Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Uniform and dense coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

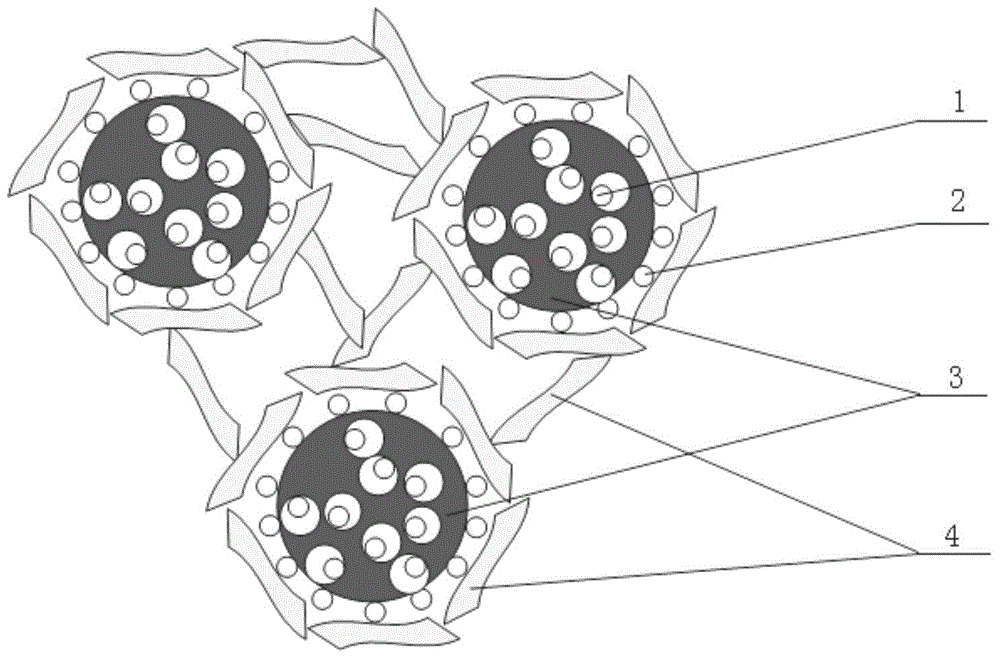

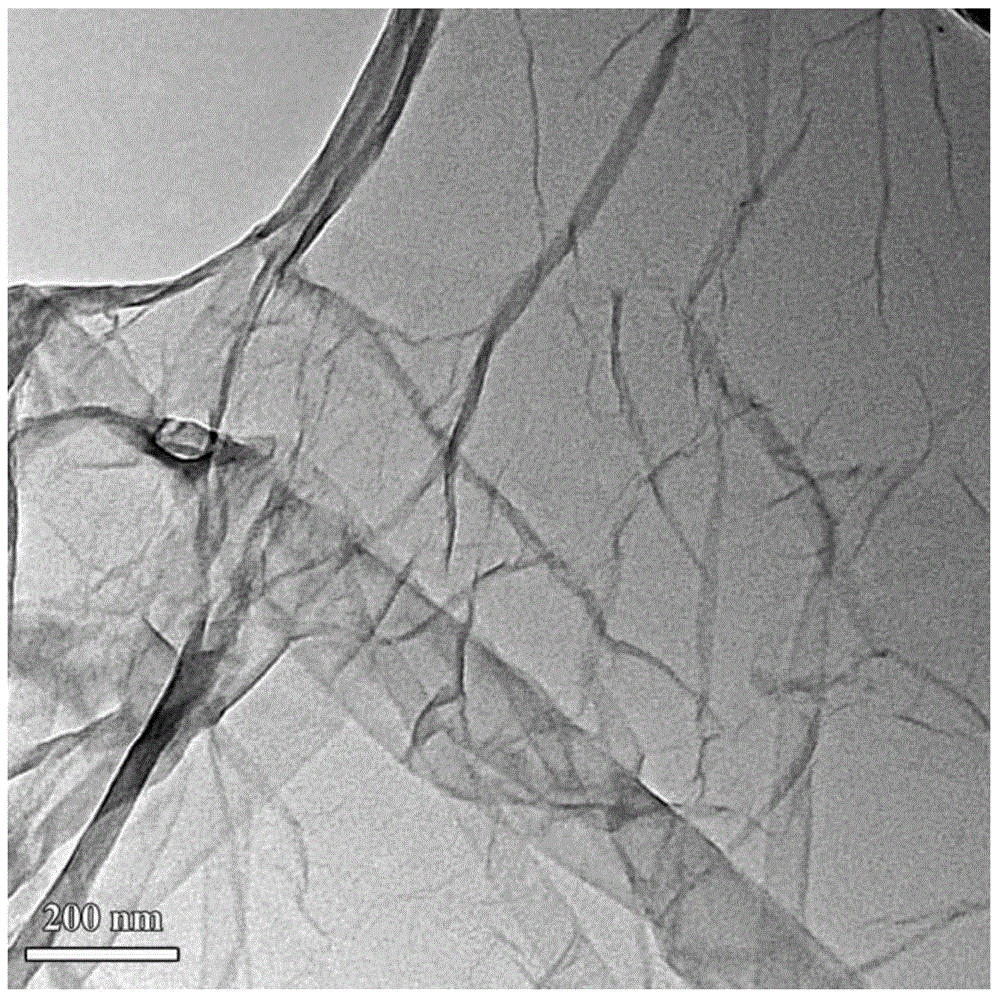

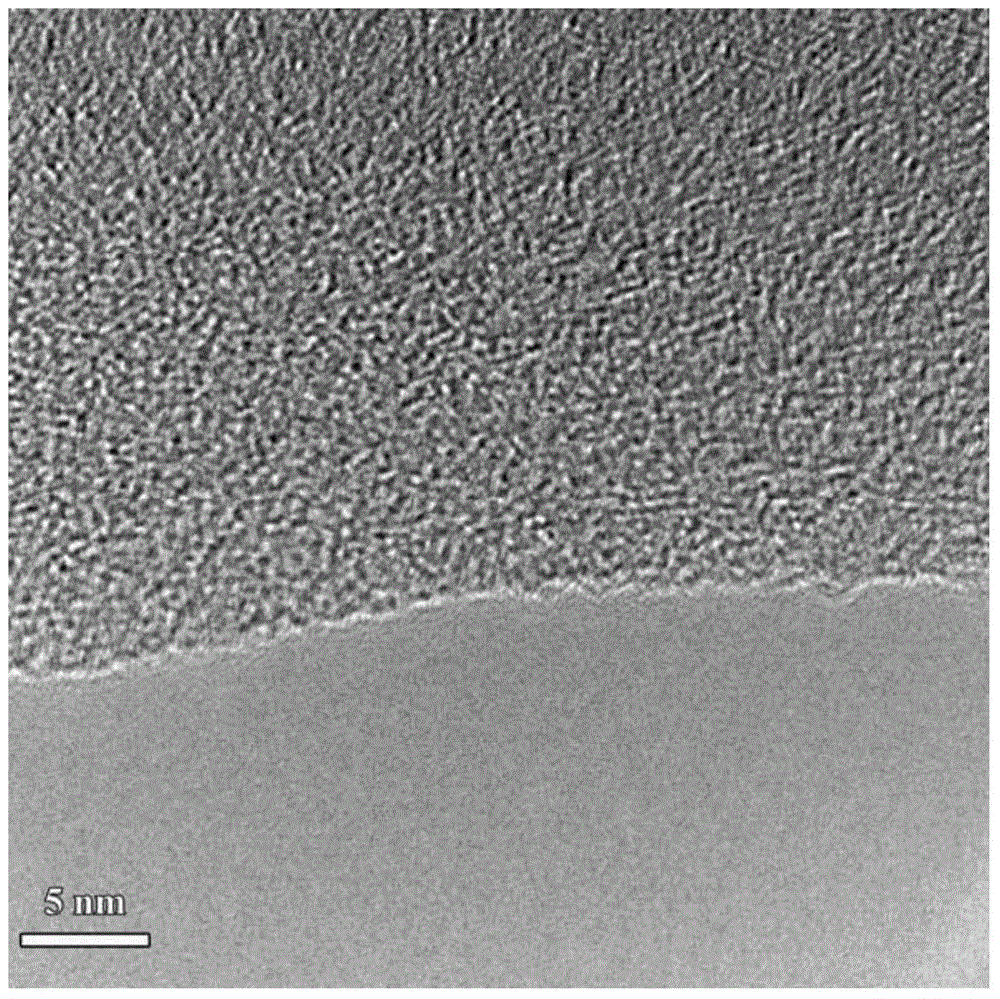

Graphene-coated sulfur/porous carbon composite positive electrode material and preparation method thereof

ActiveCN103560235AUnique hierarchical core-shell structureIncrease contentCell electrodesHigh ratePorous carbon

The invention provides a grapheme-coated sulfur / porous carbon composite material and a preparation method thereof, and relates to a grapheme-coated sulfur / porous carbon composite material used as the positive electrode material of a lithium-sulfur secondary battery and a preparation method thereof. The grapheme-coated sulfur / porous carbon composite positive electrode material provided by the invention can be used for solving the technical problem that the existing grapheme-coated sulfur-containing composite material used as the positive electrode material of a lithium-sulfur battery is low in electrochemical properties. The external surface of each of the particles of the grapheme-coated sulfur / porous carbon composite material provided by the invention is evenly covered with a graphene sheet, and a graphene conductive network is formed between the particles; the obtained grapheme-coated sulfur / porous carbon composite material has a hierarchical core-shell structure. The preparation method of the grapheme-coated sulfur / porous carbon composite material is obtained by adding a sulfur / porous carbon composite material to graphene slurry which is stable for a long time and in which graphene sheets are highly dispersed in water for mixing and coating. The positive electrode material has high specific capacity, long cycle life and excellent high-rate performance. Besides, the grapheme-coated sulfur / porous carbon composite material can be used as the positive electrode material of a lithium secondary battery.

Owner:HARBIN INST OF TECH

Surface repairing method for thin-strip continuous casting crystallizing roller or casting blank continuous casting crystallizer

The invention discloses a surface repairing method for a thin-strip continuous casting crystallizing roller or a casting blank continuous casting crystallizer, comprising the following steps of: firstly, pre-processing the surface of the crystallizing roller or the crystallizer properly, then plating monolayer nickel base alloy on the surface of the crystallizing roller or the crystallizer, ending plating when the clad layer meets the requirement on size of the product and machining the crystallizing roller or the crystallizer. The nickel base alloy can be replaced by a nickel base composite clad layer which is formed by diffusing more than one micron-scale or nano-scale solid particles or fiber evenly in a substrate metal by taking pure nickel or the nickel base alloy as the substrate metal; the clad layer is even or of gradient; the clad layer further can be a multi-layer clad layer covered with the nickel base alloy or the nickel base composite clad layer again thereon by using pure nickel as a bottom clad layer. The method has the advantages that the clad layer of the crystallizing roller or the crystallizer is even and compact, has low inner stress, and high bonding strength with the matrix, thereby prolonging service life, reducing the manufacturing cost of continuous casting of the thin strip and casting blank and improving production efficiency and quality of product.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

Polyvinylpyrrolidone modified graphene coated sulfur/porous carbon composite anode material and preparation method thereof

ActiveCN104078685AIncrease contentImprove the utilization rate of active substancesCell electrodesLi-accumulatorsCvd grapheneHigh rate

The invention relates to a polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite anode material and a preparation method thereof, which relates to a sulfur / carbon composite material applied to a lithium-sulfur secondary battery anode material and a preparation method of the composite material, and solves the technical problem of the existing lithium-sulfur battery anode material graphene-coated sulfur-containing composite material that the electrochemical property is low. The polyvinylpyrrolidone modified graphene coated sulfur / porous carbon composite material is characterized in that the outer surface of a sulfur / porous carbon composite material particle is uniformly coated with a polyvinylpyrrolidone modified graphene slab layer, a graphene conductive network is formed between every two adjacent particles, and a grading core-shell structure is formed. The preparation method comprises the steps of adding the sulfur / porous carbon composite material into graphene slurry modified by the polyvinylpyrrolidone, and mixing the sulfur / porous carbon composite material with the graphene slurry, and coating the sulfur / porous carbon composite material with the graphene slurry modified by the polyvinylpyrrolidone. The anode material is high in specific capacity, long in cycle life and good in high-rate performance.

