Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Alleviate thermal expansion mismatch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidation and fatigue resistant metallic coating

InactiveUS6919042B2Excellent oxidation and fatigue resistance propertyAlleviate thermal expansion mismatchMolten spray coatingPropellersRheniumHafnium

The present invention relates to a metallic coating to be deposited on gas turbine engine components. The metallic coating comprises up to 18 wt % cobalt, 3.0 to 18 wt % chromium, 5.0 to 15 wt % aluminum, 0.1 to 1.0 wt % yttrium, up to 0.6 wt % hafnium, up to 0.3 wt % silicon, 3.0 to 10 wt % tantalum, up to 9.0 wt % tungsten, 1.0 to 6.0 wt % rhenium, up to 10 wt % molybdenum, and the balance nickel.

Owner:RAYTHEON TECH CORP

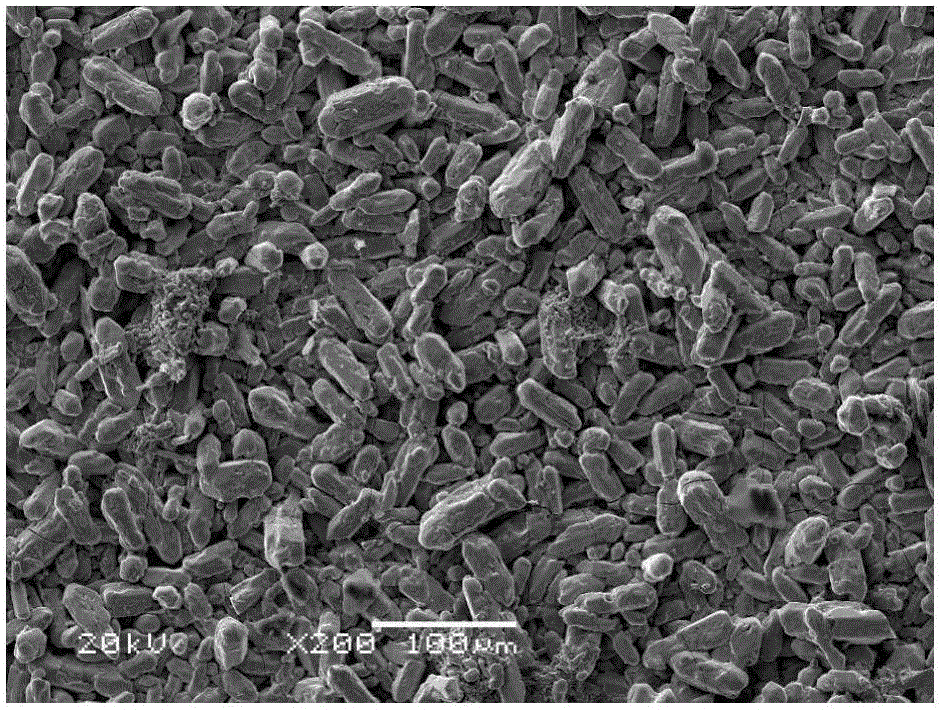

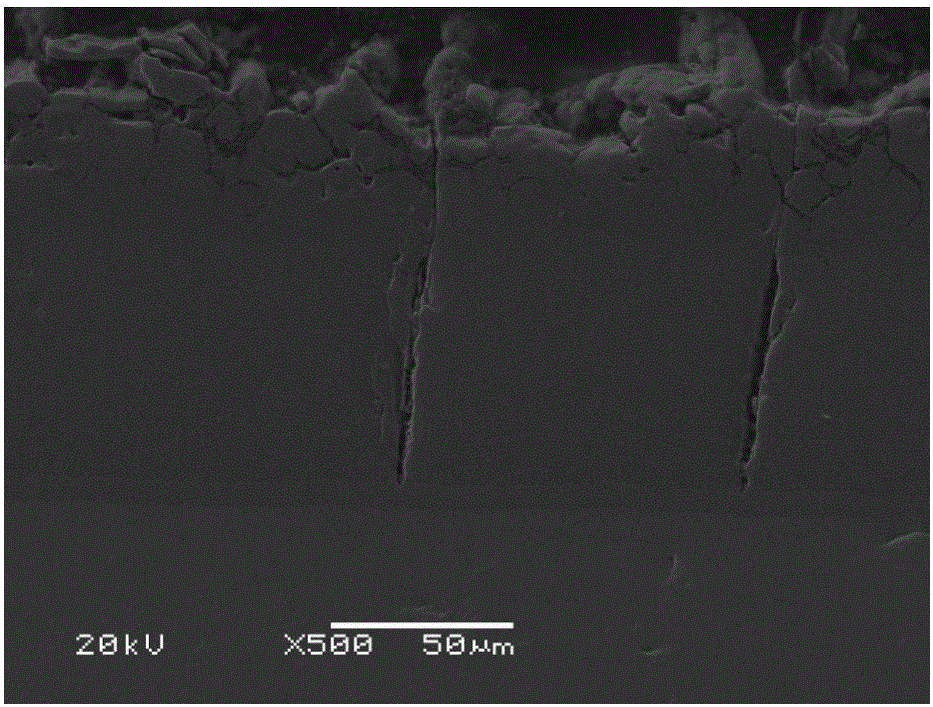

High-temperature brazed connection method for C/C composite material and nickel-based high-temperature alloy

The invention discloses a high-temperature brazed connection method for a C / C composite material and nickle-based high-temperature alloy. The method comprises the following steps: preparing a SiC coating on the surface of the C / C composite material through an embedding method, and cleaning and drying the C / C composite material having the surface modified and the nickel-based high-temperature alloy having the surface polished; uniformly spreading BNi71CrSi nickel-based brazing alloy on the surface of the C / C composite material having the surface modified to form a sandwich structure of the C / C composite material / BNi71CrSi and the nickel-based high-temperature alloy, and placing the structure in a vacuum hot-pressing furnace for connection. The method realizes the connection of the C / C composite material and nickel-based alloy, effectively relieves the problems of wettability and mismatch of thermal expansion coefficients of nickel alloy and the C / C composite material, lowers the residual stress between connectors, and enables the room-temperature shearing strength of a C / C composite material and a nickel-based alloy connector to reach 35.08 MPa.

Owner:无锡博智复合材料有限公司

Environmental barrier coating used for poly-carbon and ceramic base compound material and preparation method thereof

The invention relates to an environmental barrier coating used for a poly-carbon and ceramic base compound material and a preparation method thereof. The environmental barrier coating includes, successively from a substrate material to exterior, a silicon adhesion layer being 60-70 [mu]m in thickness, a mullite layer being 60-80 [mu]m in thickness, a rare earth silicate layer being 100-120 [mu]m in thickness, and a rare earth zirconate layer being 100-150 [mu]m in thickness. In the environmental barrier coating, the rare earth silicate layer can effectively inhibit an element diffusion reaction between the mullite layer and the rare earth zirconate layer, and the rare earth zirconate layer can significantly reduce volatilization of SiO2, so that a defect of poor high-temperature stability of the rare earth silicate layer is solved. During use, the components of the whole coating is not liable to change, so that service life of the coating under environment of an aero-engine can be greatly prolonged, and protective effect is improved.

Owner:BEIHANG UNIV

Electrochemical method for preparing HA/ZrO2 (hydroxylapatite/zirconia) gradient coating on surface of medical titanium

InactiveCN101880890AUniform and dense coatingAlleviate thermal expansion mismatchElectrolysis componentsCoatingsIonBiocompatibility Testing

The invention discloses an electrochemical method for preparing a HA / ZrO2 (hydroxylapatite / zirconia) gradient coating on the surface of medical titanium. The method comprises the following steps of: carrying out electro-deposition in an electrolytic cell with a three-electrode system, wherein the medical titanium to be coated is a working electrode; carrying out electro-deposition to obtain a Zr (OH) 4 coating in a zirconium oxynitrate solution with certain concentration and pH value, wherein the deposition current is 20mA, and the deposition time is 600s; then, depositing a CaHPO42H2O coating in an electrolyte which has certain concentration and pH value and consists of calcium nitrate and ammonium dihydrogen phosphate, wherein the deposition current is 1.5mA, and the deposition time is 900s; and finally, carrying out vacuum sintering on the obtained coating materials, and raising the sintering temperature to 650 DEG C at a heating rate of 10 DEG C / min, then preserving the heat for two hours, and subsequently cooling the coating materials with a furnace so as to obtain the HA / ZrO2 composite coating. The electrochemical method of the invention has the advantages that: the ingredients of the coating are deposited on a substrate in the form of ions, so that the bonding strength of the HA / ZrO2 gradient coating and the Ti substrate is improved greatly; and the anti-corrosion and simulated body fluid experiment shows that even the HA on the surface is dissolved completely due to the biological effect, the remaining ZrO2 coating still has good anti-corrosion performance and certain biocompatibility.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

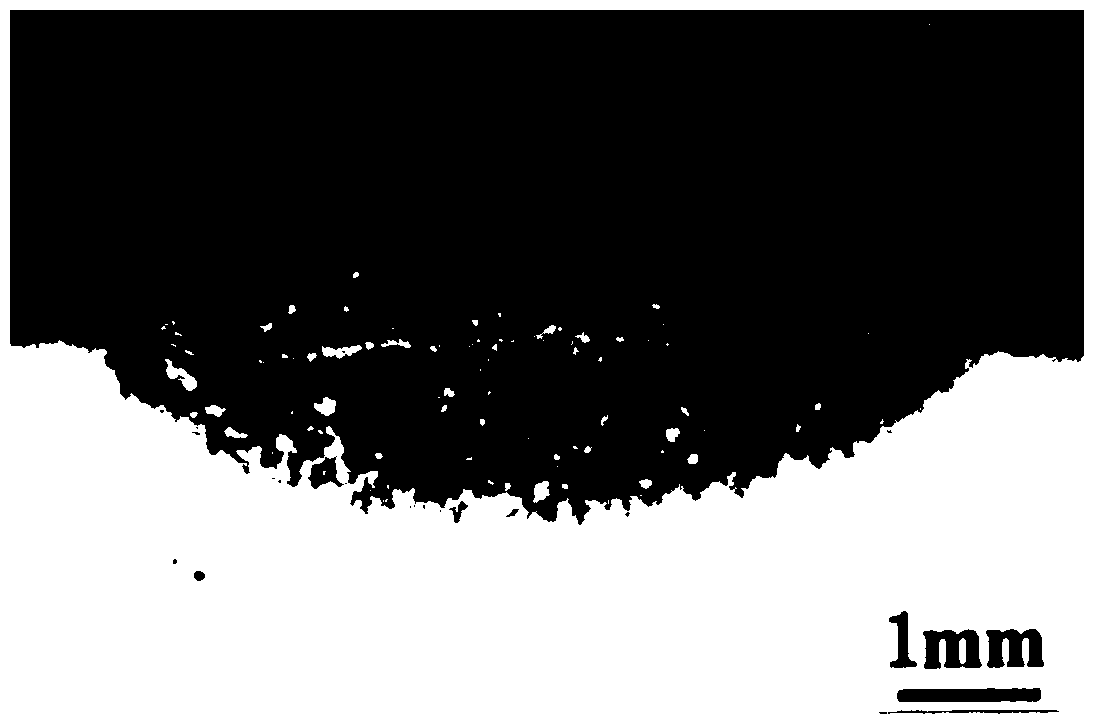

Method for strengthening surface of laser-clad titanium alloy

InactiveCN103774139AReduce Thermal Expansion MismatchReduce residual stressMetallic material coating processesAlloy substrateOxide

The invention discloses a method for strengthening a surface of a laser-clad titanium alloy. The method comprises the following steps: 1), pretreatment of the to-be-clad surface of a titanium alloy substrate, namely removing an oxide film on the to-be-clad surface of the titanium alloy substrate; 2), preparation of a cladding material, namely preparing the cladding material from NiCrBSi alloy powder and TiC according to the condition that the volume ratio of NiCrBSi to TiC is (50-100):(0-50), and mixing evenly; 3) pre-application of the cladding material, namely blending the evenly mixed cladding material with a volatile organic solvent into a paste, coating the to-be-clad surface of the titanium alloy substrate with the plaste so that the coating layer is 0.6-1.5mm thick, and then drying the coating layer; 4) laser cladding, namely irradiating the coating layer by use of a laser so that the coating layer is clad on the titanium alloy substrate. The method is capable of reducing thermal expansion mismatching of the coating layer, reducing residual stress and improving the properties of the coating layer.

