Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Adjust the coefficient of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

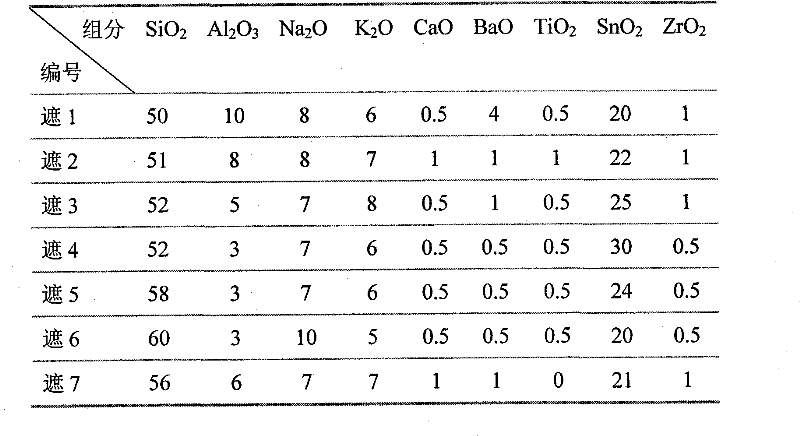

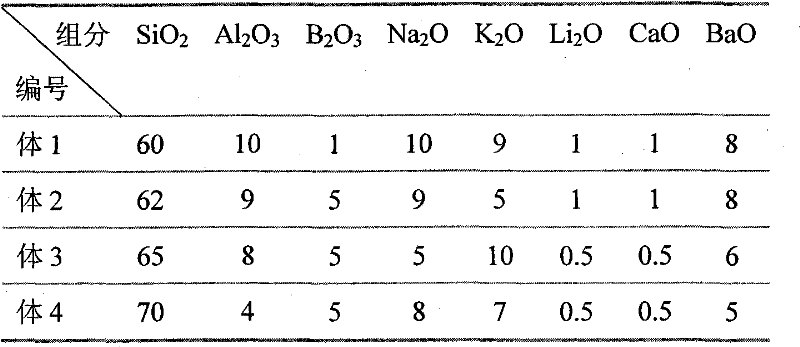

Complete set of titanium ceramic powder for dental department and preparation method thereof

InactiveCN101664368AFusion temperature decreasedAdjust the coefficient of thermal expansionImpression capsDentistry preparationsThermal dilatationTitanium