Owner:HARBIN INST OF TECH

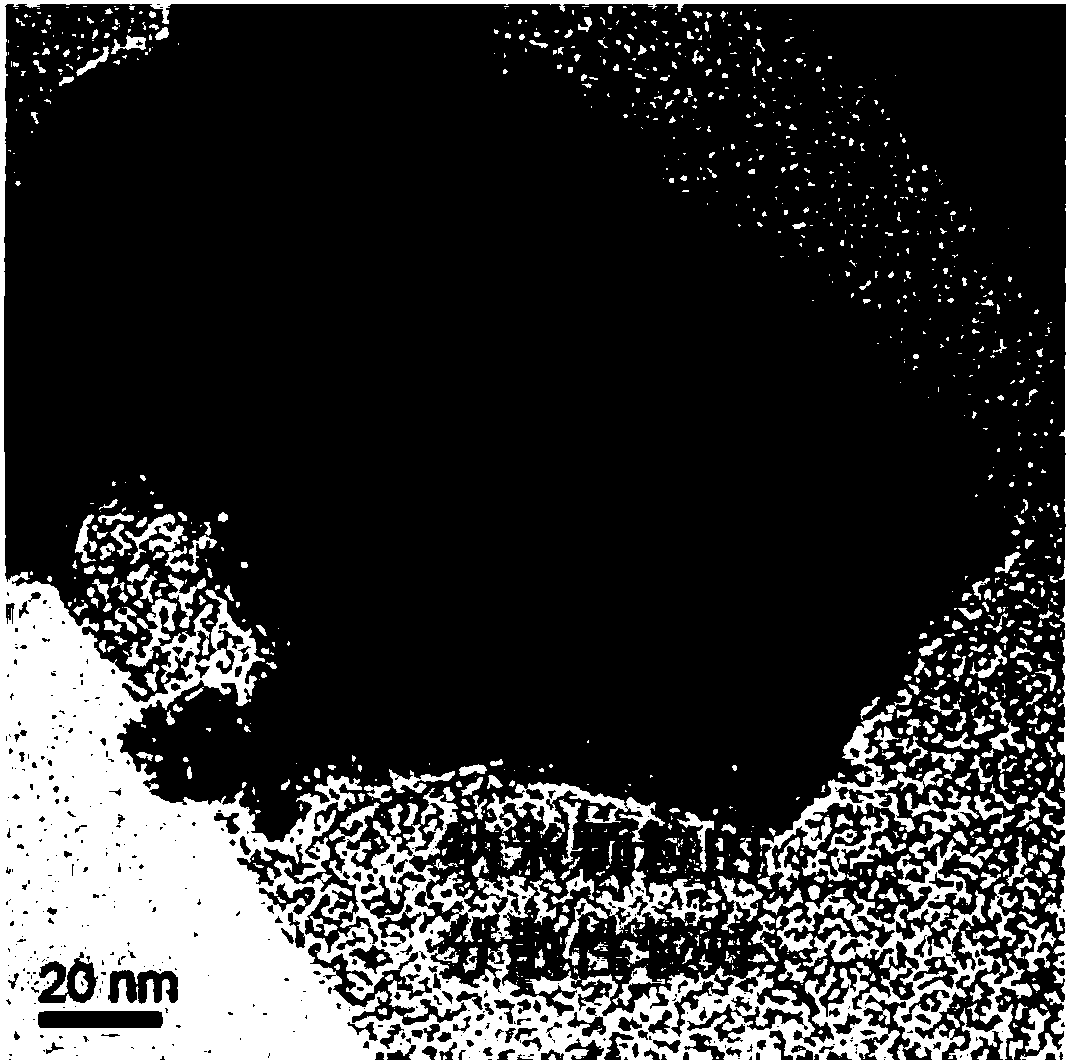

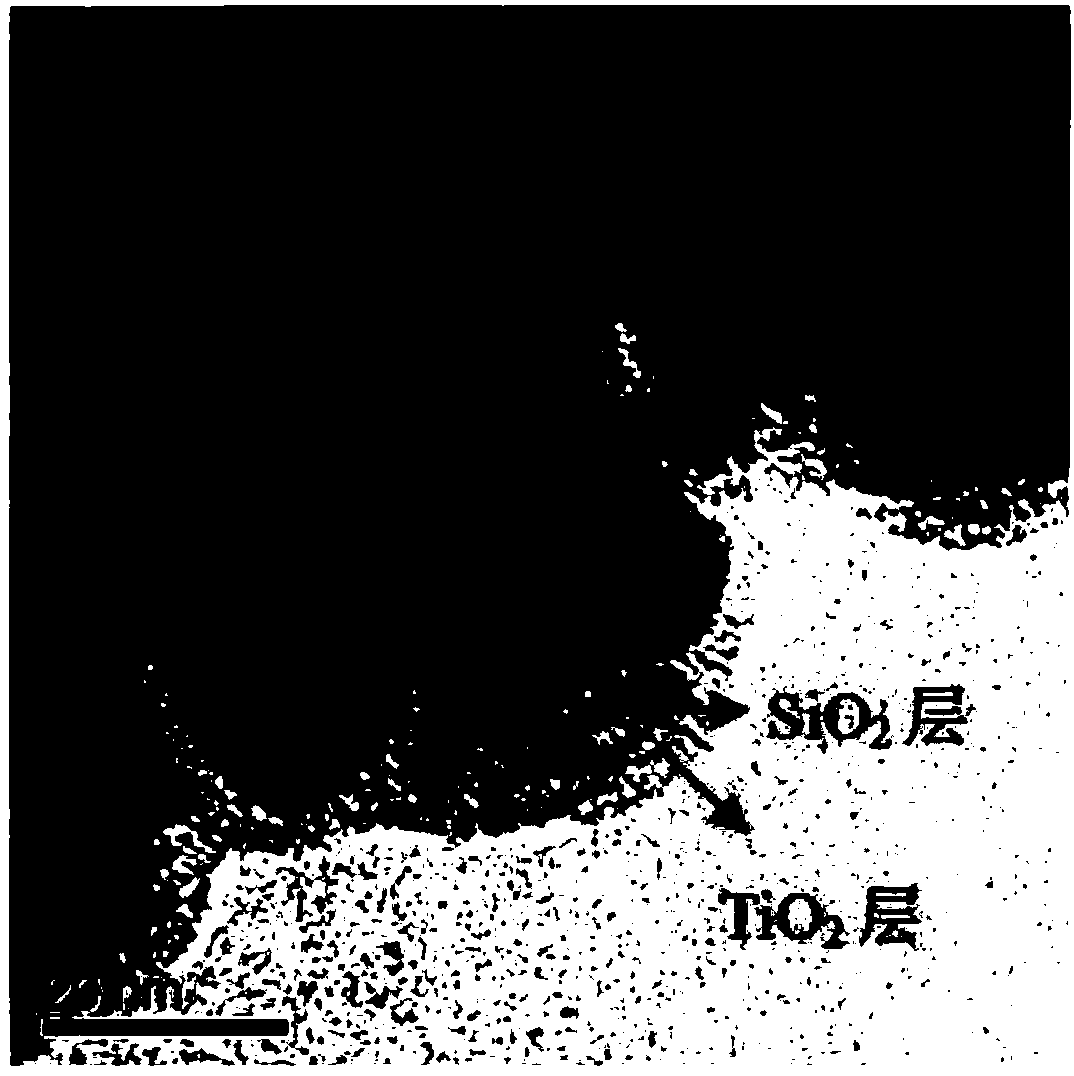

Nanosized ferrite composite material with double-shell structure and preparation method of nanosized ferrite composite material

ActiveCN108101114AAvoid performance impactGood chemical stabilityMaterial nanotechnologyInorganic material magnetismMaterials preparationChemical stability

The invention discloses a multifunctional nanosized ferrite composite material with a double-shell structure and a preparation method of the multifunctional nanosized ferrite composite material. The composite material is prepared from spinel type nanosized ferrite as a nucleus, silicon dioxide as an intermediate layer and titanium dioxide as an outer shell layer. With adoption of the intermediatelayer, on one hand, chemical stability of a magnetic nucleus of the nanosized ferrite can be improved and the applicable range of the material can be extended, and on the other hand, influence of themagnetic nucleus on performance of the outer shell layer is prevented; the outer shell layer not only can endow the material with special characteristics of light, electricity, catalysis and the like,but also can be integrated with the characteristics of the magnetic nucleus, so that multifunctional nanoparticles are obtained. The preparation method mainly comprises steps as follows: a three-stepsol-gel method for material preparation, surface modification with function of improving dispersity and coating effect, ball milling, heat treatment process under atmosphere control and the like. Thenanosized ferrite particles with the double-shell structure have the advantages of relatively good dispersity, high specific surface area, tight combination of the shell layer and the nucleus; meanwhile, the application field of the material can be further expanded by modification of the shell layer.

Owner:HUNAN UNIV

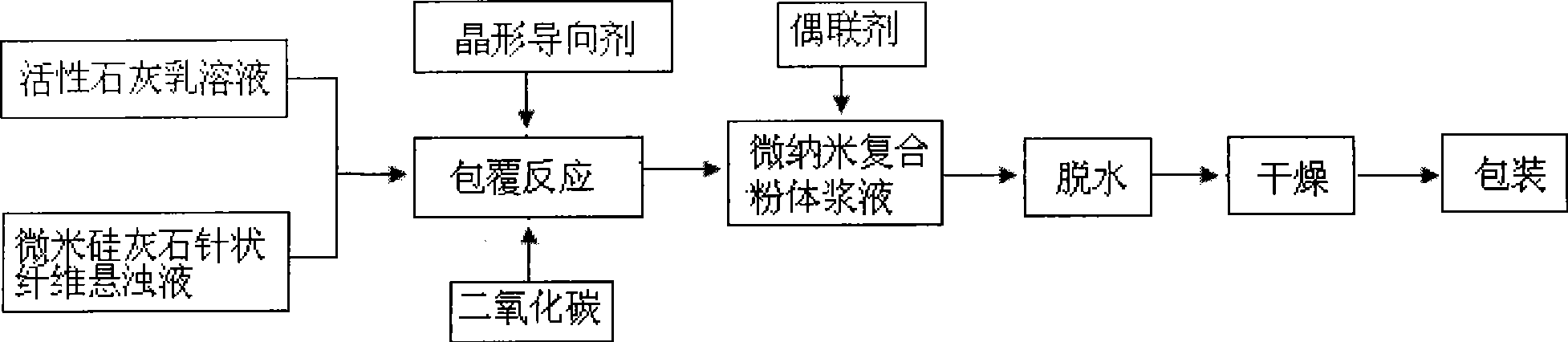

Grammite raphioid fibre crystal-nano calcium carbonate micro-nano composite powder material and production method

InactiveCN101498052AHigh surface energyHigh chemical activityPolycrystalline material growthAfter-treatment detailsMicro nanoFiber crystal

The invention relates to a surface modified product of an acicular wollastonite crystal and a production method thereof. The product is micro-nano composite powder by coating a nanometer calcium carbonate crystal on the surface of the acicular wollastonite fiber crystal. The method comprises the following steps: firstly, preparing an active lime milk solution and an acicular wollastonite fiber solution; compounding the two solutions into a suspension; adding a crystalline directing agent to the suspension and filling CO2 gas for a coating reaction so that the nanometer calcium carbonate crystal gradually grows on the surface of an acicular aedelforsite fiber, and the micro-nano composite powder by coating a nanometer calcium carbonate crystal on wollastonite is obtained; and coating a layer of coupling agent on the surface of the micro-nano composite powder to obtain the acicular wollastonite fiber crystal-nanometer calcium carbonate crystal-coupling agent composite powder material. The product keeps the superior characteristics of the acicular wollastonite crystal and the nanometer calcium carbonate crystal, improves the surface energy and the chemical activity of wollastonite composite particles and can be well stuck with organic polymers so as to form a favorable interface and improve the bonding force between fillings and basal bodies, such as plastics, pulp, and the like.

Owner:颜鑫 +3

Method for plating magnesium alloy based on ionic liquid plating solution

The invention discloses a method for plating a magnesium alloy based on an ionic liquid plating solution, relates to the technical field of magnesium alloy surface treatment, and in particular relates to the plating of the pre-plated magnesium alloy in a plating solution in which deep eutectic solvent serves as a solvent. A plated layer obtained through the method is uniform and compact and can be firmly combined with a matrix, and the whole process has the characteristics of simple process, environmental friendliness and the like.