Owner:TIANJIN POLYTECHNIC UNIV

Thermal/environment barrier coating based on ceramic composite material and preparation method of thermal/environment barrier coating

ActiveCN109336647AGive full play to the high temperature water vapor corrosion resistanceHigh temperature water vapor corrosion resistance performance guaranteeCeramic compositeThermal insulation

The invention relates to a thermal / environment barrier coating based on a ceramic composite material and a preparation method of the thermal / environment barrier coating. The thermal / environment barrier coating comprises a silicon layer, a ytterbium silicate layer, a transition layer and a hafnium oxide layer in sequence from inside to outside, wherein the transition layer is made by mixing hafniumoxide and ytterbium silicate. The preparation method comprises the following steps: respectively loading silicon powder, ytterbium silicate powder and hafnium oxide powder into a powder conveyer of low-pressure plasma spraying equipment, and carrying out drying treatment; immobilizing a ceramic composite material on a rotating platform in a vacuum chamber of the low-pressure plasma spraying equipment; preparing the silicon layer, the ytterbium silicate layer, the transition layer and the hafnium oxide layer in sequence on the surface of the ceramic composite material by using a low-pressure plasma spraying method to obtain the thermal / environment barrier coating on the surface of the ceramic composite material. The thermal / environment barrier coating provided by the invention is good in thermal insulation effect and excellent in high-temperature moisture corrosion resistance, and the preparation method provided by the invention has the advantages of being high in deposition efficiency, low in cost, uniform in coating and the like, and the thermal / environment barrier coating can be rapidly and integrally prepared.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

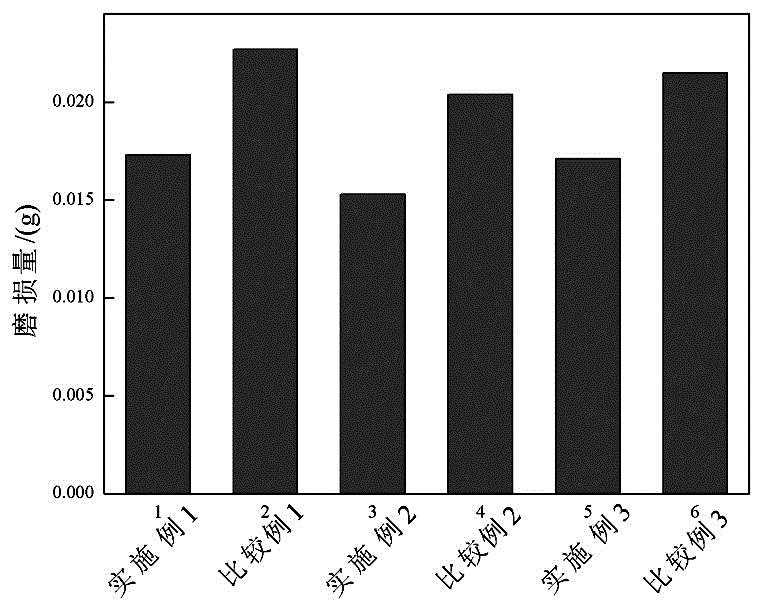

Ceramic composite material for titanium alloy surface laser cladding

ActiveCN106835126AHigh hardnessImprove toughnessMetallic material coating processesCeramic compositeComposite ceramic

The invention relates to a ceramic composite material for titanium alloy surface laser cladding. The ceramic composite material is prepared by mixing 20-65wt% of Ti powder, 25-75wt% of TiBCN ceramic powder and 2-10wt% of B4C powder. The ceramic composite material has the advantages that composite ceramic cladding coating metallurgically bonding with a titanium alloy matrix is formed on the surface of titanium alloy through the laser cladding technology, coating hardness can reach 3.5-4.5 times of that of the titanium alloy matrix, coating wear resistance is increased evidently, and a sample wear rate is only 1 / 3-1 / 4 of that of the titanium alloy matrix and is lowered evidently as compared with that of the matrix; multiple laser cladding operation can be repeatedly performed on the surface of the titanium alloy so as to regulate cladding coating thicknesses according to needs.

Owner:山西维科机械设备工程有限公司

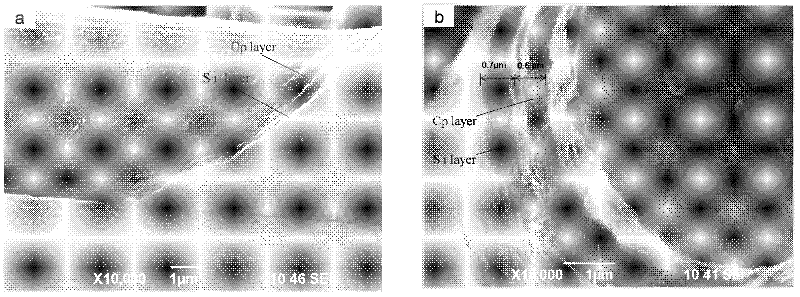

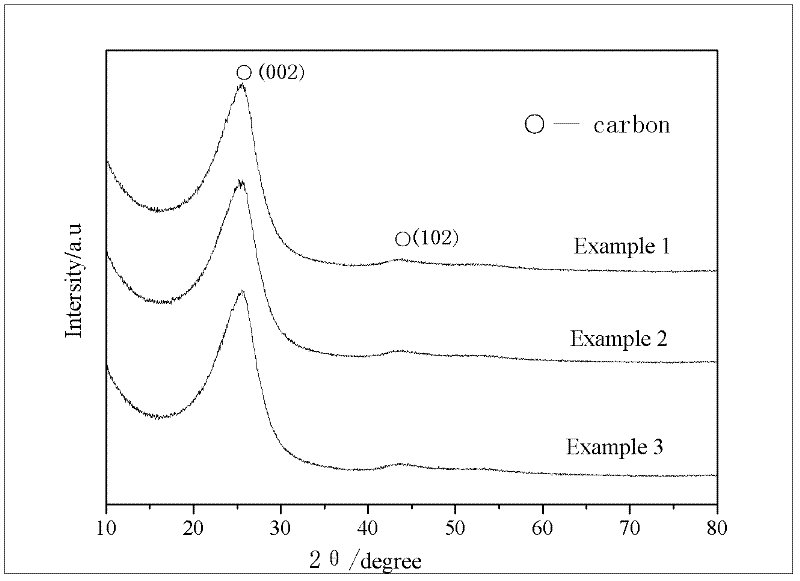

Carbon fiber surface C/Si composite coating and preparation method thereof

The invention discloses a carbon fiber surface C / Si (carbon / silicon) composite coating and a preparation method thereof. The carbon fiber surface C / Si composite coating is prepared by using SiCl4 and CH4 as raw materials, using Ar as protective gas and carrier gas, using H2 as reduction gas and using a negative pressure chemical vaporous deposition method. The prepared pyrolytic carbon coating has thickness of about 0.3 to 1mum. The prepared Si-system outer coating has thickness of about 0.5 to 1.2mum. The prepared coating is uniform, compact and flat and has excellent combination among layers. According to the invention, on one hand, the oxidation resistance of carbon fibers is improved and the high-strength performance of the carbon fibers is protected, and on the other hand, the wettabilities of the carbon fibers and a metal matrix are improved and the success rate of preparation of the composite material is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Oxidation-resistant material and method employing same for preparing tantalum-tungsten alloy anti-oxidation coating

ActiveCN105112915AWide operating temperature rangeStrong anti-oxidation ability under continuous static loadMetallic material coating processesAntioxidant capacityThrust chamber

The invention relates to an oxidation-resistant material and a method employing the same for preparing a tantalum-tungsten alloy anti-oxidation coating. The oxidation-resistant material is characterized by comprising a first anti-oxidation material and a second anti-oxidation material, wherein the first anti-oxidation material comprises 1-5wt% of Cr, 1-5wt% of Ti, 0.1-2wt% of Y2O3, 0.5-3wt% of W, 0.5-3wt% of Nb, 1-5wt% of HfO2, and the balance Si; the second anti-oxidation material comprises 6-15wt% of Mo, 0.5-3wt% of W, 0.5-3wt% of Nb, 0.3-2.2wt% of Y, 1-5wt% of HfO2, and the balance Si. The tantalum-tungsten alloy anti-oxidation coating prepared by the method has a wide operating temperature range, and is high in continuous static load and antioxidant capacities, and is particularly suitable for high-temperature structural components such as a thrust chamber, a nozzle jet, a front edge and a guide tube of an airspace engine.