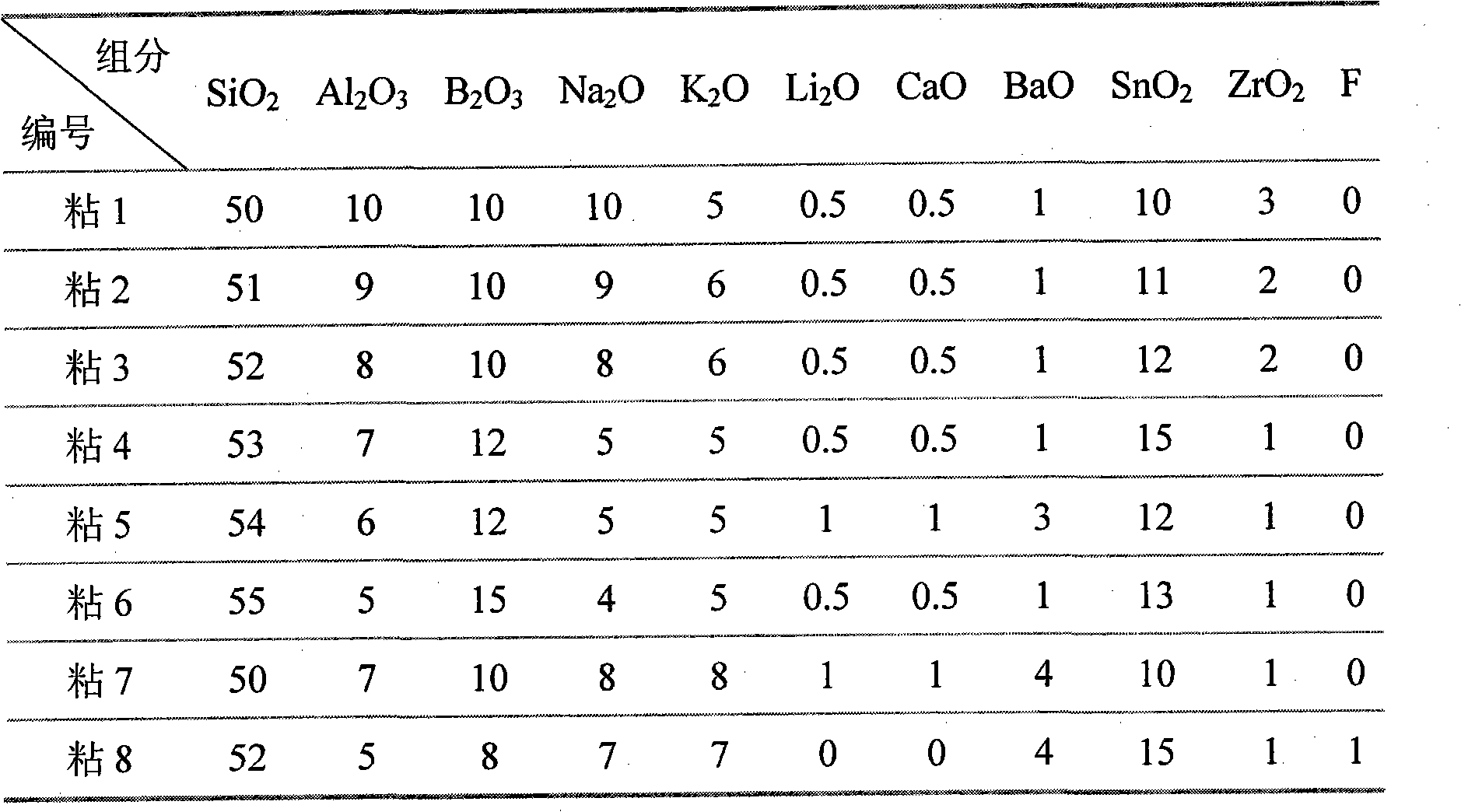

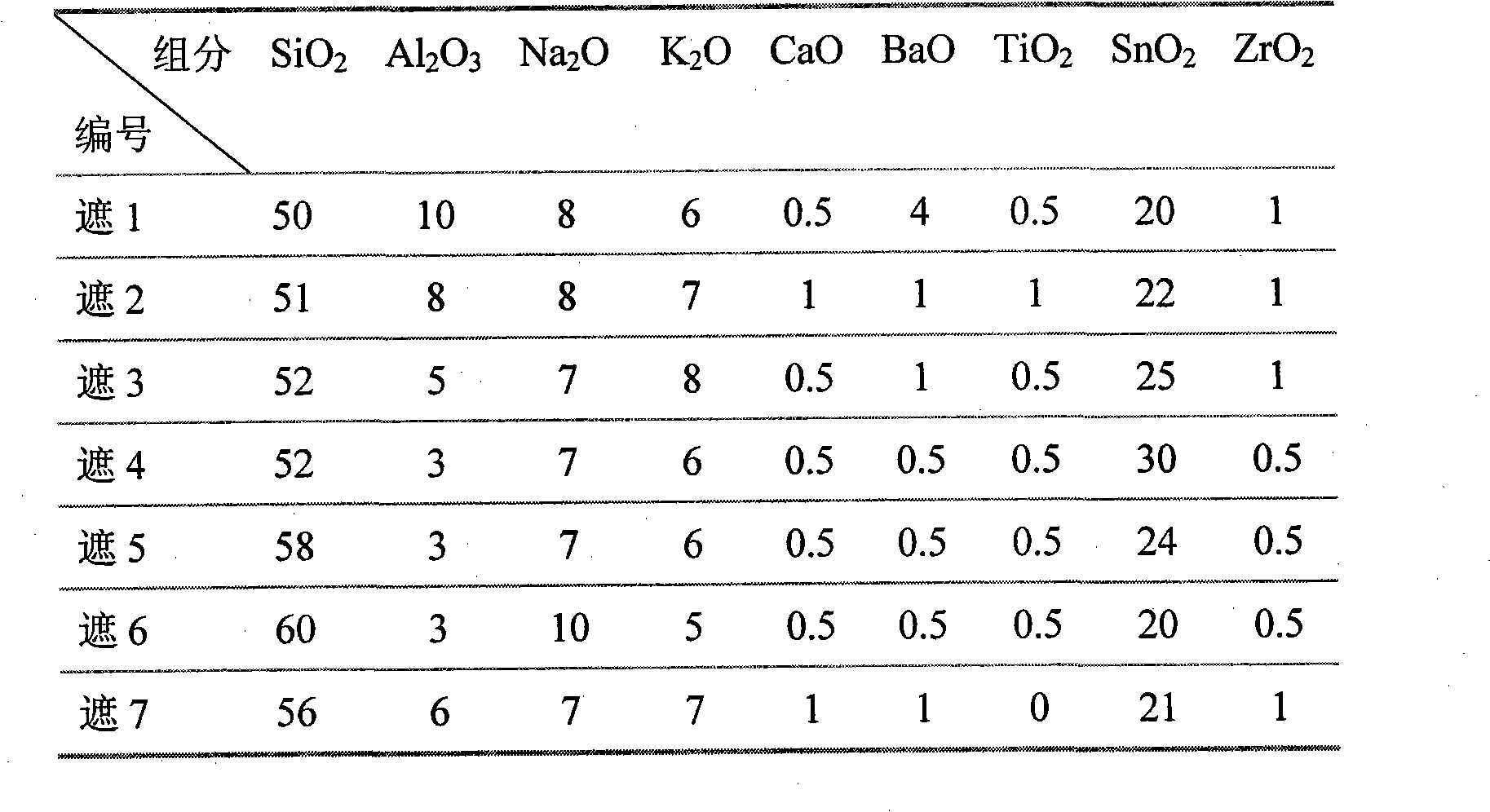

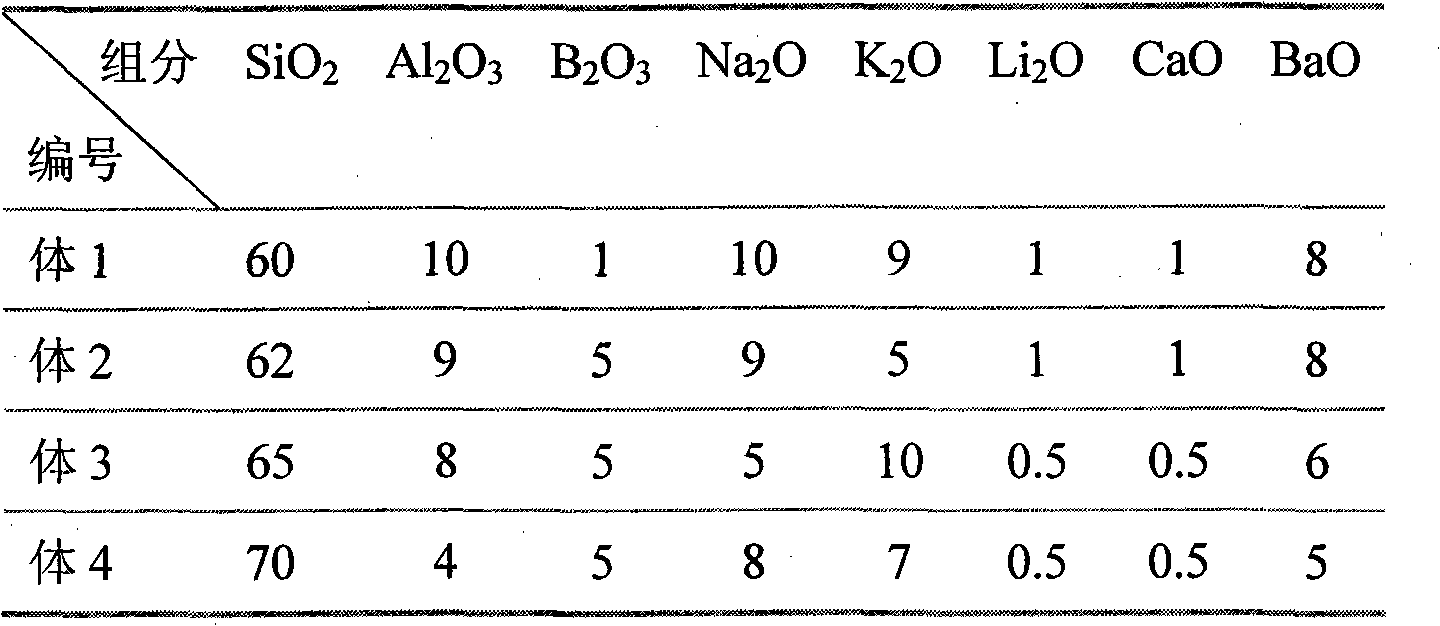

The invention discloses a complete set of a titanium ceramic powder for a dental department and a preparation method thereof. The titanium ceramic powder comprises bonded ceramic powder, color-maskingceramic powder and body ceramic powder. The bonded ceramic powder comprises the following components in percentage by weight: 50-55 percent of SiO2, 5-10 percent of Al2O3, 8-15 percent of B2O3, 10-15percent of SnO2, 0-1 percent of CaO, 1-3 percent of ZrO2, 4-10 percent of Na2O, 5-8 percent of K2O, 0-1 percent of Li2O, 1-4 percent of BaO and 0-1 percent of F; the color-masking ceramic powder comprises 50-60 percent of SiO2, 3-10 percent of Al2O3, 0.5-1 percent of CaO, 20-30 percent of SnO2, 0-1 percent of TiO2, 0.5-1 percent of ZrO2, 7-10 percent of Na2O, 5-8 percent of K2O and 0.5-4 percentof BaO; and the body ceramic powder comprises 60-70 percent of SiO2, 4-10 percent of Al2O3, 0.5-1 percent of CaO, 1-5 percent of B2O3, 5-10 percent of Na2O, 5-10 percent of K2O, 0.5-1 percent of Li2Oand 5-8 percent of BaO. In the titanium ceramic powder, besides the body ceramic powder, a crystal phase is added in the bonded ceramic powder and the color-masking ceramic powder by an intermediate material technology for secondary synthesis process, thereby not only regulating the thermal expansion coefficient of ceramic materials, but also being beneficial to reducing the ceramic temperature and being simultaneously beneficial to improving the bonding strength of titanium and ceramic.