Owner:合肥金盟工贸有限公司

Composite wave absorbing material and preparation method thereof

ActiveCN108251054ALow densityHigh strengthOther chemical processesMagnetic/electric field screeningMXenesMaterials science

The invention relates to the field of wave absorbing materials, in particular to a composite wave absorbing material and a preparation method thereof. The composite wave absorbing material is characterized in that the surface of each of MXene layers is coated with a ferrite, and the different MXene layers and the ferrites on the surfaces of all the layers jointly form a sandwich structure. The composite wave absorbing material and the preparation method thereof provided by the invention have the benefits that MXene is prepared by adopting a chemical etching process, the ferrites prepared by adopting a hydrothermal preparation process are compounded with the MXene so as to grow in situ on the surface of MXene powder, the degree of integration between the ferrites and the MXene powder is high, and the coating is uniform and compact; the prepared MXene / ferrite composite wave absorbing material with the sandwich structure is light in density, high in strength, adjustable in dielectric constant and excellent in wave absorbing performance. In addition, the preparation method is simple, used equipment is simple, the process is stable, the production efficiency is high, the cost is reduced, the compactness and the uniformity of the material are good.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

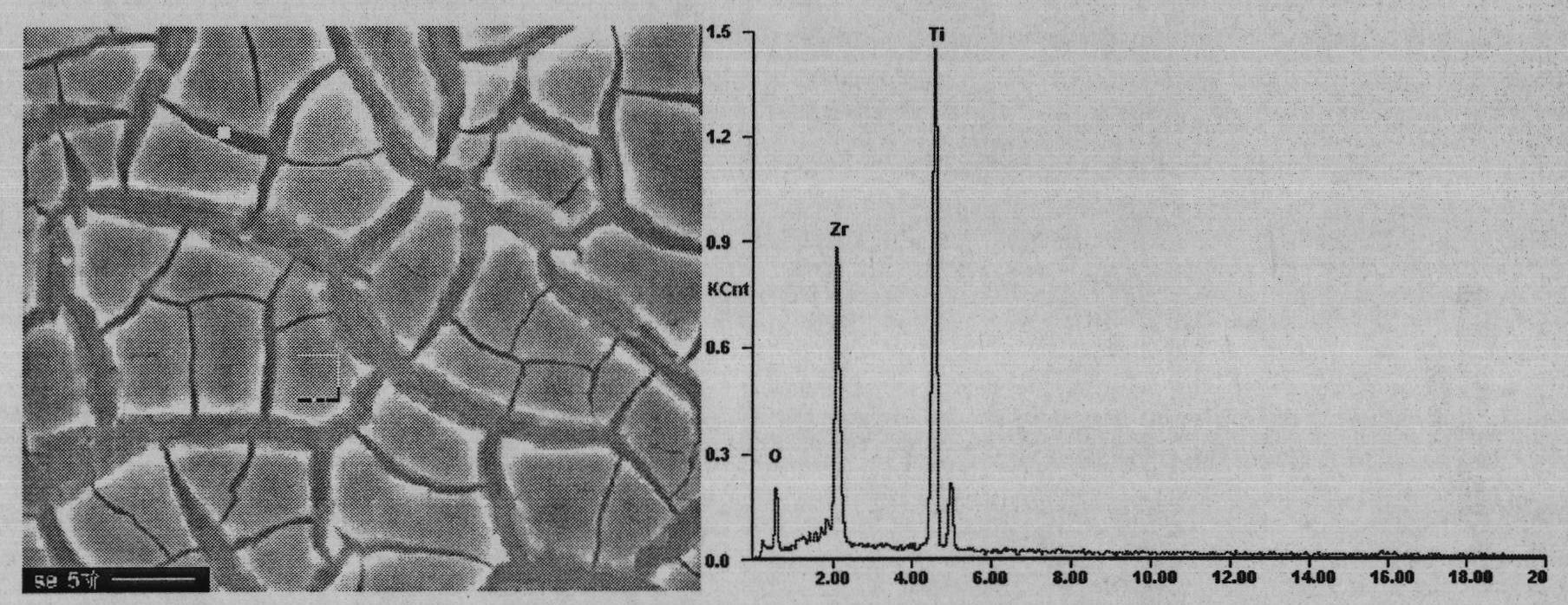

Electrochemical method for preparing HA/ZrO2 (hydroxylapatite/zirconia) gradient coating on surface of medical titanium

InactiveCN101880890AUniform and dense coatingAlleviate thermal expansion mismatchElectrolysis componentsCoatingsIonBiocompatibility Testing

The invention discloses an electrochemical method for preparing a HA / ZrO2 (hydroxylapatite / zirconia) gradient coating on the surface of medical titanium. The method comprises the following steps of: carrying out electro-deposition in an electrolytic cell with a three-electrode system, wherein the medical titanium to be coated is a working electrode; carrying out electro-deposition to obtain a Zr (OH) 4 coating in a zirconium oxynitrate solution with certain concentration and pH value, wherein the deposition current is 20mA, and the deposition time is 600s; then, depositing a CaHPO42H2O coating in an electrolyte which has certain concentration and pH value and consists of calcium nitrate and ammonium dihydrogen phosphate, wherein the deposition current is 1.5mA, and the deposition time is 900s; and finally, carrying out vacuum sintering on the obtained coating materials, and raising the sintering temperature to 650 DEG C at a heating rate of 10 DEG C / min, then preserving the heat for two hours, and subsequently cooling the coating materials with a furnace so as to obtain the HA / ZrO2 composite coating. The electrochemical method of the invention has the advantages that: the ingredients of the coating are deposited on a substrate in the form of ions, so that the bonding strength of the HA / ZrO2 gradient coating and the Ti substrate is improved greatly; and the anti-corrosion and simulated body fluid experiment shows that even the HA on the surface is dissolved completely due to the biological effect, the remaining ZrO2 coating still has good anti-corrosion performance and certain biocompatibility.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Preparation method of oxide ceramic coating layer on surface of silicon carbide fiber

InactiveCN104213099AGood lookingUniform and dense coatingChemical vapor deposition coatingOxide ceramicCarbide silicon

The invention discloses a preparation method of an oxide ceramic coating layer on a surface of a silicon carbide fiber. The preparation method comprises the following steps: (1) the silicon carbide fiber is removed glue for cleaning; (2) the silicon carbide fiber is put in an ALD reaction chamber to repeatedly vacuumize and replace nitrogen for three times; (3) a reaction precursor is selected according to the type of a deposited oxide coating layer; and the parameters of a deposition process are set; (4) precursor steam is guided in the ALD reaction chamber under the carrying of nitrogen or argon; (5) the reaction chamber is blown by the nitrogen or argon; (6) oxygen source steam is guided in the ALD reaction chamber under the carrying of the nitrogen or argon; (7) the reaction chamber is blown by the nitrogen or argon; (8) the steps (4)-(7) are repeated until the needed thickness of the coating layer is deposited; and (9) the coating layer is put in a high-temperature tube furnace, and is thermally treated under the nitrogen protection. The preparation method can be used for preparing the uniform and compact oxide ceramic coating layer with few impurities and precisely controlled thickness on the surface of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

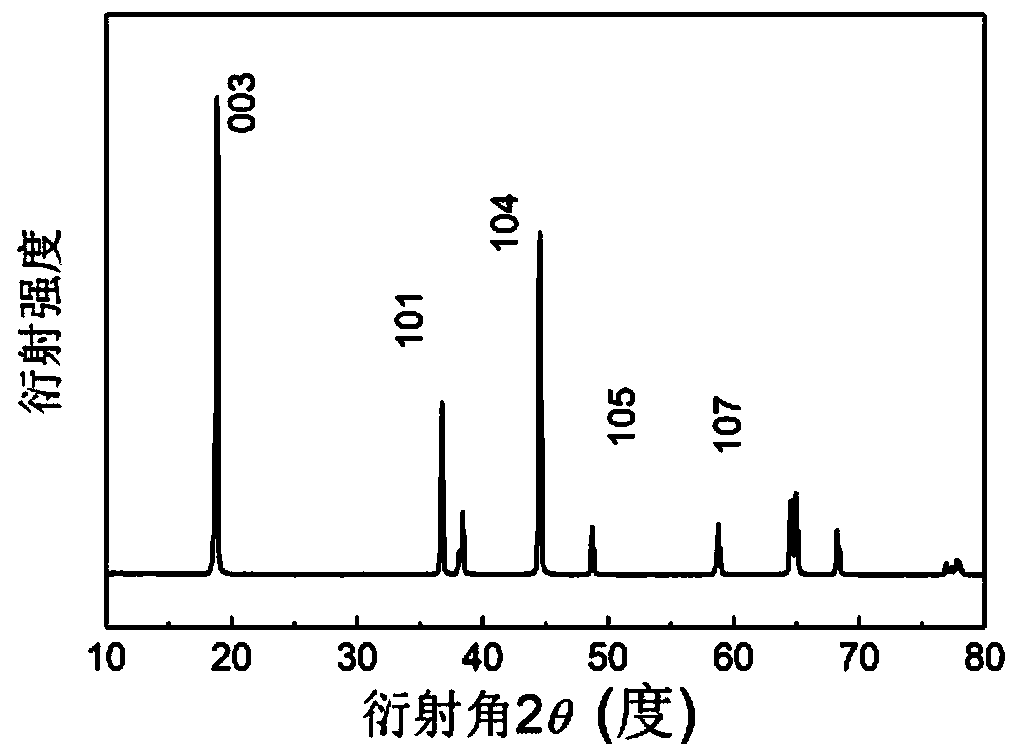

Nanometer oxide coated lithium titanate negative electrode material of lithium battery, and preparation method for negative electrode material

ActiveCN103035901AUniform and dense coatingEasy to coverMaterial nanotechnologyCell electrodesComposite materialSurface-active agents

Owner:DONGFANG ELECTRIC CORP LTD

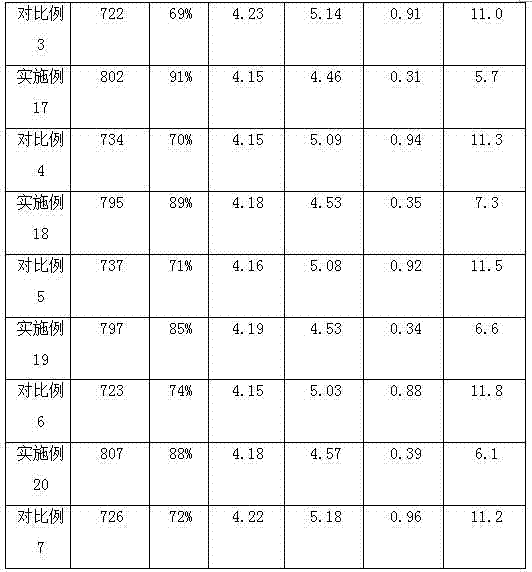

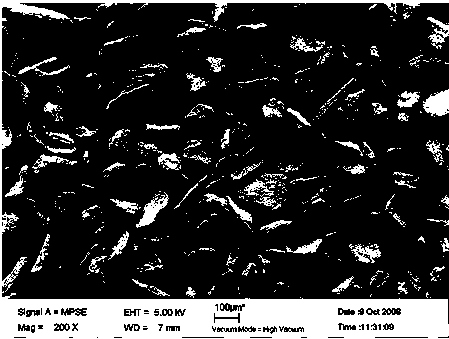

Nickel-coated graphite electric conduction powder used for electric conduction rubber and manufacturing method thereof

InactiveCN103817323ALow densityLow costLiquid/solution decomposition chemical coatingElectricityAcid etching

The invention concretely discloses a nickel-coated graphite electric conduction powder used for electric conduction rubber and a manufacturing method of the nickel-coated graphite electric conduction powder. The nickel-coated graphite electric conduction powder used for the electric conduction rubber comprises 50-80% of nickel and 20-50% of graphite. The manufacturing method of the nickel-coated graphite electric conduction powder used for the electric conduction rubber mainly includes the four steps of oil removing treatment on graphite powder, acid etching and roughening treatment on the graphite powder, surface activating treatment on the graphite powder and chemical nickel plating. The nickel-coated graphite electric conduction powder has the advantages of pure nickel and pure graphite, is low in cost and not prone to rusting and further can improve the mechanical strength of the electric conduction rubber material. The chemical nickel plating method is easy to operate and simple in technology, plated layers are even and compact, the throwing power is high, plating can be performed on particles in any shape, the covering power is high, and the even, fine and dispersed composite powder can be manufactured.

