Preparation method of superfine modified kaolin

A kaolin and modification technology, which is applied in the fields of ultra-fine modified kaolin, preparation of ultra-fine modified kaolin, rubber and plastic materials and oil-based coatings, and can solve the problems of easily damaged kaolin crystal structure, low intercalation rate, poor control, etc. problem, to achieve the effect of good peeling effect, strong control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of preparation method of superfine modified kaolin

[0028] Consists of the following steps in turn:

[0029] The first step is to weigh 50g of kaolin powder (brand name RF0) and 50g of urea from China Kaolin Co., Ltd. respectively, and then mix the two evenly in a non-airtight vortex mixer to obtain a mixture. After the mixture fully absorbs the moisture in the air reserve;

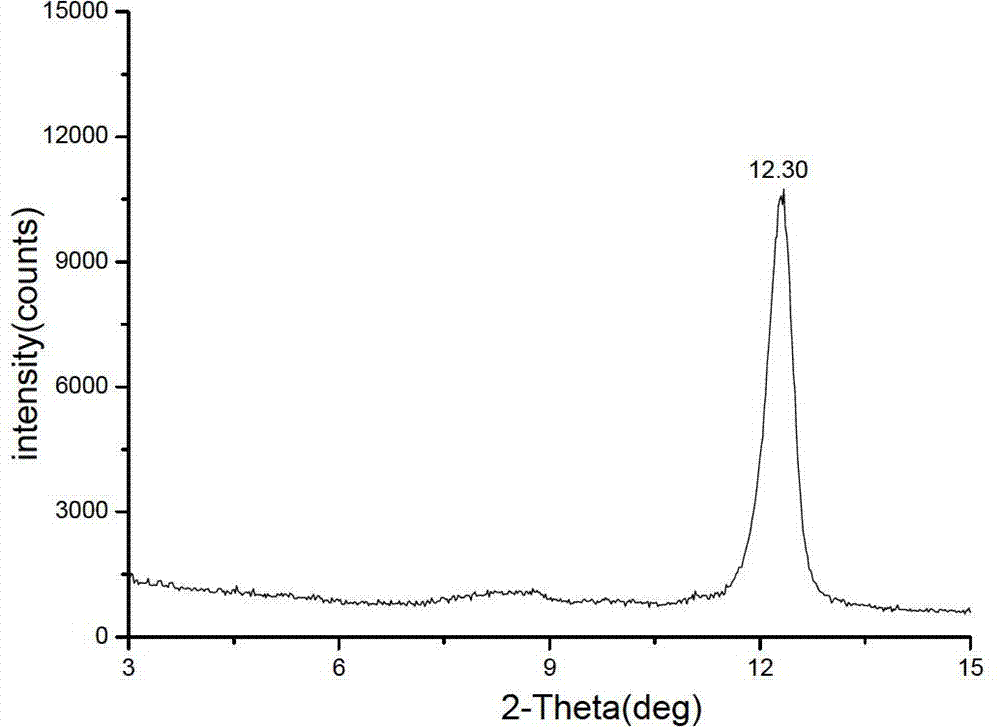

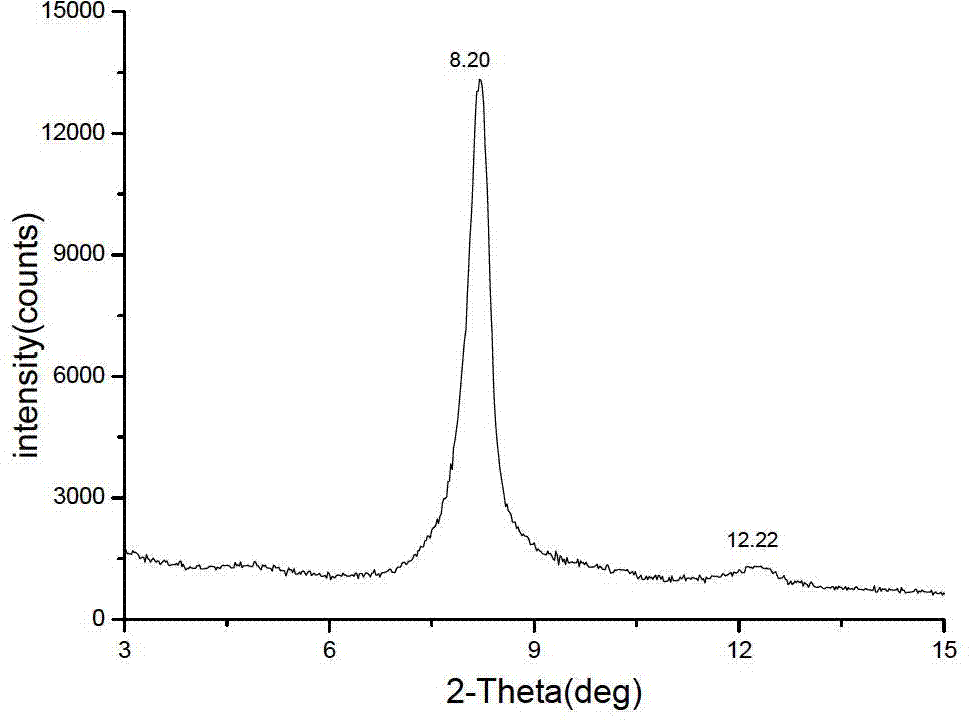

[0030] In the second step, the mixture prepared in the first step is heated in a closed environment, and the mixture is reacted at 120° C. for 48 hours, so that the urea molecules are inserted between the kaolin sheets to obtain a kaolin-urea intercalation complex, The intercalation rate reaches 98%. According to attached figure 1 And attached figure 2 According to the X-ray diffraction pattern shown, the kaolin 001 plane diffraction peak 2θ≈12.30o without intercalation, and the interlayer distance d001=0.74nm. When urea is intercalated, its 001 plane diffraction peak sh...

Embodiment 2

[0042] Embodiment 2: A kind of preparation method of superfine modified kaolin

[0043] The first step is to weigh 70g of kaolin powder (brand RF0) and 30g of urea from China Kaolin Clay Co., Ltd. respectively, and then mix the two evenly in a non-airtight vortex mixer to obtain a mixture. After the mixture fully absorbs the moisture in the air reserve;