Owner:XI AN JIAOTONG UNIV

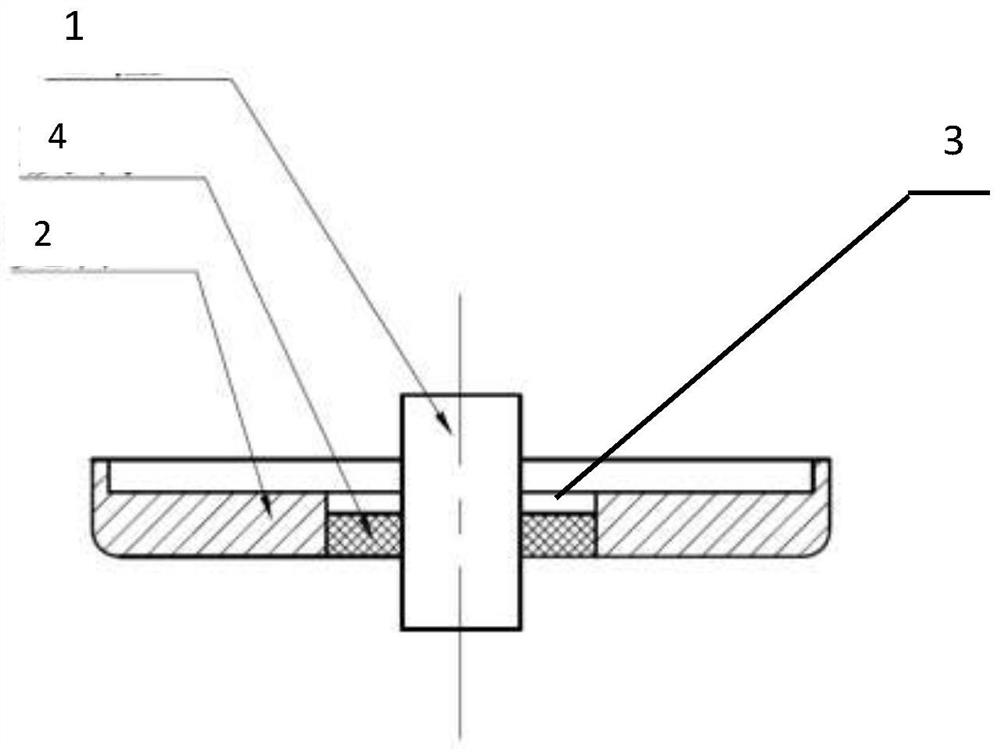

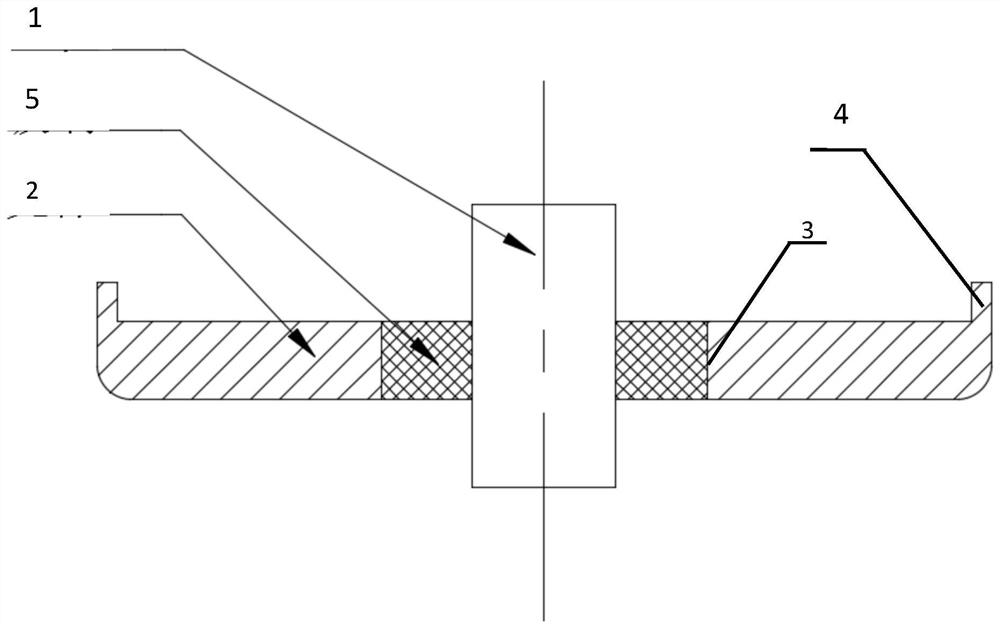

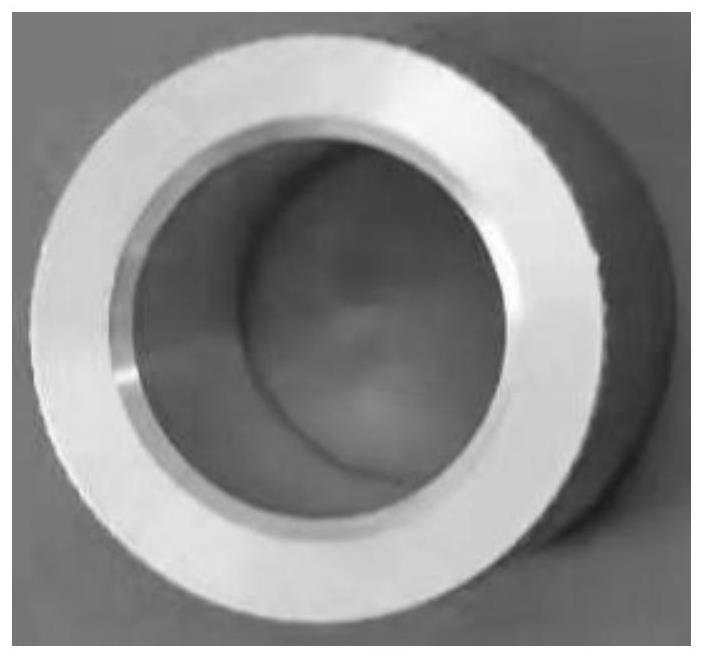

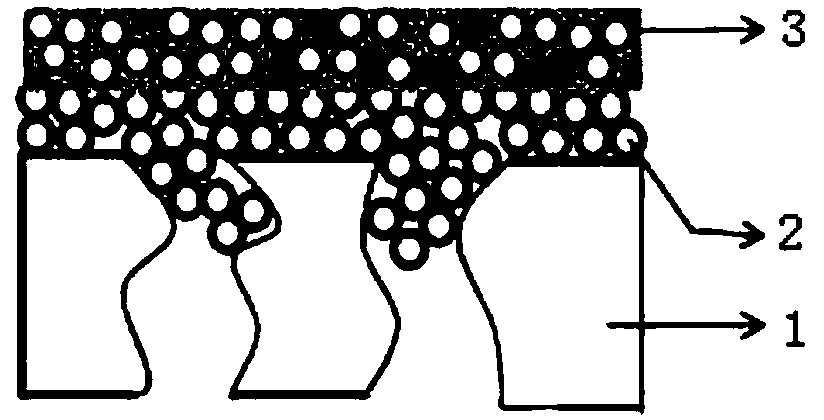

Copper line-clad aluminum silicon carbide ceramic substrate applicable to radiation of high-power LED

InactiveCN102569625AImprove thermal conductivityImprove thermal stabilitySemiconductor devicesCopperPorous silicon carbide

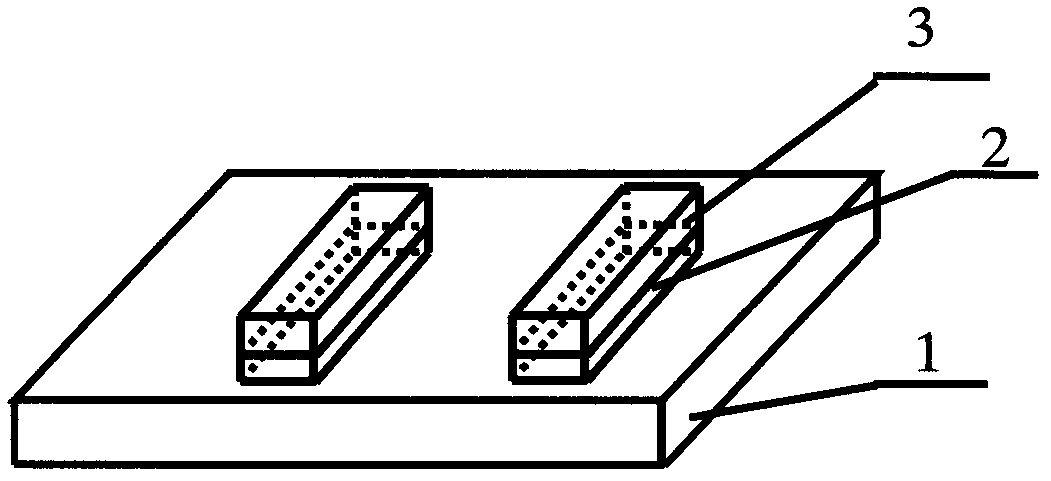

A copper line-clad aluminum silicon carbide ceramic substrate applicable to radiation of a high-power LED is characterized by consisting of an aluminum silicon carbide layer (1), a copper and aluminum oxide layer (2) and copper lines (3), wherein the copper and aluminum oxide layer (2) is arranged on the alumina layer (1); the copper lines (3) are arranged on the copper and aluminum oxide layer (2); the distance between the copper lines (2) is 0.1-1mm; the widths of the copper lines (2) are 200-1000 microns; the heights of the copper lines (2) are 0.01-2mm; the copper line-clad aluminum silicon carbide ceramic substrate is manufactured by the following steps: weighing SiO2, coke and a fluxing agent, and preparing the raw materials into porous silicon carbide; heating an aluminum block and melting the aluminum block into liquid aluminum, mixing the liquid aluminum with the porous silicon carbide in a certain ratio, and preparing the mixture into aluminum silicon carbide powder and a high-thermal conductivity aluminum silicon carbide substrate; cladding copper on the aluminum silicon carbide substrate, heating at a high temperature to form an eutectic melt, and forming an aluminum silicon carbide ceramic substrate layer, the copper and aluminum oxide layer and a copper layer from the bottom up; and etching conductive copper lines. The ceramic substrate has a good application prospect in the aspect of the radiation of the high-power LED.

Owner:CHINA JILIANG UNIV

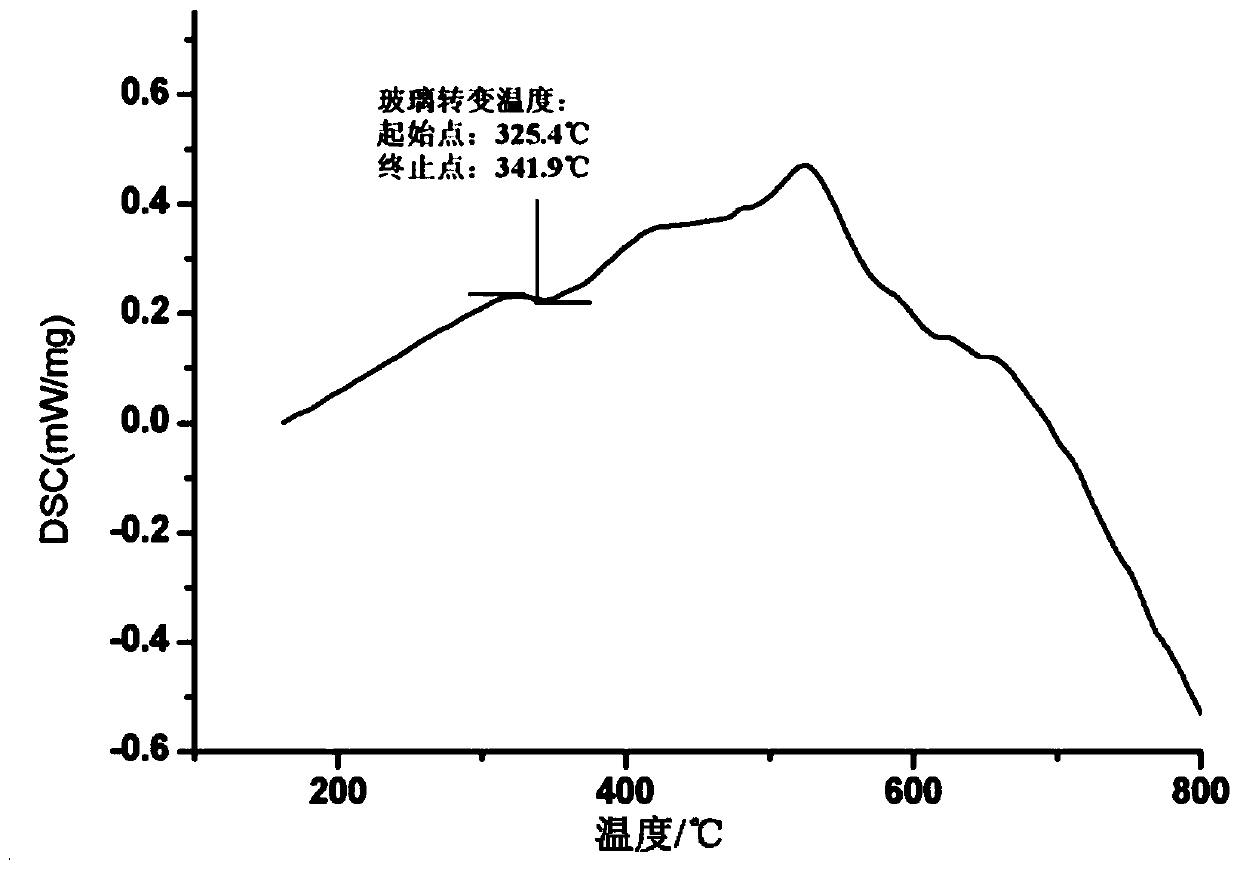

Bismuthate low-melting point and lead-free sealing grass and preparation method thereof

