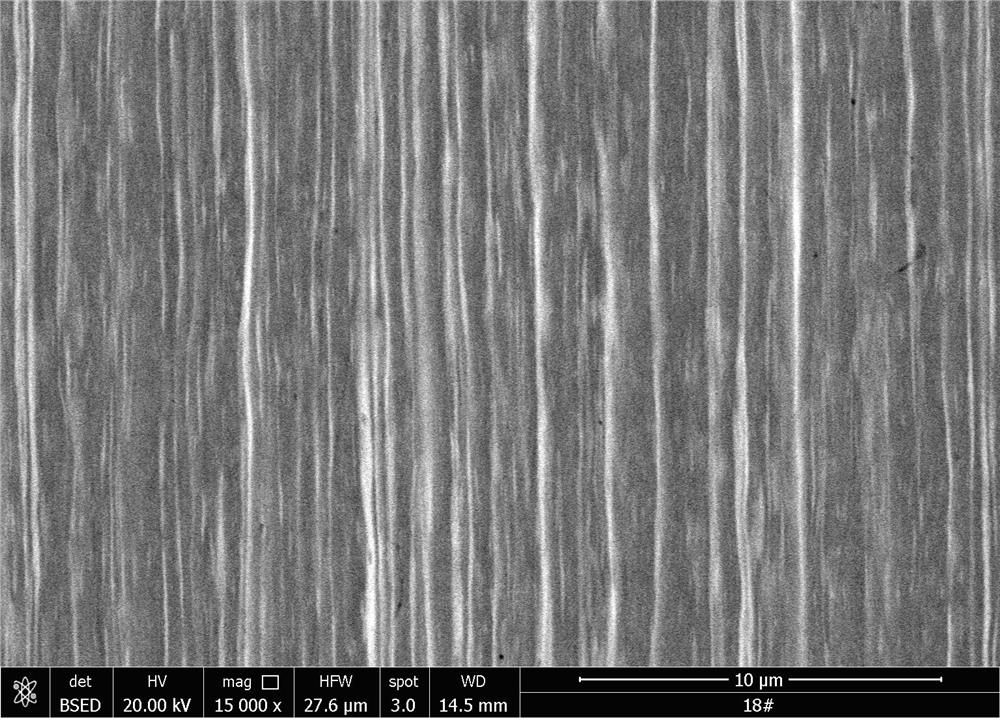

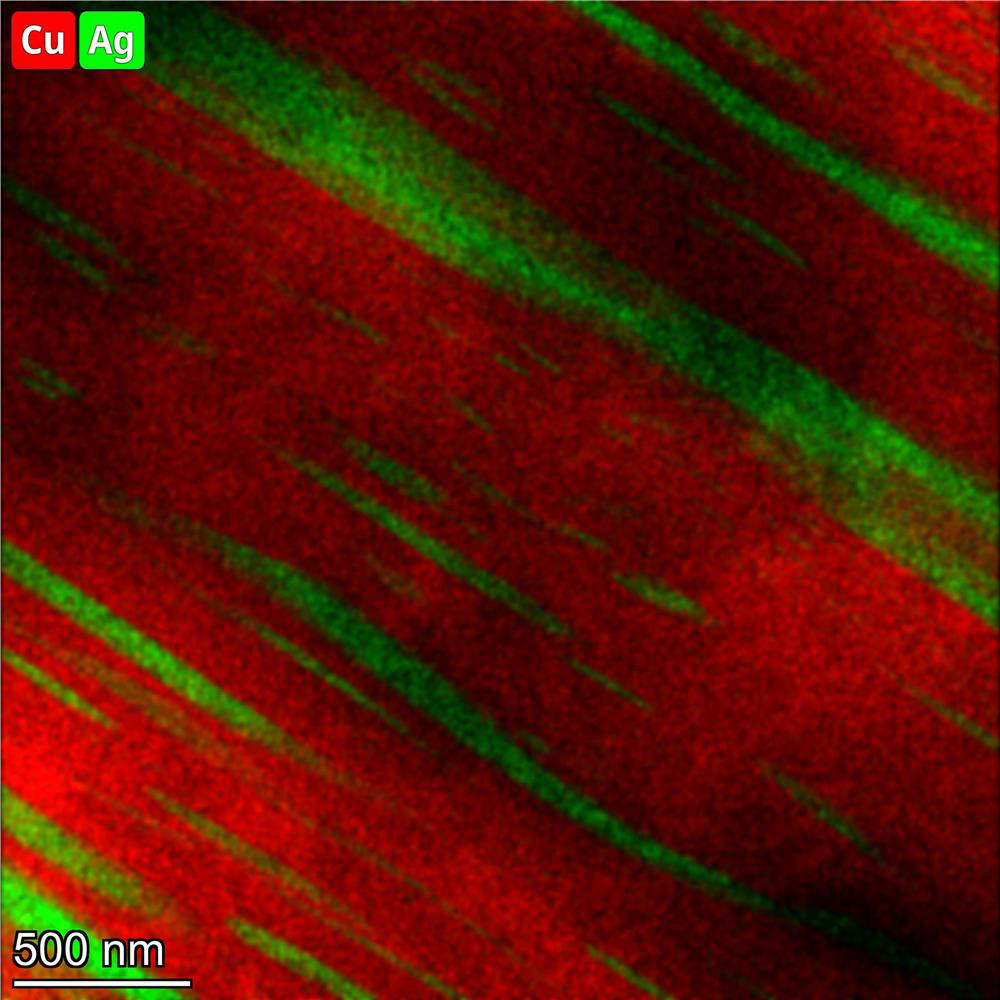

Preparation method of copper-silver alloy wire

ActiveCN114561566AProtective substrateImprove conductivityFurnace typesHeat treatment furnacesWire rodRare-earth element

The invention discloses a preparation method of a copper-silver alloy wire. A copper-silver alloy comprises the following components in percentage by weight: 18-26% of Ag, 0.02-0.25% of La, a mass ratio of Sc to La being 0.5-1.5, and the balance of Cu. And drawing for a plurality of passes to obtain a wire rod finished product. According to the copper-silver alloy wire, only two rare earth elements Sc and La are added, the mass ratio of Sc to La is controlled to be 0.5-1.5, and after the strengthening treatment process, the copper-silver alloy wire with the room temperature tensile strength reaching 1050-1520 MPa, the electric conductivity reaching 75-87% IACS and the electrical resistivity lower than 1.982-2.30 mu omega.cm can be obtained; when the environment temperature is-196 DEG C, the low-temperature tensile strength of the alloy is 1450-1860 MPa, the low-temperature resistivity is 0.70-0.87 mu omega.cm, and the comprehensive performance is excellent.

