Zirconium carbide-silicon carbide composite powder material and preparation method thereof

A composite powder and silicon carbide technology, which is applied in the field of zirconium carbide-silicon carbide composite powder materials and its preparation, can solve the problems of restricting large-scale industrial application, complex raw material components, and long aging time, and achieve the goal of improving carbon heat. The effect of reduction reaction rate, wide range of raw material sources and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

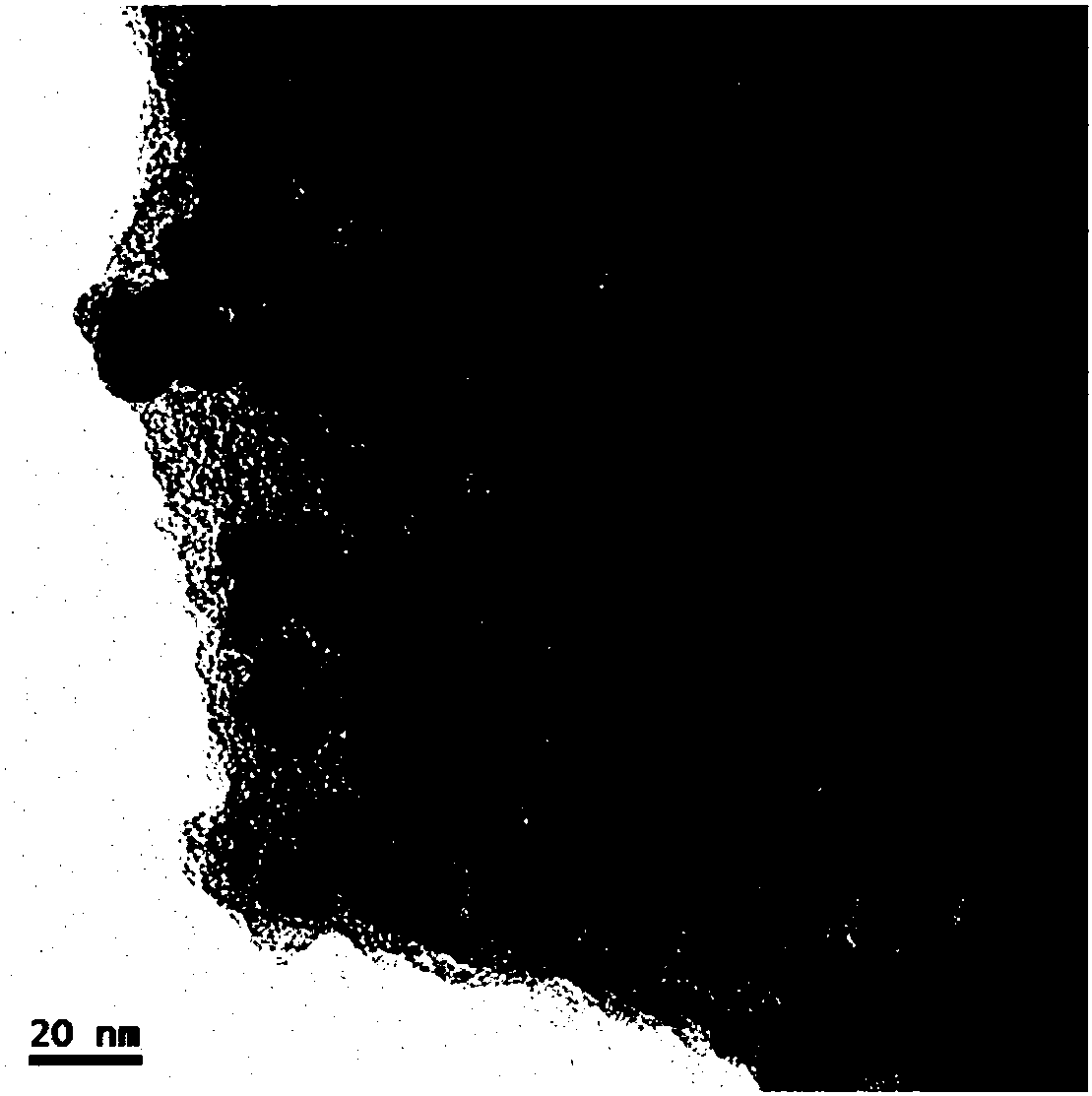

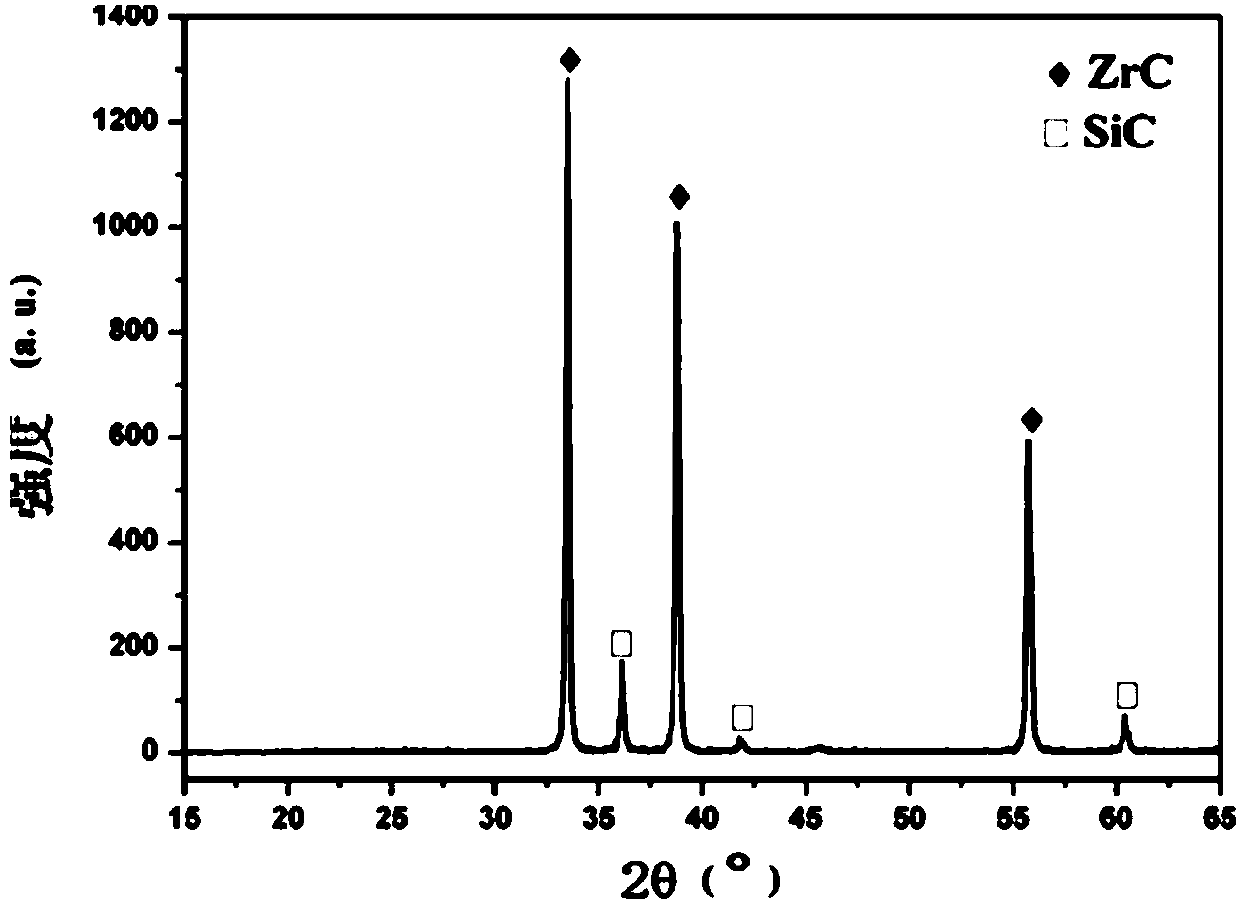

[0053] Example 1 Preparation of zirconium carbide-silicon carbide composite powder material 1#

[0054] Zirconium oxychloride (ZrOCl 2 ·8H 2 O), tetraethyl orthosilicate (TEOS), and glucose were added to 100ml of deionized water respectively, stirred and dissolved to make them evenly mixed; wherein the molar ratio of Zr:Si element was 1:1; (Zr+Si):(C) element ratio It is 1:2.5; the total molar concentration of (Zr+Si) elements in the solution is 0.2mol / L. Put the above solution in a reactor and carry out hydrothermal reaction treatment, the reaction temperature is 220°C, and the reaction time is 24 hours; the hydrothermal product is washed with deionized water until the pH value is neutral, and vacuum dried at 80°C for 12 hours to obtain coordination polymerization A homogeneous hydrothermal precursor that is solidified and has a certain degree of carbonization of carbohydrates; the resulting precursor is calcined at 900°C in a nitrogen atmosphere for 2 hours to obtain a pyr...

Embodiment 2

[0055] Example 2 Preparation of zirconium carbide-silicon carbide composite powder material 2#