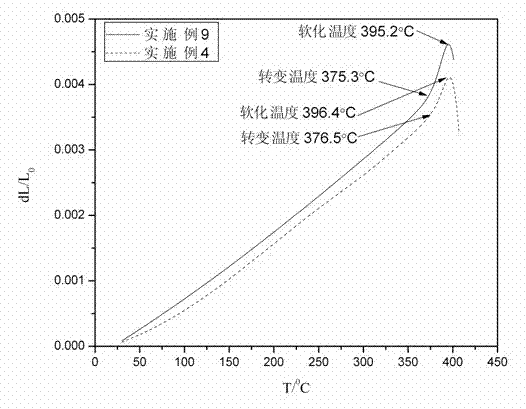

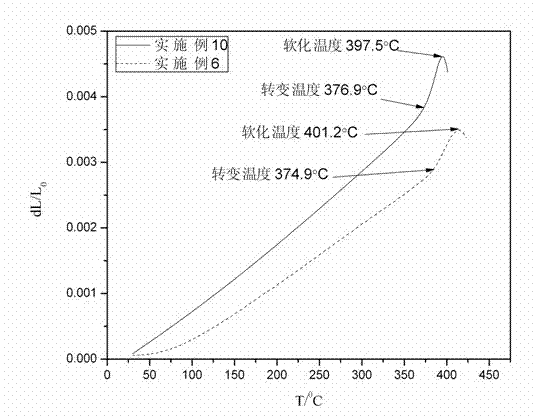

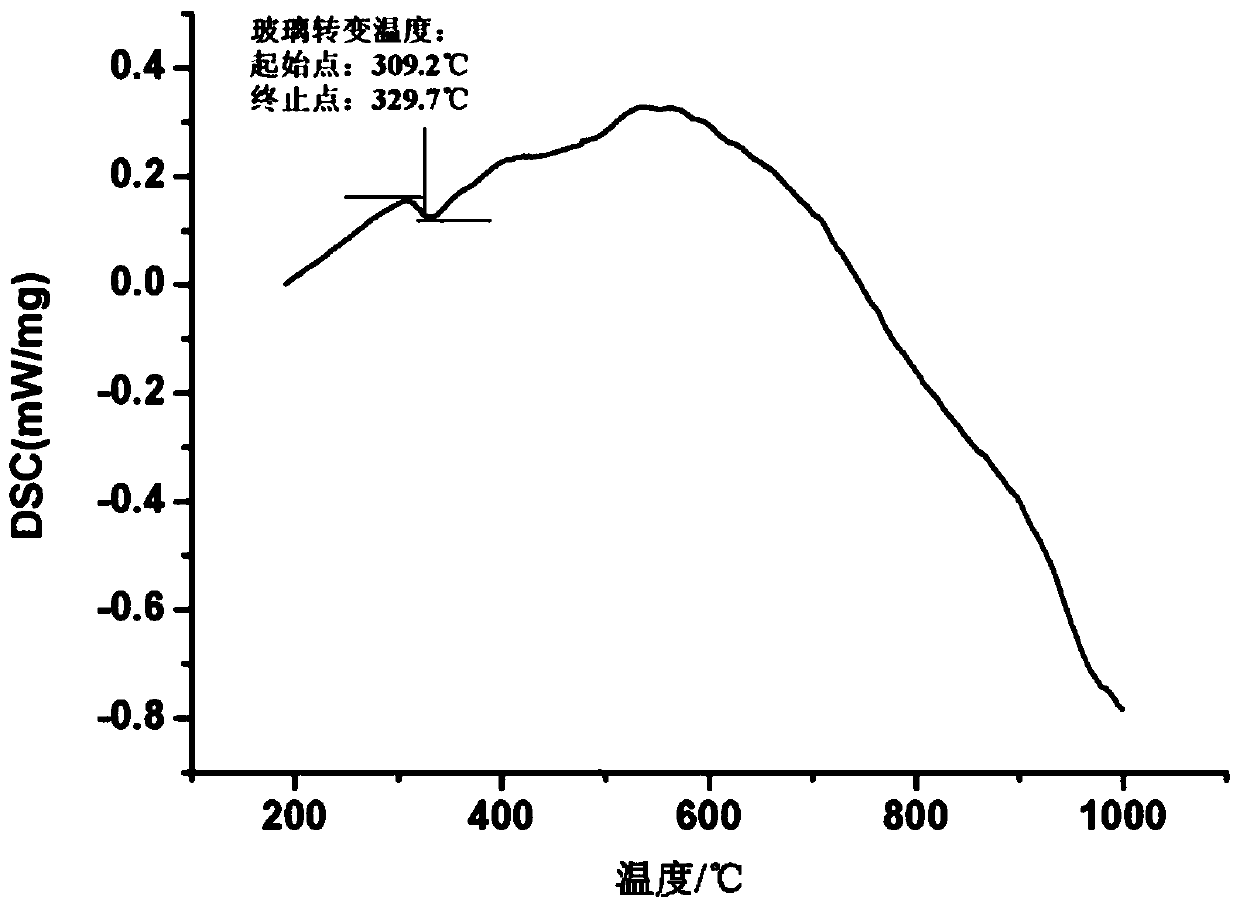

The present invention discloses a bismuthate low-melting point and lead-free sealing grass and a preparation method thereof. The bismuthate low-melting point and lead-free sealing grass powder comprises, by mass, 75-90% of base glass and 10-25% of a filler, wherein the filler is a zirconium phosphate salt with an expansion coefficient of -5*10<-6>k<-1>-5*10<-6>k<-1>. The bismuthate low-melting point and lead-free sealing grass of the present invention has characteristics of lead-free property and green environmental protection, can replace the lead-containing glass so as to eliminate the pollution due to the lead, and has excellent chemical stability. The production process is simple and the cost is low. Compared to other filler-doped sealing glass powders, the sealing temperature of the present invention is low, the glass transition temperature of the present invention is 330-370 DEG C, the softening temperature of the present invention is 370-410 DEG C, the sealing temperature of the present invention is less than 450 DEG C. With adjusting the proportion of the filler, the adjustable expansion coefficient can be realized at the low sealing temperature, wherein the adjustment range is (70-90)*10<-7> / DEG C, such that different requirements of the sealing device to the expansion coefficient of the sealing material can be met, and the sealing for VFD, PDP, CRT and other glass products can be directly performed.

Owner:CHINA JILIANG UNIV

Composite high-temperature molybdenum disilicide-base material and preparation method thereof

InactiveCN101531519AImprove antioxidant capacityAdjust the coefficient of thermal expansionComposite substrateRoom temperature

The invention relates to a composite high-temperature molybdenum disilicide-base material and a preparation method thereof. The method can prepare the composite high-temperature material under lower production cost, which has the highest room temperature toughness equivalent to that of high-temperature alloys, higher high temperature intensity, high temperature creep resistant performance and certain plastic processing performance; the substrate of the composite high-temperature material is a composite substrate composed of MoSi2 and Si3N4, wherein the average crystal grain size of the MoSi2 is smaller than 2 microns, and the average grain diameter of the Si3N4 particulates is smaller than 1 microns. The method adopts the following technical proposal: Mo2N powder or powder of Mo5Si3 or Mo3Si are used as initial powder to obtain composite powder Mo3Si-Mo5Si3-Si3N4 or Mo5Si3-MoSi2-Si3N4 after being processed by siliconization or nitridation-siliconization, the composite powder is further enhanced and mixed with materials such as Si powder, SiC powder and the like, and is pressing molded, and then a blank is sintered under the temperature of 1415 to 1550 DEG C, and finally the sintered blank is plastic deformed, thus obtaining a required dense article of the composite high-temperature material.

Owner:李琎 +1

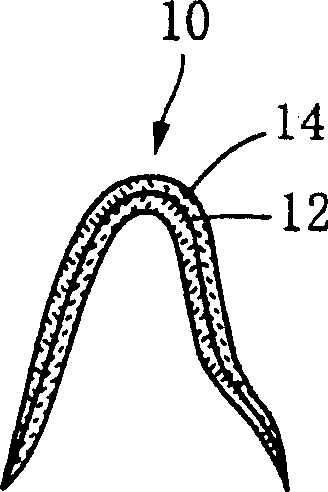

Process for producing dental prosthesis and kit for use therein

ActiveCN1822796AImprove toughnessAdjust the coefficient of thermal expansionTooth crownsArtificial teethViscosityDental prosthesis

Providing a method of manufacturing a dental prosthesis which is excellent in beauty and which prevents movement of a back coating layer even where a cast coating layer is formed on a surface of the back coating layer by casting, and a kit used in the manufacturing method. In the dental-prosthesis manufacturing method and kit according to the present invention, since viscosity of a second porcelain forming the cast coating layer (36) at a predetermined casting temperature is lower than that of a first porcelain forming the back coating layer (14), movement of the back coating layer (14) is advantageously restrained.

Owner:KURARAY NORITAKE DENTAL

Rapid diffusion welding connection method for skutterudite thermoelectric material and electrode

ActiveCN111014929AImprove thermoelectric conversion efficiencyGuaranteed thermoelectric conversion efficiencyWelding/soldering/cutting articlesNon-electric welding apparatusSkutteruditeElectroplating

The invention discloses a rapid diffusion welding connection method for a skutterudite thermoelectric material and an electrode, and relates to a diffusion welding connection method. The method aims to solve the problems of Sb element volatilization and element diffusion when the existing skutterudite thermoelectric material is connected with an electrode. The method comprises the steps of takingan electrode, cleaning a to-be-welded surface, electroplating an alloy barrier layer on the surface of the to-be-welded surface of the electrode, cleaning the to-be-welded surface of the skutteruditethermoelectric material, and performing diffusion welding. The barrier layer is prepared on the electrode side through an electroplating method, diffusion welding is achieved between the barrier layerand the skutterudite thermoelectric material under the relatively low pressure and at the relatively low temperature, element diffusion of weld joint elements and skutterudite does not exist in the process, and Sb element volatilization and element diffusion can be prevented. The method is suitable for welding the skutterudite thermoelectric material and the electrode.

