Production method for improving strength and toughness of extra-thick steel plate based on TMCP process

An extra-thick steel plate and performance technology, which is applied in the field of preparation based on the TMCP process to improve the strength and toughness of extra-thick steel plates, can solve the problems of high production cost, difficulty in meeting high-performance steel, and low production efficiency, and achieve excellent performance and The effect of shape size, large strength and toughness margin, and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

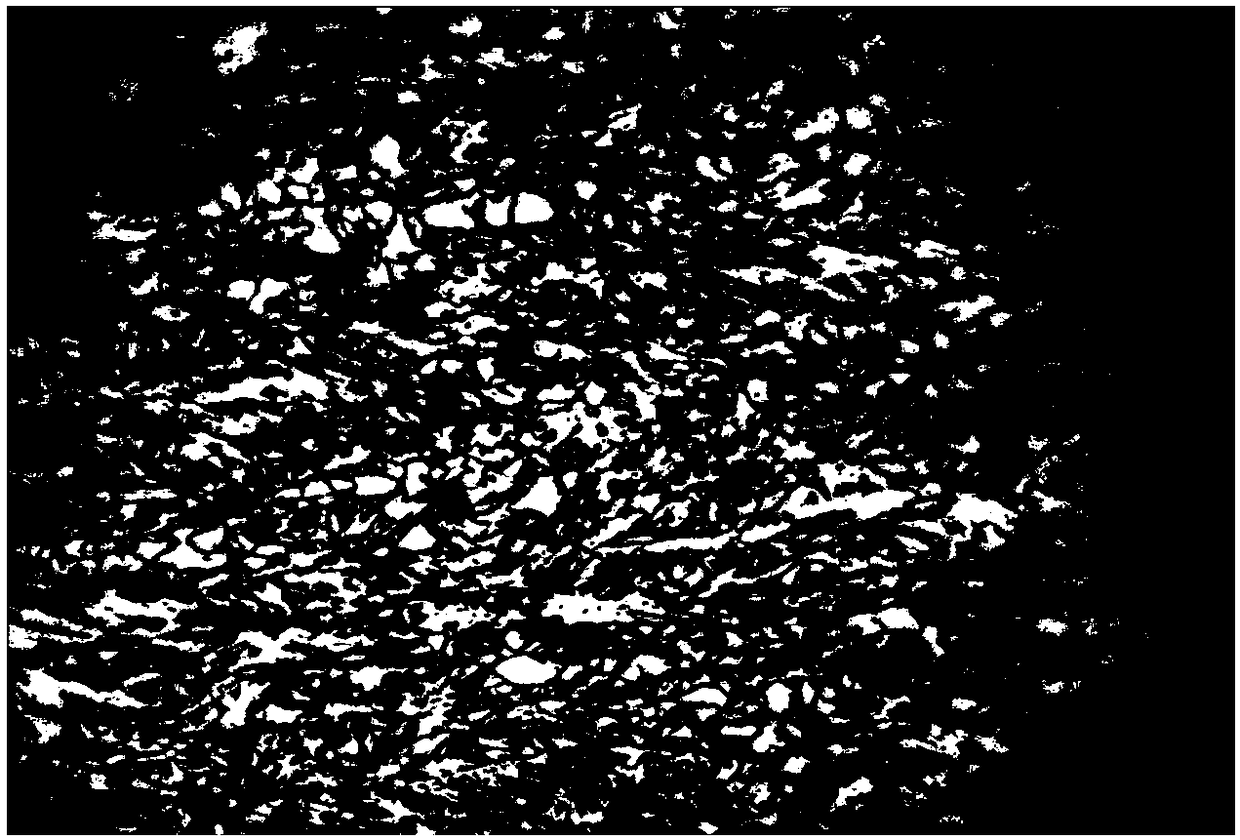

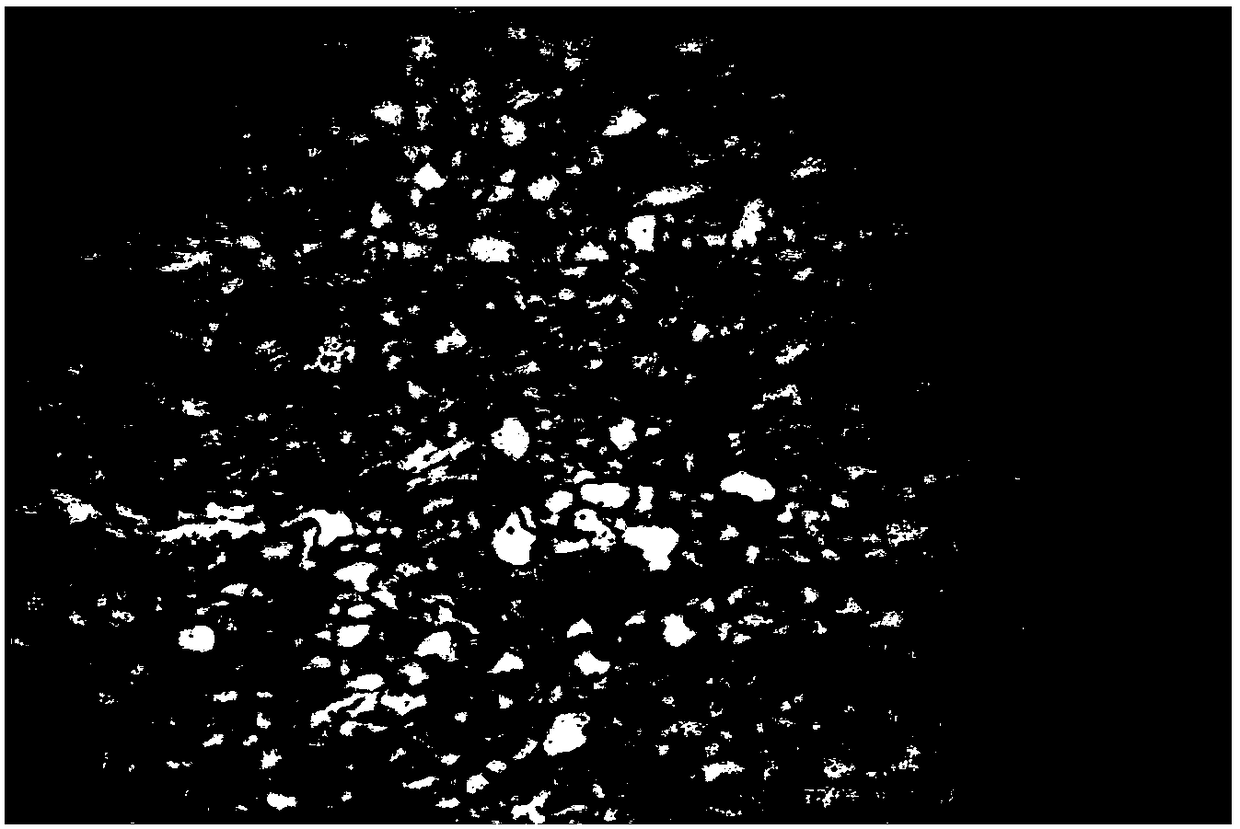

Image

Examples

preparation example Construction

[0028] A preparation method for improving the strength and toughness of extra-thick steel plates based on TMCP process, including the following steps:

[0029] a) Reheat the 250-300mm continuous casting slab with the required composition, the heating temperature is 1150-1200℃, and the heating time is 9-11min / cm;

[0030] b) The continuous casting billet is rolled into a semi-finished product: the heated rectangular continuous casting billet undergoes a rough rolling stage at a rolling temperature of 1080-1130°C, and the intermittent rolling temperature is controlled in the range of 950-980°C;

[0031] c) The semi-finished product is sent to the finishing rolling mill, and the rolling schedule of the finishing rolling stage is accurately controlled, and the final rolling temperature is 780-820℃;

[0032] d) The starting temperature of the primary cooling of the steel plate after rolling is greater than 760℃, the secondary cooling is controlled within the range of the ferrite transformat...