Owner:NINGXIA ORIENT TANTALUM IND +1

Eight-beam symmetrical silicon micro-accelerometer

InactiveCN104198762AImprove protectionEasy to operateAcceleration measurementElectricityMicro structure

The invention provides an eight-beam symmetrical silicon micro-accelerometer. The capacitive micro-accelerometer comprises three portions of an upper silicon electrode plate, a sensitive chip and a lower silicon electrode plate from top to bottom, wherein the sensitive chip is of a micro-structure of 'mass block-cantilever beams'; eight cantilever beams are provided, and symmetrically distributed around a mass block, and the mass block is located at a middle horizontal position; the thickness of the mass block is the same as that of the adopted silicon slice, and the shape is a polygon so as to effectively utilize the space, thus the quality is greatly improved, and a lower device noise and a higher sensitivity can be obtained; the micro-accelerometer adopts an all-silicon process, the silicon electrode plates are bonded with the sensitive chip through silicon-silicon fusion, thus problems of thermal expansion coefficient mismatching and the like can be reduced; the patterns of the mass block and the beams are formed on the surface of the silicon slice through a double-layer SiO2 process, thus deep-groove photoetching is avoided. The eight-beam symmetrical silicon micro-accelerometer provided by the invention is high in stability, low in device noise, and capable of improving the measurement accuracy of the accelerometer.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Coatings for articles used with molten metal

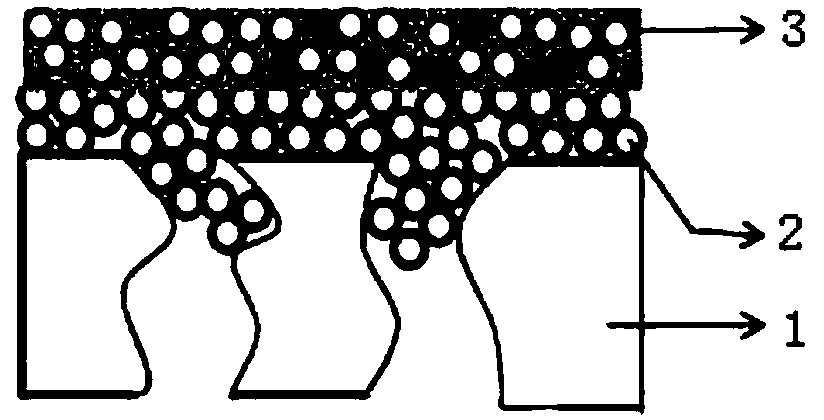

InactiveUS20060051599A1Reduces thermal expansion mismatchImprove physical bond strengthMelt-holding vesselsFurnace componentsOxidePorous layer

An improved multilayer coating for use on molten metal holding and transfer apparatus, the coating including a bound layer applied directly to the surface of molten metal holding and transfer apparatus, and a porous layer of ceramic material produced by co-deposition of a powder of said ceramic material and a powder of a suitable organic polymer material and, after the co-deposition, heating of said polymer material to thermally decompose the polymer material and form the porous layer. The bond layer preferably is formed of a metallic, intermetallic or composite particulate materials. The metal component may be in the metallic, intermetallic, oxide, clad or alloyed form consisting of any one or more of the metal components selected from the group of Mo, Ni, Al, Cr, Co, Y and W and may be in combination with yttria, alumina, zirconia, boron, carbon and have a particle size in the range of 5 to 250 m, typically 40 to 125 m. The bond layer preferably has a thickness of 5 to 300 m with a substantially uniform coating layer being provided over the surfaces to have the porous ceramic coat applied.

Owner:UDP NO 055 THE UNIV OF QUEENSLAND

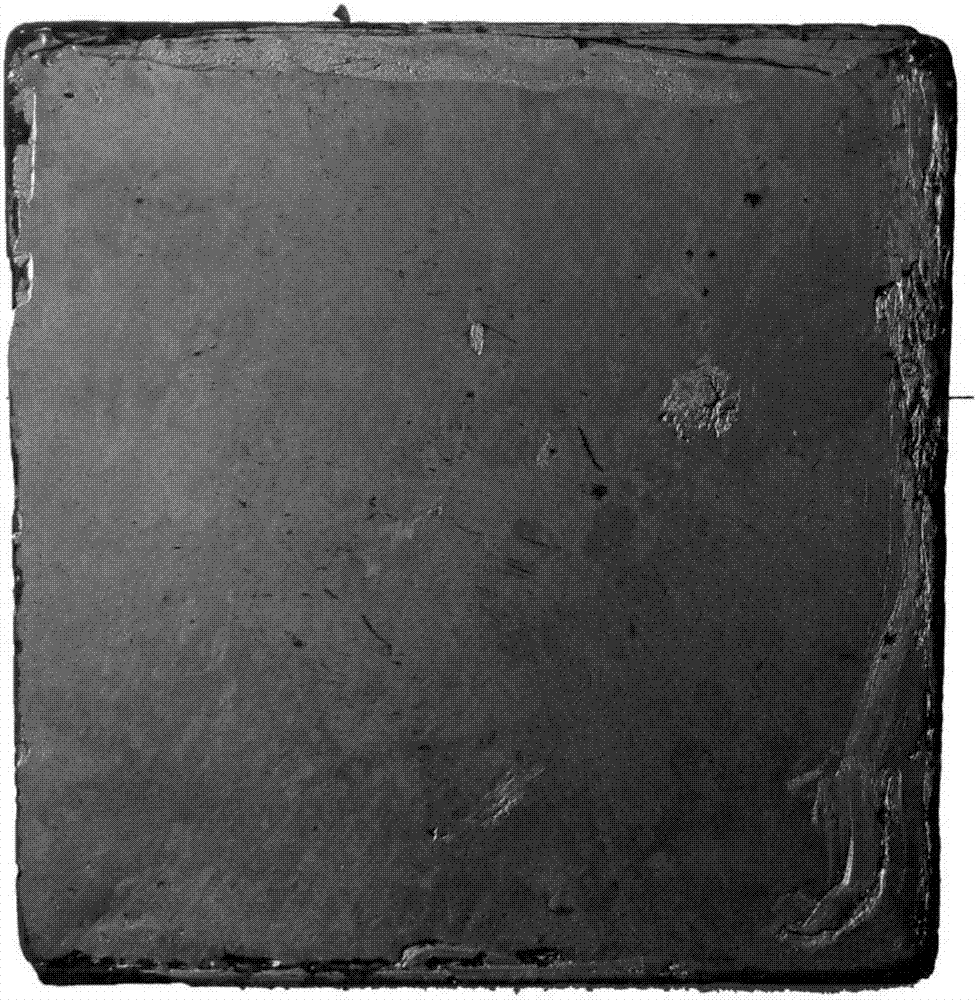

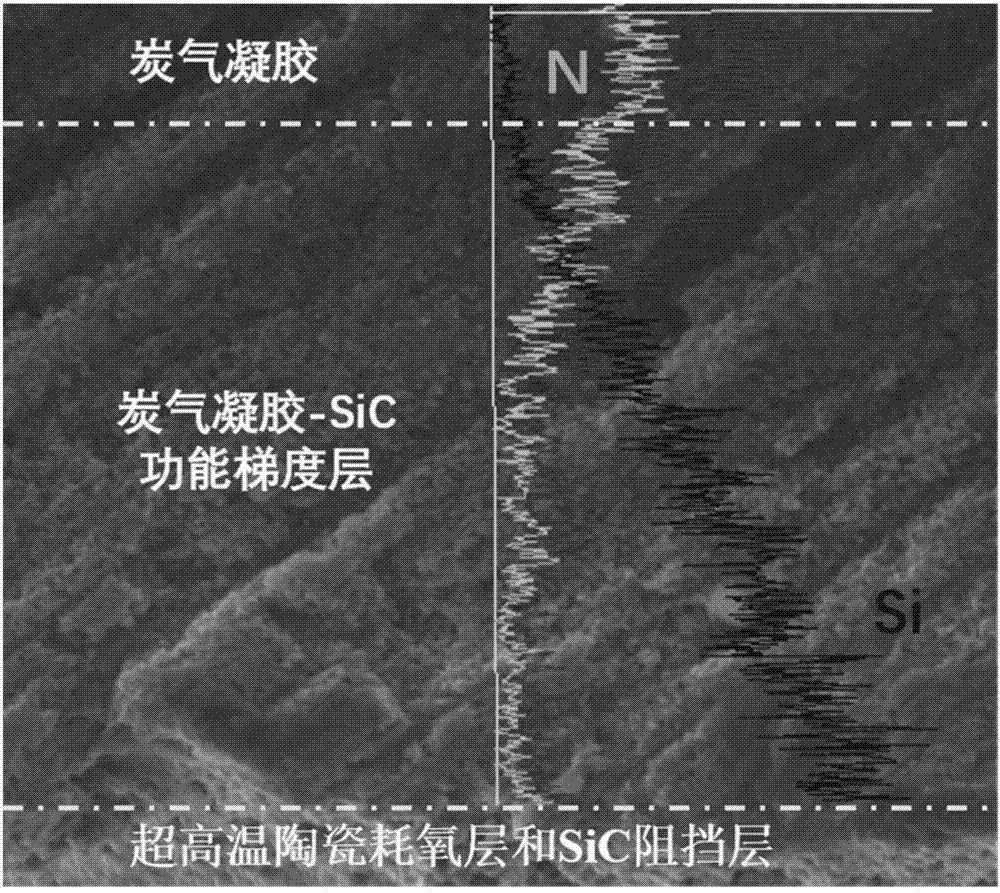

Heat-insulation-and-bearing-integrated carbon aerogel and ceramic layered composite material and preparation method and application thereof

ActiveCN107473761AGood anti-ablation propertiesHigh bonding strengthCeramicwareCeramic compositeGas phase

The invention discloses a heat-insulation-and-bearing-integrated carbon aerogel and ceramic layered composite material and a preparation method and application thereof, and belongs to the technical field of a carbon aerogel and ceramic composite material. The composite material comprises a high-strength carbon aerogel body layer, a function gradient SiC and carbon aerogel transition layer, and a superhigh-temperature ceramic and SiC antioxidant composite coating. The high-strength carbon aerogel body layer is made through five steps of solution preparation, sol-gel, solvent replacement, normal-pressure drying and high-temperature carbonization through normal-pressure drying technology. The function gradient SiC and carbon aerogel transition layer is made by deep deposition of SiC on a carbon aerogel surface through a chemical vapor infiltration process. The superhigh-temperature ceramic and SiC antioxidant composite coating is made through compound technology of spraying and chemical vapor deposition. The composite material is good in ablation and oxidation resistance, low in thermal conductivity and density, and high in strength, can resist high temperature as high as 1800 DEG C, and is suitable for heat-insulation materials of aircrafts.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum/aluminum oxide composite hydrogen resistance coating layer

InactiveCN109957756AHigh bonding strengthSmall coefficient of thermal expansionVacuum evaporation coatingSputtering coatingHydrogenMartensitic stainless steel

The invention discloses an aluminum / aluminum oxide composite hydrogen resistance coating layer. The hydrogen resistance coating layer is a single-layer coating layer which is formed on a metal substrate and composed of xAl-(1-x)Al2O3, wherein x is larger than 0 and smaller than 1. The metal substrate is made of austenitic stainless steel or martensitic stainless steel. The hydrogen resistance coating layer is prepared through a physical vapor deposition method, a magnetron sputtering method is preferred, and the hydrogen resistance coating layer is obtained by conducting sputtering on an aluminum target and an aluminum oxide target at the same time. Combination between the aluminum / aluminum oxide composite hydrogen resistance coating layer and the metal substrate is combination between metal and metal, and the combination strength is high; compared with the coefficient of thermal expansion of a metal aluminum layer, the coefficient of thermal expansion of the hydrogen resistance coating layer is lower, thermal expansion mismatching between the hydrogen resistance coating layer and a surface aluminum oxide film is reduced, and the cold and heat impact preventing performance of the hydrogen resistance coating layer is improved; and under the condition that the surface aluminum oxide film is broken, a new aluminum oxide film can be generated in situ.