Owner:HARBIN INST OF TECH

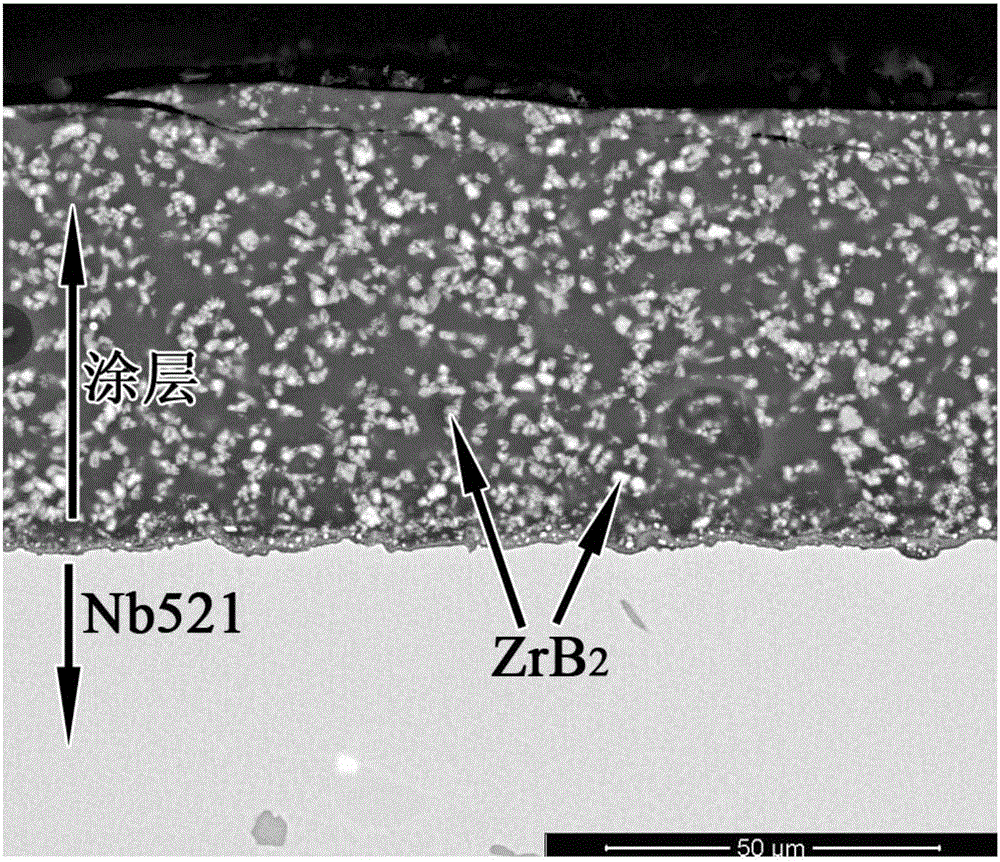

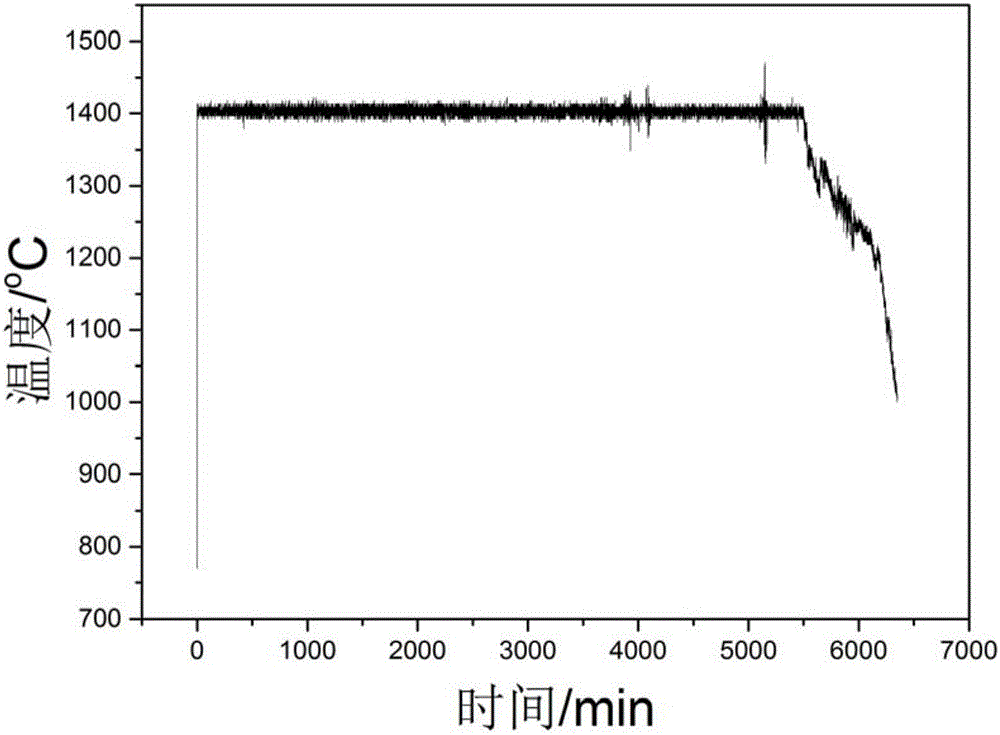

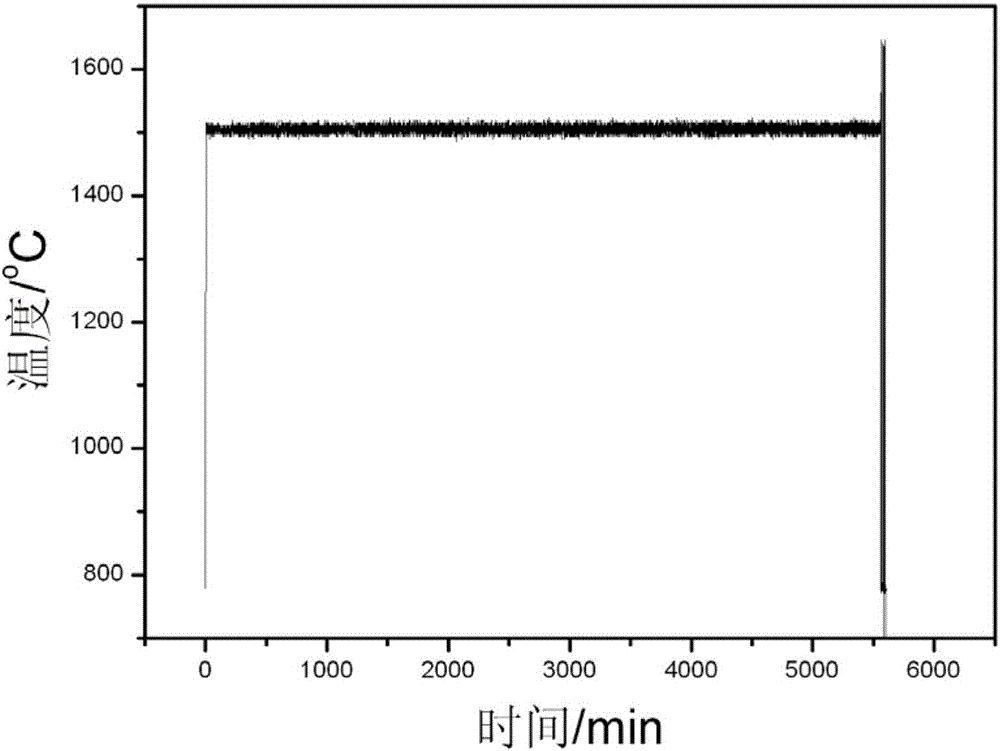

Boride modified glass ceramic based composite high-temperature oxidation resisting coating and preparation method thereof

ActiveCN106587629AGood heat erosion resistanceWide protection temperature rangeOxidation resistantBoride

The invention discloses a boride modified glass ceramic based composite high-temperature oxidation resisting coating. The composite high-temperature oxidation resisting coating fired on the surface of a refractory metal matrix is prepared from boride and silicate glass, wherein the boride is at least one or two of HfB2, ZrB2 and TiB2; besides, the invention further discloses a preparation method of the coating. The method comprises steps as follows: 1, the surface of the refractory metal matrix is treated; 2, boride particle modified glass ceramic composite slurry is prepared; 3, a preset layer is obtained by presetting the slurry on the surface of the refractory metal matrix, and the boride modified glass ceramic based composite high-temperature oxidation resisting coating is obtained vacuum high-temperature firing. The composite high-temperature oxidation resisting coating is used for high-temperature protection of the refractory metal matrix and can continuously protect the refractory metal matrix at the protection temperature of 400-1,600 DEG C for 5 h or longer.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

