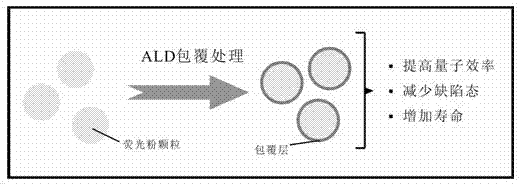

Silicate type fluorescent powder as well as device and process for coating oxide diaphragm film on surface of fluorescent powder

A surface coating and fluorescent powder technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of high consumption of pure water, uneven coating layer, and high temperature control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

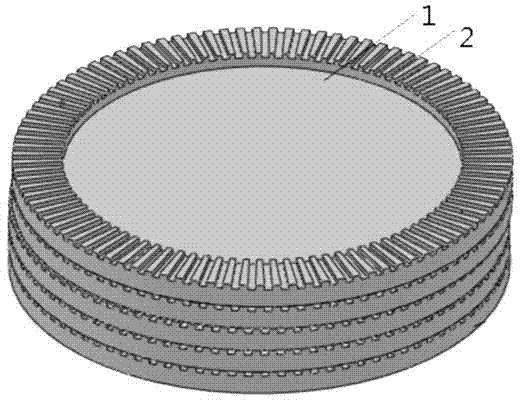

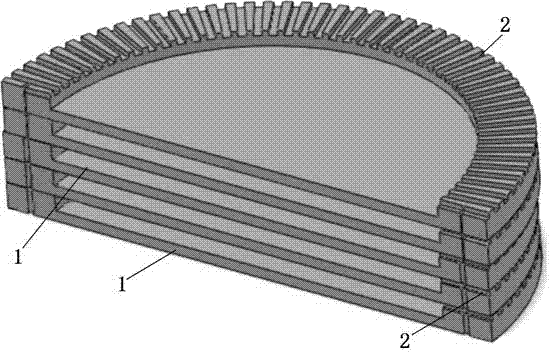

Image

Examples

Embodiment 1

[0040] Select purchased Intermex orange phosphor powder 05446 5g as a sample, undeposited sample, denoted as 0#, deposit in a 4-inch model atomic layer deposition equipment, select a layer of phosphor deposition chamber, and deposit aluminum oxide on the phosphor surface Separator film 30nm.

[0041] Put 5 g of phosphor powder 05446 into the above-mentioned phosphor deposition chamber, then put the phosphor deposition chamber into the cavity, and proceed to the next step;

[0042] Turn on the carrier gas and pulse gas of the atomic layer deposition equipment, and set parameters: the chamber substrate temperature is set to 150°C, the chamber wall temperature is set to 180°C, the pulse actuator valve temperature is set to 160°C, and the precursor trimethylaluminum container The temperature is room temperature, the temperature of the precursor water container is set to 50°C, and the temperature of other pipelines is 150°C. The deposition process selects the precursor exposure mo...

Embodiment 2

[0046] Select purchased Intermex orange phosphor powder 05446 5g as a sample, undeposited sample, denoted as 0#, deposit in a 4-inch model atomic layer deposition equipment, select a layer of phosphor deposition chamber, and deposit aluminum oxide on the phosphor surface Separator film 50nm.

[0047] Put 5 g of phosphor powder 05446 into the above-mentioned phosphor deposition chamber, then put the phosphor deposition chamber into the cavity, and proceed to the next step;

[0048] Turn on the carrier gas and pulse gas of the atomic layer deposition equipment, and set parameters: the chamber substrate temperature is set to 150°C, the chamber wall temperature is set to 180°C, the pulse actuator valve temperature is set to 160°C, and the precursor trimethylaluminum container The temperature is room temperature, the temperature of the precursor water container is set to 50°C, and the temperature of other pipelines is 150°C. The deposition process selects the precursor exposure mo...

Embodiment 3

[0052] Select the purchased Intermex orange phosphor powder 055445g as the sample, the undeposited sample is denoted as 3#, deposit it in a 4-inch model atomic layer deposition equipment, select a layer of phosphor deposition chamber, and deposit aluminum oxide diaphragm on the phosphor surface Thin film 30nm.

[0053] Put 5 g of phosphor powder 05544 into the above-mentioned phosphor deposition chamber, then put the phosphor deposition chamber into the cavity, and proceed to the next step;

[0054] Turn on the carrier gas and pulse gas of the atomic layer deposition equipment, and set parameters: the chamber substrate temperature is set to 150°C, the chamber wall temperature is set to 180°C, the pulse actuator valve temperature is set to 160°C, and the precursor trimethylaluminum container The temperature is room temperature, the temperature of the precursor water container is set to 50°C, and the temperature of other pipelines is 150°C. The deposition process selects the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com