Anti-corrosion and heat-conducting composite coating on light-alloy radiator surface, preparation method of anti-corrosion and heat-conducting composite coating and light alloy radiator

A heat-conducting composite, radiator technology, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of complex shape and size of radiator, waste water and waste gas discharge, difficult coating uniform coating, etc., to achieve anti-corrosion Excellent performance, good thermal conductivity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

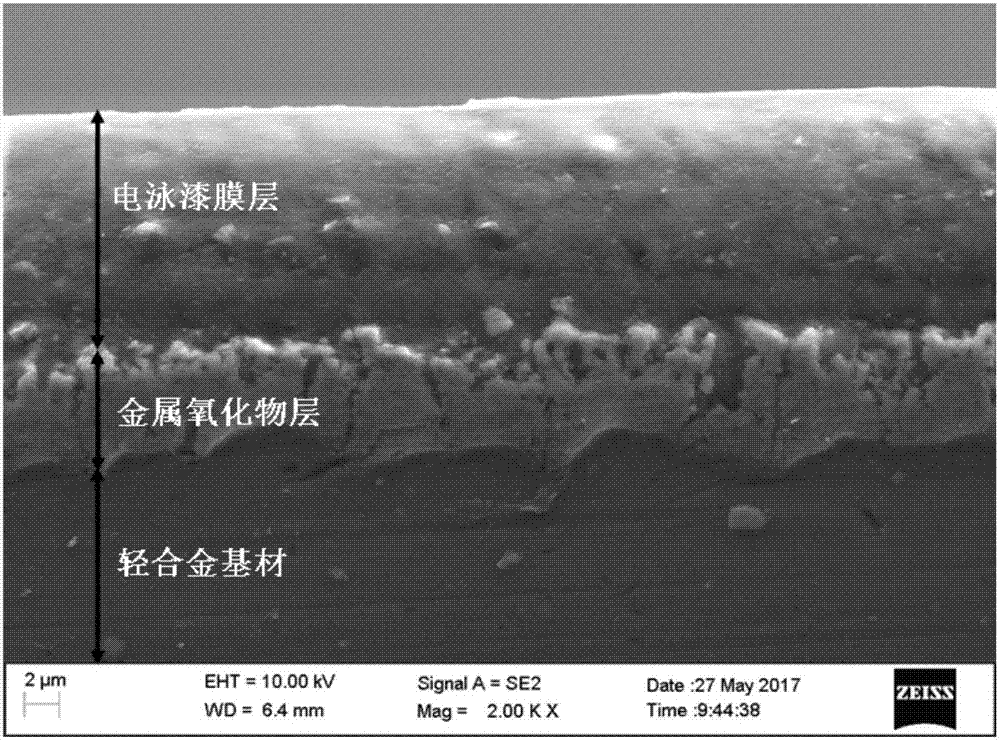

[0025] This embodiment is to prepare an anti-corrosion and heat-conducting composite coating on a 6061 aluminum alloy radiator base material, comprising the following steps:

[0026] Step 1: The 6061 aluminum alloy radiator base material to be processed is clamped by a tooling fixture, and then placed in an oxidation tank in a micro-arc oxidation (plasma electrolytic oxidation) system, and used as an anode, and the electrolyte in the oxidation tank is Sodium silicate 10g / L, sodium hexametaphosphate 30g / L, the balance is a solution of deionized water or distilled water, with 316L stainless steel as the cathode, turn on the pulse power supply, carry out micro-arc oxidation, and set the average current in cross flow during the oxidation process Density 5A / dm 2 Or constant voltage setting output voltage value is 500V, frequency 1000Hz, pulse width 160μs, oxidation time 5min; form a layer of metal oxide layer in situ oxidation of various metal elements on the surface of 6061 alumin...

Embodiment 2

[0033] This embodiment is to prepare anti-corrosion and heat-conducting composite coating on 6063 aluminum alloy radiator base material, comprises the following steps:

[0034] Step 1: The 6063 aluminum alloy radiator substrate to be processed is clamped by a tooling fixture, and then placed in an oxidation tank in a micro-arc oxidation (plasma electrolytic oxidation) system, and used as an anode, and the electrolyte in the oxidation tank is Sodium silicate 5g / L, sodium hexametaphosphate 40g / L, the balance is a solution of deionized water or distilled water, 316L stainless steel is used as the cathode, the pulse power is connected, and the micro-arc oxidation is carried out, and the average current is set in cross flow during the oxidation process Density 3A / dm 2 Or constant voltage setting output voltage value is 540V, frequency 1500Hz, pulse width 120μs, oxidation time 15min; form a layer of metal oxide layer in situ oxidation of various metal elements on the surface of 6063...

Embodiment 3

[0041] This embodiment is to prepare anti-corrosion and heat-conducting composite coating on TC4 titanium alloy radiator base material, comprises the following steps:

[0042] Step 1: The TC4 titanium alloy radiator base material to be processed is clamped by a fixture, and then placed in an oxidation tank in a micro-arc oxidation (plasma electrolytic oxidation) system, and used as an anode, and the electrolyte in the oxidation tank is Sodium silicate 5g / L, sodium hexametaphosphate 40g / L, potassium fluoride 5g / L, the balance is a solution of deionized water or distilled water, with 316L stainless steel as the cathode, connected to the pulse power supply, micro-arc oxidation, oxidation Process cross flow setting average current density 4.8A / dm 2 Or constant voltage setting output voltage value is 480V, frequency 800Hz, pulse width 100μs, oxidation time 30min; form a layer of metal oxide layer in-situ oxidized by various metal elements on the surface of TC4 titanium alloy radiat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com