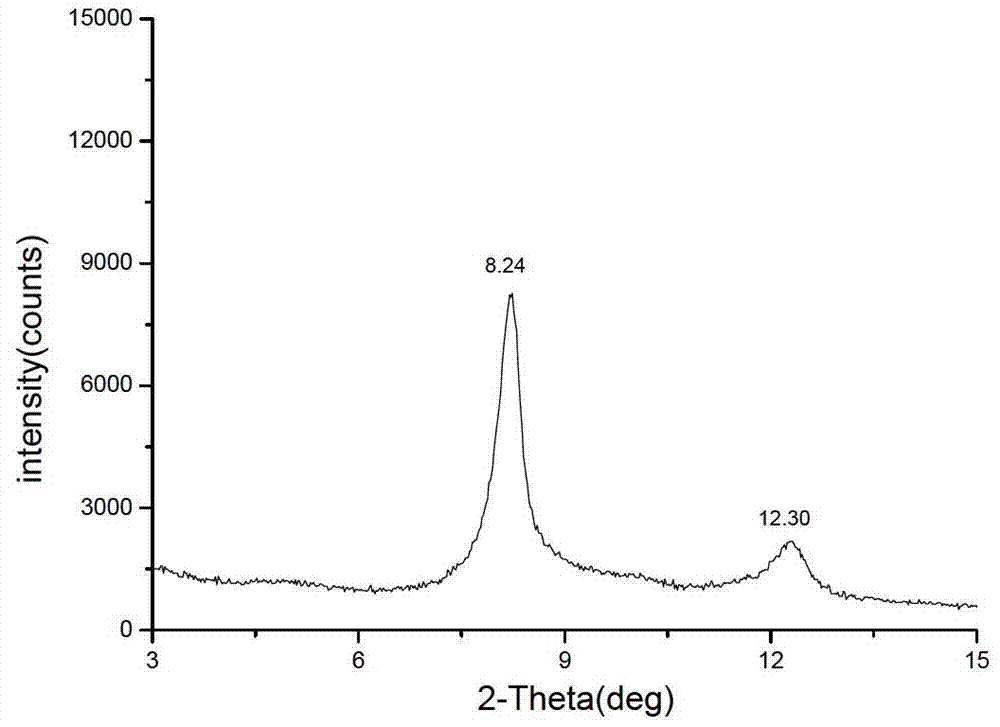

[0044] In the second step, the mixture prepared in the first step is heated in a closed environment, and the mixture is reacted at 100° C. for 24 hours, so that the urea molecules are inserted between the kaolin sheets to obtain a kaolin-urea intercalation complex, The intercalation rate reaches 88%; according to the attached image 3 As shown, the diffraction peak of kaolin 001 plane without intercalation is 2θ≈12.30o, and the interlayer distance d001=0.74nm. When urea is intercalated, its 001 plane diffraction peak shifts to a small angle to 2θ≈8.24o, and the interlayer distance d001=1.06nm. The increase of interlayer sp...

Embodiment 3

[0051] Embodiment 3: A kind of preparation method of superfine modified kaolin

[0052] Consists of the following steps in turn:

[0053] The first step is to weigh 90g of kaolin powder (brand name RF0) and 10g of urea from China Kaolin Clay Co., Ltd., and then mix the two evenly in a non-airtight vortex mixer to obtain a mixture. After the mixture fully absorbs the moisture in the air reserve;

[0054] In the second step, the mixture prepared in the first step is heated in a closed environment, and the mixture is reacted at 70° C. for 12 hours, so that urea molecules are inserted between the kaolin sheets to obtain a kaolin-urea intercalation complex, The intercalation rate reached 81%; according to the attached Figure 4 As shown, the diffraction peak of kaolin 001 plane without intercalation is 2θ≈12.30o, and the interlayer distance d001=0.74nm. When urea is intercalated, its 001 plane diffraction peak shifts to a small angle to 2θ≈8.18o, and the interlayer distance d001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com