Interface modification method of lithium battery composite single crystal positive electrode material

A positive electrode material, lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of secondary particle structure damage, uneven distribution of polymer modified materials, poor consistency, etc., and achieve cycle stability improvement , improve cycle stability, and improve the effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

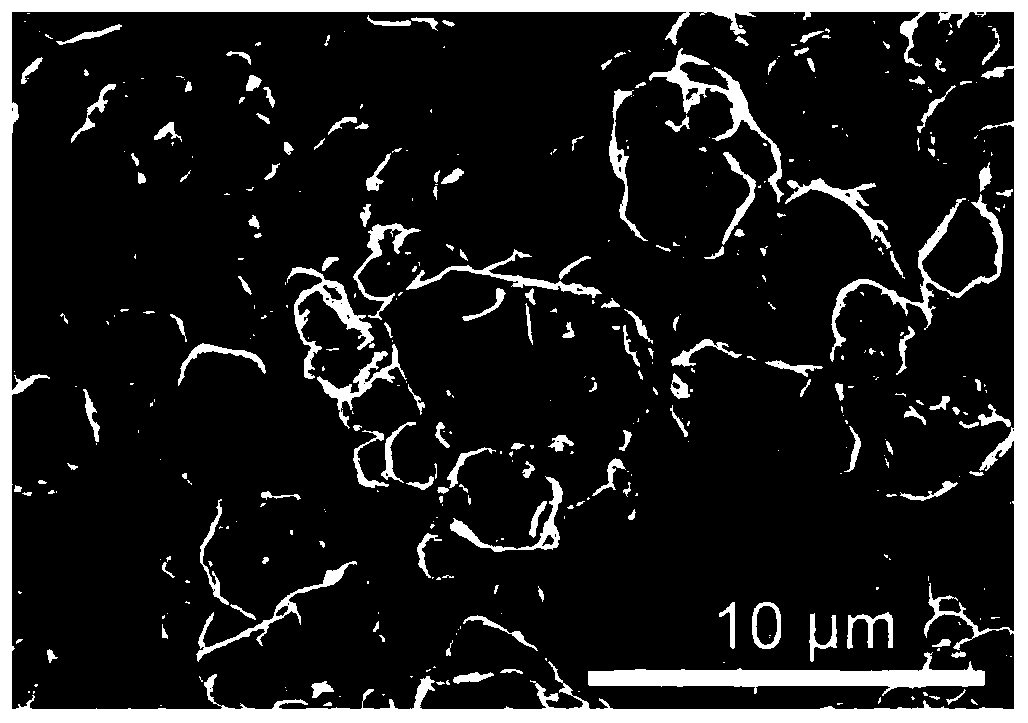

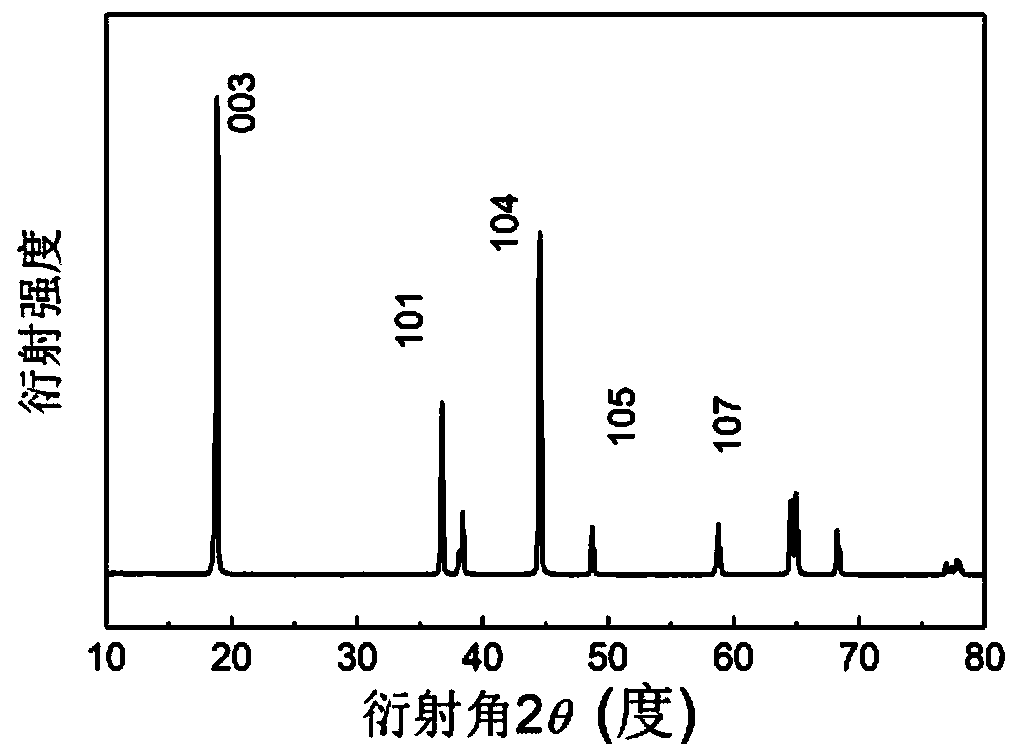

Embodiment 1

[0048] Dissolve 3.12g of acrylonitrile in N,N-dimethylformamide to prepare a 1mol / L monomer solution, add 10mg of diphenyl ethyl ketone to it, stir well, and atomize the monomer solution through compression Pump atomization, the diameter of the atomized small droplets is about 100μm, sprayed on the surface of 31.45g single crystal positive electrode material, then place the treated positive electrode material in a mechanical fusion machine, and run it at 1500rpm for 0.5h to fully fuse; The single crystal cathode material is LiNi 0.8 co 0.1 mn 0.1 ;