Owner:JIANGXI UNIV OF SCI & TECH

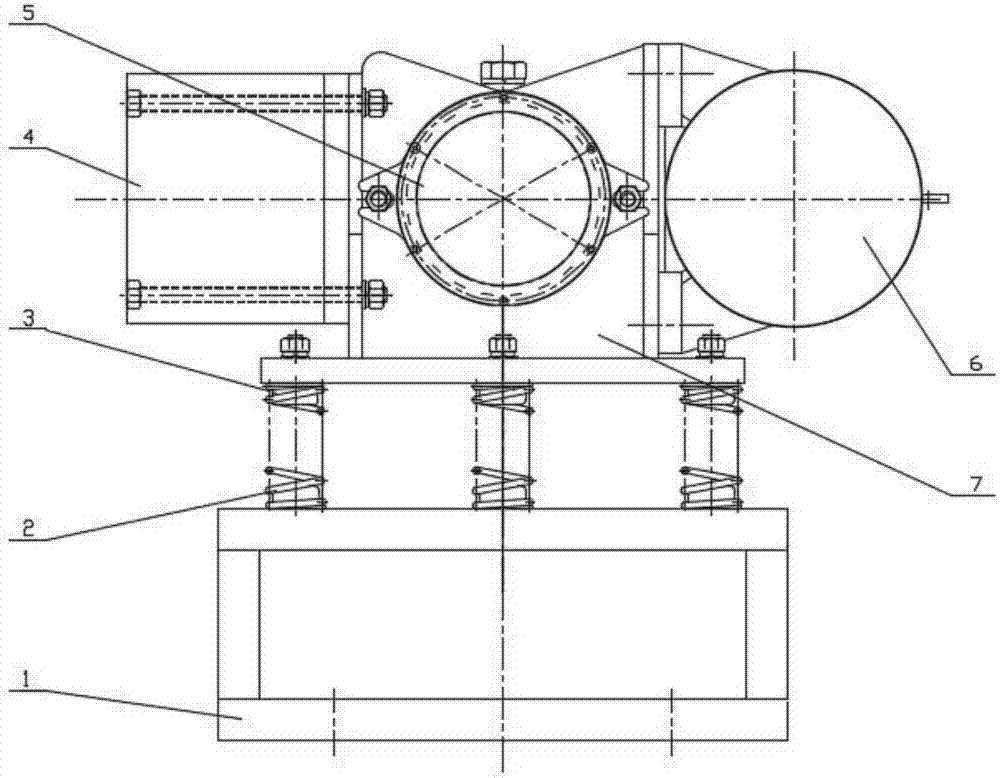

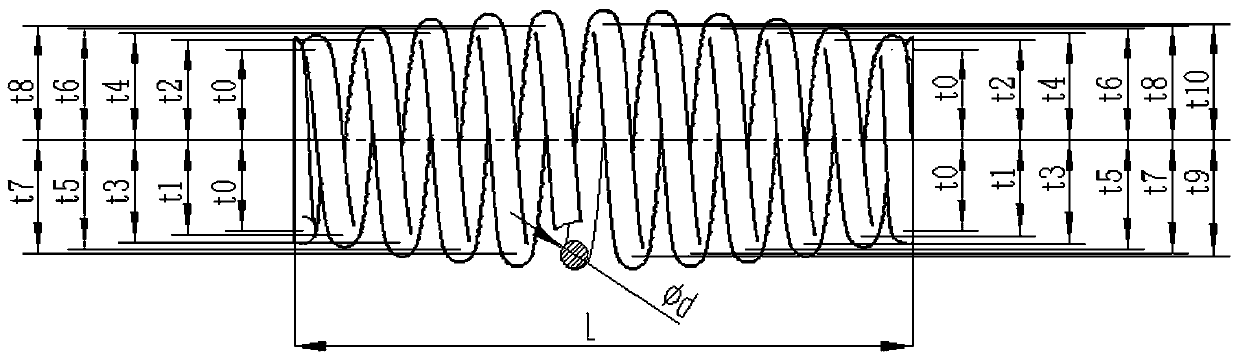

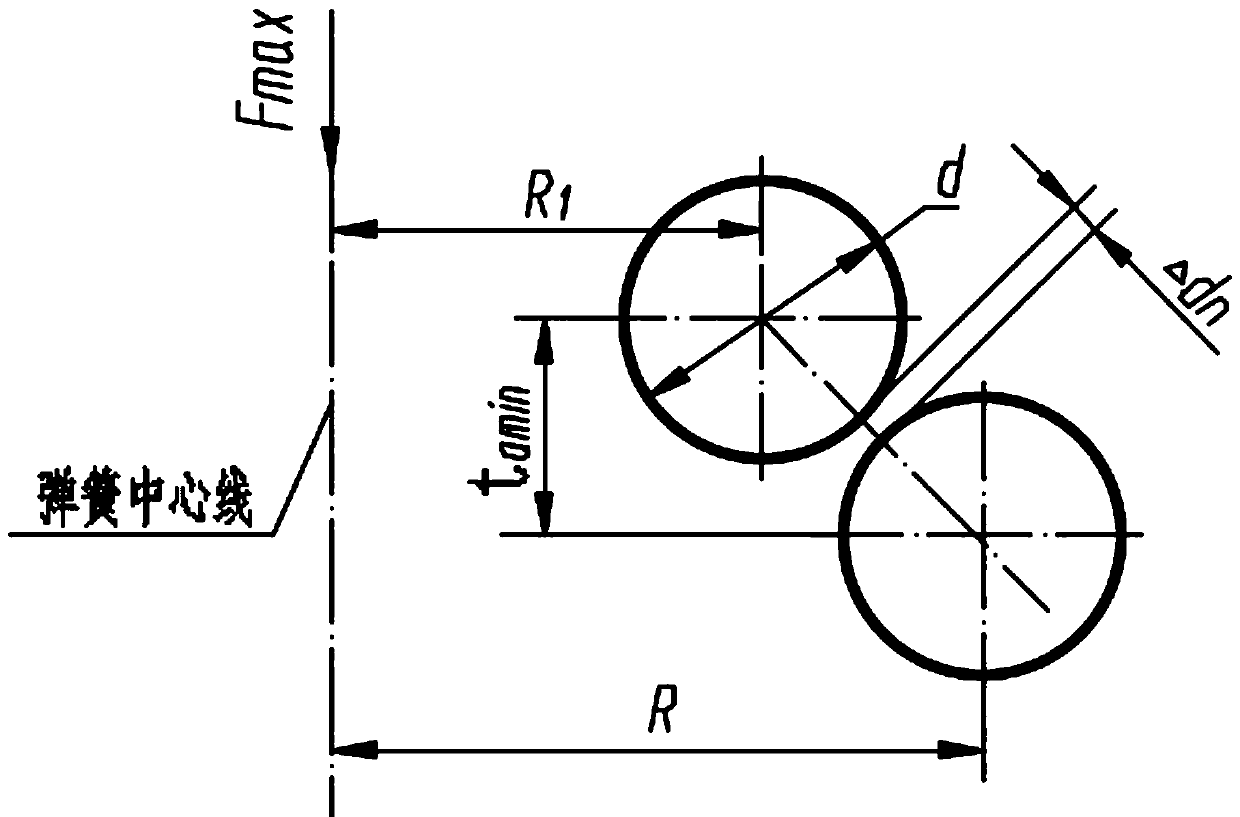

Side vibration mill adopting variable-pitch non-closed-coil springs and media in mixed density

The invention discloses a single-drum vibration mill adopting variable-pitch non-closed-coil springs and media in the mixed density. A main vibration system comprises a vibration motor which is controlled by a frequency converter and used as a vibration exciting source and a grinding drum fixed to the vibration motor; the vibration motor, the grinding drum and an upper mass plate form an upper mass; one end of a main vibration spring group is connected with the upper mass; the other end of the main vibration spring group is connected with a base; and the main vibration spring group comprises the multiple variable-pitch non-closed-coil helical springs, and each spring is formed by coiling one steel wire. The vibration mill has the positive, obvious and unique effects and has the characteristics of being capable of realizing ultrafine particle refining, realizing de-agglomeration and narrowing the powder product distributing zone, low in energy consumption, high in grinding efficiency, high in energy utilization rate, capable of realizing effective energy storage, saving energy, running stably and remarkably reducing the noise, good in vibration isolating effect and the like.

Owner:NANJING INST OF TECH

Wet grinding machine for industrial treatment of concrete admixture

ActiveCN106345576ALarge amount of processingImprove economic efficiencyGrain treatmentsRebarWet grinding

The invention relates to a wet grinding machine for industrial treatment of concrete admixtures. An embedded component is connected onto a tube body; the embedded component is fixed on a reinforced concrete column; power equipment is connected onto a rotating shaft, and the lower part is born by a bearing component; the bearing component is provided with a wear-resistant steel ball horizontal round groove; the bearing component is firmly connected with a basic concrete structure; the rotating shaft is connected with a stirring disc through a connecting key; a feeding opening is formed in the upper side of the tube body; a discharging opening is formed in the lower side of the tube body, and consists of a movable baffle plate and a grille outside the movable baffle plate; a cooling water jacket is arranged outside the tube body; a cooling guide pipe is arranged in the tube body, and is connected with the cooling water jacket; medium grinding balls are arranged in the tube body. The stirring disc is driven through the rotating shaft and the power equipment fixed at the upper part of the support frame; the stirring disc drives materials and the medium grinding balls to generate collision, friction, shearing and extrusion, so that materials are finely ground. The wet grinding machine has the advantages that the mechanical structure and the heat radiation principle are utilized; the material wet grinding disposal superfining is realized; the treatment quantity is great; the resource waste is reduced; the cyclic utilization of solid wastes is realized.

Owner:湖北青垚环境有限公司

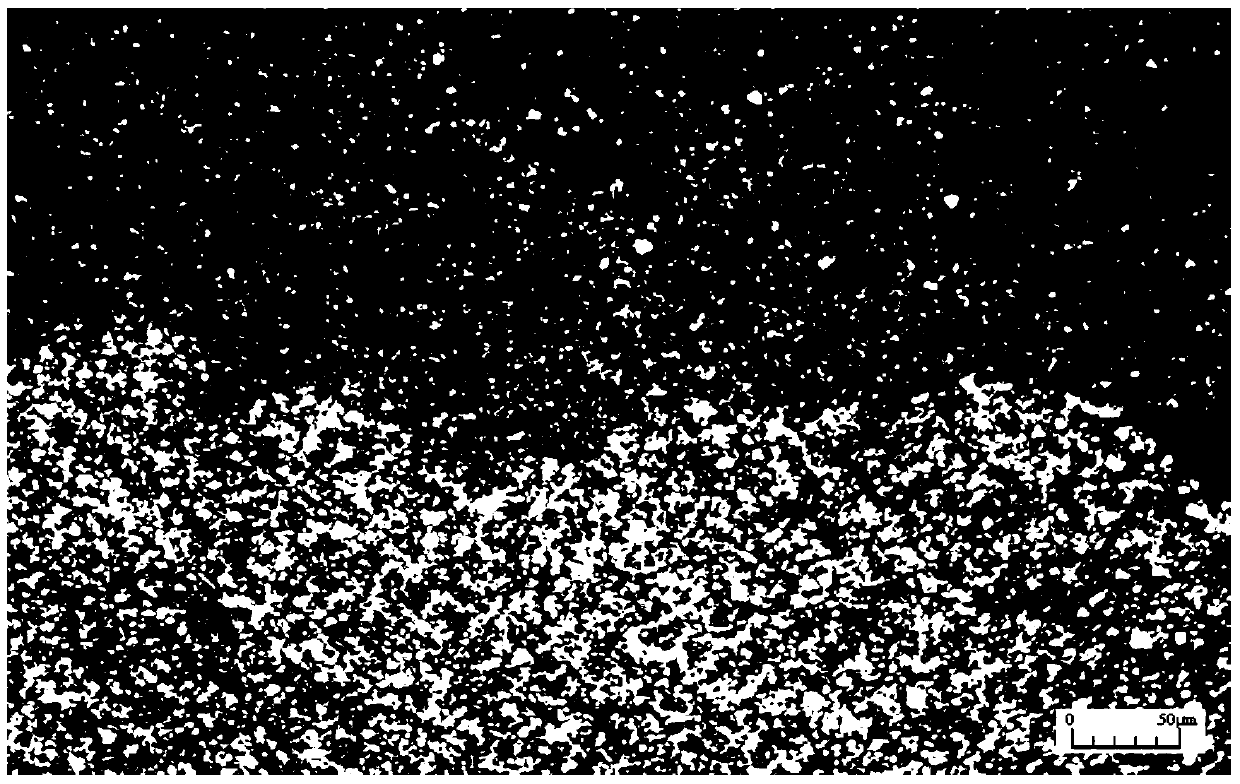

Preparation method of iron-based continuous casting profile based on graphite nodule ultra-fining

ActiveCN113500171AIncrease nucleation rateIncreased nucleation rate and growth rateProcess efficiency improvementMetalIron based

The invention discloses a preparation method of an iron-based continuous casting profile based on graphite nodule ultra-fining. A proper nucleating agent and a proper nodulizer are added into molten iron in the continuous casting process of an iron-based profile, so that the nucleation rate of graphite in the solidification process of the molten iron is far greater than the nucleation rate of the graphite when a conventional nucleating agent and nodulizer are used for inoculation and spheroidizing treatment; and graphite nodules in the continuous casting iron profile are ultra-refined, so that the density number of the graphite nodules at the position, 50 mm from the outside to the inside, of the continuous casting iron profile is not less than 500 / mm2 and is far larger than the density number of the graphite nodules obtained after the nodular cast iron profile is treated through the conventional nucleating agent and nodulizer at present. Due to the fact that the density number of the graphite nodules is greatly increased, the diameter of the graphite nodules in the continuous casting iron profile is greatly reduced, the roundness and the distribution uniformity of the graphite nodules are greatly improved, and therefore damage to a metal matrix caused by irregular shapes and uneven distribution of the graphite nodules is remarkably reduced, and therefore, the related performance of the iron profile is obviously improved.

Owner:西安共晶金属科技有限公司

Preparation method of efficient and environment-friendly composite fire retardant

InactiveCN102010585BAbundant resourcesGood synergyPigment treatment with organosilicon compoundsFire retardantPhysical property

The invention discloses a preparation method of an efficient and environment-friendly composite fire retardant, which comprises the following steps: modifying attapulgite to obtain nano attapulgite; and using the nano attapulgite as a substrate, coating a proper amount of inorganic fire retardant and phosphate fire retardant on the surface so as to form the efficient and environment-friendly composite fire retardant. By using the preparation method, the obtained fire retardant can be superfine, and the influence of the fire retardant on the processability and the physical properties of the high molecular substrate material can be weakened. At the same time, by the fire retardant property of the nano attapulgite and the synergetic effect of multiple fire retardants, the fire retardant efficiency is enhanced, the industrial cost of the fire retardant is lowered and a new way is provided for the development and the application of attapulgite.