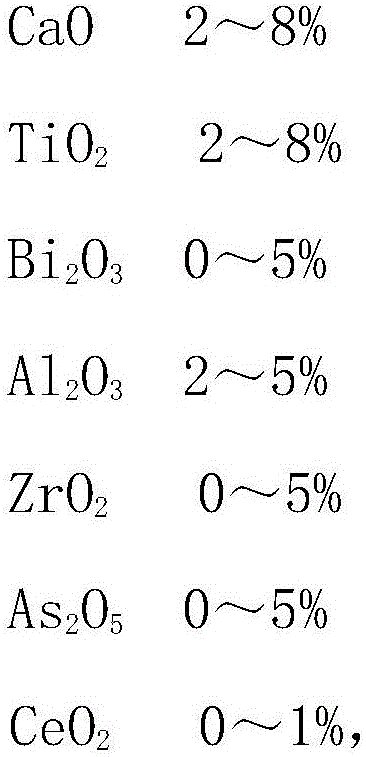

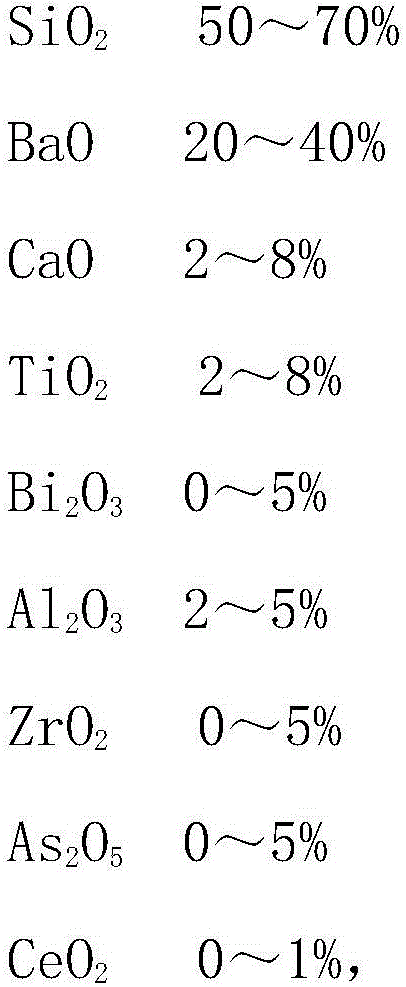

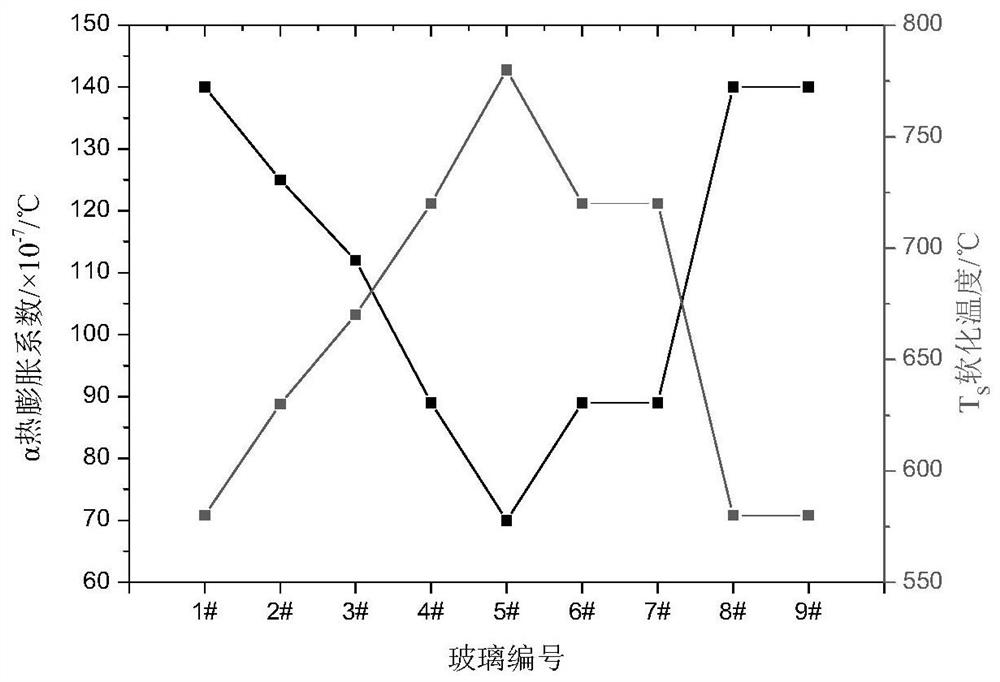

High temperature-resistant and high-insulation sealing glass and preparation method thereof

The invention discloses a preparation method of a high temperature-resistant and high-insulation sealing glass. The preparation method has the advantages that silicon dioxide is used as a skeleton structure; by adding BaO (barium oxide) as a generating body of glass, the melting temperature of the glass is lowered, the heat expansion coefficient of the glass is adjusted, and the fluidity of the glass is improved; by adding Al2O3 (aluminum oxide), an AlPO4 (aluminium phosphate) unit can be formed in the glass, and a straight chain is changed into a network structure, so that the structure of the glass is stable, and the chemical stability is improved; by adding ZrO2 (zirconium dioxide), the chemical stability of the glass is favorably improved; by replacing one part of BaO by other divalent metal oxides, such as CaO (calcium oxide), the melting temperature of the glass is lowered, the expansion coefficient of the glass is adjusted, and the chemical stability of the glass is improved; by adding TiO2 (titanium dioxide), the glass has high and low dielectric constants, and the electric insulation property of the glass is improved; by adding As2O5 (diarsenic pentoxide) into the formation of the glass structure, the separating from the network skeleton of the glass is avoided; the sealing temperature of the sealing glass is 1000 to 1050 DEG C, and the heat expansion coefficient is 70 to 100*10<-7> / DEG C; after sealing, the high temperature and high pressure resistant properties are good, and the insulation property is excellent.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Lithium-sodium-potassium codoped dental microcrystalline glass and preparation method and application thereof

ActiveCN106927681ARaw materials are readily availableProcess stabilityImpression capsMedical preparationsLithiumDevitrification

The invention discloses lithium-sodium-potassium codoped dental microcrystalline glass and a preparation method and application thereof. The glass is prepared from, by mass, 65%-75% of SiO2, 5%-10% of Li2O, 5%-10% of Na2O, 5%-10% of K2O, 4%-6% of P2O5 and 4%-6% of ZrO2. The sum of the mass fractions of the components is 100%. A glass block is firstly obtained through a fusion pouring method, a glass intermediate R2SiO3 (R=Li, Na and K) easy to machine is obtained after devitrification treatment is carried out, then secondary thermal treatment is carried out, and the finished microcrystalline glass with R2Si2O5 (R=Li, Na and K) as a main crystalline phase is obtained. The microcrystalline glass has excellent bending strength and other mechanical properties and can be used for dental all-ceramic repair materials.

Owner:FUZHOU RUIKE BULANG MEDICAL TECH CO LTD

High-temperature-resistant coating for solar device and preparation method of high-temperature-resistant coating

InactiveCN108384387AImprove adhesionHigh glossFireproof paintsEpoxy resin coatingsEthylenediamineTriethoxysilane

The invention discloses high-temperature-resistant coating for a solar device and a preparation method of the high-temperature-resistant coating, and relates to the technical field of wall materials.The high-temperature-resistant coating is prepared from a liquid material component and a powder material component, wherein the liquid material component is prepared from polymer emulsion, ethylenediamine, 3-amino propyl triethoxysilane, dioctyl phthalate, poly(2-hydroxyacrylicacid) sodium salt, a co-solvent and the like. The high-temperature-resistant coating has excellent aging resistance and high temperature resistance.

Owner:HEFEI TONGYOU ELECTRONICS TECH CO LTD

Complete set of titanium ceramic powder for dental department and preparation method thereof

InactiveCN101664368BFusion temperature decreasedAdjust the coefficient of thermal expansionImpression capsDentistry preparationsTitaniumThermal expansion

Owner:XI AN JIAOTONG UNIV

Preparation method and sealing process of explosion-proof primary lithium battery cover group and sealing glass

PendingCN112694257AControl the compressive strengthAdjust the coefficient of thermal expansionCell sealing materialsThermal dilatationElectrolytic agent

The invention discloses a preparation method and a sealing process of an explosion-proof primary lithium battery cover group and sealing glass. A glass material which is resistant to electrolyte corrosion, excellent in electrochemical performance, controllable in mechanical strength and used for sealing the primary lithium battery cover group is provided, and the compressive strength of the glass is controlled by designing glass components and the sealing thickness. The explosion-proof principle is that when the internal pressure of the battery is greater than the designed pressure in the use process, namely the pressure of the battery is overloaded, the pressure-bearing strength of the glass material is just reached, so that the glass is cracked, the internal pressure of the battery is slowly released, and the battery does not have dangerous situations such as violent explosion. The shell is made of stainless steel series and carbon steel series, the stainless steel series comprises 304L, 316L and the like, and the core column is made of series iron-nickel alloys such as alloys 4J28, 4J50, 4J52 and the like. A SiO2-B2O3-BaO-Na2O3 glass system is selected as a main body, and various metal oxides are added to adjust the thermal expansion coefficient, the glass softening temperature, the chemical stability and the mechanical properties of the glass.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

Titanium alloy protective coating and preparation method thereof

ActiveCN103803800AExcellent high temperature oxidation resistanceIncrease high temperature viscosityOxidation resistantAluminium oxide

The invention discloses a titanium alloy protective coating which is characterized in that the coating is an amorphous silica-glass composite coating formed by diffusing and distributing 20-40 weight percent of amorphous silica particles in a glass matrix, wherein the glass matrix in the composite coating comprises the following raw materials in parts by mass: 30-40 parts of silica, 20-30 parts of boron oxide, 2-5 parts of aluminum oxide, 5-15 parts of magnesium oxide, 5-15 parts of calcium oxide and 10-20 parts of sodium oxide. The method for preparing the titanium alloy protective coating comprises the following steps: preparing glass powder; preparing slurry for the composite coating, pretreating the surface of the titanium alloy, coating the slurry and sintering the composite coating. The composite coating prepared in the invention can be sintered at a low temperature and has excellent high-temperature oxidization resistance. Meanwhile, the composite coating is low in raw material cost, simple and feasible in preparation process and suitable for industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