Owner:GRIMAT ENG INST CO LTD

Metal and oxide interface assembly to sustain high operating temperature and reduce shaling

InactiveUS20090033200A1Alleviate thermal expansion mismatchOxide/hydroxide preparationLamp incadescent bodiesOptoelectronicsThermal expansion

The invention relates to a barrier layer provided on the electrode assembly of a discharge lamp comprising at least a layer of nanoclusters of a non-oxidizing material. Further, the invention relates to an electrode assembly for a discharge lamp comprising an electrode having a foil attached thereto to create an electrode assembly, the assembly being coated with a multi-layer coating comprising at least a layer of non-oxidizing material in the form of nanoclusters, and at least another layer of non-oxidizing material, such that the total coating thickness is up to 1500 nm. A method to reduce thermal expansion mismatch between an electrode assembly and a discharge lamp envelope is also provided, the method comprising providing an electrode assembly and depositing on the surface of the assembly a coating having at least a nanocluster layer of a non-oxidizing material, and subsequently subjecting the lamp envelope in the electrode assembly area to pinching to create a pinch area, this lamp being able to operate at elevated temperature for extended periods, in excess of 1000 hours.

Owner:GENERAL ELECTRIC CO

Tungsten/silicon nitride/tungsten symmetrical laminated gradient composite material as well as rapid preparation method and application thereof

ActiveCN111085688AExcellent high temperature mechanical propertiesImprove thermal shock resistanceIncreasing energy efficiencyCell sealing materialsComposite ceramicPlasma activation

The invention discloses a W / Si3N4 / W symmetrical laminated gradient composite material as well as a rapid preparation method and an application thereof, and belongs to the technical field of preparation for ceramic matrix composite materials. According to the tungsten / silicon nitride / tungsten symmetrical laminated gradient composite material as well as the rapid preparation method and the application thereof, the W / Si3N4 / W symmetrical laminated gradient composite material is prepared through an SPS sintering technology; in the method, an electric field is further introduced on the basis of a temperature field and a pressure field, a plasma activation effect on raw materials can be acted, so that a compact composite ceramic material can be rapidly prepared under the conditions of a low sintering temperature and a short heat-insulation time; and meanwhile, the activation effect of plasmas also contributes to the diffusion of atoms, then the interlayer bonding of W and Si3N4 can be promoted, and the high-performance connection between W and Si3N4 is realized. The method has the advantages of being high in heating speed, low in sintering temperature and short in heat-insulation time, and the W / Si3N4 / W symmetrical laminated gradient composite material with high compactness, low impurity content and good interface bonding can be rapidly prepared via the method.

Owner:XI AN JIAOTONG UNIV

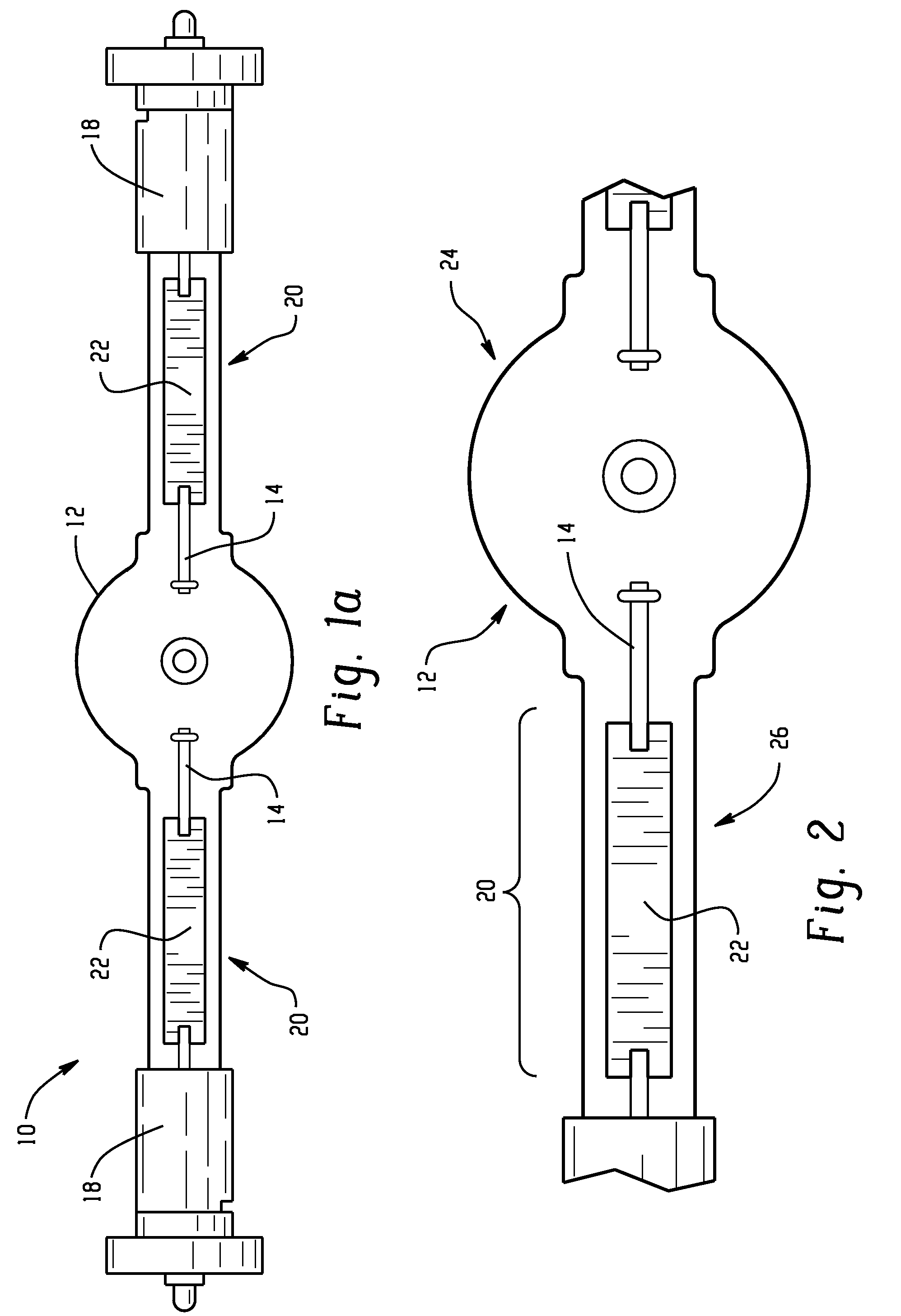

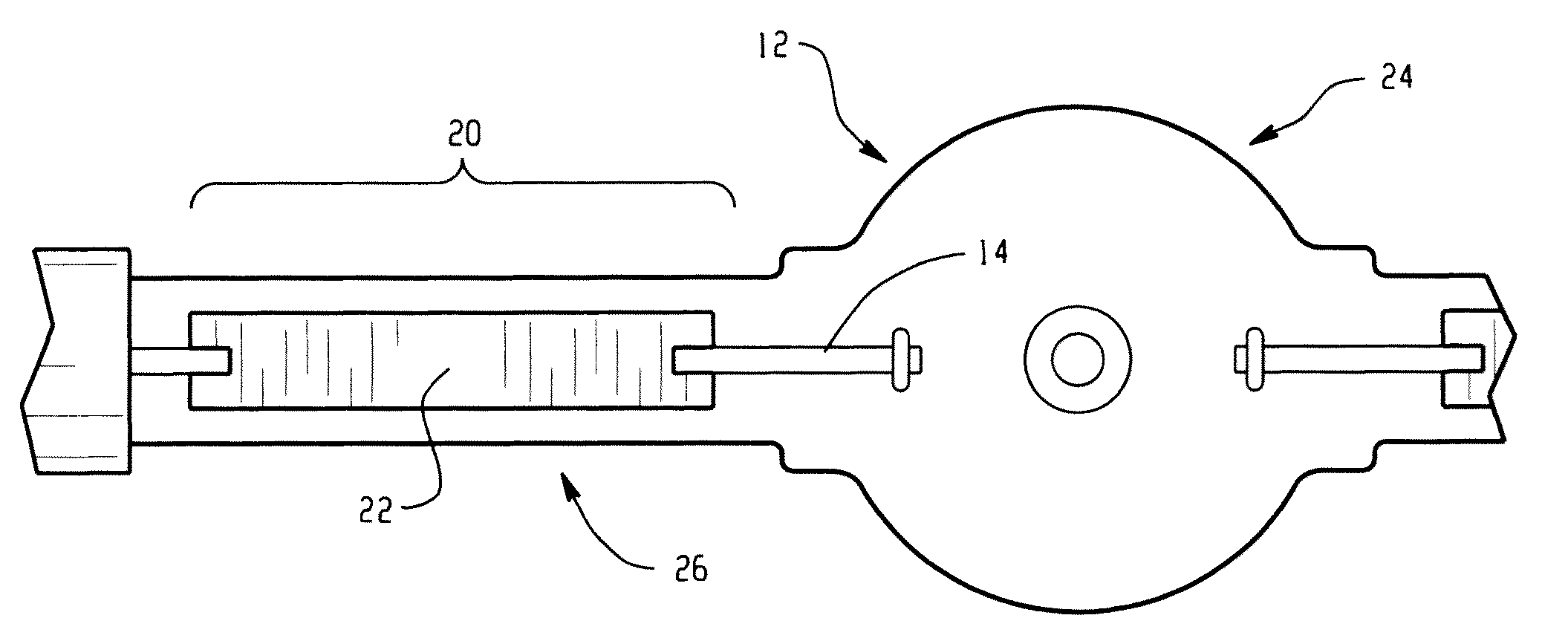

Thermally stable high temperature pressure and acceleration optical interferometric sensors

ActiveUS20160202135A1Alleviate thermal expansion mismatchFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsOptical cavityInterferometric sensor

Certain example implementations of the disclosed technology include an optical-interferometer sensor assembly for measuring pressure or acceleration. The sensor assembly includes a diaphragm configured to deflect responsive to an applied stimulus, a diaphragm support structure in communication with the diaphragm, a sensing optical interferometer having a first optical cavity in communication with at least a portion of the diaphragm and the diaphragm support structure, and a reference optical interferometer having a second optical cavity in communication with the diaphragm support structure. The sensor assembly can include a sensing optical fiber in communication with the sensing optical interferometer and a reference optical fiber in communication with the reference optical interferometer. The sensor assembly can include a housing in communication with the diaphragm and the diaphragm support structure, and configured to reduce a thermal expansion mismatch in the sensor assembly.