Owner:杨福河

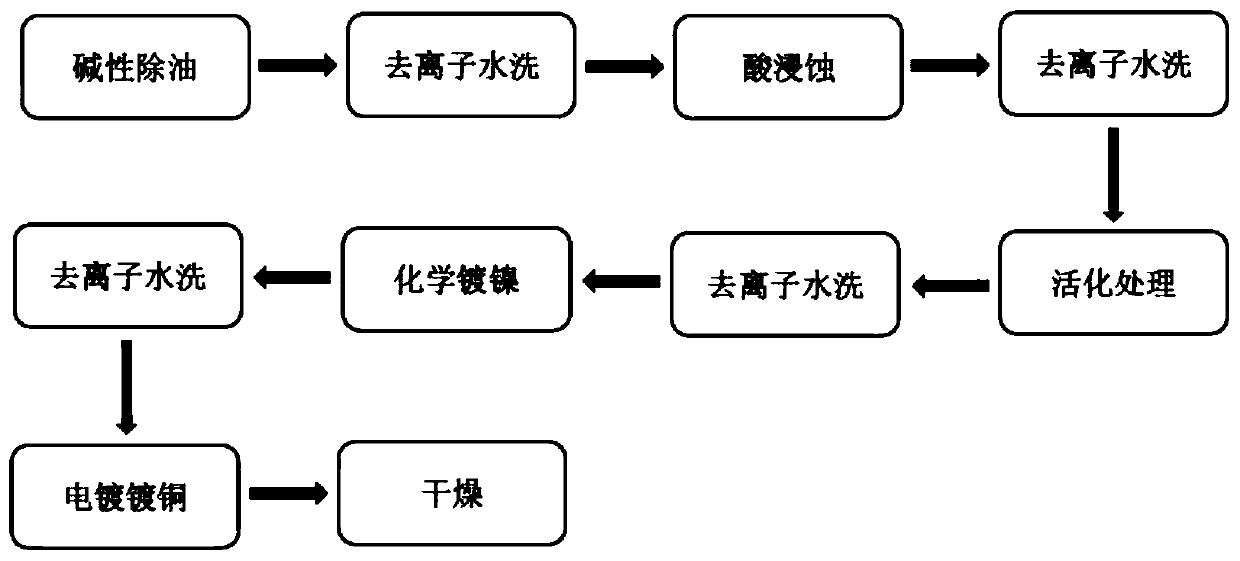

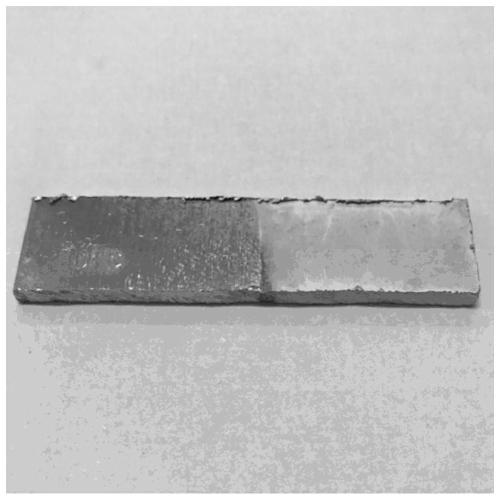

Rapid pre-treatment method for copper electroplating on aluminum substrate

InactiveCN109898115AImprove bindingRemoval of natural oxide film on the surface of aluminum substrateSuperimposed coating processAcid etchingCopper plating

The invention belongs to the technical field of printed circuit boards and discloses a rapid pre-treatment method for copper electroplating on an aluminum substrate. The method mainly comprises the following steps of alkaline de-oiling, acid etching, activating treatment, chemical nickel plating and copper electroplating. First, alkaline de-oiling and acid etching are carried out on the aluminum substrate to remove a surface oxide film and increase roughness. By controlling palladium solution components, hydrochloric acid content and activating time, the chemical nickel plating rate is greatlyincreased, plating is rapidly started, and a nickel plating with great bonding force can be stably obtained. By controlling copper plating solution components, current density and electroplating time, a uniform and dense copper plating with great bonding force is prepared. The preparing method for the copper plating on the aluminum substrate is high in stability, zinc dipping pretreatment is notneeded, the production technology is simplified, the environment is prevented from being polluted by a plating solution, and the service life of the plating solution is prolonged. By using the method,the obtained copper plating has the characteristics of evenness, density, great bonding force and the like and is suitable for industrial large-scale stable production.

Owner:GUANGDONG UNIV OF TECH

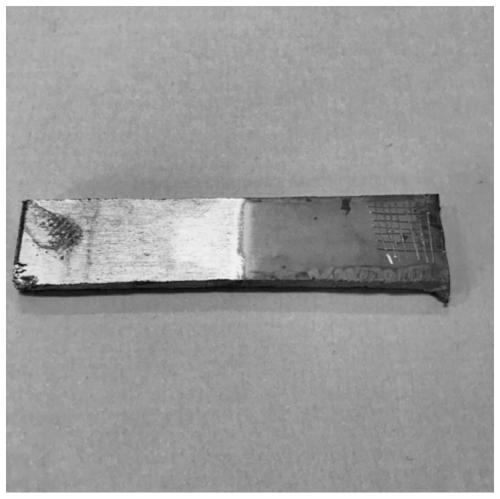

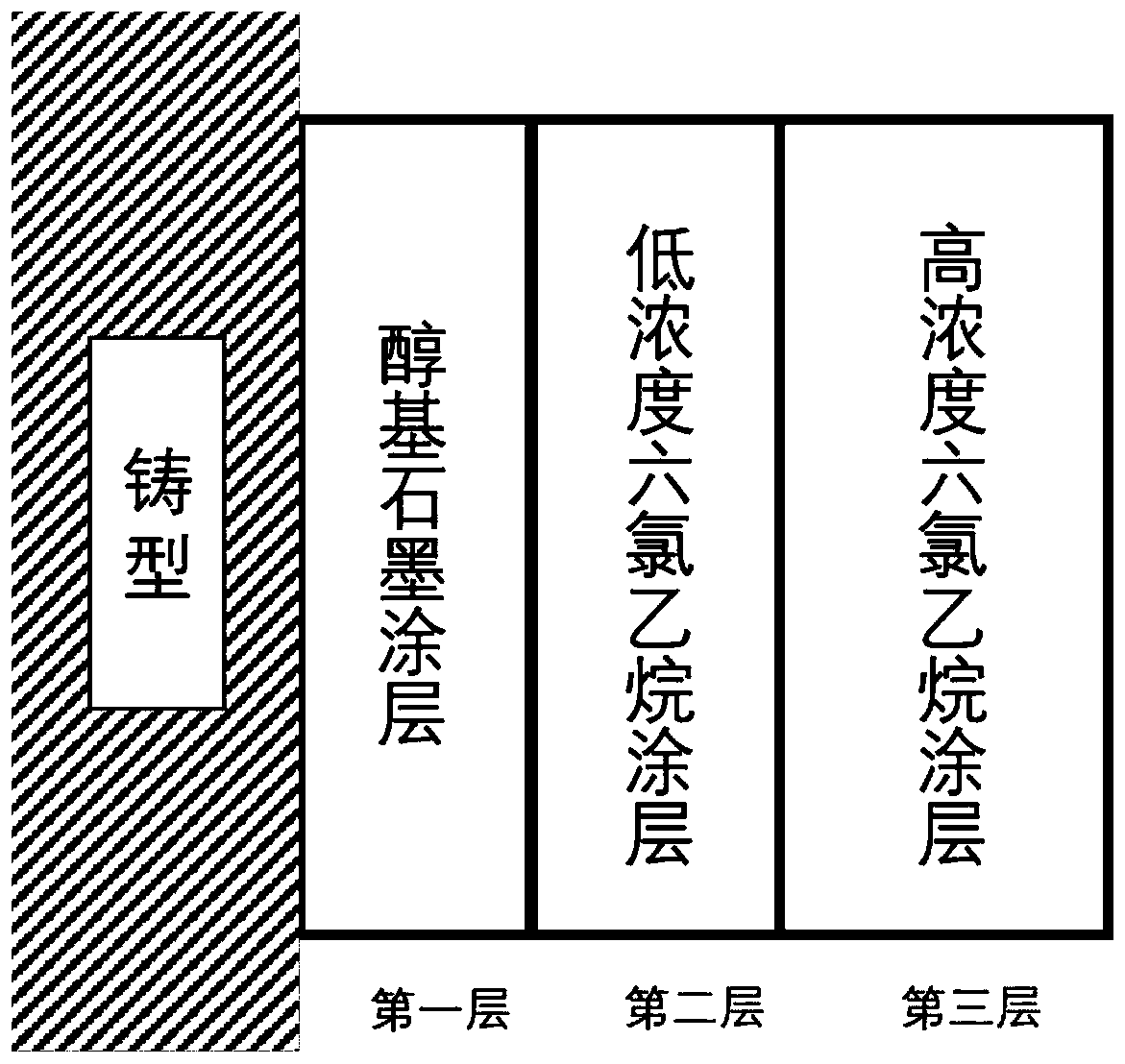

Multi-layer composite mold coating for aluminum-lithium alloy sand casting and coating method thereof

The invention discloses a multi-layer composite mold coating for aluminum-lithium alloy sand casting and a coating method thereof. The multi-layer composite coating comprises an alcohol-based graphitecoating, a low-concentration hexachloroethane coating and a high-concentration hexachloroethane coating which are sequentially arranged. The coating method adopts a combination manner of brushing andspraying, the alcohol-based graphite coating is brushed by adopting a brushing method, and the low-concentration hexachloroethane coating and the high-concentration hexachloroethane coating are sprayed by adopting a spraying method, and waited for natural volatilization and drying of the low-concentration hexachloroethane coating and the high-concentration hexachloroethane coating after the tlcohol-based graphite coating is ignited and dried. According to the coating, the hexachloroethane coating is added to react with aluminum lithium alloy melt to form an air film to prevent the alloy liquid from being in contact with a casting mold, and the problem that the high-activity lithium element is easy to react with a binder, a suspending agent, an auxiliary agent and the like in the sand moldand the coating in the aluminum lithium alloy sand mold casting process is solved. Meanwhile, the hexachloroethane coating can also generate a refining effect on the melt, deslagging and degassing are carried out, and the surface quality of the aluminum lithium alloy casting can be greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

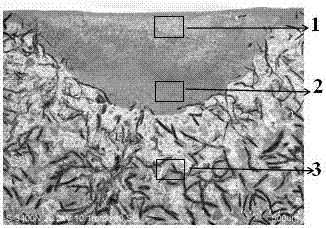

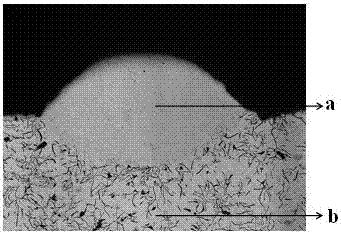

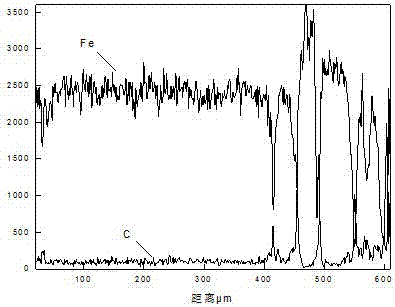

Method for manufacturing defect-free clad layer at surface of cast iron

InactiveCN107043933ANo porosity defectUniform and dense coatingMetallic material coating processesPorosityChemical composition

The invention discloses a method for manufacturing a defect-free clad layer at the surface of cast iron. The method comprises the following steps: after pretreating a cast iron base material, firstly performing surface pretreatment on the surface of the base material by adopting laser remelting; regulating chemical ingredients of the surface of the base material without changing the overall performance of the base material; and subsequently performing laser cladding to make sure that the laser-remelted base material surface and the cladding material are simultaneously molten and are quickly solidified to form the clad layer. The clad layer manufactured by the method disclosed by the invention is free of the defects of air holes and cracks, so the problem about liable occurrence of defects of air holes and cracks caused by high carbon content of a cast iron part in a laser cladding process can be fundamentally solved.

