Air-cooled hardened steel plate with ultra-high strength, high toughness and ultra-fine structure and preparation process of air-cooled hardened steel plate

An ultra-high-strength, microstructure technology, applied in the direction of manufacturing tools, heat treatment equipment, furnace types, etc., can solve the problems of strict sample size and equipment requirements, unfavorable large-scale industrial production, unfavorable environmental protection and other problems, to promote micro-stress Strain distribution, excellent comprehensive mechanical properties, fine grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

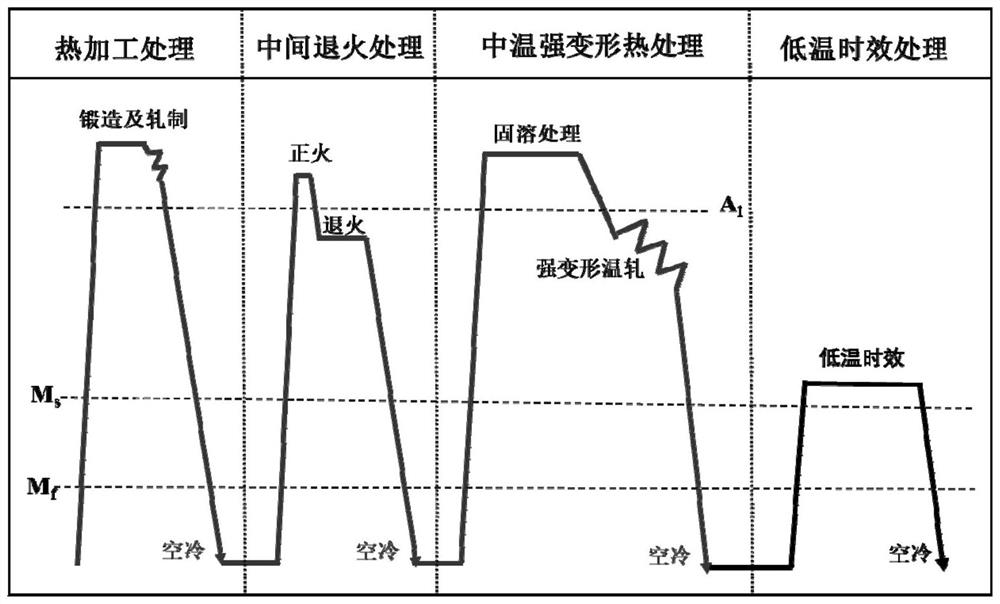

[0037] A method for preparing an air-cooled hardened steel plate with ultra-high strength, high toughness, and ultrafine structure, such as figure 1 As mentioned, the steps are as follows:

[0038] (1) Alloy smelting: The mass percentage of the chemical composition of the alloy is: C: 0.08%, Si: 0.1%, Mn: 0.2%, Cr: 10%, W: 2.0%, Co: 2.0%, V: 0.1%, Nb : 0.025%, N: 0.03%, Ta: 0.05%, Nd: 0.02%, the B content is controlled below 0.0005%, and the remaining ingredients are Fe and unavoidable impurities; Stir evenly for smelting, detect and adjust the composition to the requirements before the furnace, and then cast into ingots. The smelting method can be vacuum electric arc furnace smelting, vacuum induction plus electroslag remelting, vacuum smelting plus vacuum self-consumption, or a combination of both. Vacuum electric arc furnace smelting is used in this embodiment;

[0039] (2) Homogenization treatment and billet opening: the ingot is cast at 1250°C, the holding time is 4h, t...

Embodiment 2

[0045] A method for preparing an air-cooled hardened steel plate with ultra-high strength, high toughness, and ultrafine structure, the steps are as follows:

[0046] (1) Alloy smelting: The mass percentage of the chemical composition of the alloy is: C: 0.08%, Si: 0.35%, Mn: 0.8%, Cr: 15%, W: 3.0%, Co: 3.0%, V: 0.3%, Nb : 0.08%, N: 0.06%, Ta: 0.1%, Nd: 0.04%, the B content is controlled below 0.0005%, and the remaining ingredients are Fe and unavoidable impurities; Stir evenly for smelting, detect and adjust the composition to the requirements before the furnace, and then cast into ingots. The smelting method can be any one or a combination of vacuum electric arc furnace smelting, vacuum induction plus electroslag remelting, vacuum smelting plus vacuum self-consumption;

[0047] (2) homogenization treatment and blanking are the same as example 1 step (2);

[0048] (3) high temperature thermal processing is with example 1 step (3);

[0049] (4) Secondary intermediate anneal...

Embodiment 3

[0054] A method for preparing an air-cooled hardened steel plate with ultra-high strength, high toughness, and ultrafine structure, the steps are as follows:

[0055] (1) Alloy smelting: The mass percentage of the chemical composition of the alloy is: C: 0.08%, Si: 0.25%, Mn: 0.4%, Cr: 12%, W: 2.5%, Co: 2.5%, V: 0.2%, Nb : 0.05%, N: 0.04%, Ta: 0.08%, Nd: 0.03%, the B content is controlled below 0.0005%, and the remaining components are Fe and unavoidable impurities; Stir evenly for smelting, detect and adjust the composition to the requirements before the furnace, and then cast into ingots. The smelting method can be any one or a combination of vacuum electric arc furnace smelting, vacuum induction plus electroslag remelting, vacuum smelting plus vacuum self-consumption;

[0056] (2) homogenization treatment and blanking are the same as example 1 step (2);

[0057] (3) high temperature thermal processing is with example 1 step (3);

[0058] (4) Secondary intermediate anneal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com