Environment-friendly demolding equipment for heating and heat-preserving lunch box

A heating, heat preservation and environment-friendly technology, which is applied in the field of demoulding equipment for environment-friendly heating and heat preservation lunch boxes, can solve the problems that the lunch boxes cannot be demoulded quickly, the use effect is not ideal, and the production efficiency is affected, so as to achieve accurate and rapid demoulding Effect of mold release and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objects, technical solutions, and advantages of the present invention, the technical solutions of the present invention will be described in detail below. Obviously, the described embodiments are merely the embodiments of the invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative labor are in the range protected by the present invention.

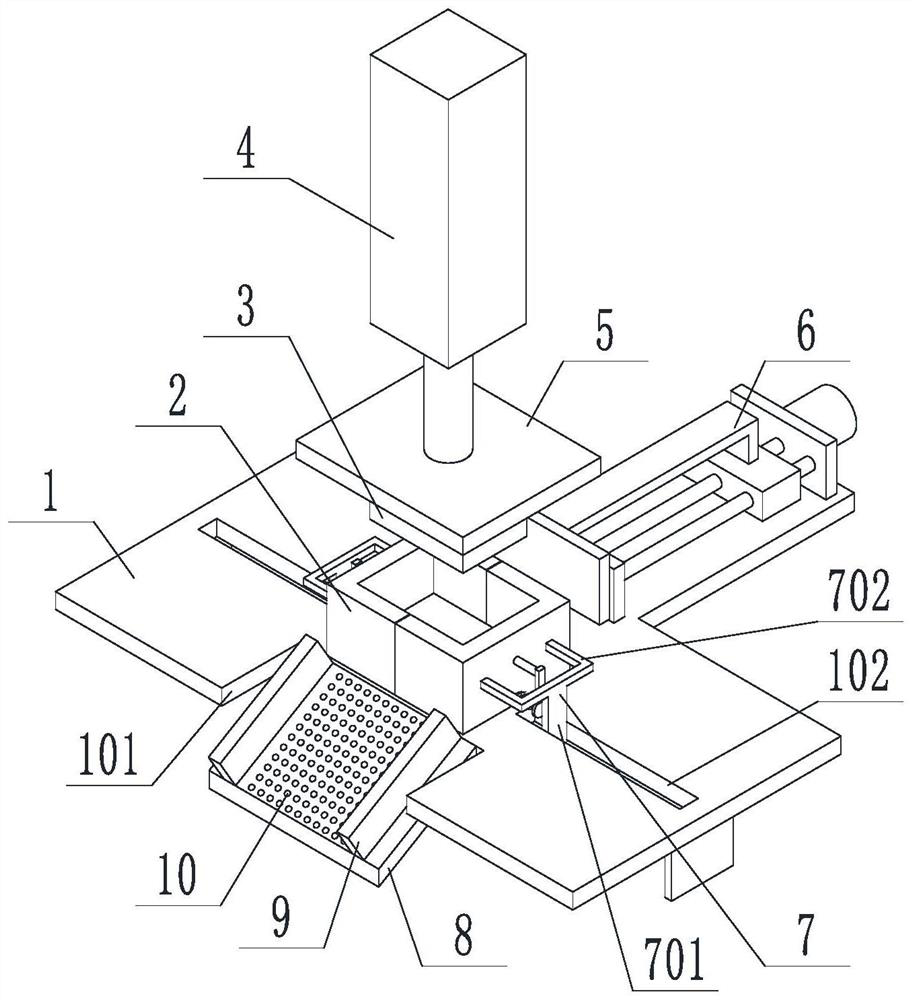

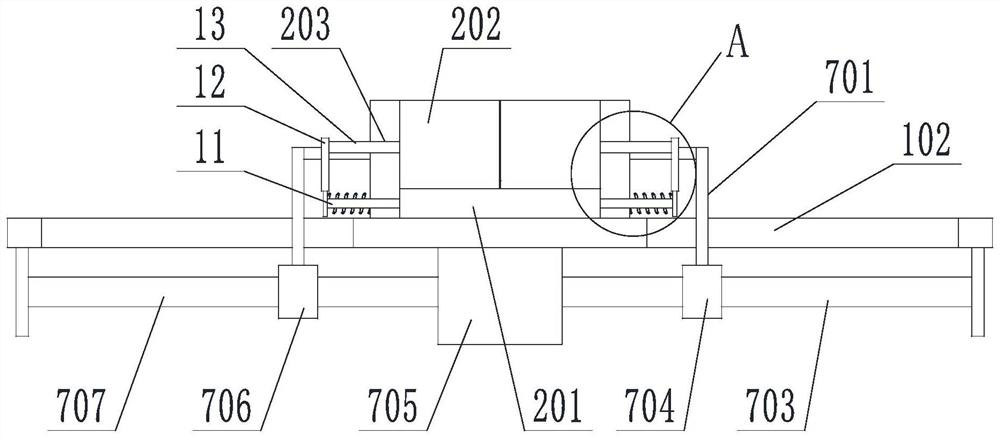

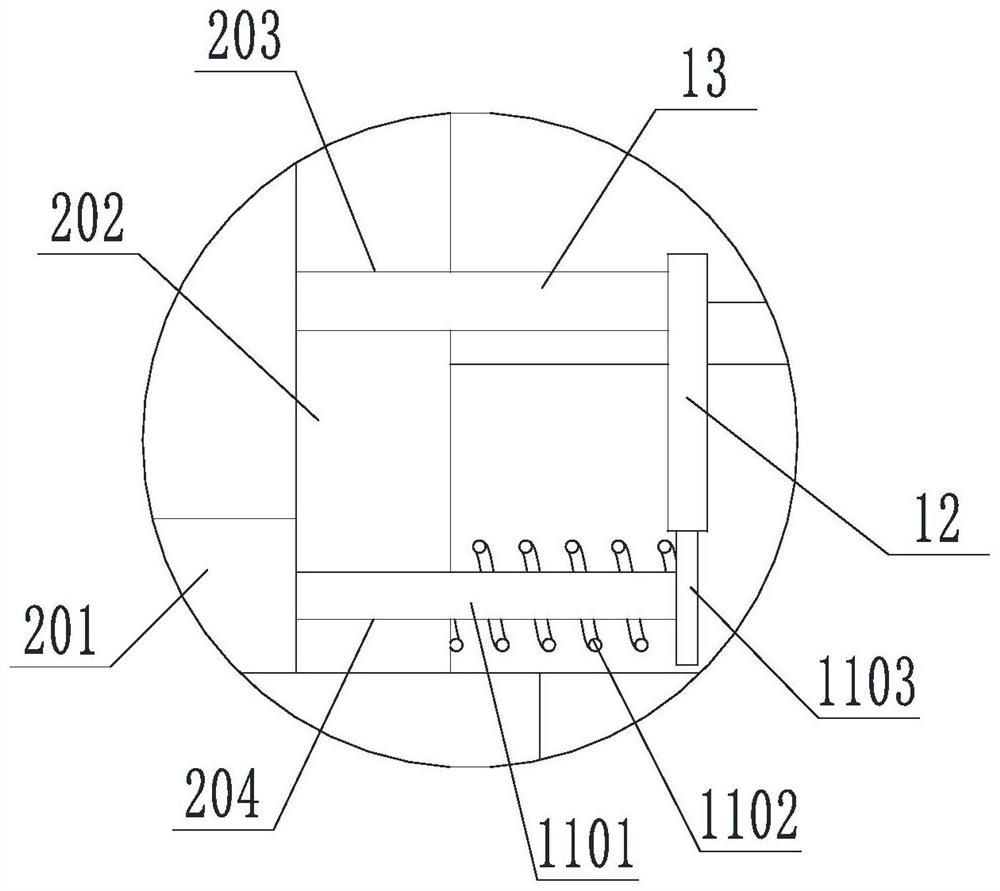

[0024] See Figure 1 - Figure 4 As shown, the present invention provides a demolding apparatus of an environmentally friendly heating insulation meal case, including a table 1 and a lifting cylinder 4 above the table 1, and a lower mold 2 is provided on the surface of the table 1, and the lower mold 2 includes The bottom plate 201 and the side frame 202 on the bottom plate 201, the side frame 202 consists of two U-shaped plates, and the two U-shaped plate horizontal docks form a cavity, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com