[0056] Zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O), tetraethyl orthosilicate (TEOS), and sucrose were added to 100ml of deionized water, stirred and dissolved to make them evenly mixed; wherein, the molar ratio of Zr:Si element was 1:2; (Zr+Si):(C) element The ratio is 1:3.5; the total molar concentration of (Zr+Si) elements in the solution is 0.5mol / L. Put the above solution in a reactor, and carry out hydrothermal reaction treatment, the reaction temperature is 200°C, and the reaction time is 36 hours; the hydrothermal product is washed with deionized water until the pH value is neutral, and vacuum-dried at 100°C for 10 hours to obtain the complex A homogeneous hydrothermal precursor that is polymerized and solidified and has a certain degree of carbohydrate carbonization; the obtained precursor is calcined at 900°C in a nitrogen atmosphere for 2 hours to obtain a pyrolysis precur...

Embodiment 3

[0057] Example 3 Preparation of zirconium carbide-silicon carbide composite powder material 3#

[0058] Zirconium sulfate (Zr(SO 4 ) 2 4H 2 O), tetraethyl orthosilicate (TEOS), and soluble starch were respectively added to 100ml of deionized water, stirred and dissolved to make them evenly mixed, wherein the molar ratio of Zr:Si element was 2:1; (Zr+Si):(C) element The ratio is 1:4.5; the total molar concentration of (Zr+Si) elements in the solution is 0.8mol / L. Put the above solution in a reactor and carry out hydrothermal reaction treatment, the reaction temperature is 180°C, and the reaction time is 48 hours; the hydrothermal product is washed with deionized water until the pH value is neutral, and freeze-dried for 8 hours to obtain coordination polymerization solidification And a homogeneous hydrothermal precursor with a certain degree of carbonization of carbohydrates; the obtained precursor is calcined at 900 ° C in a nitrogen atmosphere for 2 hours to obtain a pyroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com