Owner:HUAIYIN TEACHERS COLLEGE

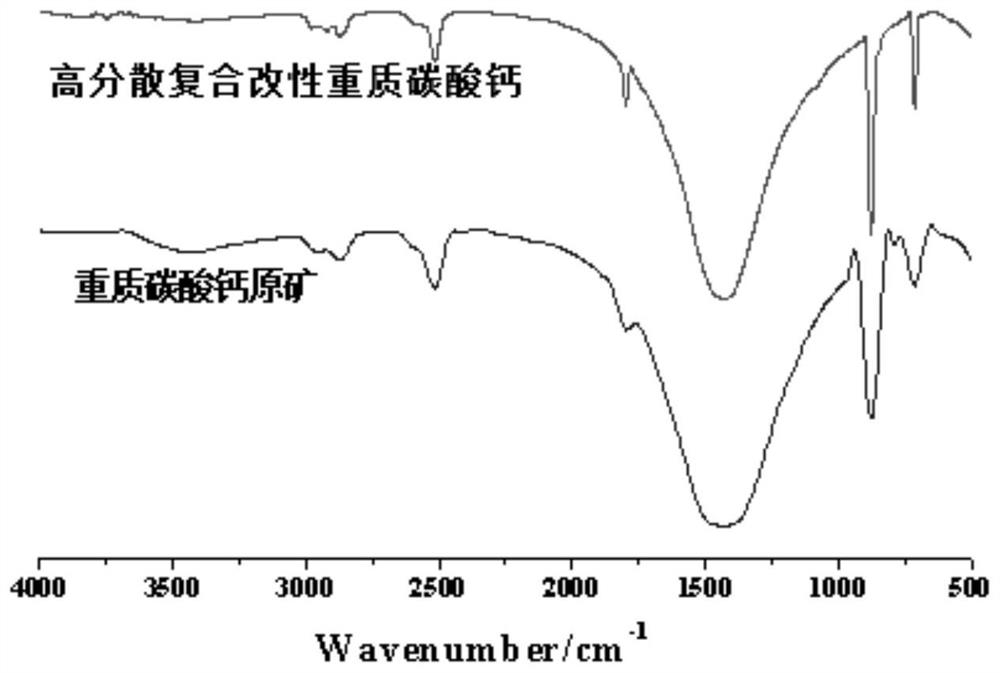

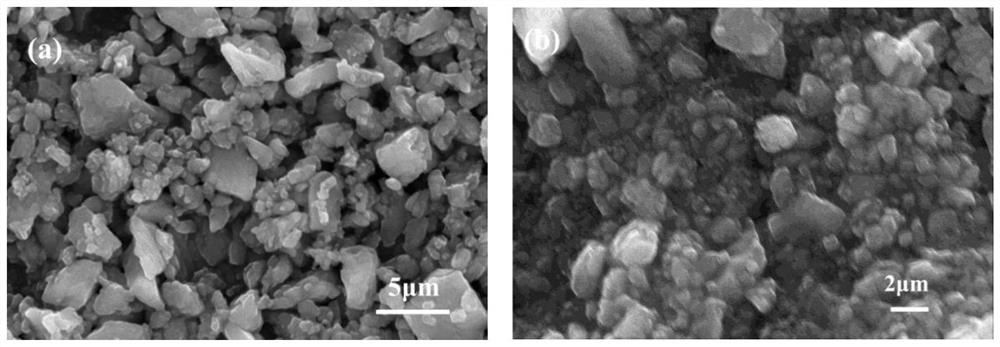

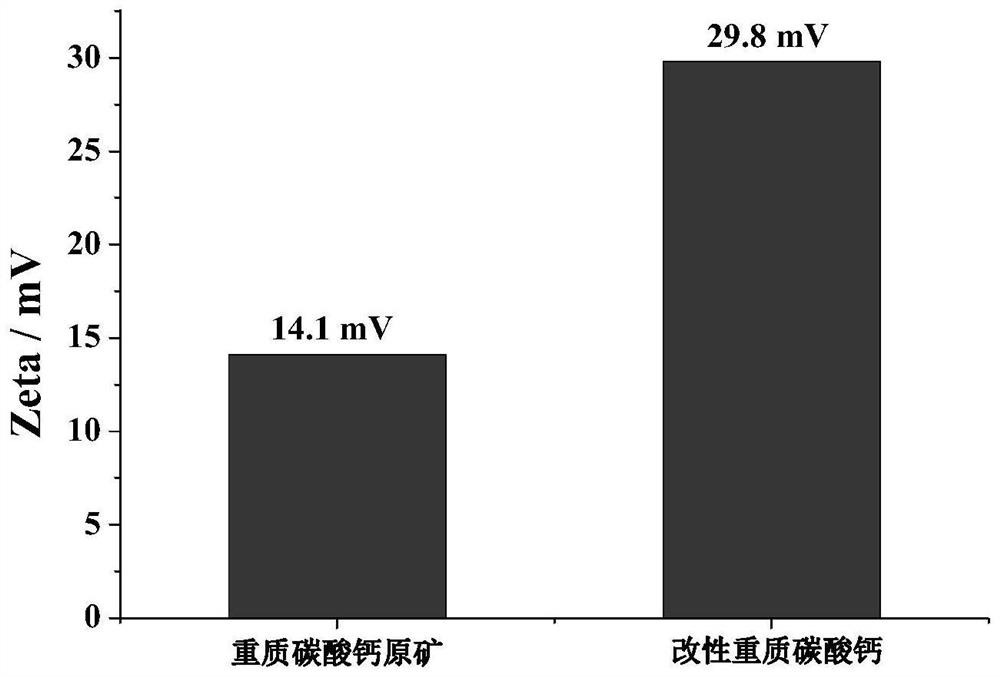

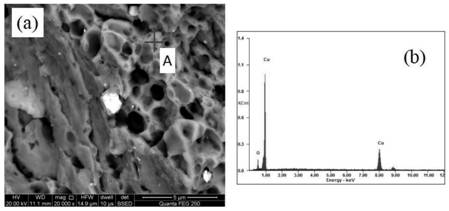

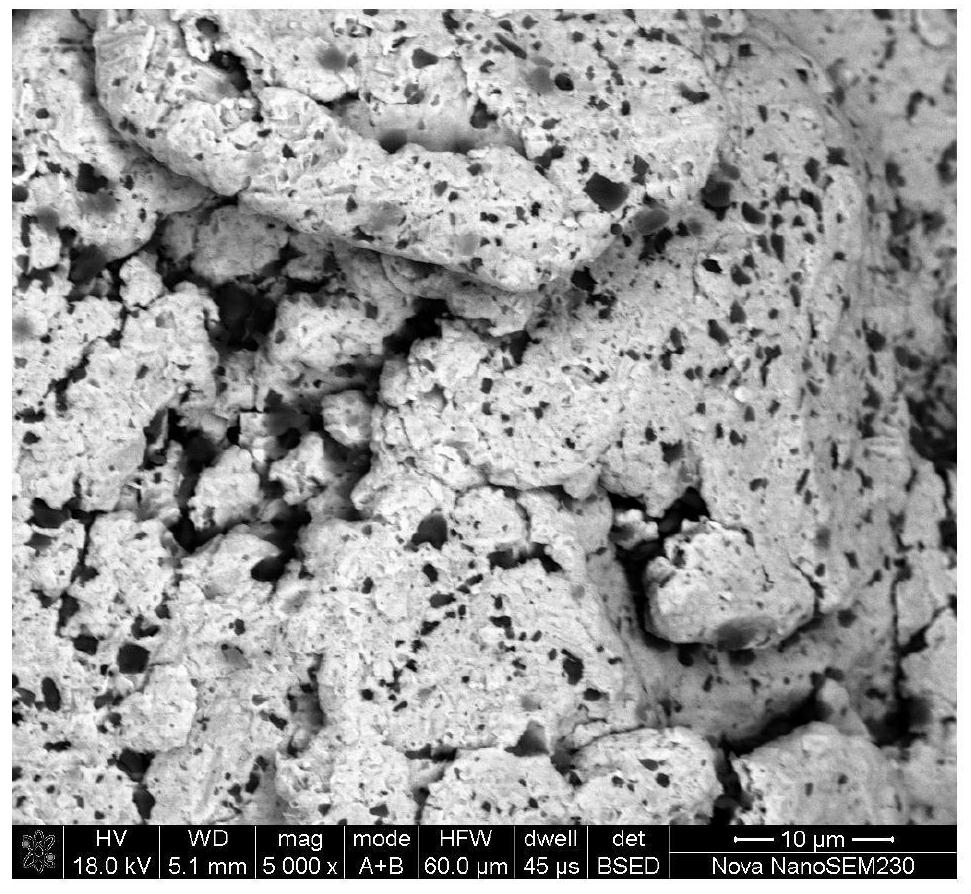

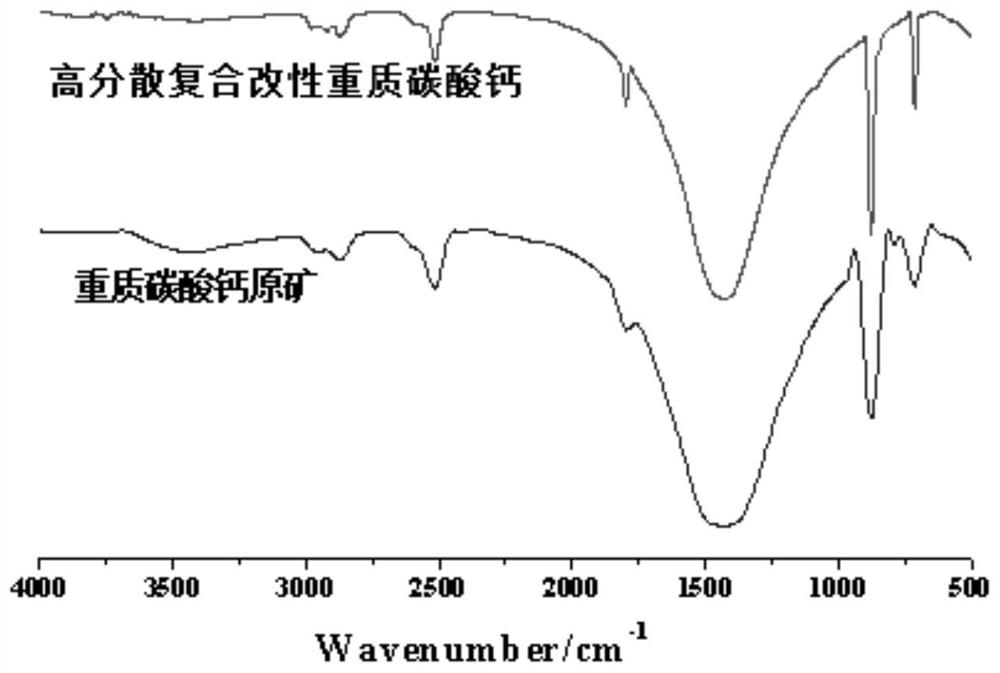

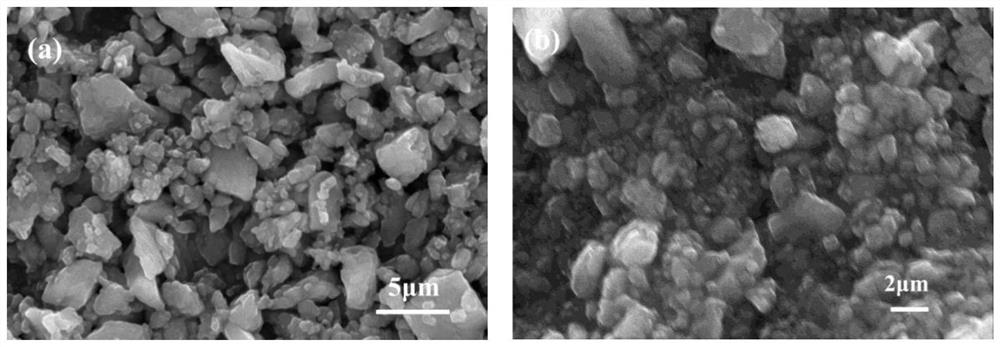

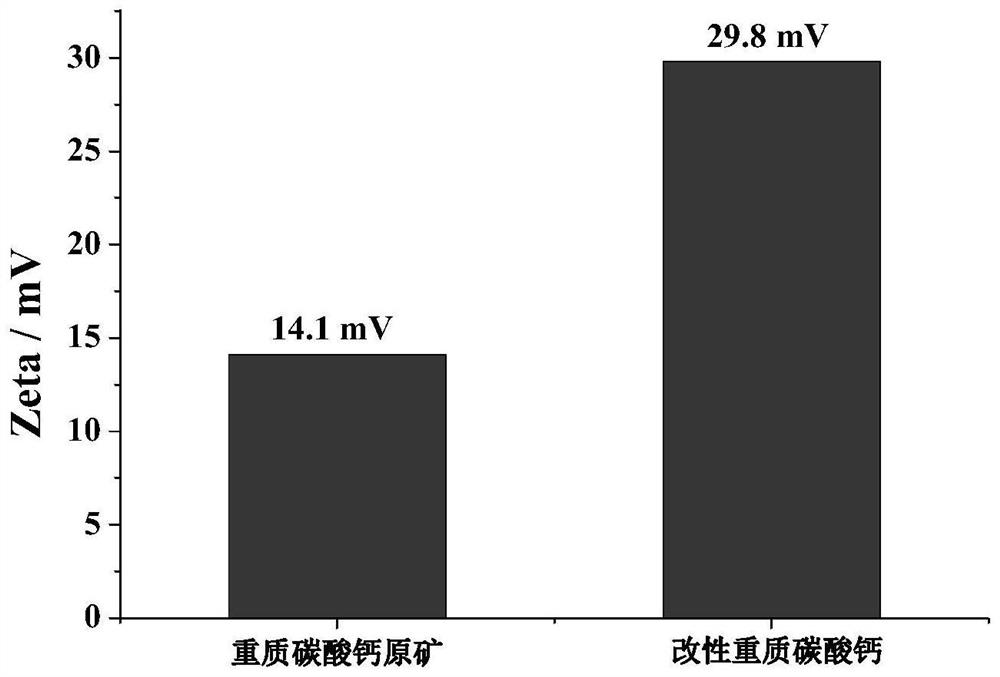

High-dispersion composite modified heavy calcium carbonate and preparation method thereof

ActiveCN111763435AGood dispersionAchieve ultra-finePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolymethyl methacrylatePhysical chemistry

The invention discloses high-dispersion composite modified ground calcium carbonate and a preparation method thereof, and belongs to the technical field of powder modification. The method specificallycomprises the following steps: firstly, putting heavy calcium carbonate into a drying oven and dehydrating at 100-110 DEG C; mixing the heavy calcium carbonate with a polymethyl methacrylate emulsionby using an electric stirrer, wherein the dosage of the polymethyl methacrylate is 2.0-4.0% of the mass of the heavy calcium carbonate; and adding a secondary modifier (such as any one of stearic acid, titanate and sodium tripolyphosphate), and electrically stirring at 80-85 DEG C for 40-120 minutes to obtain the high-dispersion modified heavy calcium carbonate powder. The prepared modified heavycalcium carbonate is good in dispersity, the surface zeta potential is larger than 29.8 mV, the average particle size is not larger than 500 nm, the activation rate is larger than 90.8%, and the oilabsorption value is smaller than 0.30 ml / g. The high-dispersion modified heavy calcium carbonate powder prepared by the invention has the main characteristics of high dispersion and high activation rate, and can be used in the field of polymer composite materials.

Owner:HUBEI UNIV FOR NATITIES +1

Preparation method of ultrahigh-strength pure aluminum

InactiveCN111545585AHigh strengthThe plasticity will not be significantly weakenedExtrusion diesTemperature control devicePlasticityAluminium

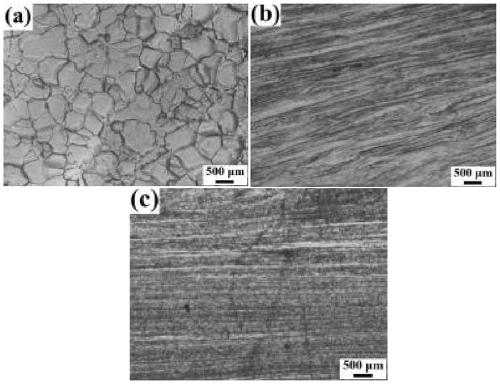

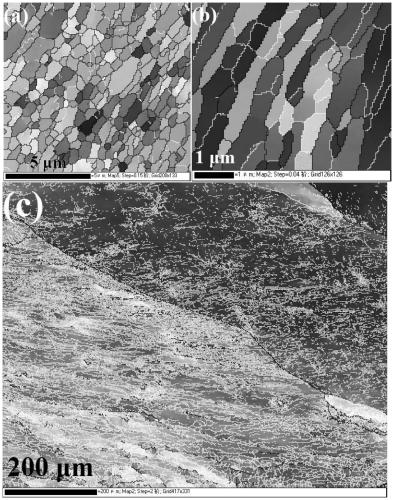

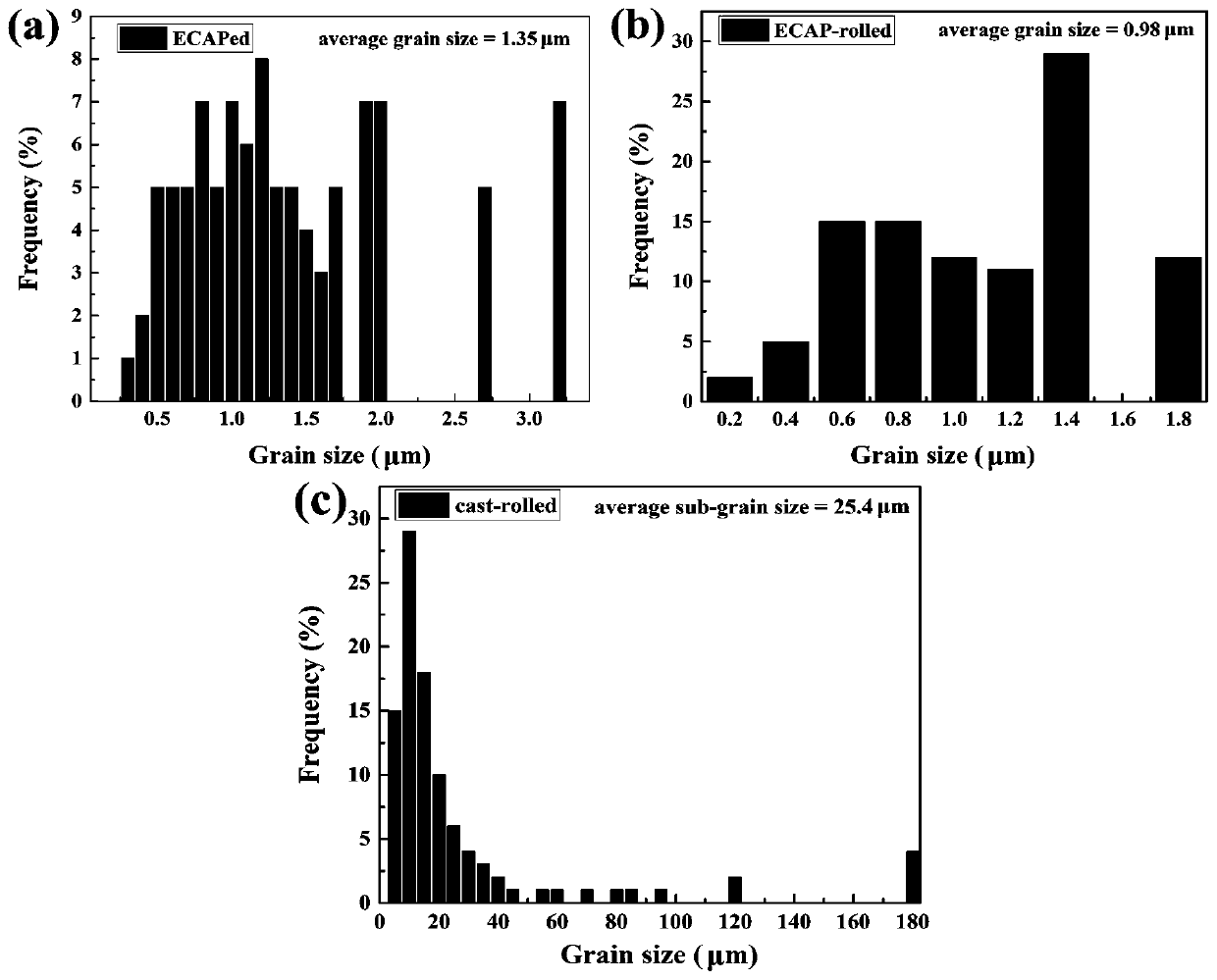

The invention relates to the technical field of alloy machining, in particular to a preparation method of ultrahigh-strength pure aluminum. The preparation method includes the following steps of putting as-cast pure aluminum into an equal-channel-angle die for equal-channel-angle extrusion deformation to obtain an extrusion-state billet, wherein the angle of the equal-channel-angle die is 90 degrees; and soaking the extrusion-state billet in liquid nitrogen for cooling, rolling the cooled billet to obtain a rolled billet, and repeatedly executing the cooling and rolling process until the billet subjected to the last time of rolling is thinned to reach a target thickness to obtain the ultrahigh-strength pure aluminum. By means of the preparation method, the strength of the pure aluminum isgreatly improved, and plasticity cannot be obviously weakened.