Owner:KULITE SEMICON PRODS

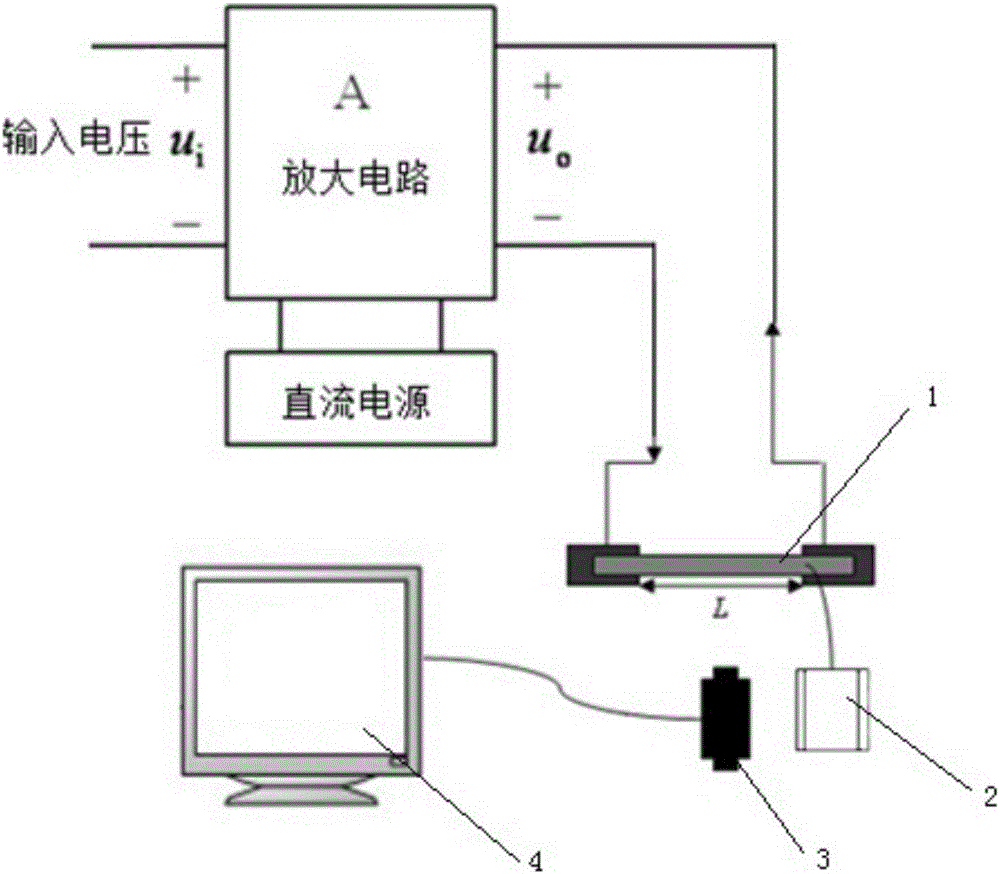

Local fast heating experimental device for novel ultra-high temperature ceramic test piece

InactiveCN106644799AIncreased resistance to crack growthImprove safety and reliabilityStrength propertiesUltra-high-temperature ceramicsCopper electrode

The invention relates to a local fast heating experimental device for a novel ultra-high temperature ceramic test piece. The local fast heating experimental device is characterized in that a positive pole and a negative pole of amplified voltage U0 are connected to the left and right sides of a copper electrode respectively and is connected with a positive pole and a negative pole of an amplifying circuit respectively, the amplifying circuit is connected with a positive pole and a negative pole of input voltage Ui, the copper electrode is connected with a thermocouple which is placed within a measurement range of an infrared thermometer, the infrared thermometer is connected with a computer through a data line, and the amplifying circuit is used for supplying power through a direct-current source. The local fast heating experimental device is used for local fast heating of the ultra-high temperature ceramic test piece.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

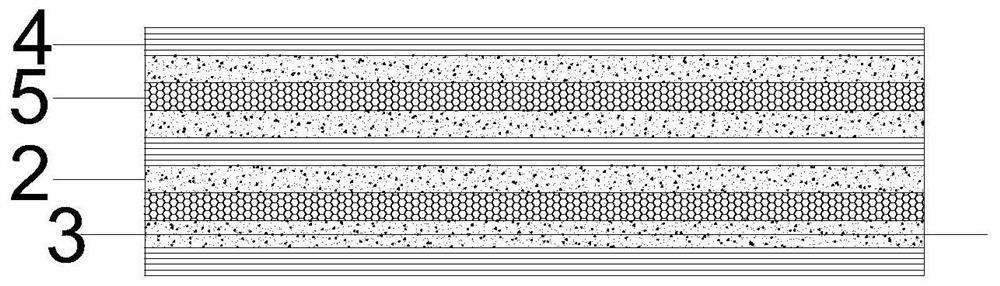

Multiphase environmental barrier coating formed on base material and preparation method thereof

ActiveCN111876714AImprove the performance of high temperature water-oxygen corrosion resistanceAlleviate thermal expansion mismatchMolten spray coatingEfficient propulsion technologiesLutetiumLutetium oxyorthosilicate

The invention relates to a multiphase environmental barrier coating formed on a base material and a preparation method thereof. The multiphase environmental barrier coating sequentially comprises a silicon bonding layer, a mullite layer and a Lu2SiO5-Sc2Si2O7 multiphase ceramic layer from the base material to the outside, wherein the Lu2SiO5-Sc2Si2O7 multiphase ceramic layer is formed by mixing lutetium silicate and scandium silicate. The method comprises the following steps: filling silicon powder, mullite powder and mixed powder formed by mixing lutetium silicate powder and scandium silicatepowder into a powder feeder of ultra-low pressure plasma spraying equipment and carrying out drying treatment; fixing the base material to a rotating table in a spraying cabin; and sequentially preparing the silicon bonding layer, the mullite layer and the Lu2SiO5-Sc2Si2O7 multiphase ceramic layer on the surface of the base material to prepare the multiphase environmental barrier coating. The multiphase environmental barrier coating is long in thermal shock resistance life and excellent in high-temperature water-oxygen corrosion resistance; and the method provided by the invention can be usedfor rapidly and integrally preparing the multiphase environmental barrier coating at low cost in an ultra-low pressure environment.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Cmc with outer ceramic layer

InactiveUS20190062890A1Increasing mechanical interlockingAlleviate thermal expansion mismatchMolten spray coatingSuperimposed coating processRough surfaceCeramic coating

By cutting a surface of a CMC component which has to receive a TBC a rough surface is yielded, which is rough enough to have a good adhesion of a following ceramic coating.

Owner:SIEMENS AG

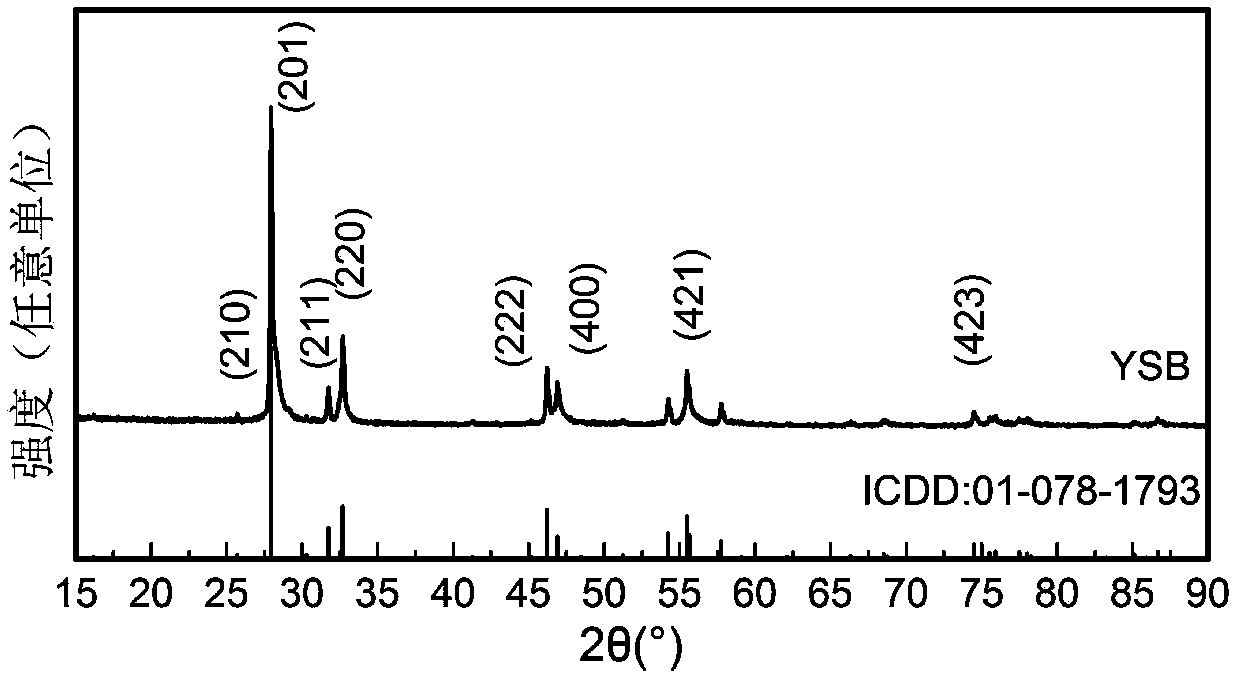

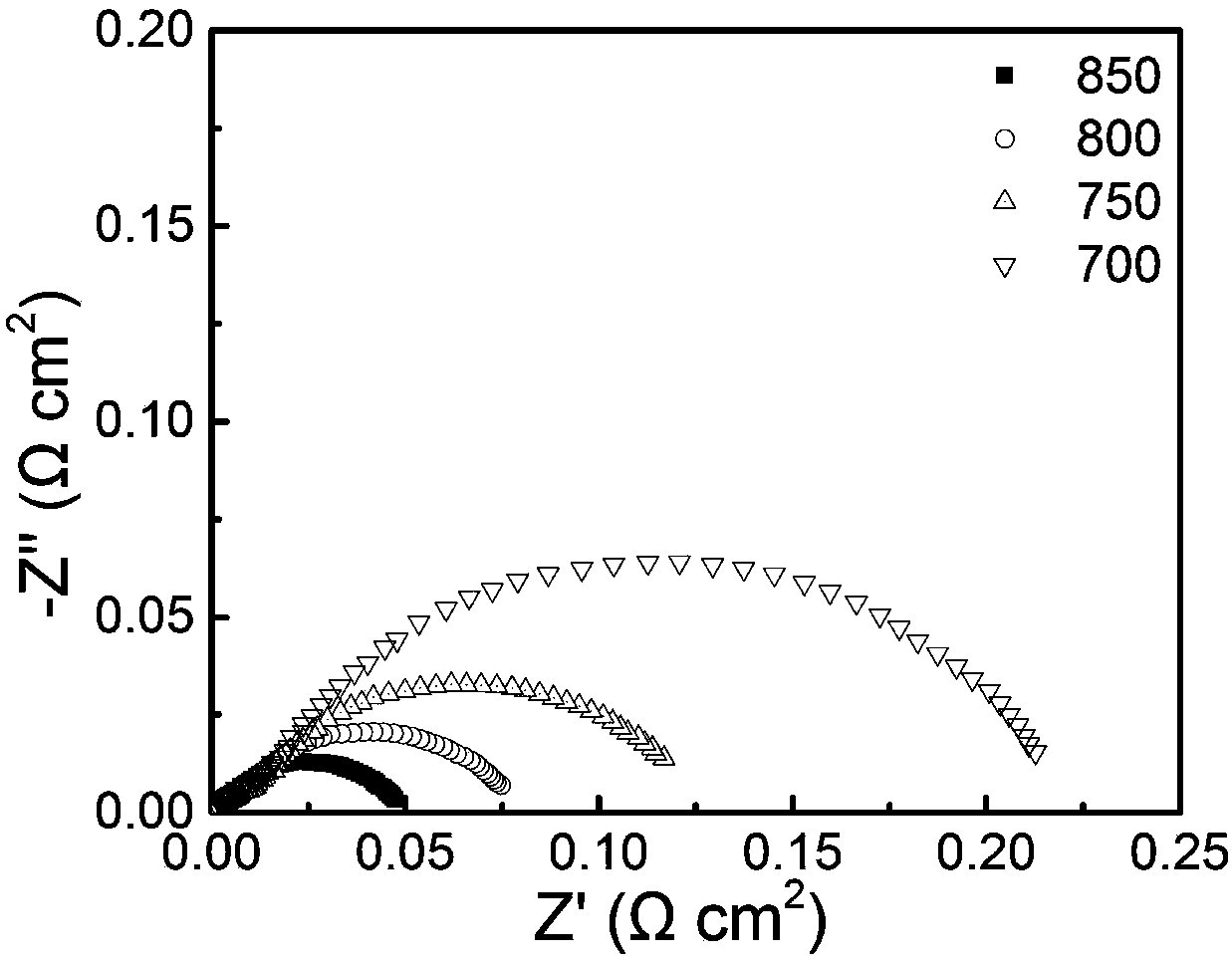

Preparation method of barrier layer yttrium oxide-doped bismuth oxide of solid oxide fuel cell