Owner:GUANGXI UNIV +1

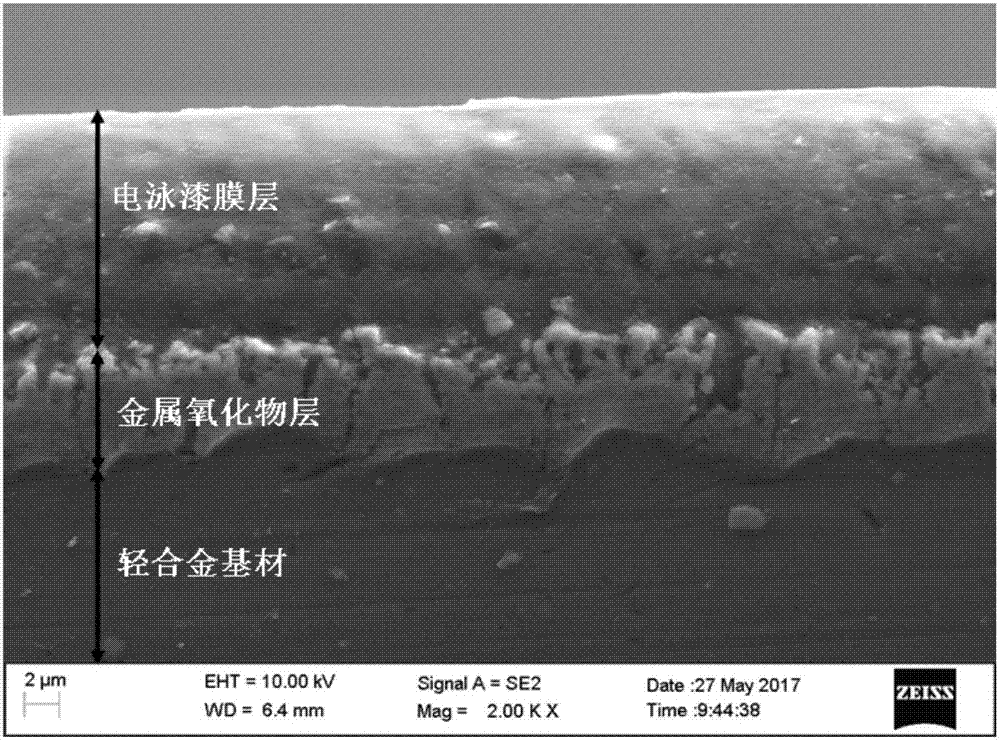

Anti-corrosion and heat-conducting composite coating on light-alloy radiator surface, preparation method of anti-corrosion and heat-conducting composite coating and light alloy radiator

InactiveCN107513746AImprove heat transfer performanceImprove cooling effectAnodisationElectrophoretic coatingsMicro arc oxidationPlasma electrolytic oxidation

The invention discloses an anti-corrosion and heat-conducting composite coating on the light-alloy radiator surface, a preparation method of the anti-corrosion and heat-conducting composite coating and a light alloy radiator with the anti-corrosion and heat-conducting composite coating. The composite coating comprises a metal oxide layer formed by oxidizing light alloy radiator base metal in situ and an electrophoretic paint film layer provided with carbon nano-particles dispersedly distributed and located on the metal oxide layer in a covering manner. The preparation method comprises the steps that (1), micro-arc oxidation is conducted, and the metal oxide layer formed by oxidizing the light alloy radiator base metal in situ is formed on the surface of the light alloy radiator base material; and (2), electrophoretic deposition is conducted, and the layer of electrophoretic paint film is deposed on the surface of the metal oxide layer. The composite coating has the beneficial effects of being uniform, dense, excellent in anticorrosion performance, good in thermal conductivity, ultralong in service life and the like. The preparation method is environmentally-friendly, safe, reliable, good in repeatability, capable of achieving automatic large-batch industrial production with low cost and short processes.

Owner:NANJING UNIV OF TECH

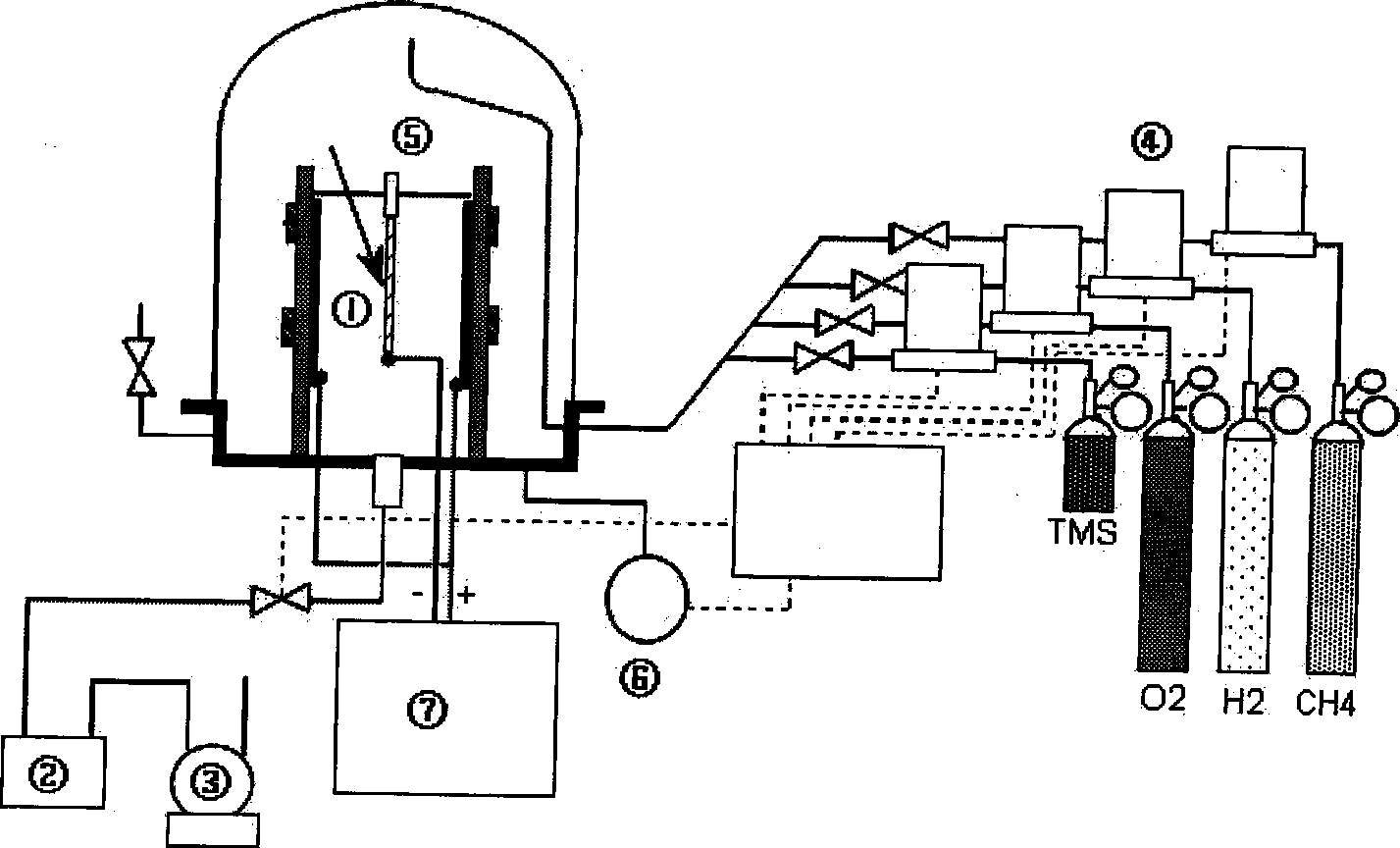

Nano coating combined with micropore surface method for modifying endovascular stent

The invention provides an endovascular stent modification method with the combination of a nanometer coating and a microporous surface, which comprises the steps of: forming micropores on the surface of an implantable medical device, namely an NiTi alloy or 316L stainless steel endovascular stent, preparing a layer of SiOx: H nanometer coating on the surfaces of the micropores, ensuring that the stent can be quickly endothelialized after implanted into a human body and has good blood compatibility and corrosion resistance, and selecting a trimethyl silane (TMS) monomer or mixed gas of the trimethyl silane monomer and oxygen O2 as reaction gas aerated for preparing the nanometer coating, or orderly aerating the TMS, CH4 and O2 gas monomers respectively. The stent modified by the method can be quickly endothelialized after implanted into a pathological change position, and effectively reduce the formation of thrombus; and the biocompatibility (such as corrosion resistance, and the like) of the stent is obviously superior to that of an unmodified stent, so that the incidence rate of ISR is reduced after the sent is implanted through surface modification technology based on stents which have come into the market.