Owner:南通南京大学材料工程技术研究院 +1

Mixed density medium double-plastid vibration mill with convex springs without join of cycles

InactiveCN107138237ARealization without mergingAvoid resonanceGrain treatmentsHigh energyCoil spring

The invention provides a mixed density medium double-plastid vibration mill with convex springs without join of cycles. The vibration mill comprises a main vibration system and a vibration isolation system; the main vibration system comprises a vibration motor controlled by a frequency converter and used as an excitation source, and a milling cylinder fixed to the vibration motor; an upper plastid is made up of the vibration motor, the milling cylinder and an upper plastid plate, and one end of a lower plastid is connected to a main vibration spring set; the lower plastid is connected to the vibration isolation system through the main vibration spring set; the vibration isolation system comprises isolation springs connected to the other end of the lower plastid, and each isolation spring is connected to a foundation through a base; and the main vibration spring set is composed of a plurality of convex coil springs without join of cycles, and each spring is formed by winding a steel wire. The vibration mill provided by the invention has the characteristics of ultrafine particle refinement, disaggregation, narrowing of powder product distribution zone, low energy consumption, high grinding efficiency, high energy utilization rate, effective energy storage, energy saving, stable operation, obvious noise reduction, good vibration isolation effect, etc.

Owner:NANJING INST OF TECH

A kind of preparation method of porous metal oxide

The invention relates to a preparation method of a porous metal oxide, which belongs to the intersection field of metal powder technology and metal material surface treatment. The preparation method is as follows: degumming the short carbon fibers first, then passing the degummed short carbon fibers and metal powder through a proper ball milling process to obtain metal powder embedded with ultrafine carbon particles, and then sintering in a protective atmosphere or vacuum after pressing. Or direct loose-pack sintering, and finally perform short-term annealing in oxygen-containing air. While removing carbon particles in the metal powder, the surface of the metal particles is partially oxidized to obtain a porous metal with a partially oxidized surface. The porous metal oxide prepared by the invention exhibits good properties of oil storage, hydrogen storage, paraffin wax storage, lithium storage, and catalytic performance, and the preparation process is simple and the cost is low.