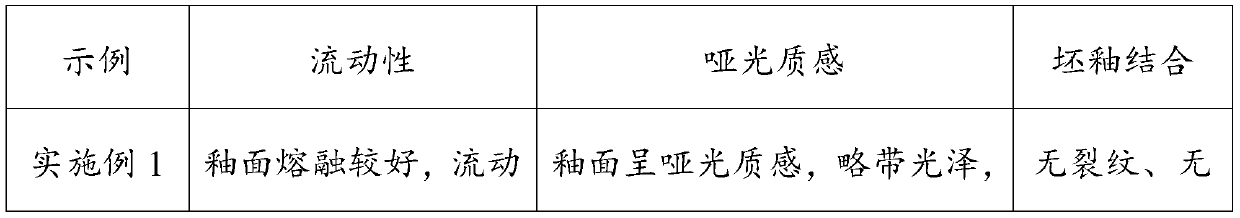

Composition for preparing matte white glaze, and firing method of matte white glaze

The invention belongs to the technical field of ceramic glaze preparation, and particularly relates to a composition for preparing matte white glaze, and a firing method of the matte white glaze. According to the matte white glaze provided by the invention, slag powder, calcined kaolin and talc are matched for use, so that the problem that bubbles are generated on the glaze due to the fact that alarge amount of gas is released in the slag powder firing process can be avoided, the texture of the glaze is improved, the roughness of the glaze is improved, the thermal expansion coefficient of theglaze is adjusted, and the problem that the glaze cracks due to the fact that a large amount of slag powder is added into the glaze is reduced; the slag powder has high fluidity under a high-temperature firing condition, and the calcined kaolin and the talc are matched for use, so that bubbles generated on the glaze surface can be inhibited while the problem of high fluidity of the slag powder ata high temperature is controlled, the glaze surface is smooth, and the glaze surface texture is improved; and a large amount of slag powder can be utilized to realize recycling of the slag powder, and environmental pollution and resource waste can be effectively reduced.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Preparation method and packaging process of sealing glass material for lithium-manganese dioxide battery cover group

PendingCN112645598AAdjust the coefficient of thermal expansionAdjust softening temperatureCell sealing materialsPhysical chemistryManganese oxide

The invention belongs to the field of sealing glass and preparation thereof, and particularly relates to a preparation method and a packaging process of a sealing glass material for a lithium- manganese dioxide battery cover group. The preparation method of the sealing glass material for the lithium-manganese dioxide battery cover group comprises the following steps: 1) selecting the following raw materials in molar percentage: 40-60% of SiO2, 5-25% of B2O3, 0-5% of Al2O3, 5-15% of BaO, 5-15% of Na2O, 0-5% of K2O, 0-5% of MgO, 0-5% of CaO, 0-5% of TiO2, 0-5% of ZrO2, 0-5% of ZnO and 0-5% of Cr2O3, wherein various oxides should comprise various salts and acid-base compounds thereof. According to the preparation method of the sealing glass material for the lithium-manganese dioxide battery cover group and the sealing process of the sealing glass material, the corrosion resistance of the lithium-manganese dioxide battery cover group glass is improved, the air tightness of a sealing piece is guaranteed, the chemical stability and high-temperature and high-pressure insulativity of the sealing piece are improved, and the preparation process is simple, and suitable for industrial production.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

