Preparation method of organic-inorganic ferroelectric polymer composite film

A composite film and polymer technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, circuits, etc., to achieve ferroelectric performance improvement and easy process The effect of simple control and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing an organic-inorganic ferroelectric polymer composite film, comprising the following steps:

[0022] 1) Dissolve 1.973g of P(VDF-TrFE) powder in 20ml of tetrahydrofuran, and form a homogeneous solution with a mass fraction of 10% after magnetic stirring;

[0023] 2) 0.395g of ground single crystal PbTiO 3 The mesoporous material powder is added to the homogeneous solution prepared in step 1), and further magnetically stirred to obtain a mixed solution;

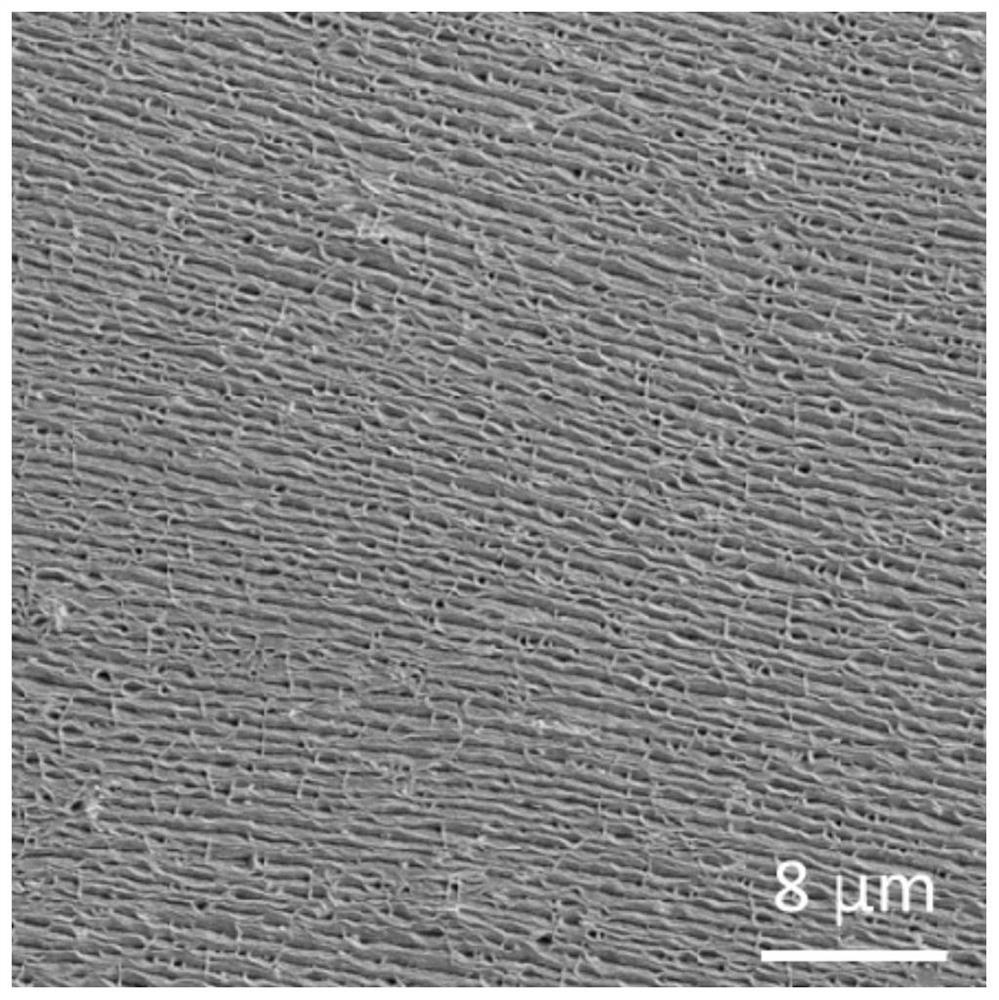

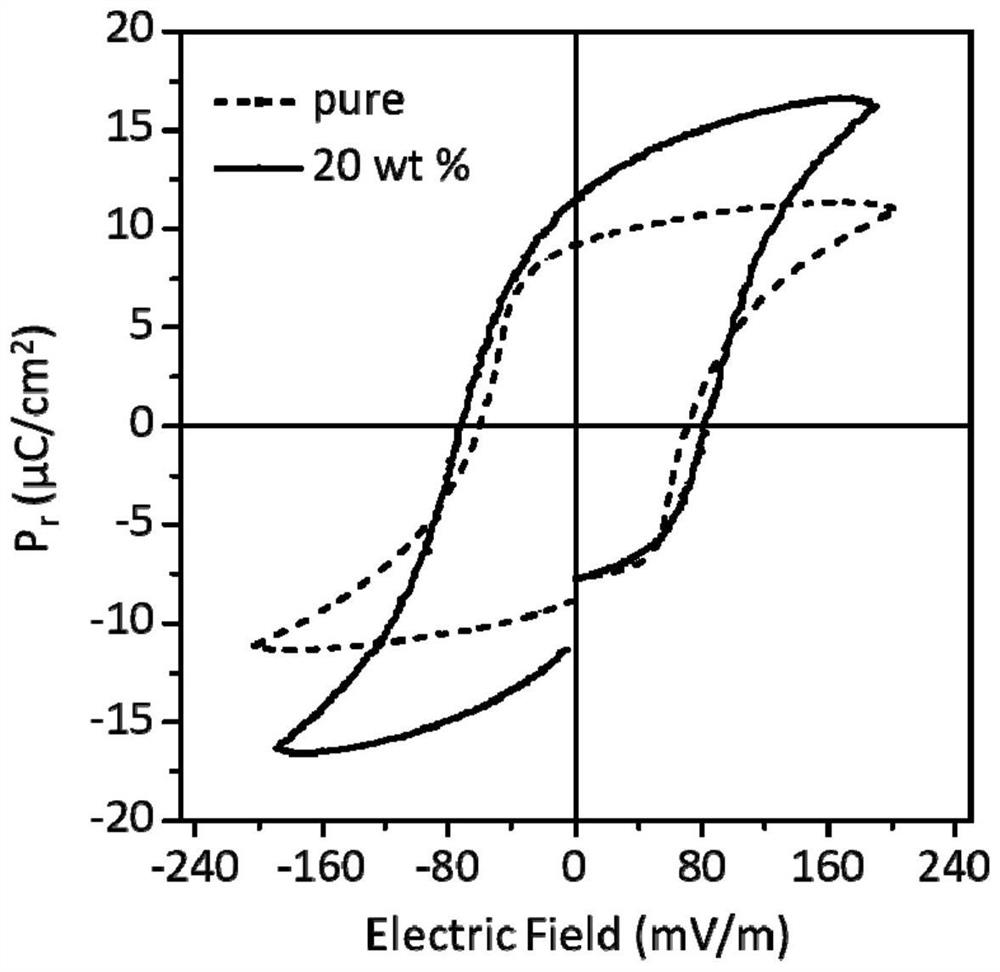

[0024] 3) Take the mixed solution obtained in step 2) and drop it on the graphene / copper (122) substrate, place it on a homogenizer for spin-coating, first spin-coat at a speed of 1000rpm for 3s, and then spin-coat at a speed of 3000rpm for 30s; The graphene / copper (122) substrate surface has a one-dimensional periodic potential;

[0025] 4) Finally, put the spin-coated substrate into a vacuum oven for annealing at 180° C. for 2 hours in a vacuum to obtain an organic-inorganic ferroelectric polym...

Embodiment 2

[0029] A method for preparing an organic-inorganic ferroelectric polymer composite film, comprising the following steps:

[0030] 1) Dissolve 1.973g of P(VDF-TrFE) powder in 20ml of tetrahydrofuran, and form a homogeneous solution with a mass fraction of 10% after magnetic stirring;