Owner:CENT SOUTH UNIV

Alloy tool steel in multi-type super-fine carbonates

InactiveCN100494461CHigh hardnessImprove wear resistanceHeat treatment process controlHigh carbonQuenching

This invention relates to alloying and heat treatment craft of tool die steel, it belongs to one kind of DM8B-2 multi-types superfine carbide high carbon alloy tool steel. Using alloy design method which voluntarily developing, do the phase equilibrium thermo dynamics, electronic / atom level binding energy computation,quenching and the tempered hardness computation as well as to synthesis appraisal its toughness and sintensity. Its ingredient characteristic is appropriate C quantity and Cr / (W+Mo) ratio, reasonable Si, Mn as well as few Ni; Its microstructure characteristic has the superfine carbide, annealing carbide size is between 0.05-0.8mum, when quenching, the undissolved carbide size should not to be smaller than 0.5mum. after quenching to add 200degree C-300degree C, tempering may enable the tempering hardness to achieve 61-64HRC by using carbide precipitation hardening. It has high yield strength and the impact toughness.In the thin edge cutting tool, cutting die and weightily attacking die areas, it has widespread application prospect.

Owner:DALIAN MARITIME UNIVERSITY

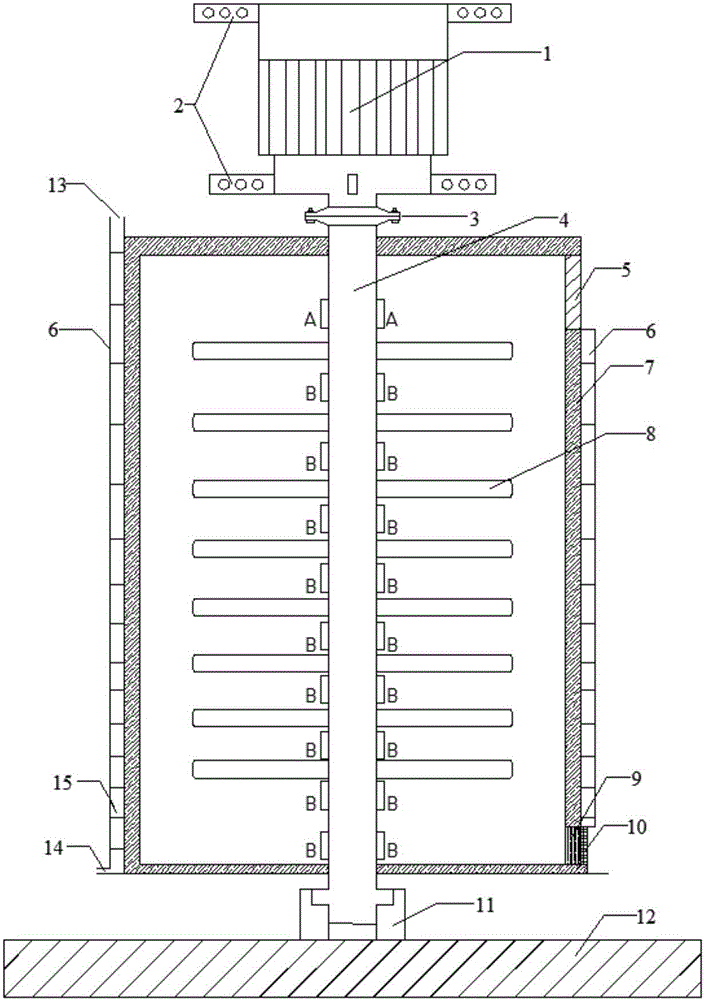

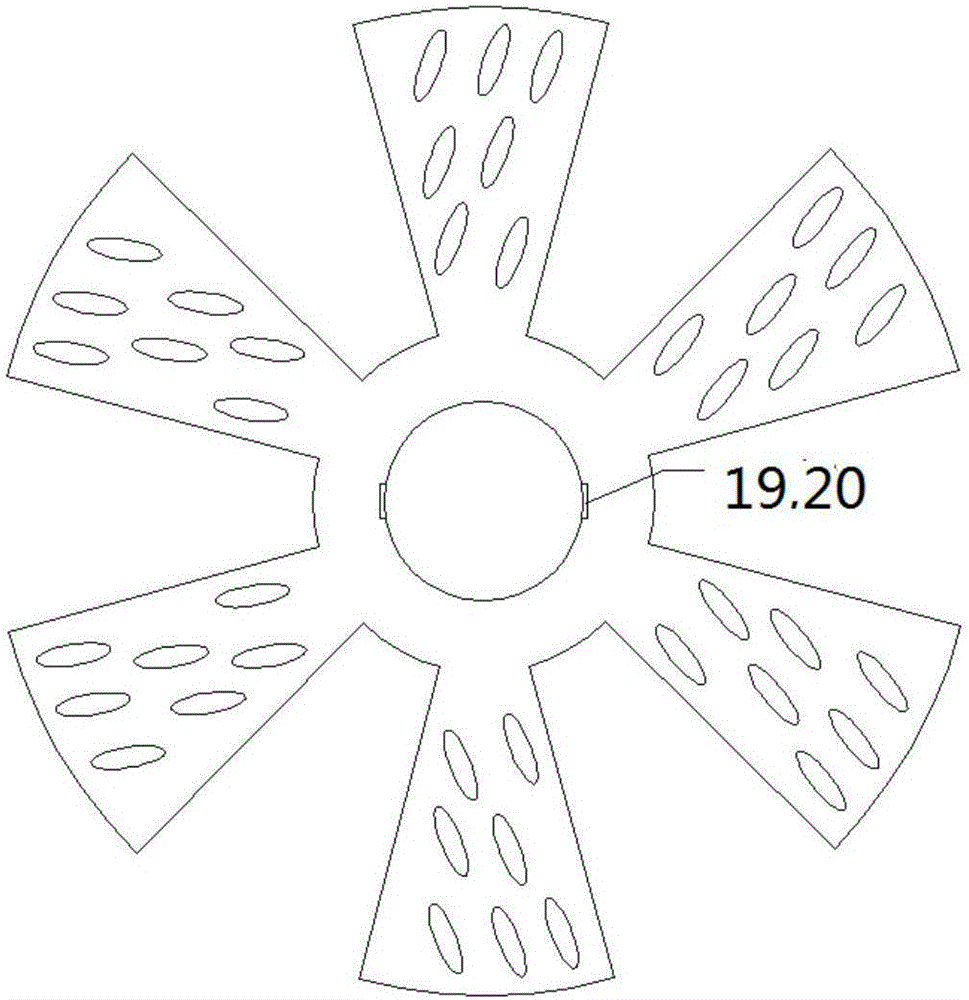

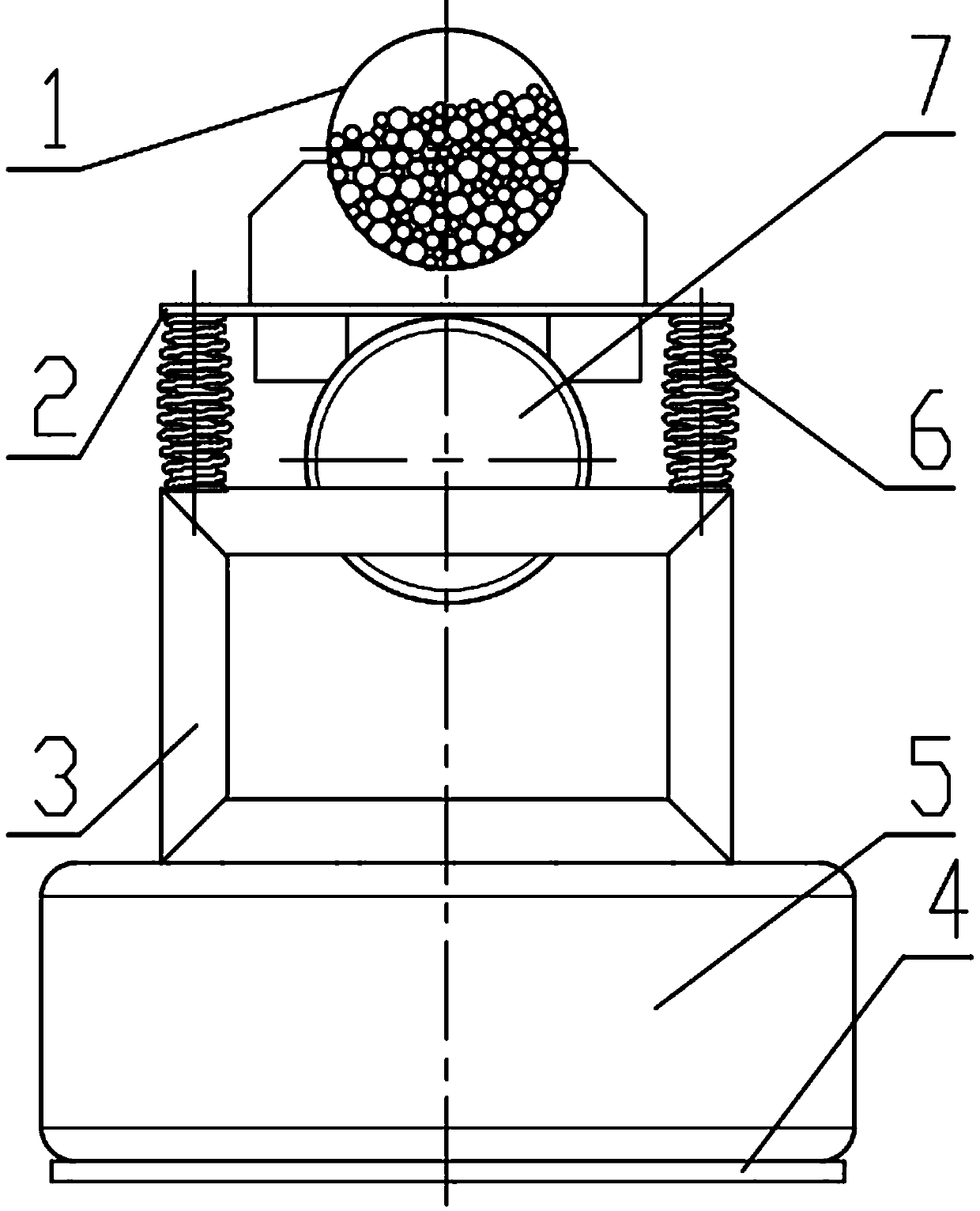

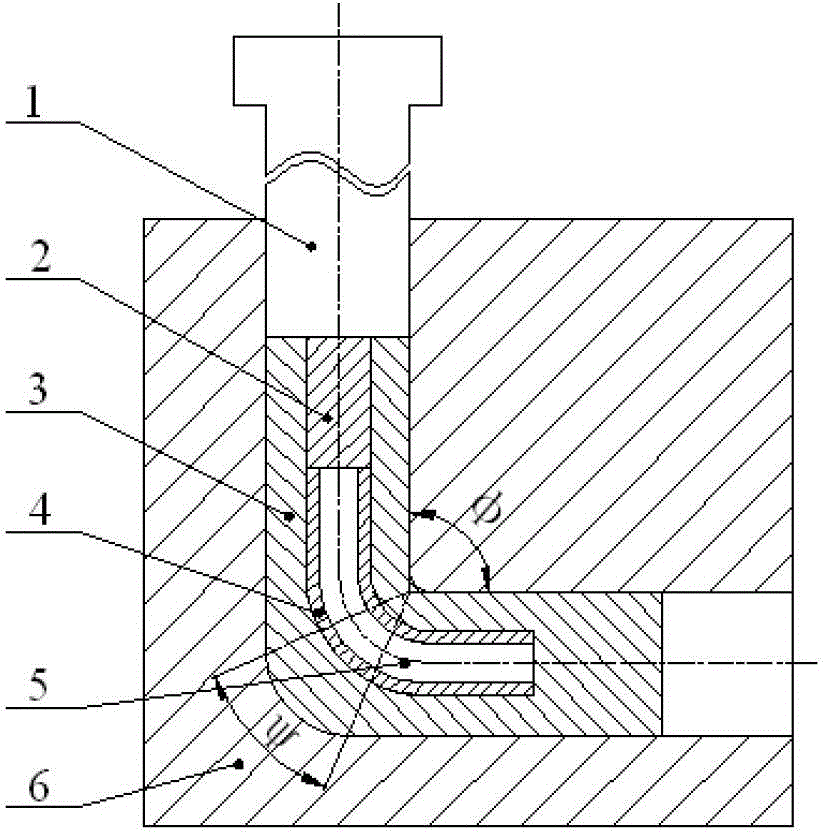

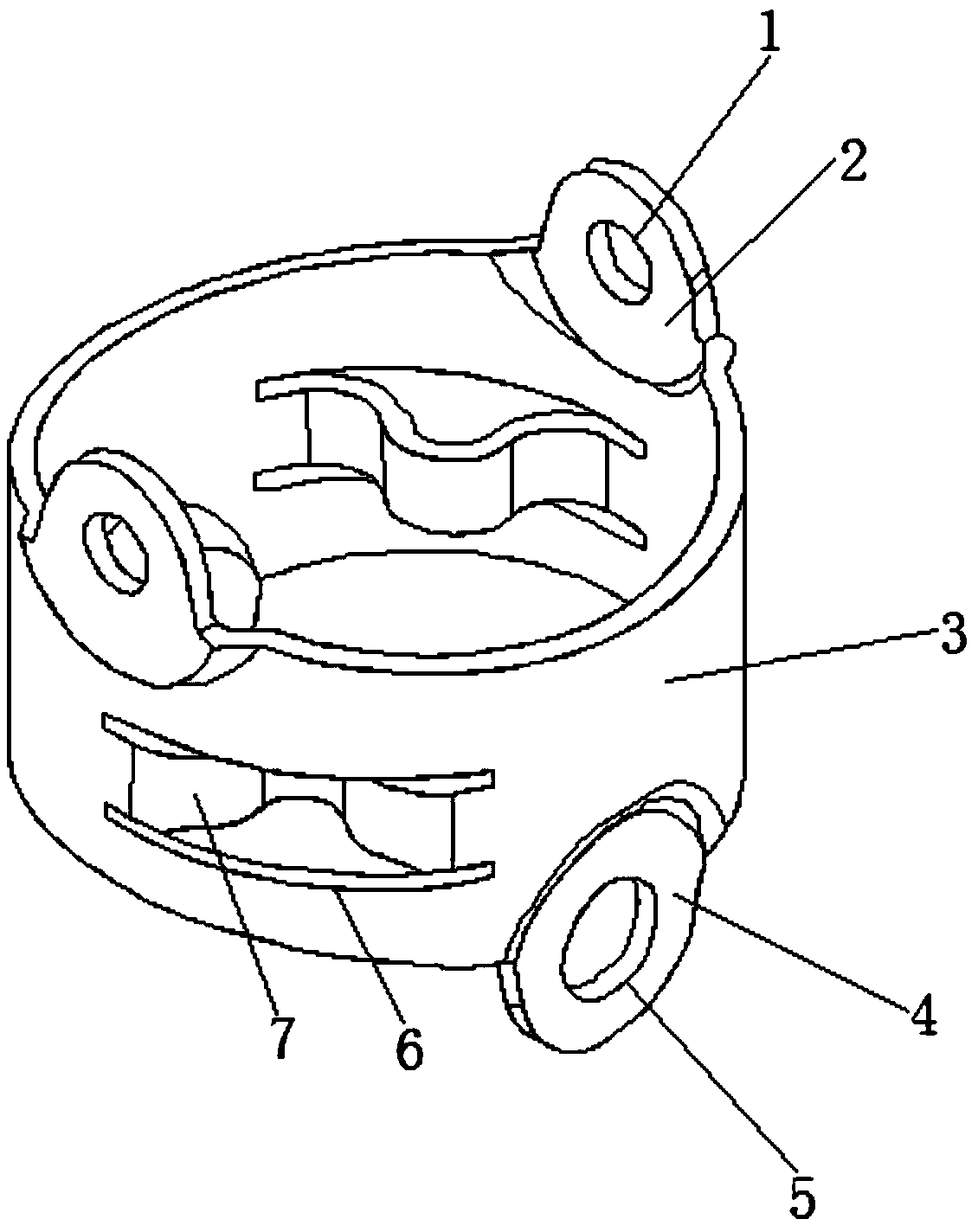

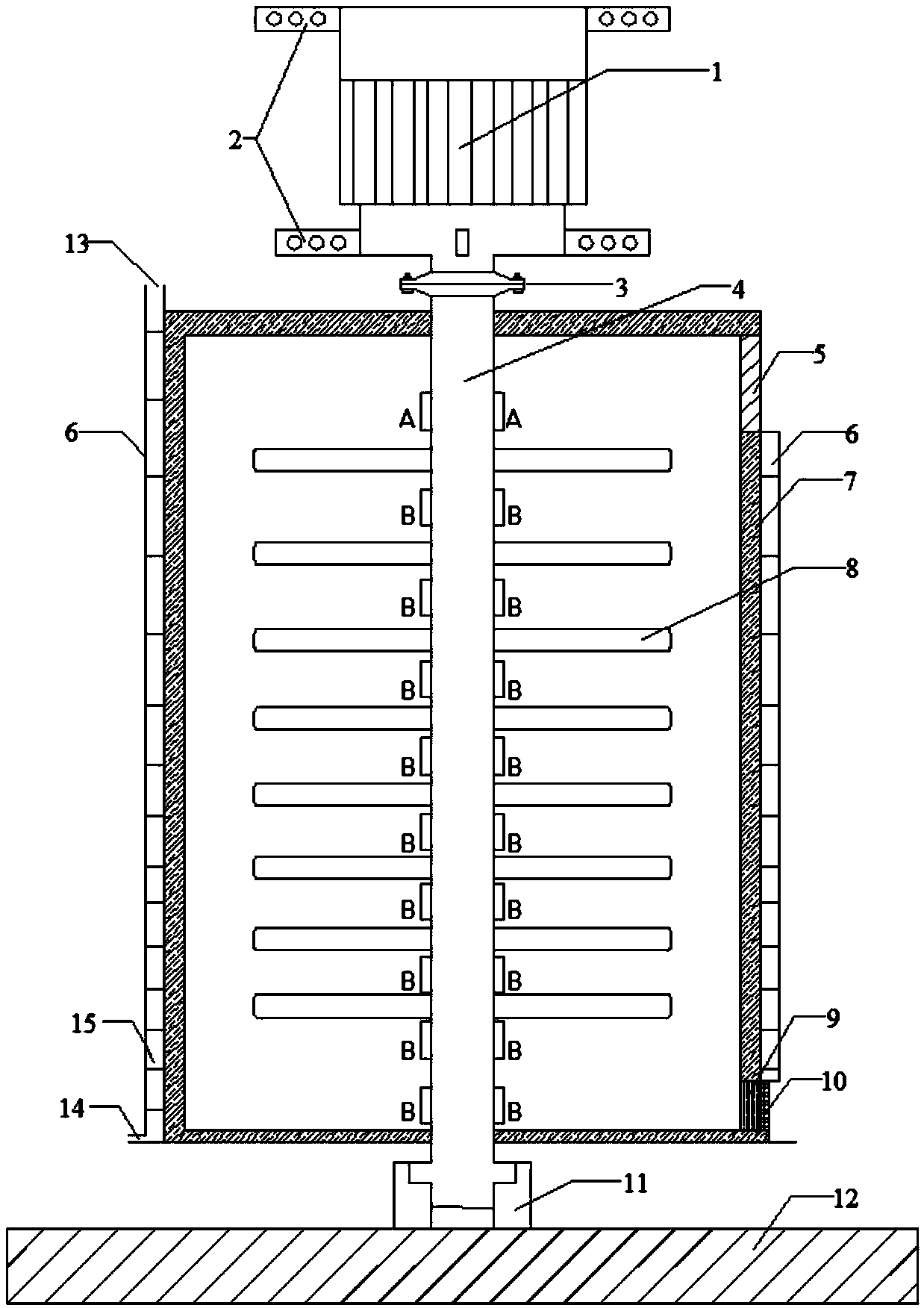

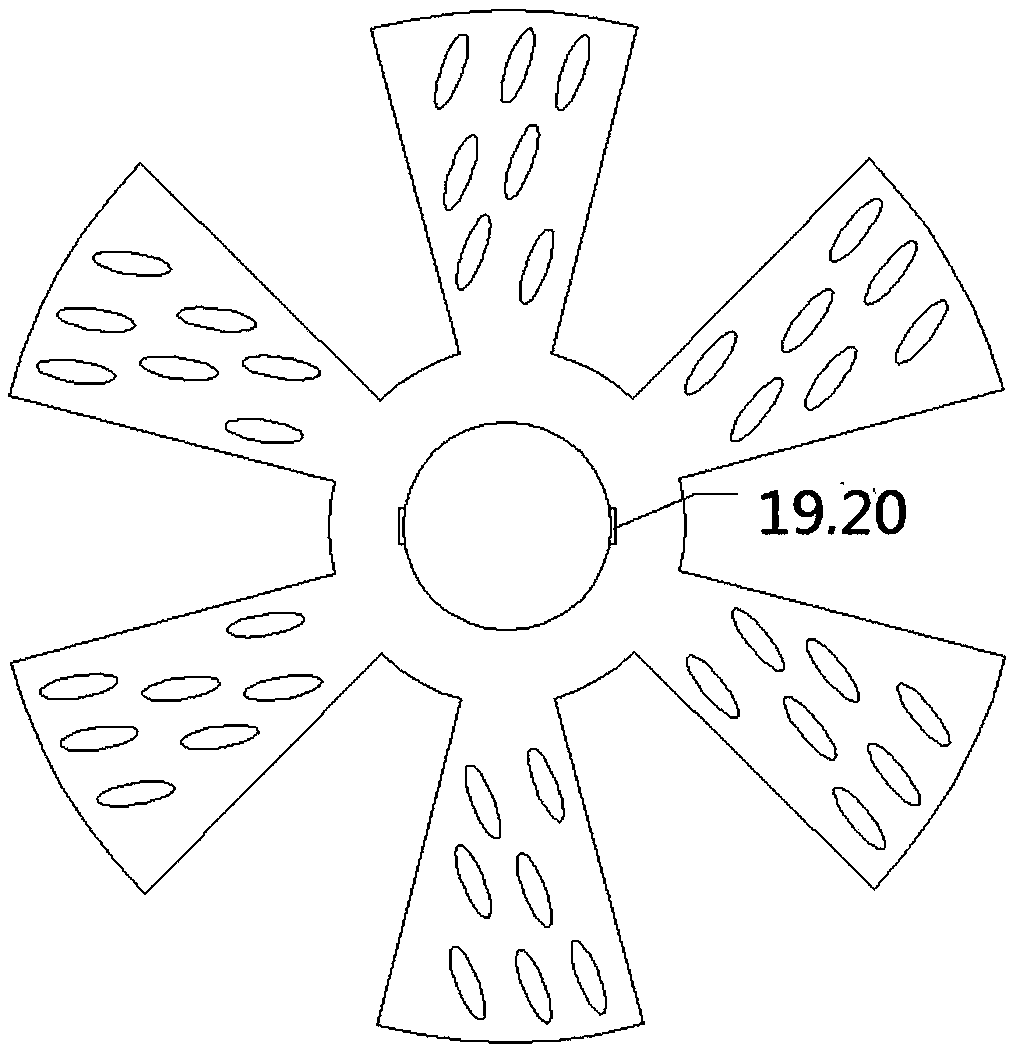

A centrifugal melt electrospinning device

ActiveCN104088024BAchieve ultra-fineRealize orderly collectionFilament/thread formingFiberLiquid storage tank