InactiveCN107799788AAlleviate thermal expansion mismatchStress reliefBismuth compoundsCollectors/separatorsThermal expansionCobalt

The invention discloses a preparation method of a barrier layer yttrium oxide-doped bismuth oxide of a solid oxide fuel cell, and belongs to the technical field of preparation of a battery material. The preparation method comprises the following steps of 1, taking Bi(NO<3>).5H<2>O and Y(NO<3>).6H<2>O as the raw materials, and preparing Y<x>Bi<2-x>O<3> powder through a coprecipitation method; 2, adding ethyl cellulose into Y<x>Bi<2-x>O<3>; 3, adding terpilenol, and grinding for 10-30min through an agate mortar; 4, performing silk screen printing on the obtained Y<x>Bi<2-x>O<3> paste on an electrolyte; 5, performing drying; 6, performing silk screen printing and drying for 1-3 times repeatedly to obtain Y<x>Bi<2-x>O<3> barrier layers of different thicknesses; and 7, performing heat treatmenton the electrolytes of the Y<x>Bi<2-x>O<3> barrier layers. The preparation method has the advantages as follows: by taking Y<x>Bi<2-x>O<3> with high oxygen ionic conductivity as the barrier layer, the problem of mismatching of coefficients of thermal expansion between a negative electrode and the electrolyte and between the barrier layer and the electrolyte can be effectively relieved, a reactionbetween a cobalt-based and a barium ferrite-based negative electrode material and a zirconium-based electrolyte can be avoided, and the interface resistance can be lowered; and the preparation methodis free of complex equipment, simple in preparation process, low in cost, and amplification and popularization can be realized easily.

Owner:HARBIN INST OF TECH

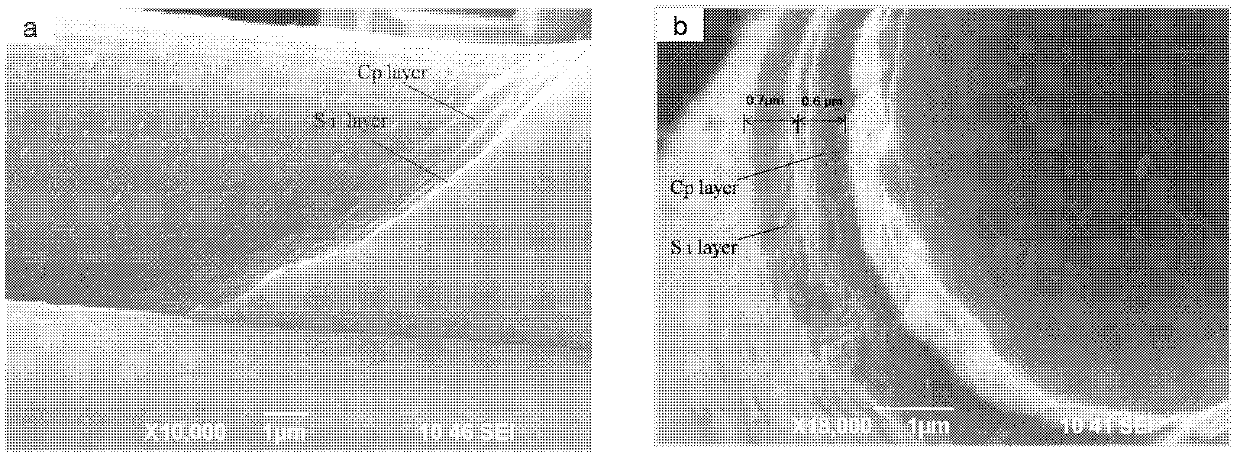

High-temperature brazed connection method for C/C composite material and nickel-based high-temperature alloy

ActiveCN103408317BAlleviate thermal expansion mismatchActive connectionThermal dilatationNickel alloy

The invention discloses a high-temperature brazed connection method for a C / C composite material and nickle-based high-temperature alloy. The method comprises the following steps: preparing a SiC coating on the surface of the C / C composite material through an embedding method, and cleaning and drying the C / C composite material having the surface modified and the nickel-based high-temperature alloy having the surface polished; uniformly spreading BNi71CrSi nickel-based brazing alloy on the surface of the C / C composite material having the surface modified to form a sandwich structure of the C / C composite material / BNi71CrSi and the nickel-based high-temperature alloy, and placing the structure in a vacuum hot-pressing furnace for connection. The method realizes the connection of the C / C composite material and nickel-based alloy, effectively relieves the problems of wettability and mismatch of thermal expansion coefficients of nickel alloy and the C / C composite material, lowers the residual stress between connectors, and enables the room-temperature shearing strength of a C / C composite material and a nickel-based alloy connector to reach 35.08 MPa.

Owner:无锡博智复合材料有限公司

Carbon fiber surface C/Si composite coating and preparation method thereof

The invention discloses a carbon fiber surface C / Si (carbon / silicon) composite coating and a preparation method thereof. The carbon fiber surface C / Si composite coating is prepared by using SiCl4 and CH4 as raw materials, using Ar as protective gas and carrier gas, using H2 as reduction gas and using a negative pressure chemical vaporous deposition method. The prepared pyrolytic carbon coating has thickness of about 0.3 to 1mum. The prepared Si-system outer coating has thickness of about 0.5 to 1.2mum. The prepared coating is uniform, compact and flat and has excellent combination among layers. According to the invention, on one hand, the oxidation resistance of carbon fibers is improved and the high-strength performance of the carbon fibers is protected, and on the other hand, the wettabilities of the carbon fibers and a metal matrix are improved and the success rate of preparation of the composite material is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A thermal/environmental barrier coating for ceramic matrix composites and its preparation method

ActiveCN109336647BGive full play to the high temperature water vapor corrosion resistanceHigh temperature water vapor corrosion resistance performance guaranteeCeramic compositeThermal insulation

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

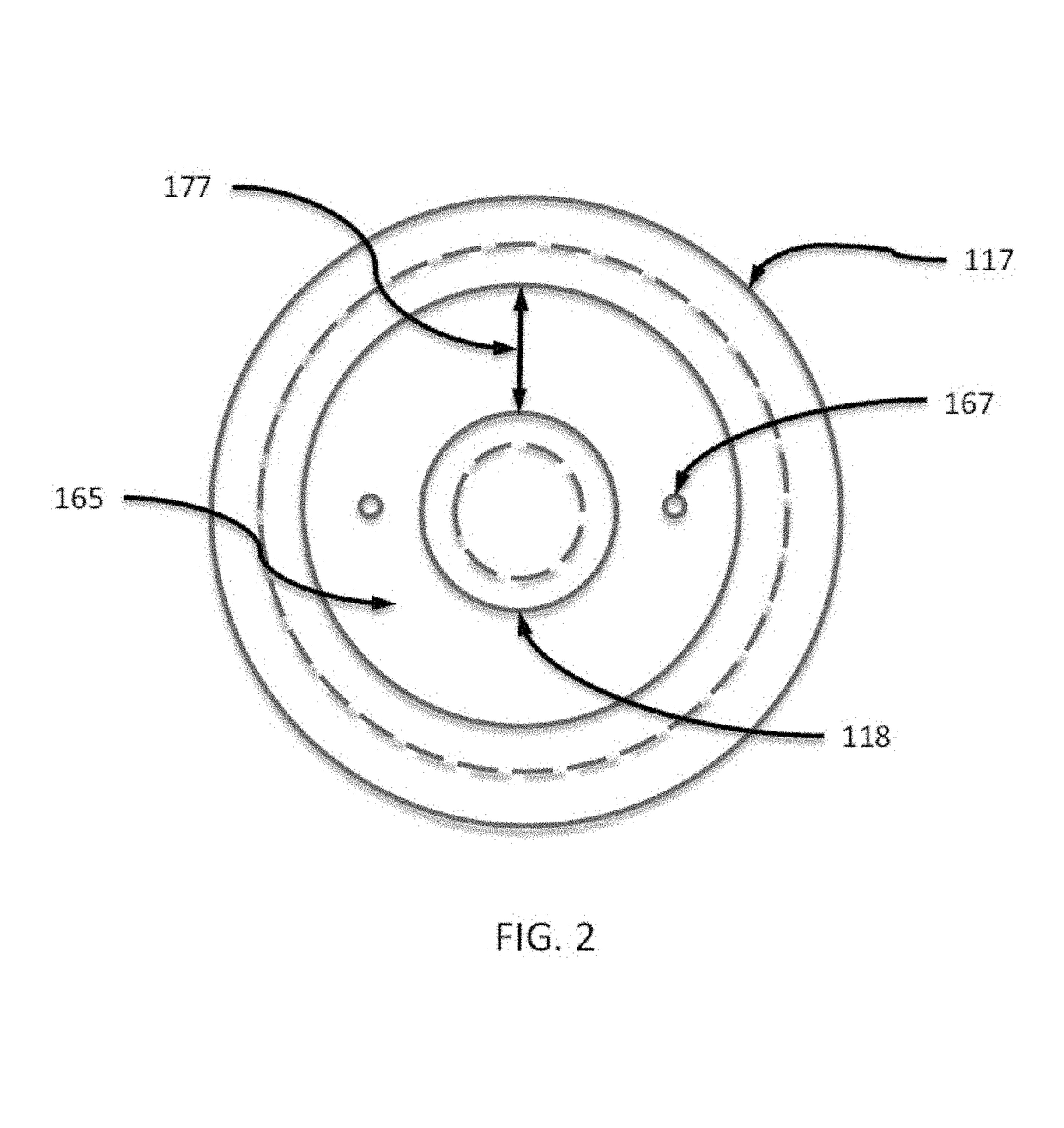

Thermally stable high temperature pressure and acceleration optical interferometric sensors

ActiveUS9810594B2Alleviate thermal expansion mismatchFluid pressure measurement by electric/magnetic elementsAcceleration measurementOptical cavityInterferometric sensor

Certain example implementations of the disclosed technology include an optical-interferometer sensor assembly for measuring pressure or acceleration. The sensor assembly includes a diaphragm configured to deflect responsive to an applied stimulus, a diaphragm support structure in communication with the diaphragm, a sensing optical interferometer having a first optical cavity in communication with at least a portion of the diaphragm and the diaphragm support structure, and a reference optical interferometer having a second optical cavity in communication with the diaphragm support structure. The sensor assembly can include a sensing optical fiber in communication with the sensing optical interferometer and a reference optical fiber in communication with the reference optical interferometer. The sensor assembly can include a housing in communication with the diaphragm and the diaphragm support structure, and configured to reduce a thermal expansion mismatch in the sensor assembly.