[0031] 2) 0.197g ground single crystal PbTiO 3 The mesoporous material powder is added to the homogeneous solution prepared in step 1), and further magnetically stirred to obtain a mixed solution;

[0032] 3) Take the mixed solution obtained in step 2) and drop it on the graphene / copper (122) substrate, place it on a homogenizer for spin-coating, first spin-coat at a speed of 1000rpm for 3s, and then spin-coat at a speed of 3000rpm for 30s; The graphene / copper (122) substrate surface has a one-dimensional periodic potential;

[0033] 4) Finally, put the spin-coated substrate into a vacuum oven for annealing at 180° C. for 2 hours in vacuum to obtain an organic-inorganic ferroelectric polymer co...

Embodiment 3

[0036] A method for preparing an organic-inorganic ferroelectric polymer composite film, comprising the following steps:

[0037] 1) Dissolve 0.47g of P(VDF-TrFE) powder in 10ml of tetrahydrofuran, and form a uniform solution after magnetic stirring;

[0038] 2) 0.0235g ground single crystal PbTiO 3 The mesoporous material powder is added to the homogeneous solution prepared in step 1), and further magnetically stirred to obtain a mixed solution;

[0039] 3) Take the mixed solution obtained in step 2) and drop it on the graphene / copper (122) substrate, place it on a homogenizer for spin coating, first spin coating at a speed of 1000rpm for 3s, and then spin coating at a speed of 3000rpm for 30s; The graphene / copper (122) substrate surface has a one-dimensional periodic potential;

[0040] 4) Finally, put the spin-coated substrate into a vacuum oven for annealing at 180° C. for 2 hours in vacuum to obtain an organic-inorganic ferroelectric polymer composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com