Owner:CHONGQING UNIV

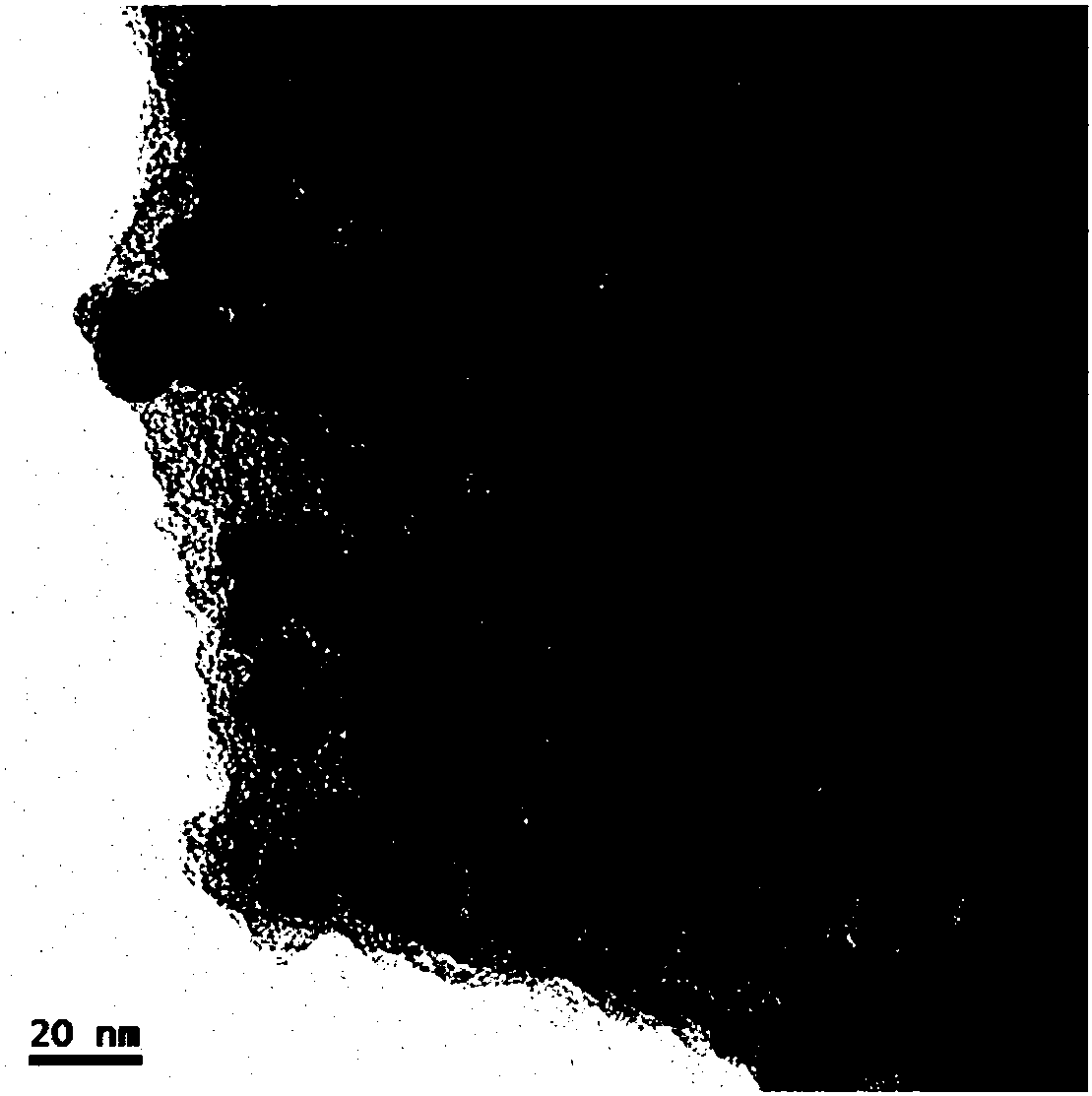

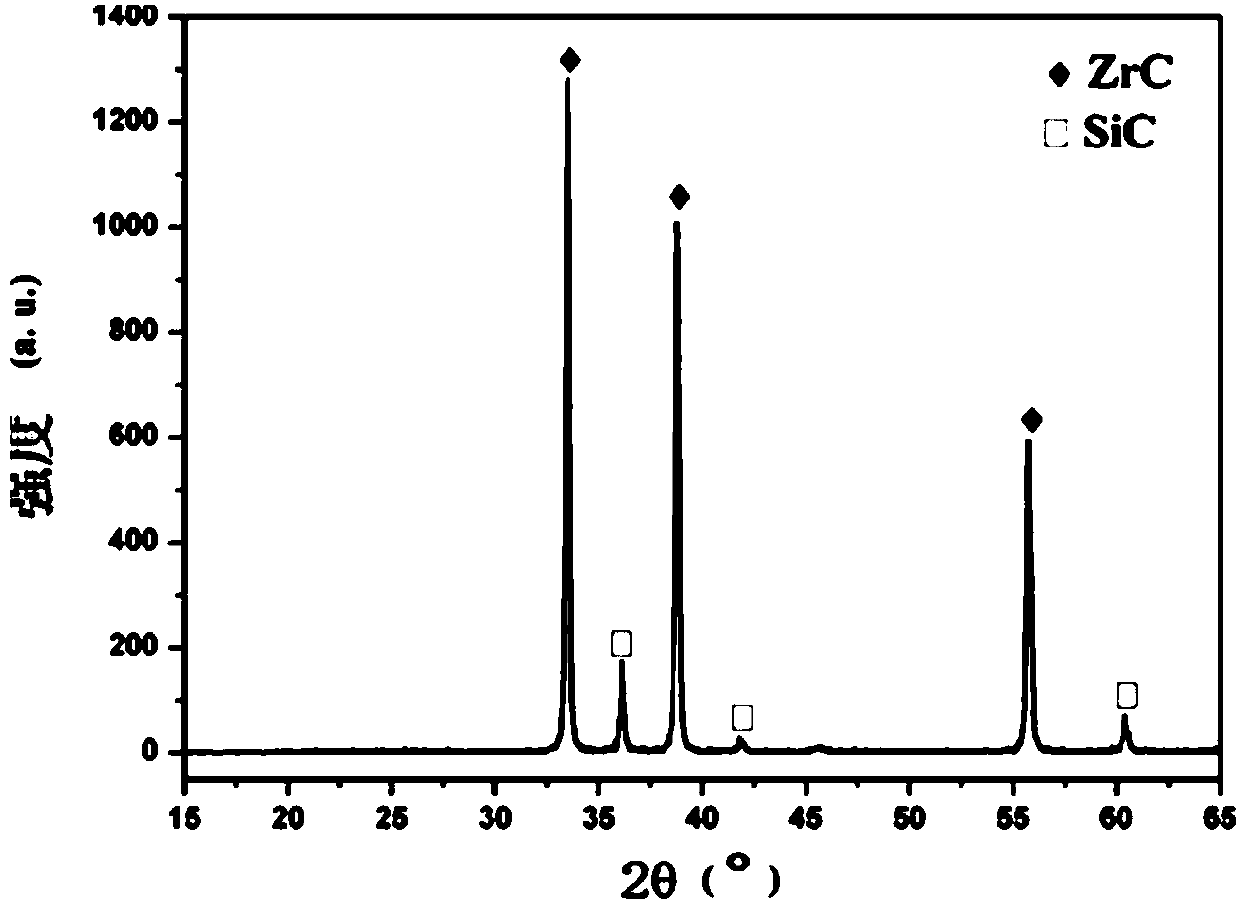

Zirconium carbide-silicon carbide composite powder material and preparation method thereof

The application discloses a zirconium carbide-silicon carbide composite powder material, wherein a molar ratio of components in the zirconium carbide-silicon carbide composite powder material satisfies ZrC:SiC=1:0.1-1:10; a preparation process is easy, the cost is low, and the process is easy to control; and the obtained zirconium carbide-silicon carbide composite powder material has the advantages of submicron level, uniform composition and high purity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +1

Stain-resistant waterborne coating

The invention discloses a stain-resistant waterborne coating which comprises raw materials in parts by weight as follows: 53-60 parts of a polytetrafluoroethylene emulsion, 1-2 parts of molybdenum disulfide, 0.1-0.3 part of cerium tetrafluoride, 1-2 parts of 2, 6- butylated hydroxytoluene, 0.4-1 part of 2-hydroxy-4-n-octoxy-benzophenone, 8-10 parts of silicon whisker, 0.8-2 parts of bisphenol A phosphite, 1-2 parts of alumina powder, 1-2 parts of alkyl phosphate diethanolamine salt, 1-2 parts of alkylolamide, 4-6 parts of maleic anhydride-acrylic copolymer, 5-10 parts of calcium silicate, 4-6 parts of an auxiliary and 10-25 parts of deionized water. The waterproof coating has good stain resistance, the adhesion on a substrate is high, the coating is stable, the drying speed is high, the coating is compact and uniform, the appearance is flat, the applicability is high, and the application range is wide.

Owner:王传福

Modified carbon fiber reinforced phenolic resin-based composite material and preparation thereof

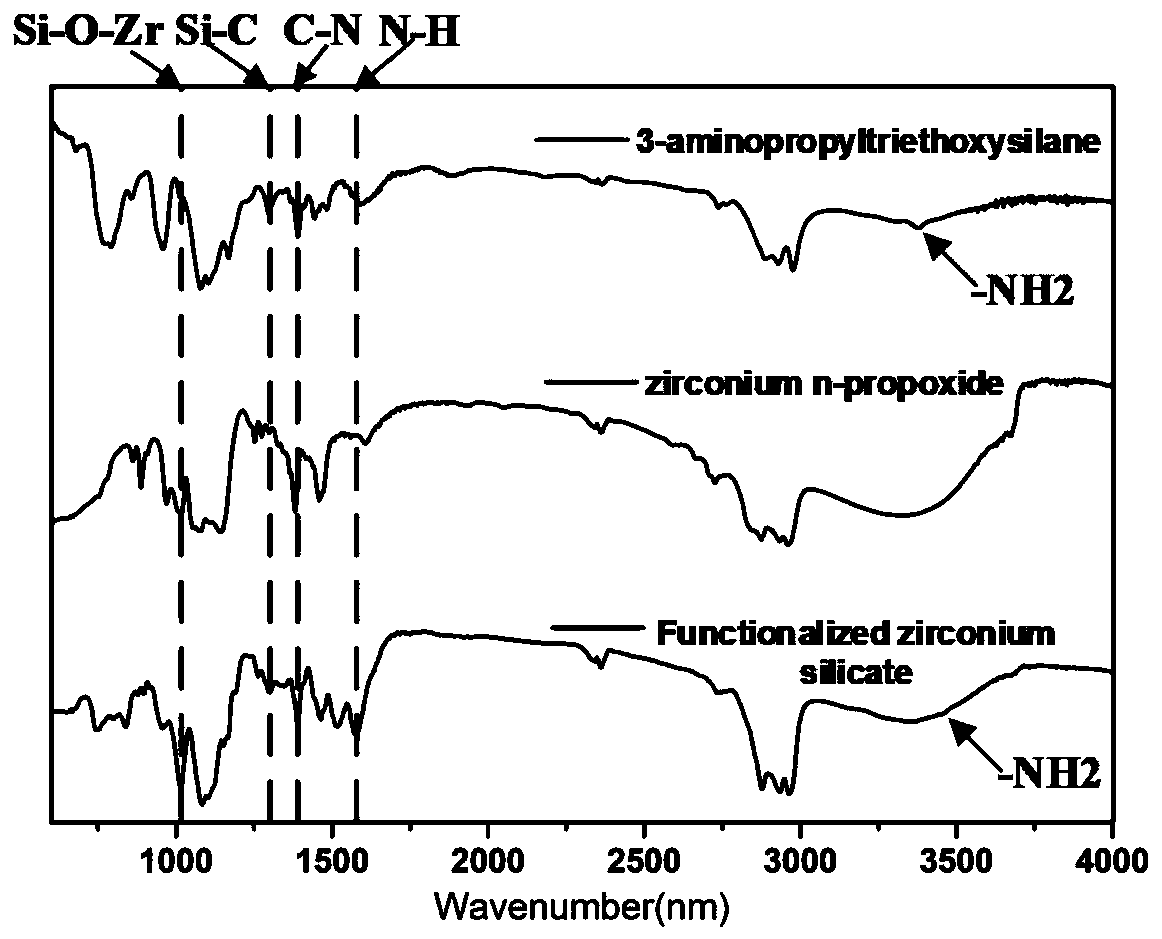

The invention relates to a modified carbon fiber reinforced phenolic resin-based composite material and preparation thereof, and belongs to the technical field of resin-based composite materials. Thepreparation method comprises the following steps of: coating the surface of carbon fiber cloth with an organic-inorganic hybrid zirconium silicate sol coating, dipping the carbon fiber cloth in phenolic resin, and carrying out curing molding to prepare a composite material, wherein due to the existence of the organic-inorganic hybrid zirconium silicate sol, the compatibility between the carbon fiber and the phenolic resin is effectively improved, the interface problem is optimized, the mechanical property of the composite material is improved, and a ceramic layer formed by decomposing the organic-inorganic hybrid zirconium silicate sol in a high-temperature ablation environment can effectively prevent oxygen and heat flow from entering, so that the oxidation ablation resistance of the composite material is improved. The composite material provided by the invention has good interface bonding performance and oxidation ablation resistance, can meet ablation thermal protection requirementsunder high-temperature and high-speed combustion flow service conditions, and has the advantages of the simple preparation method, the low cost and the good application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

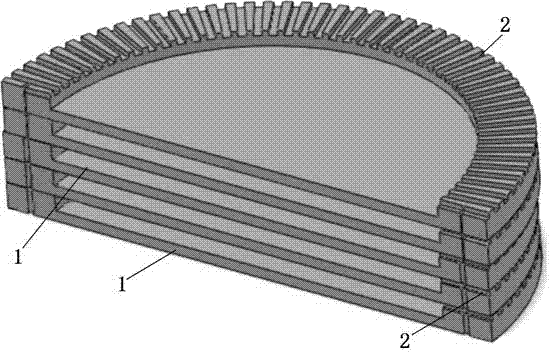

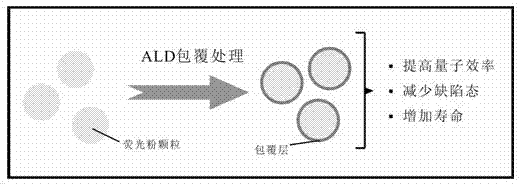

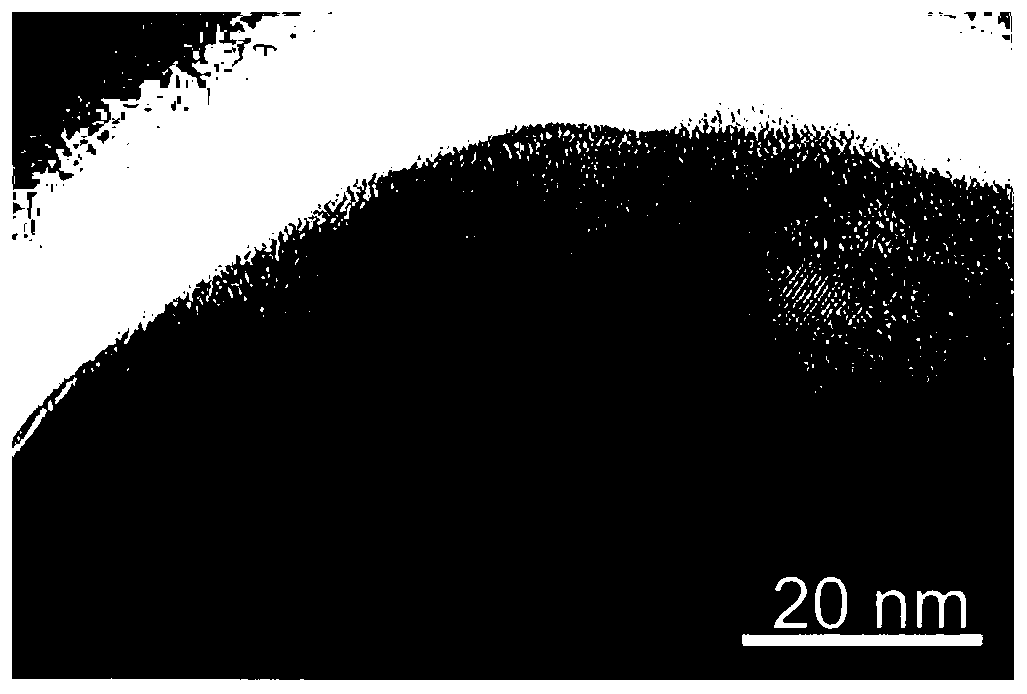

Silicate type fluorescent powder as well as device and process for coating oxide diaphragm film on surface of fluorescent powder

ActiveCN103668119AMeet the requirements for wrappingPrecise thickness controlChemical vapor deposition coatingMaterials scienceChemical engineering

The invention discloses silicate type fluorescent powder as well as a device and process for coating an oxide diaphragm film on the surface of the fluorescent powder. A fluorescent powder special deposition chamber is arranged in the device and has a single-layer or multi-layer structure, wherein each layer of the deposition chamber consists of a fluorescent powder deposition area (1) and air passages (2) bestrewn around the deposition area (1), and the air passages are pipelines for feeding and discharging a precursor and carrier gas for atomic layer deposition. The invention realizes the aim of coating a diaphragm film layer at the periphery of the fluorescent powder by using an atomic layer deposition (ALD) technology to improve the performance of the fluorescent powder. The deposition chamber special for coating the fluorescent powder is invented on the basis of the ALD technology, and the process for atomic layer deposition is further improved to meet requirements for coating the fluorescent powder.