Owner:KULITE SEMICON PRODS

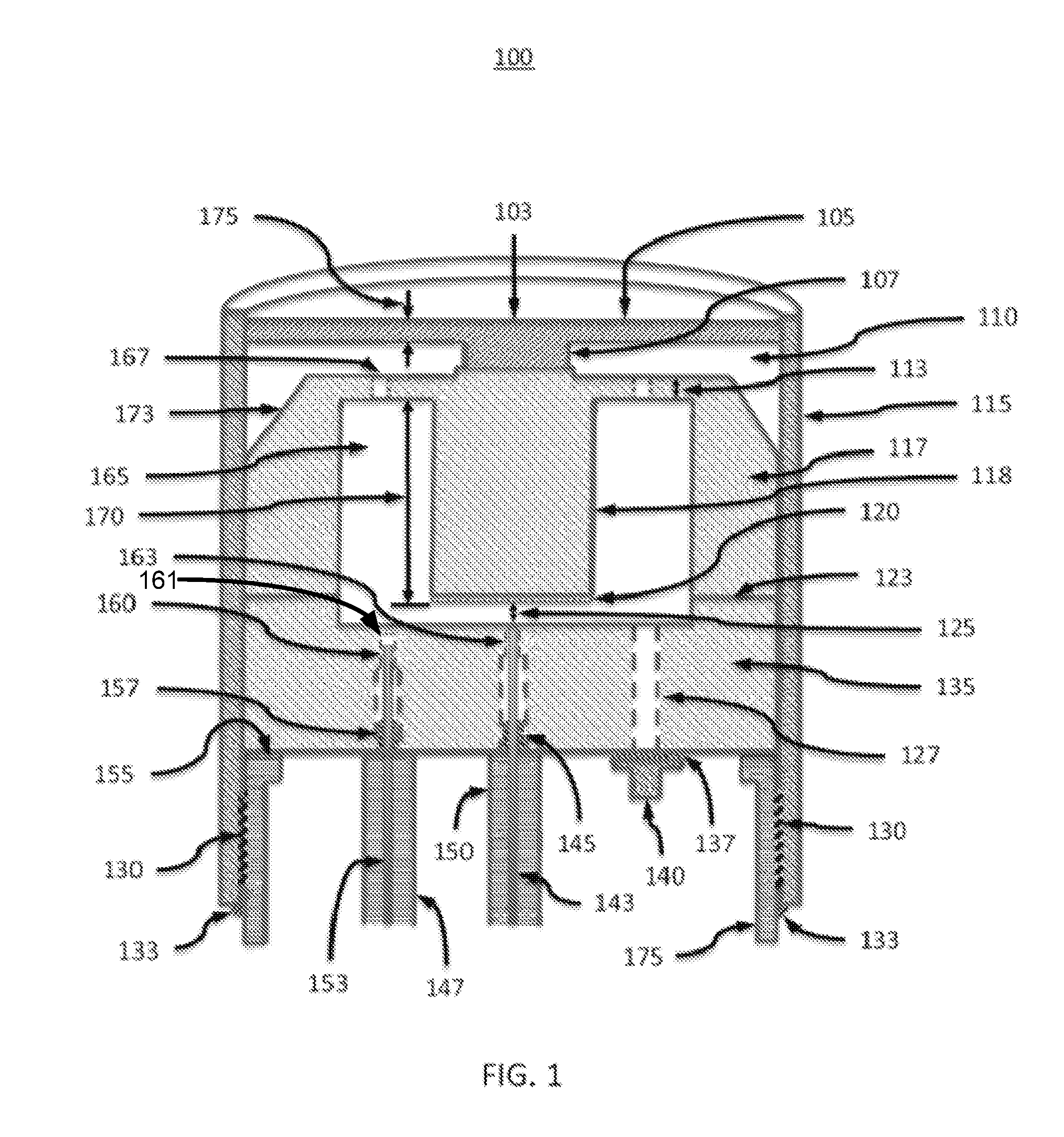

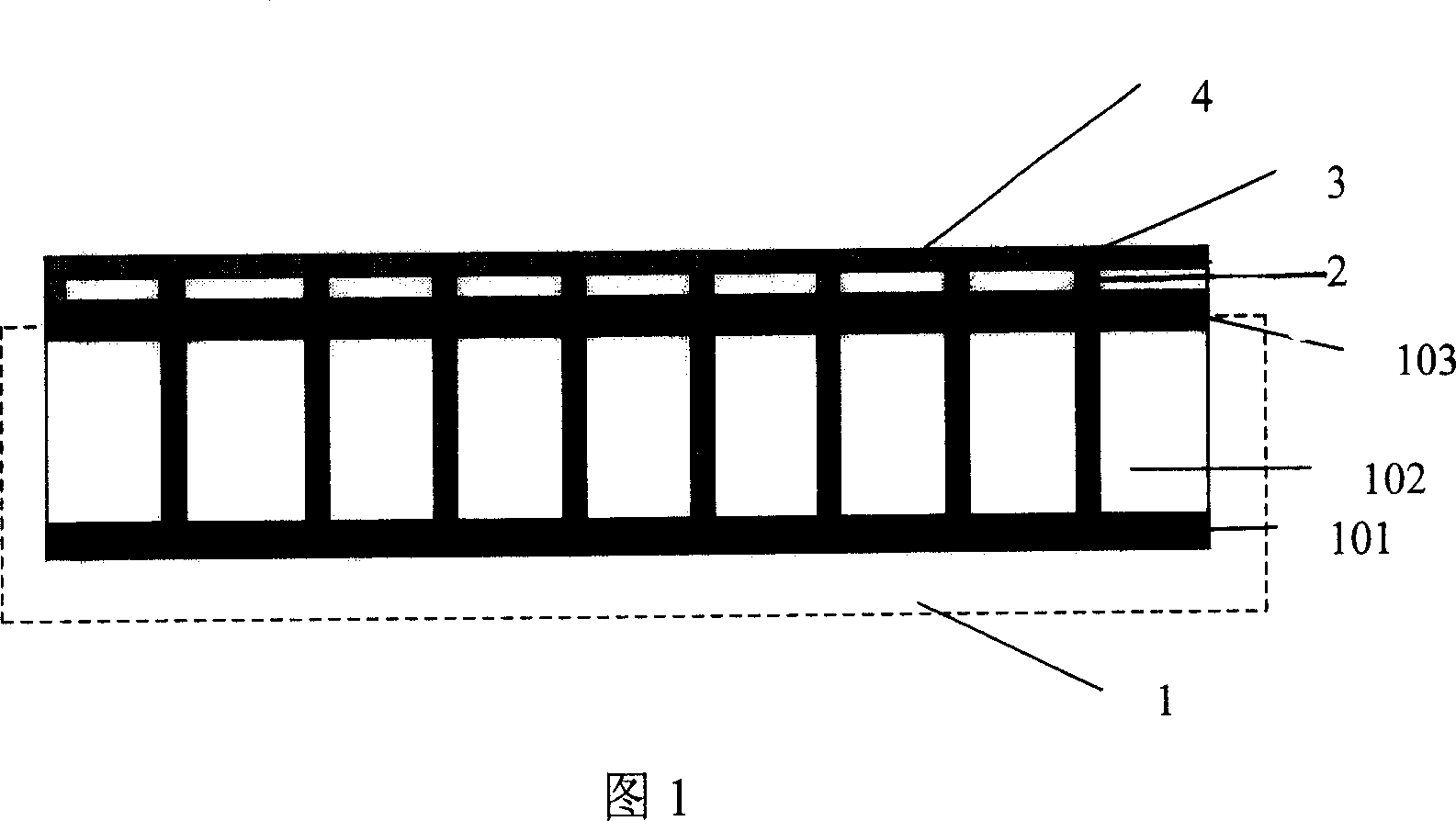

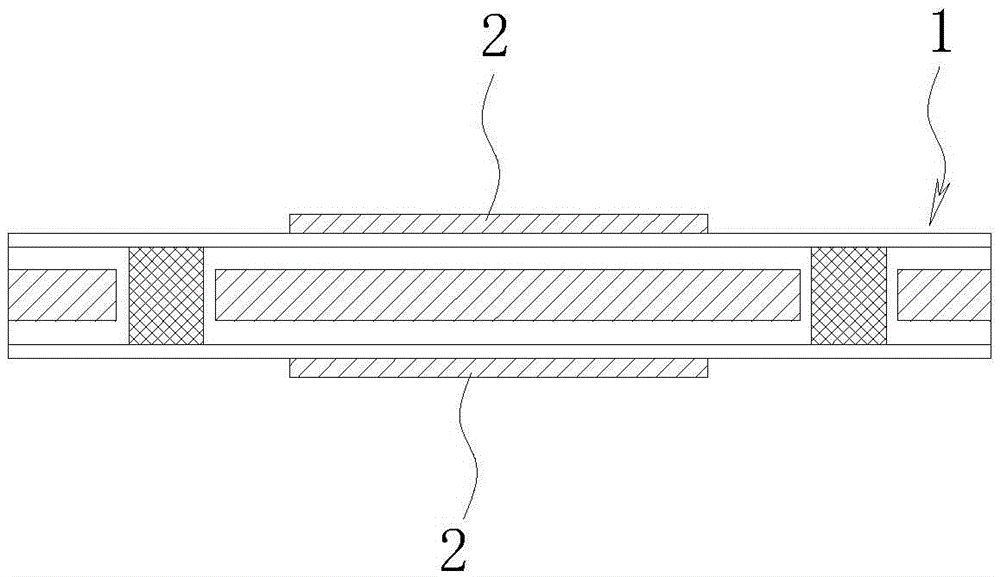

Encapsulation structure for multiple chips

InactiveCN1797764AImprove reliabilityAvoid touchingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The encapsulation structure includes lead frame, first and second chips and leads. The lead frame possesses following parts: first chip seat including opposite first face for sticking chip and first face for not sticking chip; second chip seat including opposite second face for sticking chip and second face for not sticking chip; structure for connecting first and second chip seats, and for connecting chip seats faced to first face for sticking chip and second face for not sticking chip; inner pins with connection faces for leads. First chip possesses first not active surface opposite to first active surface with first pads. The first not active surface is stuck to part of first face for sticking chip. Second chip possesses second not active surface opposite to second active surface with second pads. Part of second active surface is stuck to the second face for sticking chip. The said second face avoids covering second pad. Conducting wire connects first and second pads.

