Rapid pre-treatment method for copper electroplating on aluminum substrate

A technology for electroplating copper and aluminum substrates, applied in the field of printed circuit boards, can solve the problems of poor adhesion and adhesion of coatings, poor corrosion resistance, and pollute the environment, and achieve the advantages of improving the adhesion of coatings, improving surface roughness, and simplifying the process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

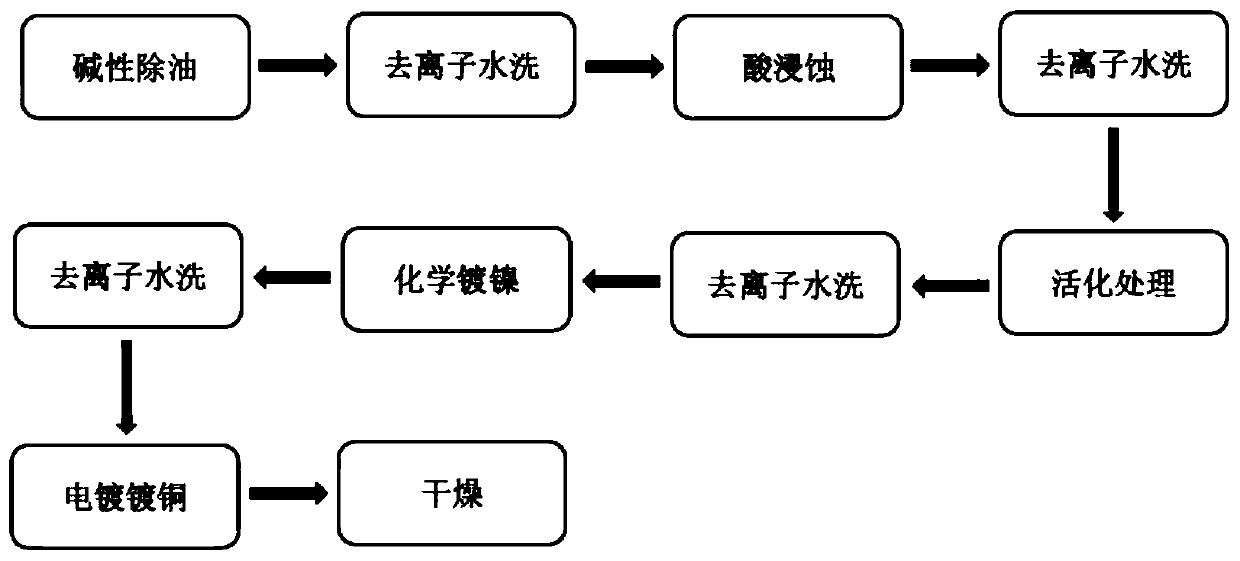

Method used

Image

Examples

Embodiment 1

[0036] Cut a certain area of the aluminum substrate and perform copper plating on the aluminum substrate according to the following steps:

[0037] 1. Alkaline degreasing liquid components: 10g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, 10g / L sodium phosphate

[0038] 2. Preparation of acid etching solution: Measure 10ml of hydrochloric acid, add it to 90ml of deionized water, and stir evenly to obtain an acid etching solution.

[0039] 3. The components of the activation solution: 50mg / L palladium chloride, 1ml / L concentrated hydrochloric acid, 10mg / L ammonium chloride

[0040] 4. Components of copper plating solution: 100g / L copper sulfate, 30ml / L sulfuric acid, 10mg / L OP-10

[0041] 5. Plating:

[0042] (1) Cut a certain area of the aluminum substrate and put it into an alkaline degreasing solution for alkaline degreasing for 5 minutes at a temperature of 70°C, and then fully wash it with deionized water;

[0043] (2) Put the degreased substrat...

Embodiment 2

[0049] Cut a certain area of the aluminum substrate and perform copper plating on the aluminum substrate according to the following steps:

[0050] 1. Alkaline degreasing liquid components: 20g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, 10g / L sodium phosphate

[0051] 2. Preparation of acid etching solution: Measure 30ml of hydrochloric acid, add it to 70ml of deionized water, and stir evenly to obtain acid etching solution.

[0052] 3. The components of the activation solution: 40mg / L palladium chloride, 1ml / L concentrated hydrochloric acid, 10mg / L ammonium chloride

[0053] 4. Components of copper plating solution: 160g / L copper sulfate, 50ml / L sulfuric acid, 10mg / L polyethylene glycol

[0054] 5. Plating:

[0055] (1) Cut a certain area of the aluminum substrate and put it into an alkaline degreasing solution for alkaline degreasing for 3 minutes at a temperature of 60°C, and then fully wash it with deionized water;

[0056] (2) Put the degreased...

Embodiment 3

[0062] Cut a certain area of the aluminum substrate and perform copper plating on the aluminum substrate according to the following steps:

[0063] 1. Alkaline degreasing liquid components: 30g / L sodium hydroxide, 20g / L sodium carbonate, 5g / L sodium silicate, 10g / L sodium phosphate

[0064] 2. Preparation of acid etching solution: Measure 50ml of hydrochloric acid, add it into 50ml of deionized water, and stir evenly to obtain acid etching solution.

[0065] 3. The components of the activation solution: 50mg / L palladium chloride, 1ml / L concentrated hydrochloric acid, 30mg / L ammonium chloride

[0066] 4. Components of copper plating solution: 150g / L copper sulfate, 50ml / L sulfuric acid, 10mg / L polyethylene glycol

[0067] 5. Plating:

[0068] (1) Cut a certain area of the aluminum substrate and put it into the alkaline degreasing solution for alkaline degreasing for 1min at a temperature of 60°C, and then fully wash it with deionized water;

[0069] (2) Put the degreased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com