Owner:江苏迈纳德微纳技术有限公司

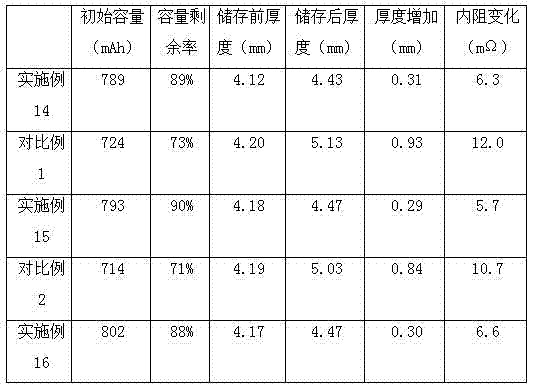

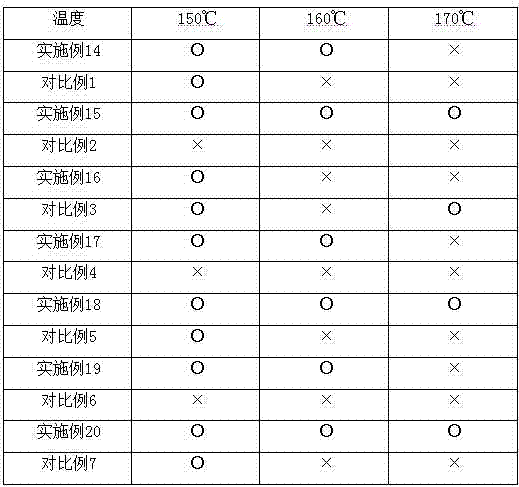

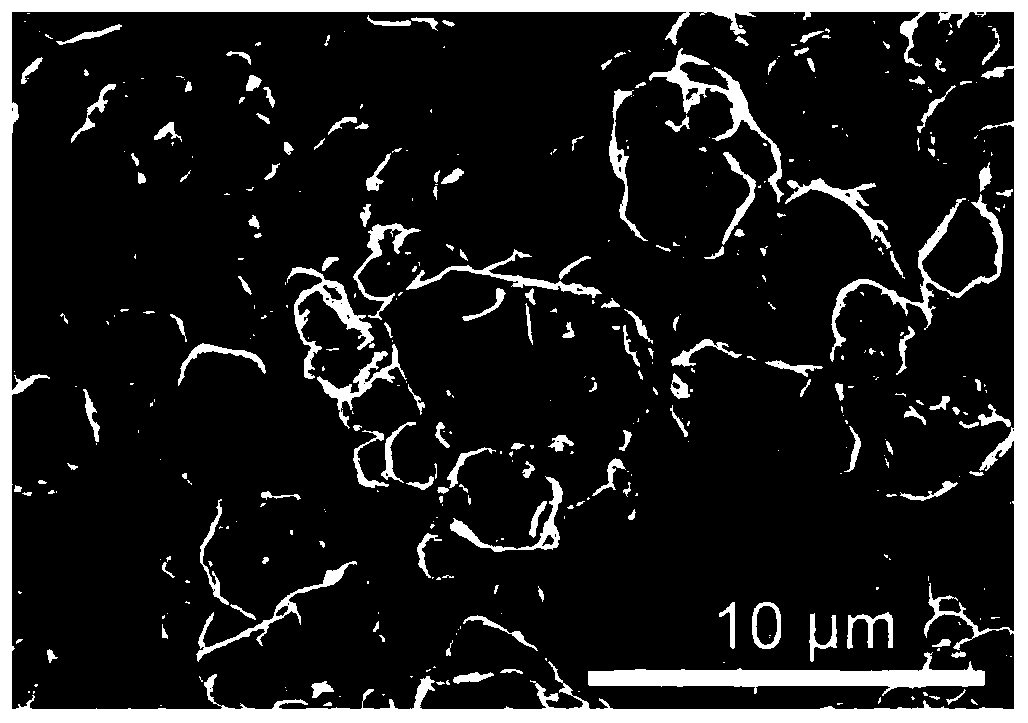

Interface modification method of lithium battery composite single crystal positive electrode material

ActiveCN110247042AImproved magnification performanceImprove cycle stabilityCell electrodesSecondary cellsTube furnacePhotoinitiator

The invention discloses an interface modification method of a lithium battery composite single crystal positive electrode material. The method comprises the following steps: 1) preparing an acrylonitrile monomer solution, adding a photoinitiator into the acrylonitrile monomer solution, atomizing the monomer solution, spraying the atomized monomer solution on the surface of the single crystal positive electrode material, and placing the treated positive electrode material in a mechanical fusion machine for fusion; 2) in a mechanical fusion machine, carrying out the polymerization reaction on the fused material under the irradiation of an ultraviolet lamp, and uniformly coating the surface of the positive electrode material with an ionic liquid monomer; 3) after the polymerization reaction is finished, placing the polymer-coated positive electrode material in a tubular furnace, and carrying out heat treatment at 150-300 DEG C to obtain the composite single crystal positive electrode material with the modified interface. After interface modification, the surface of the single crystal positive electrode is uniformly coated with the polymer, so that the contact area of the battery positive electrode material and the electrolyte can be reduced, side reaction and corrosion are avoided, the cycle life of the single crystal positive electrode material is prolonged, the rate capability of the single crystal positive electrode material is improved, and the single crystal ternary positive electrode material with excellent comprehensive performance for the lithium battery is obtained.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

Mechanical arm metal surface restoration agent and preparation method thereof

InactiveCN106752639ALow self-friction coefficientImprove the lubrication effectDrying oil coatingsAnti-corrosive paintsFuranFiber

The invention provides a mechanical arm metal surface restoration agent and a preparation method thereof. The mechanical arm metal surface restoration agent comprises the following components in parts by mass: 5-8 parts of furan resins, 5-8 parts of alkyd resins, 3-9 parts of nano-silicon sol, 0.5-3 parts of 8-hydroxy-chinolin-sulfate, 4-10 parts of China wood oil, 2-3 parts of nanometer zinc borate, 1-3 parts of brucite fibers, 0-1.5 parts of p-toluenesulfonic acid, 1.5-3 parts of coupling agents, 2-4 parts of methoxypolyethylene glycols and 1-3 parts of polyvinyl acetate emulsion. The mechanical arm metal surface restoration agent is prepared by the steps of heating, stirring, performing ultrasonic treatment, mixing and the like. The prepared mechanical arm metal surface restoration agent is low in self-friction coefficient, high in lubricating property, uniform and dense in coating and high in binding force with the metal surface, has excellent wear resistance, acid and alkali resistance and corrosion resistance, performs coating protection on the metal surface and has a certain self-restoration function on wear, corrosion, scratch and the like produced on the metal surface. The working life of the mechanical arm is greatly prolonged, and the economic benefits are improved.

Owner:安徽臣诺机器人科技有限公司

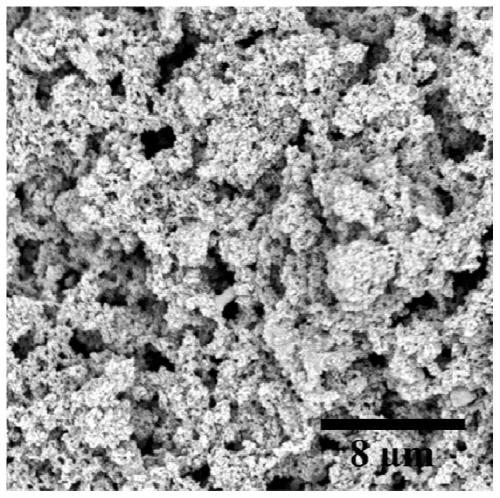

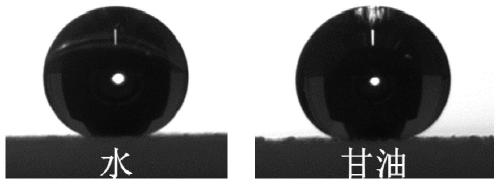

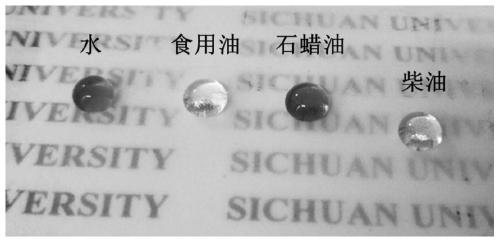

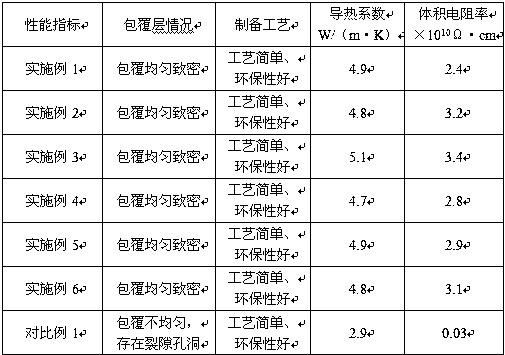

Flame-retardant, antibacterial and transparent super-amphiphobic paint and preparation method and application thereof

ActiveCN110283529ARich in practical application valueRich application valueFireproof paintsAntifouling/underwater paintsIonSolvent

The invention discloses flame-retardant, antibacterial and transparent super-amphiphobic paint and a preparation method and application thereof. The flame-retardant, antibacterial and transparent super-amphiphobic paint is prepared by the following steps: firstly preparing inorganic / organic nanoparticles modified by a nitrogen-containing positive ion silane coupling agent, and dispersing the inorganic / organic nanoparticles along with flame retardant particles and a fluorine-containing silane coupling agent in a solvent and reacting. By a spray-coating, brush-coating or dip-coating method, the paint is applied on the surface of a metallic base material, an inorganic base material or an organic polymer base material. The use amount of the coating obtained is less. It can be effectively ensured that characteristics such as color, texture, pores, air permeability, etc. of the surface of the base material are unchanged, and excellent and stable super-amphiphobic property, flame retardant property and antibacterial property can be obtained. Meanwhile, the preparation is simple, the raw materials are cheap and easily available, and no toxic organic solvent is used. The preparation condition is mild, and the preparation is carried out at normal temperature and in an ordinary state and is environmentally-friendly. The preparation cost is low. Thus, the method is suitable for large-scale production and is good for industrial application and promotion.

Owner:SICHUAN UNIV

Graphene masterbatch for thermally conductive and insulating nylon plastic and preparation method thereof

InactiveCN109181283AExcellent performanceUniform and dense coatingCvd grapheneAluminium isopropoxide

The invention belongs to the technical field of a graphene masterbatch, and provides a graphene masterbatch for thermally conductive and insulating nylon plastic and a preparation method thereof. Themethod comprises the following steps: forming a gel-coated graphene microchip by hydrolysis of aluminium isopropoxide, and then performing steps of atomizing drying, pulverizing and calcining to obtain alumina-coated graphene composite particles, mixing the alumina-coated graphene composite particles with a surfactant, a nylon carrier, and a dispersing agent, and performing extrusion granulation to obtain the graphene masterbatch. Compared with the conventional method, the graphene masterbatch prepared by the invention forms an aluminum oxide coating layer on the graphene microchip, which canavoids the direct contact of the graphene microchip and a silica gel matrix, the graphene masterbatch has excellent thermal insulation effect, and does not use an organic solvent harmful to the environment, the method has a simple preparation process, is environmentally friendly, and is easy to popularize.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Water-based lost-foam casting coating

InactiveCN107952929AEasy to prepareRaw materials are easy to getFoundry mouldsFoundry coresWater basedEconomic benefits

The invention relates to water-based lost-foam casting coating. The water-based lost-foam casting coating consists of the following raw material components in parts by weight: 1.6-2.2 parts of latex powder, 0.2-0.5 part of xanthan gum, 3-4 parts of attapulgite, 0.3-1 part of CMC, 1-1.6 parts of curing starch, 50-60 parts of quartz powder, 80-100 parts of bauxite, and 0.010-0.015 part of a penetrating agent. Compared with the prior art, the water-based lost-foam casting coating has the beneficial effects that: the formula design is reasonable, the preparation process is fine, finished product performances are stable, and the economic benefits and the social value are good.