Owner:MACRONIX INT CO LTD

Palladium/ceramic composite film

InactiveCN109957772AAdjust the coefficient of thermal expansionImprove high temperature structural stabilityVacuum evaporation coatingSputtering coatingSputteringCeramic composite

The invention discloses a palladium / ceramic composite film. The composite film is loaded on a porous carrier. The composite film is formed by combining metal palladium or a palladium alloy and ceramics, wherein the volume of the palladium or the palladium alloy accounts for 30%-99%. The composite film is prepared through a physical vapor deposition method. A magnetron sputtering method is preferably adopted for preparing, and the composite film is obtained through sputtering of a palladium or palladium alloy target and a ceramic target at the same time. Through combining of a palladium film and the ceramics, on one hand, ceramic particles are dispersed and distributed in the continuous palladium or palladium alloy, the function of pinning is achieved for the palladium grain boundary, and palladium grain high-temperature grain growth and roughening difficulty is increased; and on the other hand, through introduction of the ceramics, the function of adjusting the palladium film heat expansion coefficient can be achieved, palladium film and ceramics or glass heat expansion mismatching is reduced, and the high-temperature structure stability of the palladium film is improved.

Owner:GRIMAT ENG INST CO LTD

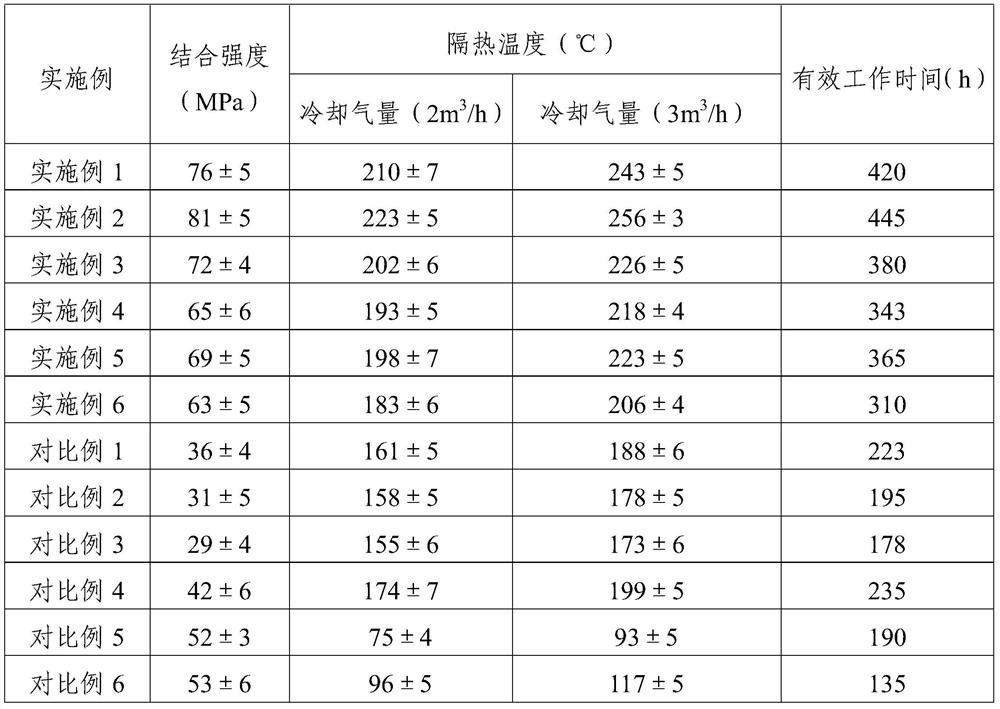

Composite structure friction material and preparation method thereof

ActiveCN112047750BImprove friction performanceImprove performanceNon-woven fabricsFiberCarbon fibers

The invention discloses a composite structure friction material and a preparation method thereof. The composite structure friction material of the present invention includes at least one inner layer group and at least one outer layer group, the part near the friction surface is the outer layer group, the part far from the friction surface is the inner layer group, and the inner layer group is straight and continuous carbon fiber Reinforced structure layer group, the outer layer group is carbon fiber corrugated continuous reinforced friction layer group; the inner layer group and the outer layer group are connected by needle-punched carbon fiber. The invention also includes a preparation method of the composite structure friction material. The friction material prepared by the present invention adopts the straight continuous carbon fiber reinforced structure of the inner layer group and the continuous corrugated carbon fiber reinforced structure of the outer layer group with gradient changes. The materials for the main bearing function and the main friction function adopt different structures, which can be Guarantee the excellent comprehensive performance and friction performance of the friction material.

Owner:中京吉泰(北京)科技有限责任公司

Light weight large-bore compound reflector

ActiveCN1327252CDifficulty avoiding uneven thicknessEliminate the effects of thermal deformationMirrorsEpoxyCarbon fibers

The invention discloses a kind of weight reduced, large-bore, and compound reflector. It includes a compound lens which is composed of folded graphite fiber / wreath oxygen resin or graphite fiber / cyanic acid fat panel + beehive interlayer + graphite fiber / wreath oxygen resin or graphite fiber / cyanic acid fat panel. It has these characteristics: On the lens, there are a microlite cylinder array and a tiny glass reflection base which are both fixed by wreath oxygen resin; On the microlite reflection base, a metallic reflection layer which is plated in vacuum exists. The advantages of the invention are as follows: It takes the microlite cylinder array as the join linking the carbon fiber compound material lens and the microlites reflection base so that the compound material lens can match the microlites reflection base's coefficient of heat expansion well and the problem of the mirror surface's anamorphic caused by heat can be solved. Moreover, the fact that the microlites reflection base has a good optical surface guarantees the reflector's heat stability and chemical stability.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

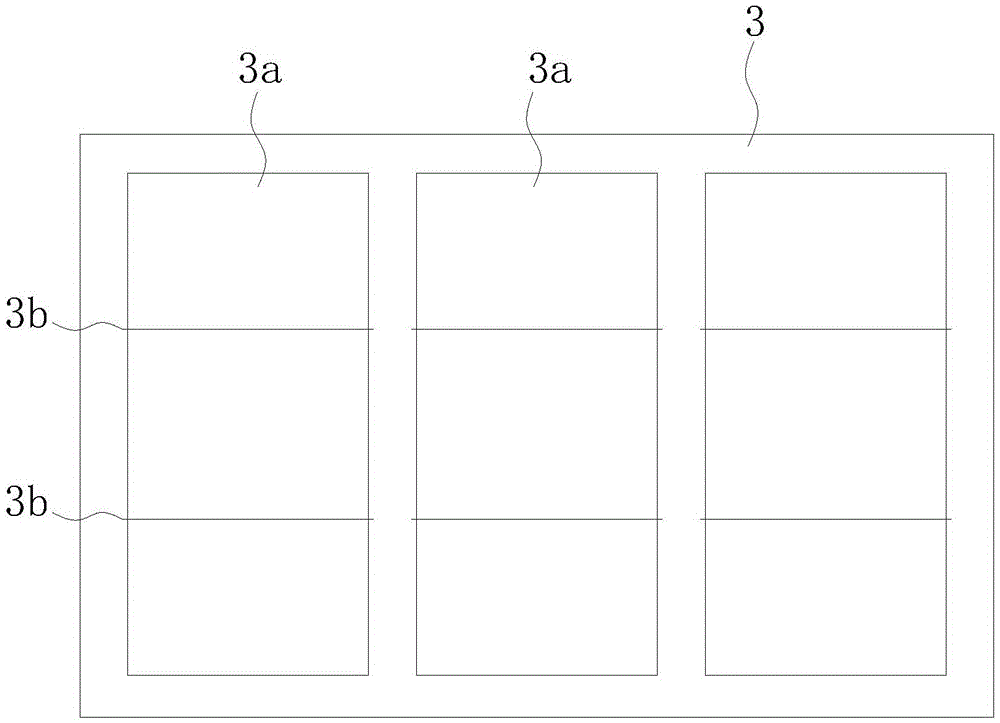

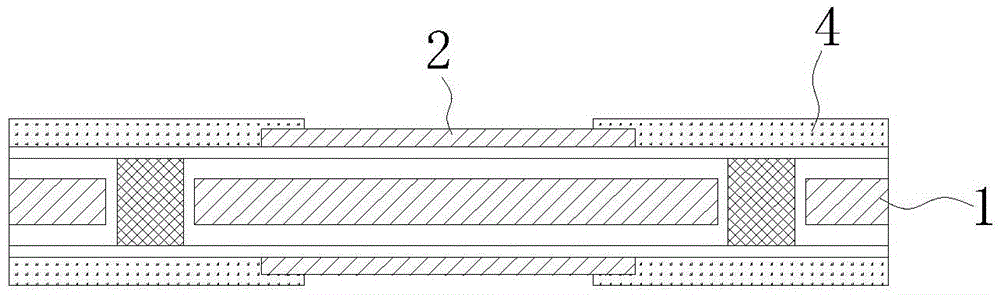

A kind of preparation method of symmetrical rigid-flex board

ActiveCN103648240BPrevent intrusionReduce usagePrinted circuit assemblingPrinted element electric connection formationResistAdhesive

The invention discloses a method for preparing a symmetrical rigid-flex board; it belongs to the technical field of rigid-flex board manufacturing technology; its technical points include the following steps: (1) preparing a flexible copper-clad board; (2) preparing a rigid copper-clad board ; (3) Groove each rigid unit on the surface of the rigid copper-clad laminate without copper foil. The size of the area between the two grooves is the same as the area of the flexible copper-clad laminate to be exposed; The board surface without copper foil of the copper plate and the flexible copper-clad laminate are bonded by adhesive to form a rigid-flexible composite board; (5) transfer the pattern of the rigid-flexible composite board, and then print and cure the solder resist ink; (6) Cut out each semi-finished unit along the outer contour of the rigid unit according to the product plan, and then perform half-cut processing on each semi-finished product by a CNC punching machine to expose the flexible area, thereby obtaining a rigid-flexible board; the present invention aims to provide a rigid-flexible board with high processing stability A method for preparing a symmetrical rigid-flex board with low cost; it is suitable for the production of rigid-flex boards.

Owner:BOMIN ELECTRONICS CO LTD +1

Coil/foil-electrode assembly to sustain high operating temperature and reduce shaling

InactiveUS7863818B2Alleviate thermal expansion mismatchOxide/hydroxide preparationLamp incadescent bodiesEngineeringThermal expansion

The invention relates to a barrier layer provided on the electrode assembly of a discharge lamp comprising at least a layer of nanoclusters of a non-oxidizing material. Further, the invention relates to an electrode assembly for a discharge lamp comprising an electrode having a foil attached thereto to create an electrode assembly, the assembly being coated with a multi-layer coating comprising at least a layer of non-oxidizing material in the form of nanoclusters, and at least another layer of non-oxidizing material, such that the total coating thickness is up to 1500 nm. A method to reduce thermal expansion mismatch between an electrode assembly and a discharge lamp envelope is also provided, the method comprising providing an electrode assembly and depositing on the surface of the assembly a coating having at least a nanocluster layer of a non-oxidizing material, and subsequently subjecting the lamp envelope in the electrode assembly area to pinching to create a pinch area, this lamp being able to operate at elevated temperature for extended periods, in excess of 1000 hours.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com