The invention discloses a novel centrifugal melt electrostatic spinning device. The device mainly comprises a spinning component, a receiving component, an electromagnetic heating component, a high voltage generating component, a power-driven component and a rack. The spinning component comprises a liquid storage tank, an end cover, first circular cone frustum spray head assemblies and second circular cone frustum spray head assemblies. The receiving component comprises a plastic bottom plate made of nylon and an aluminum receiving plate which can slide on the plastic bottom plate through bolt adjusting, wherein a groove is formed in the plastic bottom plate. The electromagnetic heating component comprises an electromagnetic coil, an electromagnetic control box, an infrared thermometer and supporting rods. The electromagnetic coil is located at the lower end of the liquid storage tank. The high voltage generating component comprises a high voltage generator, wherein a positive electrode of the high voltage generation is connected with the static receiving plate of the receiving component. The power-driven component comprises a motor and a shaft, the shaft is driven by the motor to rotate so as to drive the liquid storage tank to rotate. The rack is grounded and supports the whole spinning system. Centrifugal force is introduced into a traditional melt electrostatic spinning device, by the utilization of dual functions of electrostatic force and centrifugal force, fibers are stretched and refined, and finally nanometer fibers are manufactured in order in batch.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of superfine modified kaolin

The invention relates to a preparation method of superfine modified kaolin, which is characterized in that the preparation method comprises the following steps that (1), kaolin powder and carbamide are uniformly mixed in an open container, and fully absorb moisture in air to form a mixture; (2), the mixture is heated, and reacts at 70-120 DEG C; a kaolin-carbamide intercalation compound is prepared; an intercalation rate is 80%-98%; (3), the compound is placed into a ball mill; a certain amount of dispersing agent and water is added; wet grinding is conducted; the content of ground kaolin with a particle size less than 2 micrometers is above 90%; a kaolin mud cake is obtained through suction filtration and dehydration; (4) a certain amount of silane coupling agent and water is added into the kaolin mud cake, and stirred at 50-80 DEG C; a coupling reaction happens; the modification is achieved; and (5) the modified kaolin is dried, and the finished superfine modified kaolin is prepared. According to the preparation method, the intercalation rate is high; the influence on a crystal structure of the kaolin is small; a peeling effect is good; and the prepared superfine modified kaolin is particularly applicable to rubber and plastic materials and oil paint.

Owner:中国高岭土有限公司

A kind of porous metal oxide particle and preparation method thereof

ActiveCN109573952BEasy reunionAchieve ultra-fineOxygen/ozone/oxide/hydroxideIron oxides/hydroxidesFiberCarbon fibers

The invention relates to a porous metal oxide particle and a preparation method thereof and belongs to the technical field of metal powder. The preparation method of the porous metal oxide particle comprises degumming short carbon fiber, performing an appropriate ball-milling process on the degummed short carbon fiber and metal powder to obtain ultrafine carbon particle embedded metal powder; performing annealing treatment in an oxidizing atmosphere to obtain surface oxidation controllable porous metal powder. The prepared porous metal oxide particle is high in oil storage, hydrogen storage, paraffin storage and lithium storage performance as well as catalytic performance; meanwhile, the preparation method of the porous metal oxide particle is simple in process and low in cost.

Owner:CENT SOUTH UNIV

A kind of highly dispersed composite modified heavy calcium carbonate and preparation method thereof

ActiveCN111763435BGood dispersionAchieve ultra-finePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsEmulsionPolymethyl methacrylate

The invention discloses a high-dispersion composite modified ground calcium carbonate and a preparation method thereof, belonging to the technical field of powder modification. The method of the invention is as follows: firstly, the heavy calcium carbonate is put into an oven to be dehydrated at 100-110 DEG C, and then the heavy calcium carbonate and the polymethyl methacrylate emulsion are mixed with an electric mixer, and the polymethyl methacrylate emulsion is mixed. The dosage is 2.0% to 4.0% of the mass of heavy calcium carbonate, and then a secondary modifier (such as any one of stearic acid, titanate, and sodium tripolyphosphate) is added, and the mixture is stirred electrically for 40 minutes at 80 to 85°C. ~120min to obtain highly dispersed modified ground calcium carbonate powder. The modified ground calcium carbonate prepared by the invention has good dispersibility, the surface zeta potential is greater than 29.8mV, the average particle size is less than 500nm, the activation rate is greater than 90.8%, and the oil absorption value is less than 0.30ml / g. The high-dispersion modified heavy calcium carbonate powder prepared by the invention is mainly characterized in that it has high dispersibility and high activation rate, and can be used in the field of polymer composite materials.

Owner:HUBEI UNIV FOR NATITIES +1

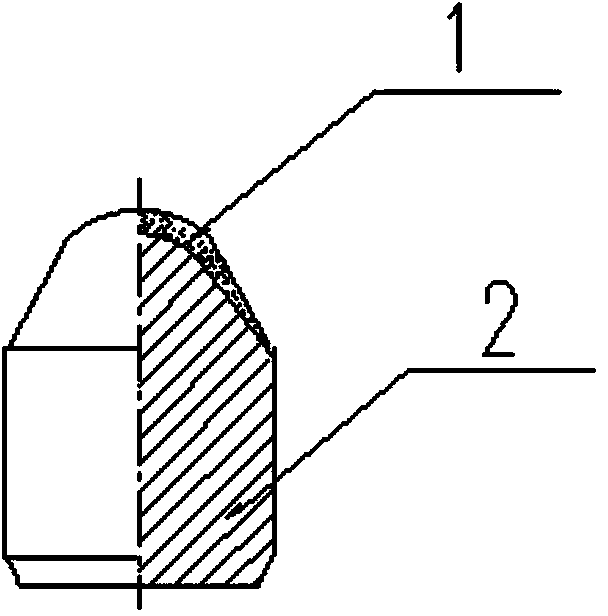

ECAE (equal channel angular extrusion) based preparation method of ultrafine crystal NiTi shape memory alloy tube

The invention provides an ECAE (equal channel angular extrusion) based preparation method of an ultrafine crystal NiTi shape memory alloy tube. A metal core is inserted into a NiTi shape memory alloy tube blank to be shaped, then the NiTi shape memory alloy tube blank is enclosed in a metal covering, and the metal covering, the NiTi shape memory alloy tube blank and the metal core are simultaneously extruded to generate shear plastic deformation in an ECAE production tool consisting of male die and a female die, so as to realize grain refinement of the NiTi shape memory alloy tube blank. Based on the fundamental of the ECAE method, a preparation method of an ultrafine crystal NiTi shape memory alloy tube is provided by the invention, so that high quality ultrafine crystal NiTi shape memory alloy tube can be produced, and production costs of the ultrafine crystal NiTi shape memory alloy tube can be reduced substantially.

Owner:HARBIN ENG UNIV

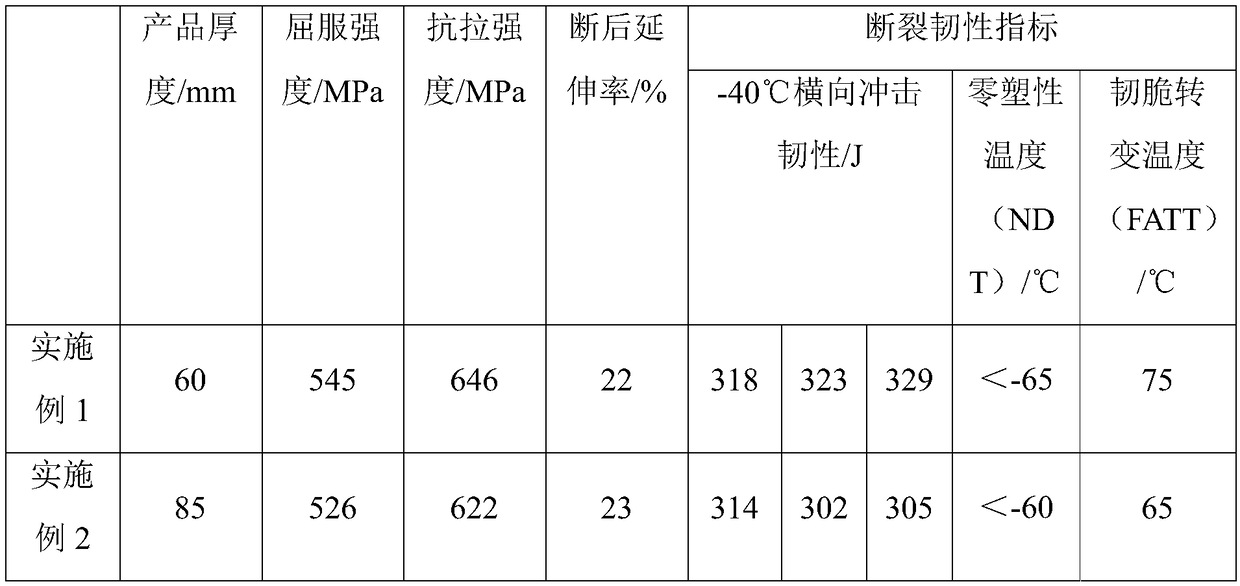

Production method for improving strength and toughness of extra-thick steel plate based on TMCP process

The invention relates to a production method for improving the strength and toughness of an extra-thick steel plate based on a TMCP process. The production method comprises the steps that a continuouscasting slab with the composition meeting the requirements is reheated, and then a qualified product is directly produced through a controlled rolling and controlled cooling process. The reasonable combination of strength and toughness is comprehensively considered on the aspects of rolling and cooling schedule optimization, the original austenite grain size is fully refined, the austenite deformation accumulation is increased, and a reasonable cooling system is adopted to ensure that the proportion of the structure is constant, so that the technological potential of modern material processing is fully reflected, the effect of phase change control technological means such as controlled rolling and controlled cooling on the improvement of strengthening and toughening of steel is brought into play, and the high fracture toughness of the low alloy ultra-thick steel product produced by the TMCP technology is ensured. The method has the beneficial effects of being low in cost, short in flow, high in precision, simplified in process and easily realizing industrialized mass production.