Owner:山东蒙沃变速器有限公司

Preparation method of surface coating of zirconium alloy cladding and surface coating

ActiveCN109576656AUniform and dense coatingImprove high temperature stabilityOptical rangefindersNuclear energy generationIonZirconium alloy

The invention provides a preparation method of a surface coating of a zirconium alloy cladding, and further provides the surface coating. The preparation method is characterized in that a carbide target material is adopted to form a carbide coating on a zirconium alloy matrix. The preparation method comprises the steps that mechanical grinding and polishing treatment are carried out on the zirconium alloy matrix; the zirconium alloy matrix is placed in a solution composed of acetone and deionized water to be subjected to ultrasonic cleaning; the zirconium alloy matrix is subjected to low-temperature drying treatment; the carbide target material is subjected to sputtering sintering through a radio frequency magnetron sputtering method, sputtering power is 1200 W or below, the bias range is0 V to 1000 V, and a carbide coating is formed; the zirconium alloy matrix on which the carbide coating is formed is taken out of a magnetron sputtering instrument, and thermal treatment is carried out under an argon environment for 1 h to 3 h at the temperature of 500 DEG C to 700 DEG C; and the zirconium alloy cladding on which the carbide coating is formed is subjected to inspection. Accordingto the preparation method of the surface coating of the zirconium alloy cladding, corrosion resistance and oxidization resistance of the zirconium alloy cladding can be improved.

Owner:STATE POWER INVESTMENT CORP RES INST

Chemical immersion tin plating solution and preparation method thereof

InactiveCN109055921AUniform and dense coatingGood solderability of the coatingLiquid/solution decomposition chemical coatingEnvironmental chemistryCompound (substance)

The invention relates to a chemical immersion tin plating solution and a preparation method thereof. The chemical immersion tin plating solution is composed of tin salt, an accelerant, a wetting agentand a stabilizer, wherein the mass concentration of the tin salt is 5-20 g / L, the mass concentration of the accelerant is 30-200 g / L, the mass concentration of the wetting agent is 0.1-0.5 g / L, the mass concentration of the stabilizer is 50-170 g / L. Under reasonable concentration proportioning and the synergistic effect of all the components, the chemical immersion tin plating solution is very stable, the plating layer is uniform, compact and semi-bright, moreover, the used working temperature is not high, the temperature is 35-45 DEG C, plating is carried out for 10-15 minutes, the thicknessof the plating layer can reach about 1.5-2 microns, and the plating layer is good in weldability.

Owner:CHONGQING LIDAO SURFACE TECH

EVA (Ethylene Vinyl Acetate) master batch as well as preparation method and application thereof

InactiveCN106674710ALuminous intensity is not affectedReduce exposureCompound organicSURFACTANT BLEND

The invention in particular discloses an EVA (Ethylene Vinyl Acetate) master batch. The EVA master batch is prepared from the following raw materials in percentage by mass: 40 percent to 50 percent of EVA, 30 percent to 40 percent of luminous powder, 1.0 percent to 1.5 percent of kaolin, 2.0 percent to 3.0 percent of a dispersant, 2.5 percent to 4.0 percent of an anti-ageing agent and 10 percent to 12 percent of a compound organic coating agent, wherein the luminous powder is alkaline earth aluminate system long afterglow luminous powder, and the grain size is 12mu m to 20mu m. According to the EVA master batch, a maleic anhydride organic ligand is introduced to the surface of the luminous powder, and the luminous powder more uniformly and densely coats the surface of the luminous powder by utilizing a gemini surfactant, so that contact between the luminous powder and external moisture or metal is reduced, and a product does not turn black; meanwhile, the combination firmness of the luminous powder and the organic ligand is improved, the hydrolyzing resistance of the product and the compatibility between the product and the EVA are greatly improved, and the influences on luminous performance of the luminous powder are very small.

Owner:JINJIANG XINBANG NEW MATERIAL TECH

Sized and coated photo-thermal phase change composite yarn and preparation method thereof

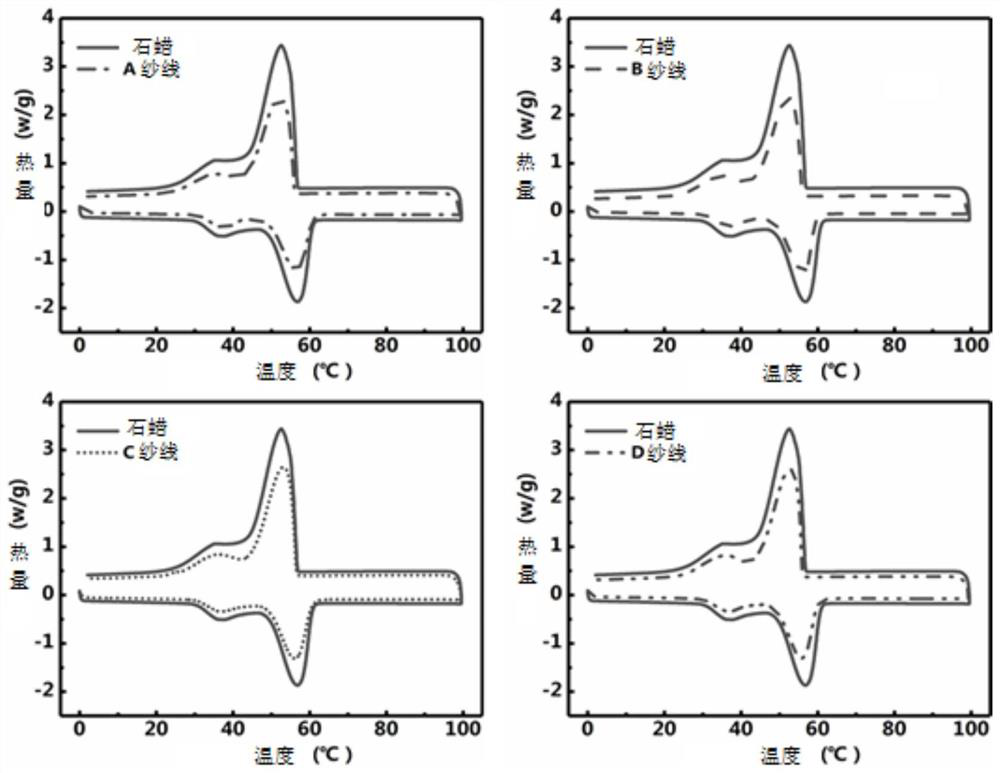

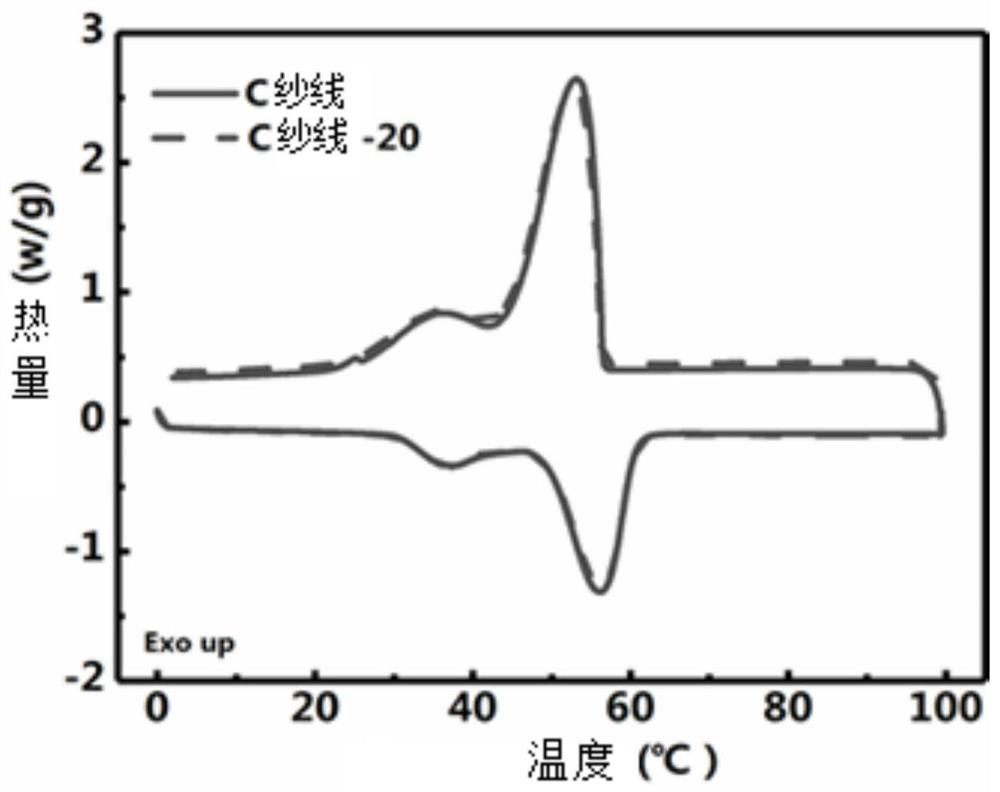

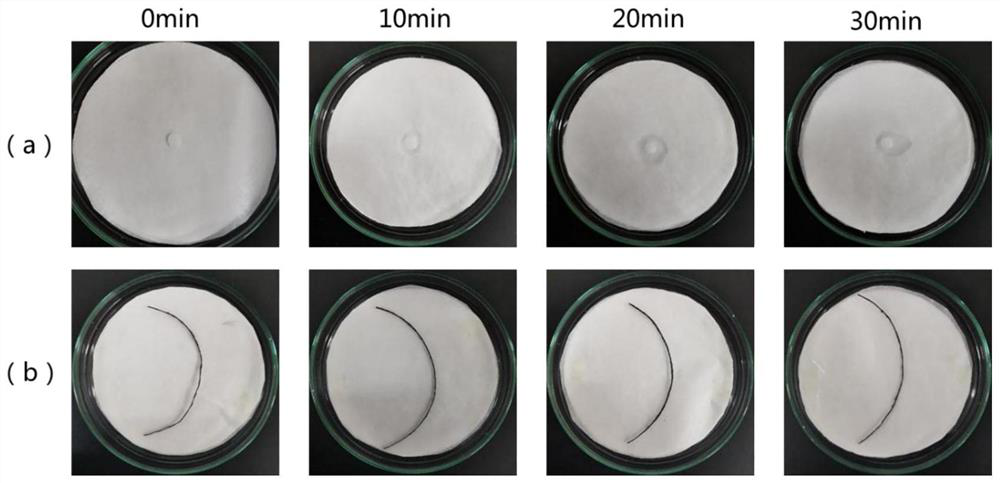

ActiveCN113529421AWith light-to-heat conversion functionHigh photothermal conversion efficiencyFibre typesYarnPolyvinyl alcohol

The invention relates to sized and coated photo-thermal phase change composite yarn and a preparation method thereof. The method comprises the following steps of 1, preparing a polyvinyl butyral / zirconium carbide / aluminum oxide suspension and a polyvinyl butyral solution; 2, preparing a molten paraffin material; and 3, by taking a polyvinyl butyral / zirconium carbide / aluminum oxide coating as a surface layer, paraffin as a middle layer and terylene / polyvinyl butyral / zirconium carbide / aluminum oxide composite yarn or pure terylene yarn as core yarn, preparing terylene / polyvinyl butyral / zirconium carbide / aluminum oxide / paraffin composite yarn through a coating method. The method has the advantages that 1, the photo-thermal conversion function is achieved, and the photo-thermal conversion efficiency is relatively high; 2, the phase change function is achieved, and the heat storage and temperature adjustment can be achieved; 3, the preparation method is simple, economic and rapid; and 4, the service life is long, and the shape stability is better.

Owner:WUHAN TEXTILE UNIV

Preparation method of oil pipeline nano-composite coating

The invention relates to a method for preparing metal matrix nano-composite materials through dual-pulse electro-deposition technology, particularly to a preparation method of an oil pipeline metal matrix Ni-W-P-SiC / CeO2-TiO2 nano-composite coating. The metal matrix Ni-W-P-SiC / CeO2-TiO2 nano-composite coating prepared through the method is uniform and flat in surface and high in hardness, corrosion resistance and wearing resistance. The preparation method of the oil pipeline metal matrix Ni-W-P-SiC / CeO2-TiO2 nano-composite coating is simple and easy to control, has the advantages of being lowin environmental pollution, low in production and maintenance costs and the like and can achieve industrial large-scale production.

Owner:昆山钴瓷金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com