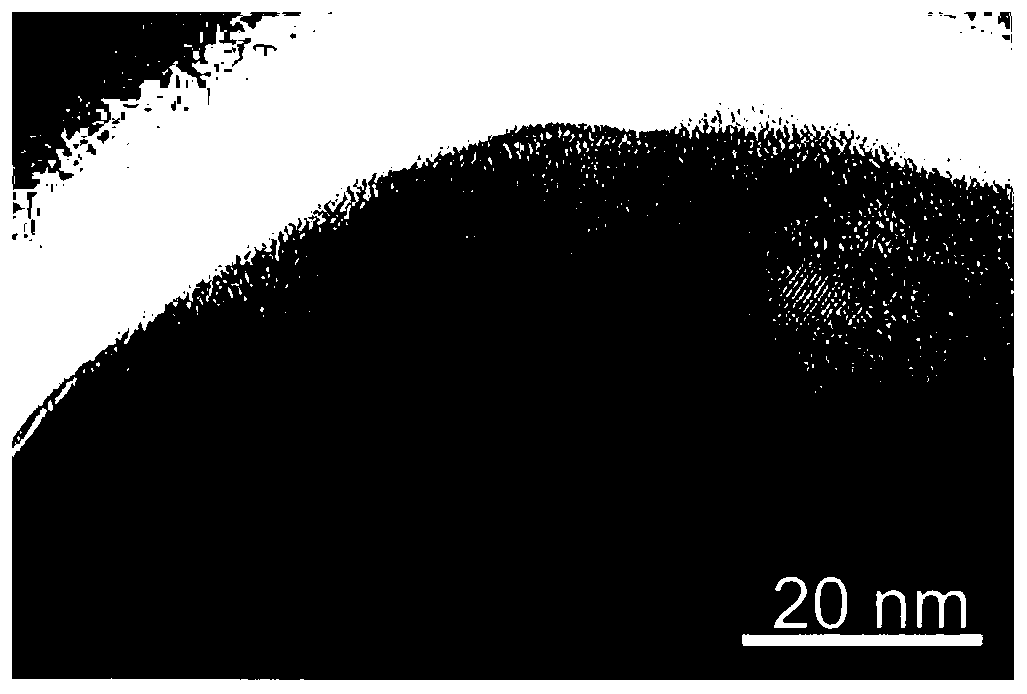

[0049] 2) In the mechanical fusion machine, the fused material is polymerized under the irradiation of a power-adjustable ultraviolet high-pressure mercury lamp, and the ionic liquid monomer is uniformly coated on the surface of the positive electrode material, wherein the wavelength of the ultraviolet lamp is 300- 369nm, light time is 3h, light intensity is 2.55mW / cm 2 ;

[0050] 3) After the polymerization reaction, the pol...

Embodiment 2

[0052] Prepare the interface-modified composite single crystal positive electrode material according to the same method as in Example 1, the difference is that the amount of acrylonitrile is changed to 2.10g

Embodiment 3

[0054] The interface-modified composite single-crystal cathode material was prepared in the same manner as in Example 1, except that the amount of acrylonitrile was changed to 1.35 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com