Owner:SD STEEL RIZHAO CO LTD

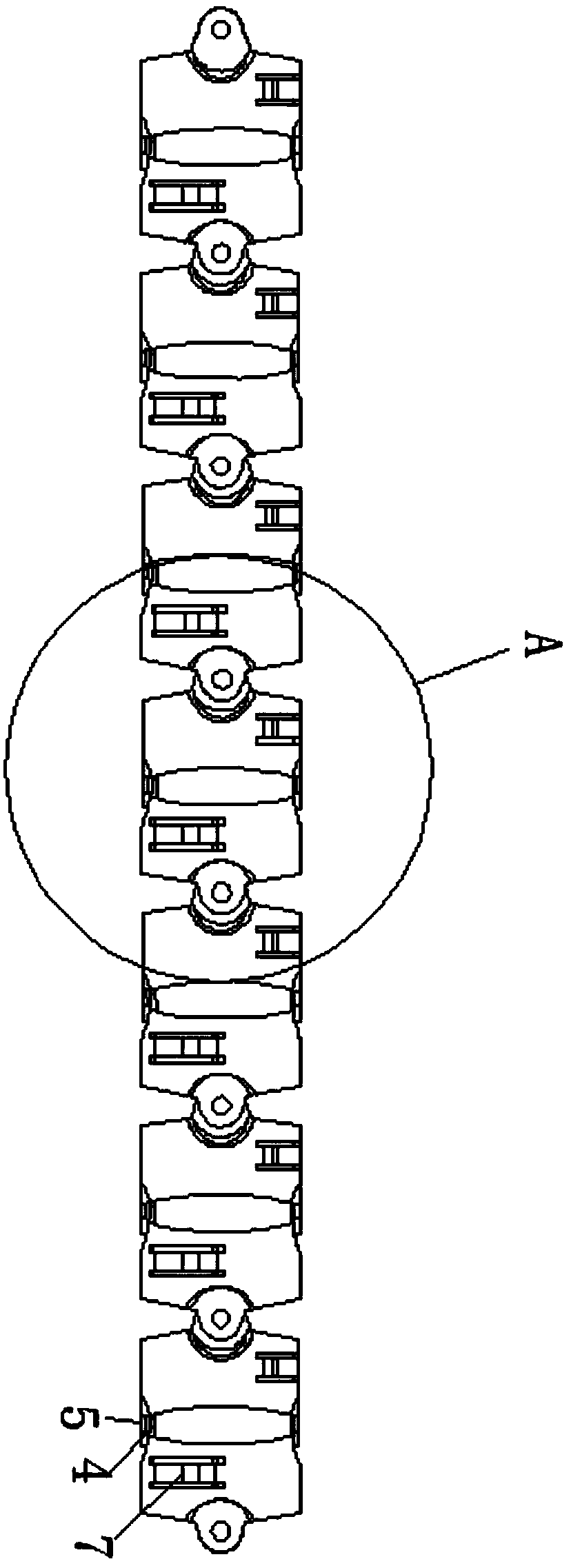

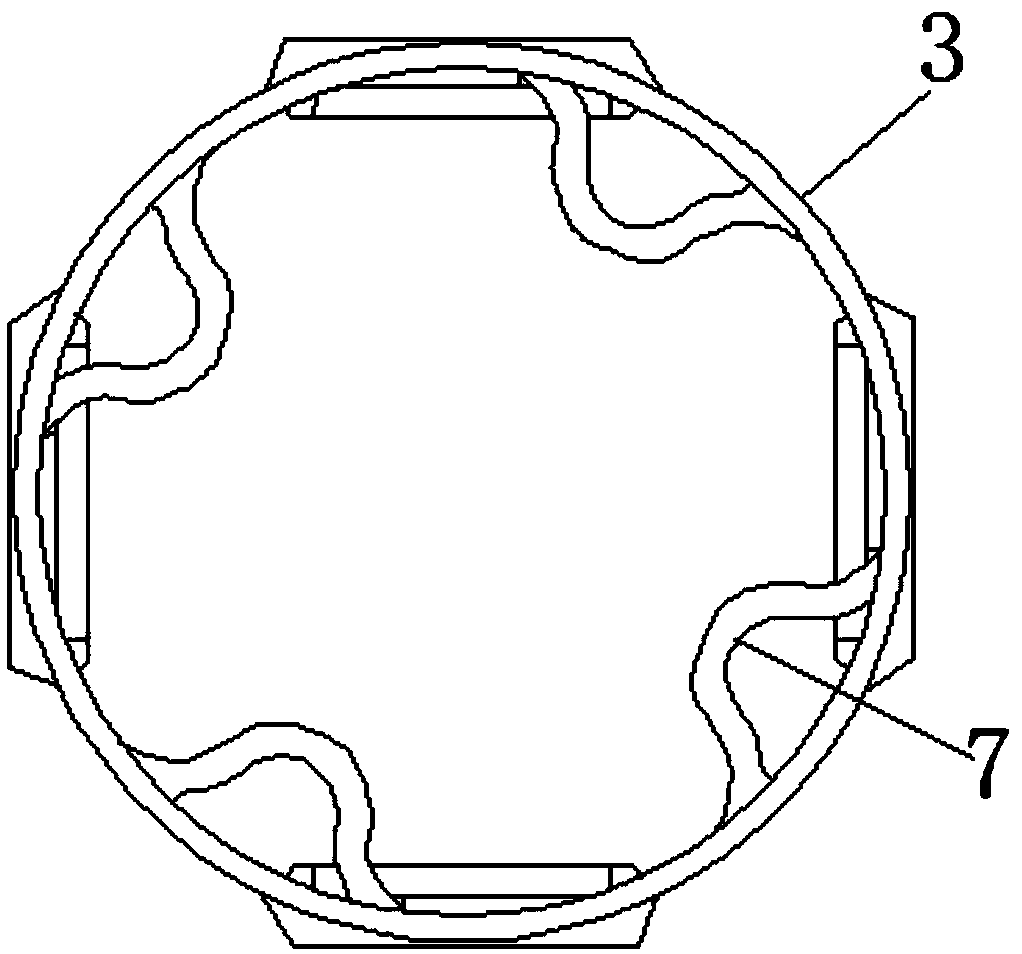

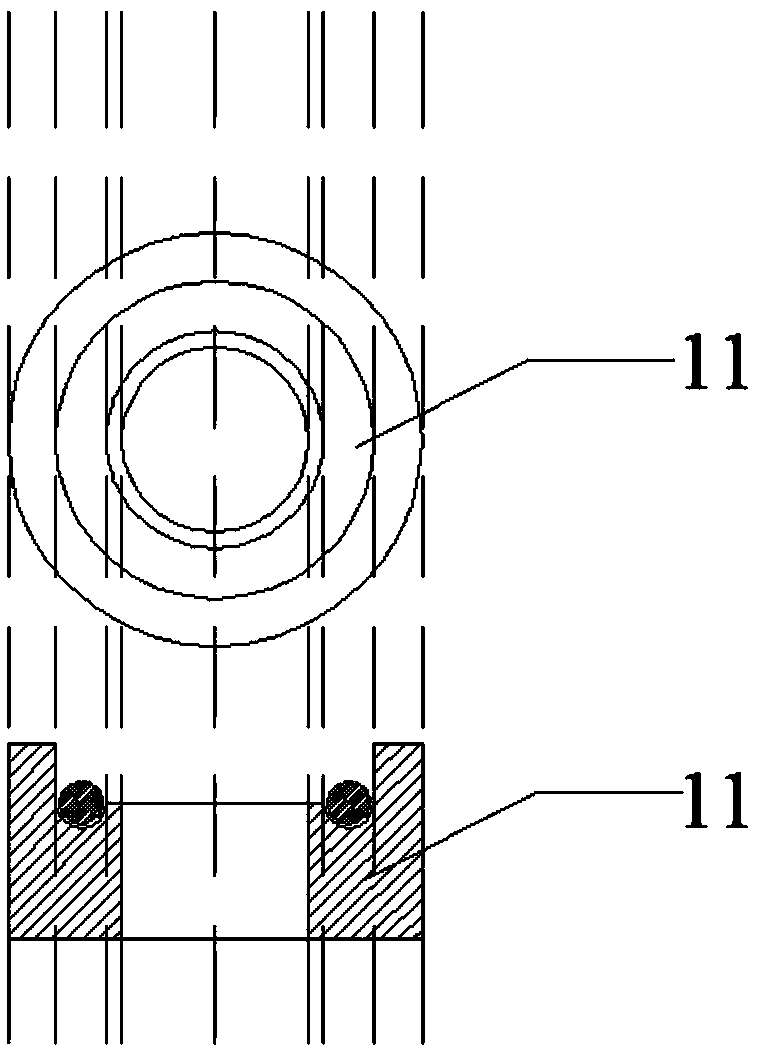

Miniaturized four-directional industrial endoscope snake bone

The invention discloses a miniaturized four-directional industrial endoscope snake bone. The snake bone includes snake bone section circles. Concave ears are mounted on two sides of the top of each snake bone section circle. Concave-ear through-holes are arranged at intermediate positions of the concave ears. Concave ears are mounted on two sides of the bottom of the snake bone section circle. Concave-ear through-holes are arranged at intermediate positions of the concave ears. Side through-holes are evenly arranged at intermediate positions outside the snake bone section circle. Steel wire grooves are arranged inside the side through-holes. According to the snake bone, a specific groove pressing manner is adopted, a conventional spot-welding small-steel-pipe manner is abandoned, a specific punching method is adopted for obtaining the steel wire grooves by punching, thus expansion of internal space can be ensured, a specific ear punching manner is adopted, conventional concave-convex-ear cooperation connection tolerance is reduced, an outer diameter of the whole snake bone is reduced for facilitating realization of ultra-thinning, the outer diameter of the snake bone is reduced from 3.2mm to 2.1mm, proper steel wire groove positions are obtained by study, and laser cutting is utilized for cutting the steel wire grooves in specific orientation.

Owner:杭州鑫泽源医疗科技有限公司

Wet mill for industrial processing of concrete admixtures

ActiveCN106345576BAchieve ultra-fineAchieve recyclingGrain treatmentsReinforced concrete columnWear resistant

The invention relates to a wet grinding machine for industrial treatment of concrete admixtures. An embedded component is connected onto a tube body; the embedded component is fixed on a reinforced concrete column; power equipment is connected onto a rotating shaft, and the lower part is born by a bearing component; the bearing component is provided with a wear-resistant steel ball horizontal round groove; the bearing component is firmly connected with a basic concrete structure; the rotating shaft is connected with a stirring disc through a connecting key; a feeding opening is formed in the upper side of the tube body; a discharging opening is formed in the lower side of the tube body, and consists of a movable baffle plate and a grille outside the movable baffle plate; a cooling water jacket is arranged outside the tube body; a cooling guide pipe is arranged in the tube body, and is connected with the cooling water jacket; medium grinding balls are arranged in the tube body. The stirring disc is driven through the rotating shaft and the power equipment fixed at the upper part of the support frame; the stirring disc drives materials and the medium grinding balls to generate collision, friction, shearing and extrusion, so that materials are finely ground. The wet grinding machine has the advantages that the mechanical structure and the heat radiation principle are utilized; the material wet grinding disposal superfining is realized; the treatment quantity is great; the resource waste is reduced; the cyclic utilization of solid wastes is realized.

Owner:湖北青垚环境有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com