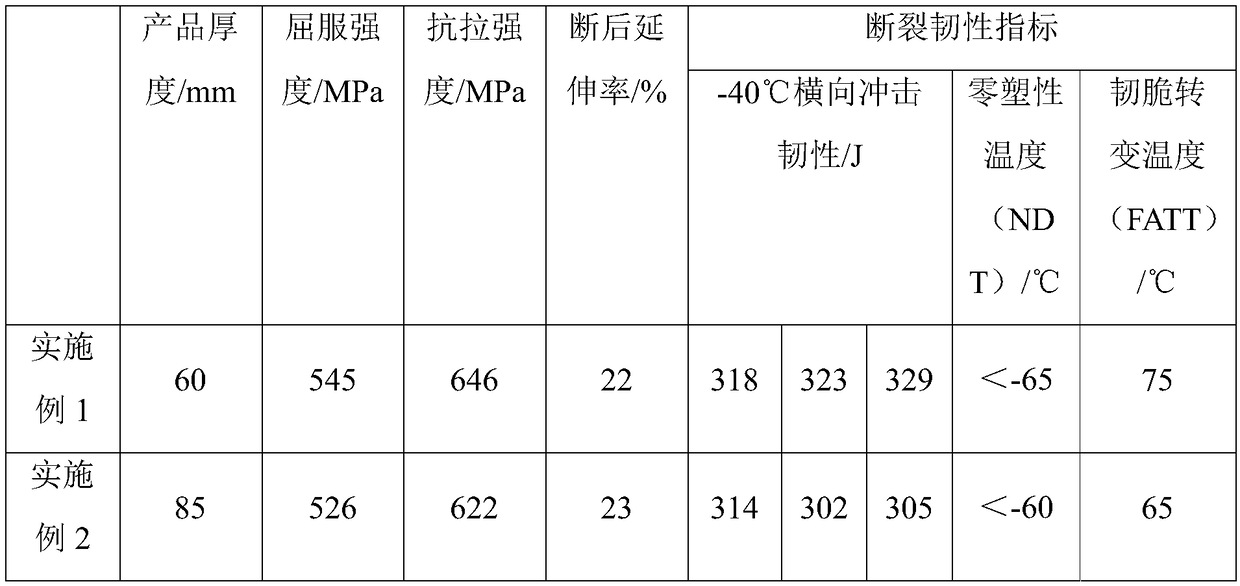

Embodiment 1

[0039] The 250mm continuous casting slab with the required composition is reheated to 1150°C for 4 hours in the furnace. After coming out of the furnace, it enters the rough rolling mill for the first stage of high-temperature rolling. The rolling is started at 1100°C. The rolling speed is controlled at 1.5-1.8m / s. After multiple passes of longitudinal rolling and widening to the required width, when the thickness of the rolled piece is reduced to When 160mm, control the steel rolling rhythm, when the temperature drops to 960℃, start intermittent rolling, and roll into 114mm semi-finished products in two passes. The interval between the control passes is more than 30 seconds; it is sent to the finishing mill for rapid rolling It is made into a 60mm steel plate with 15 seconds between passes, and the final rolling is finished at 810°C. After rolling, 790°C starts to cool to Ar3-40°C at a cooling rate of 3°C / s, and then cools to 400°C at a rapid cooling rate of 20°C / s. Then air-...

Embodiment 2

[0041] The 300mm continuous casting slab with the required composition is reheated to 1200°C for 5 hours in the furnace. After coming out of the furnace, it enters the rough rolling mill for the first stage of high temperature rolling. The rolling is started at 1120°C. The rolling speed is controlled at 0.7-1.2m / s. After multiple passes of longitudinal rolling and widening to the required width, when the thickness of the rolled piece is reduced to At 195mm, control the steel rolling rhythm, when the temperature drops to 980℃, start intermittent rolling, and roll into a 140mm semi-finished product in two passes. The interval between the control passes is more than 70 seconds; it is sent to the finishing mill for rapid rolling To 80mm steel plate, the interval between passes is 10 seconds, and the final rolling is guaranteed at 790℃. After rolling, 770°C starts to cool to Ar3-50°C at a cooling rate of 5°C / s, and then cools to 350°C at a rapid cooling rate of 30°C / s. Then air-coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com