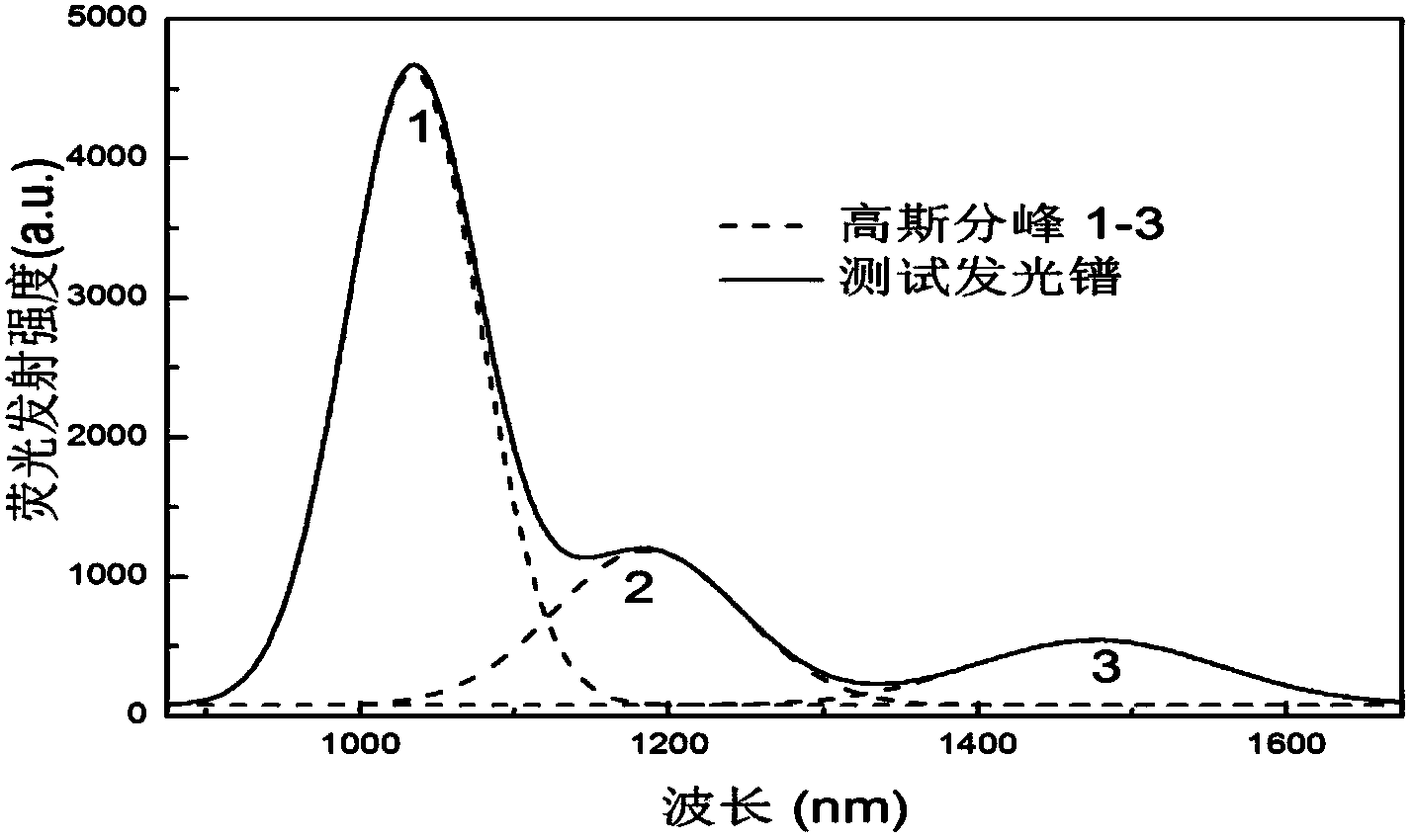

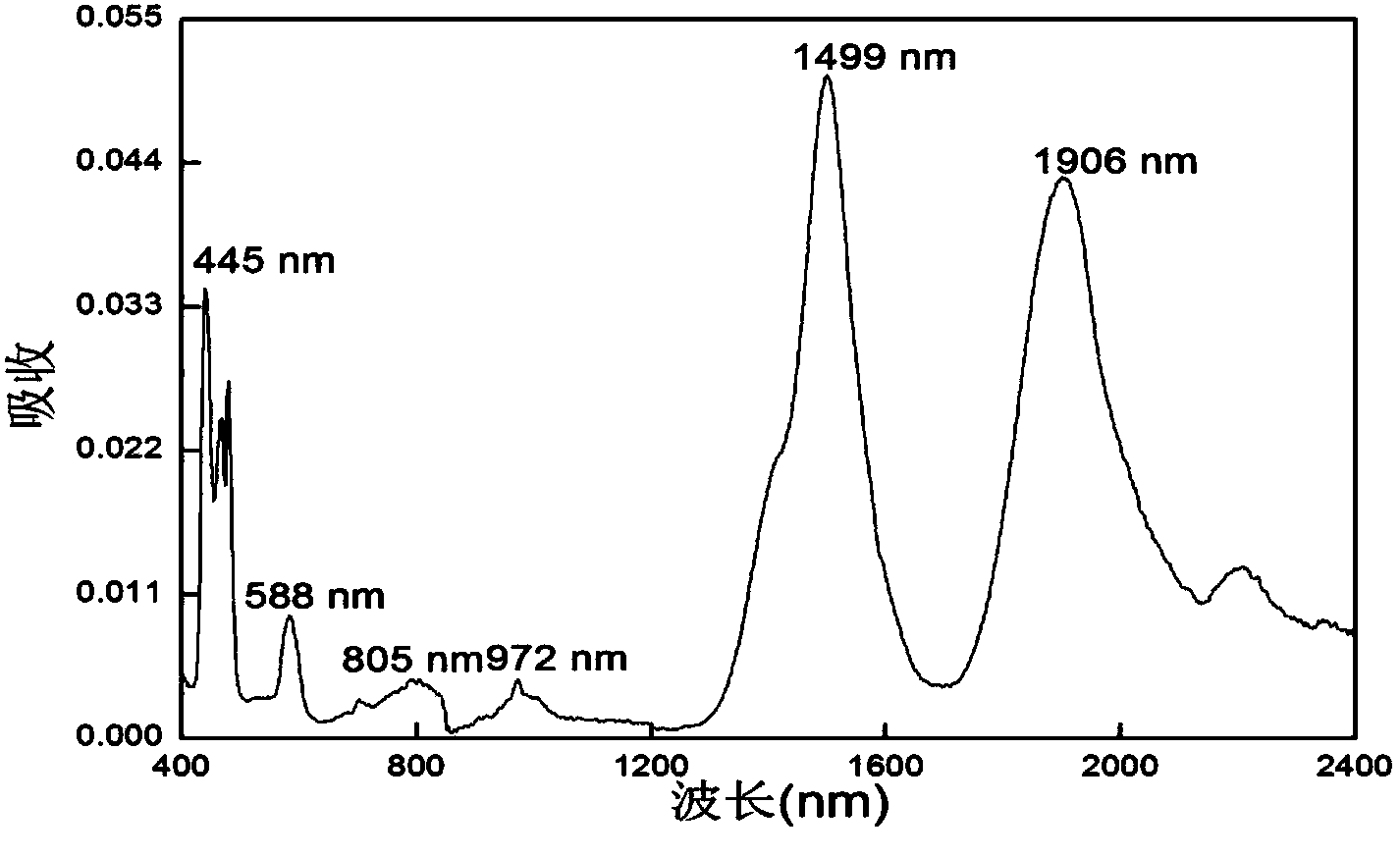

Praseodymium-doped borophosphate base near-infrared ultra wide band luminescent glass and preparation method thereof

InactiveCN102674688BComposition is differentSimple preparation conditionsLuminous intensityLength wave

Disclosed are praseodymium-doped borophosphate base near-infrared ultra wide band luminescent glass and a preparation method thereof. The glass comprises 45-83 mol% of P2O5, 5-35 mol% of B2O3, 4-23 mol% of Al2O3, 6-22 mol% of Y2O3 and 0.1-3 mol% of Pr2O3. The preparation method of the glass includes the steps of raw material weighing, presintering, founding, pouring, annealing and the like. The preparation method is simple in process, high in ultra wide band near-infrared fluorescence-emission characteristic with emission wavelength of 830-1700nm and capable of improving the stability of the glass, reinforcing the luminous intensity of praseodymium ions, and satisfying the requirement of optical fiber wiredrawing.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

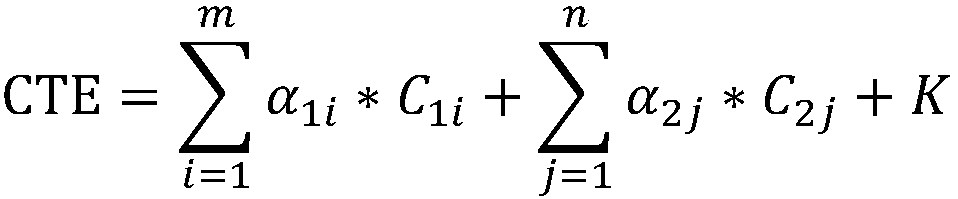

Method for preparing polyimide film

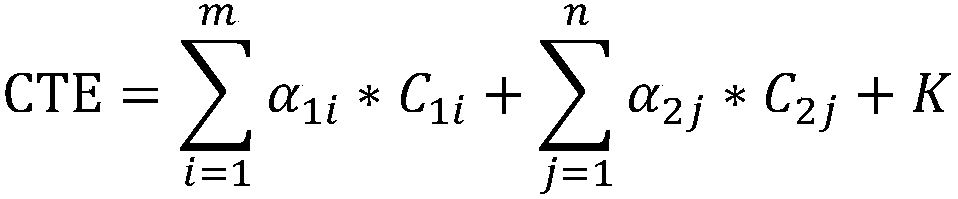

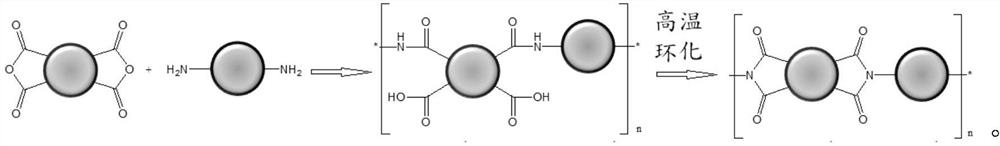

ActiveCN110272549AAdjust the coefficient of thermal expansionEffective adjustment of thermal expansion coefficientPolymer scienceMolecular materials

The invention relates to the field of high-molecular materials, and concretely relates to a method for preparing a polyimide film. The method comprises the following steps: (1) selecting at least one diamine monomer and at least one dianhydride monomer, and adjusting the molar ratio of the diamine monomer to the dianhydride monomer according to a calculating formula in order to obtain the moles of the diamine monomer and the dianhydride monomer when a target thermal expansion coefficient is achieved; and (2) reacting the selected diamine and dianhydride monomers in a solvent according to the above moles to obtain a polyamic acid solution, and performing film formation and imidization on the polyamic acid solution to obtain the polyimide film. The method of the invention adopts a structure containing a hydrogen bond, the dianhydride and diamine monomers are selected, and the ratio of the two monomers is adjusted to effectively adjust the thermal expansion coefficient of the polyimide film, so the obtained polyimide film has excellent mechanical performances and high-temperature application performances, and has the thermal expansion coefficient matching with an adhered substrate to avoid the deformation and curling of the polyimide film due to the difference in thermal expansion coefficients.

Owner:BEIJING UNIV OF CHEM TECH

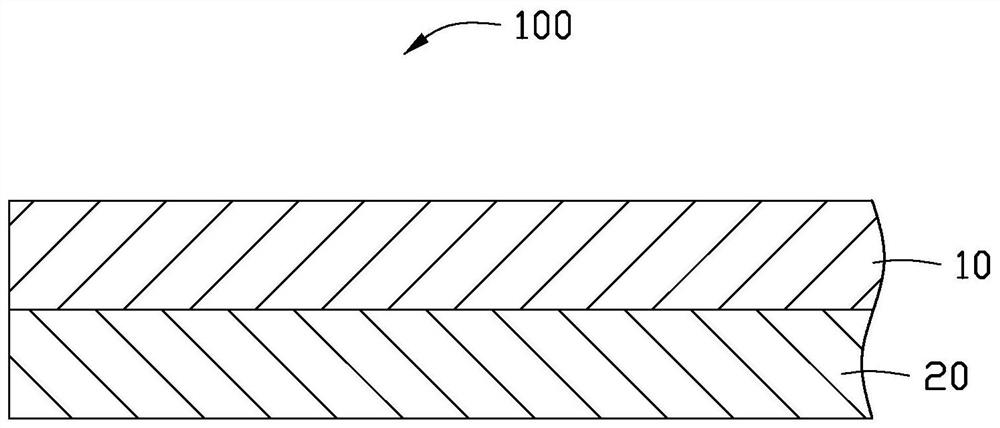

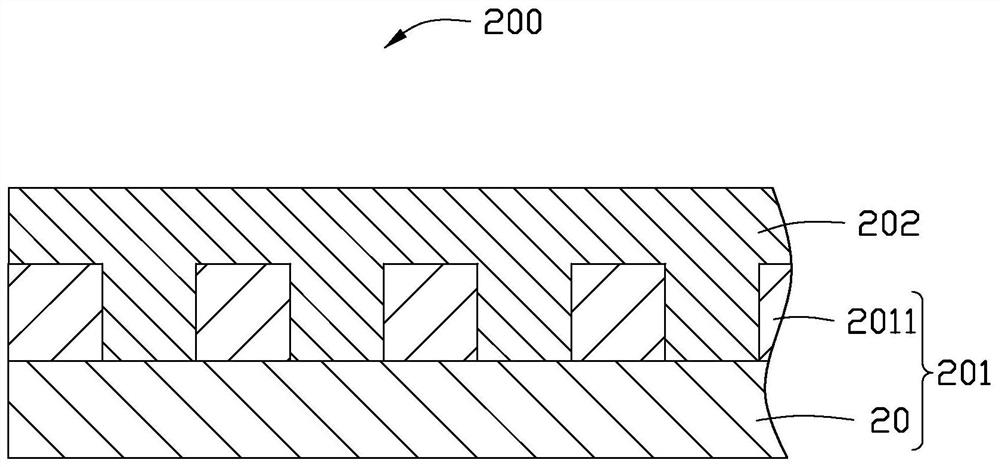

Polyamic acid composition, polyimide copper-clad plate and circuit board

PendingCN112239539AHigh bonding strengthLow mobilityLiquid crystal compositionsPrinted circuit aspectsPolymer sciencePolyamide

A polyamic acid composition is formed by polymerizing a dianhydride monomer and a diamine monomer, and the molar ratio of the dianhydride monomer to the diamine monomer ranges from 0.9 to 1.1. the diamine monomer comprises a diamine monomer containing a liquid crystal unit, a diamine monomer containing a soft structure and a diamine monomer containing a nitrogen heterocyclic ring; in the diamine monomer, the molar percentage of the diamine monomer containing the nitrogen heterocyclic ring is 3%-8%, and the sum of the molar percentage of the diamine monomer containing the liquid crystal unit and the molar percentage of the diamine monomer containing the soft structure is 92%-97%. The invention also provides a polyimide copper-clad plate prepared by cyclizing the polyamide acid composition and a circuit board prepared by applying the polyimide copper-clad plate.

Owner:ZHEN DING TECH CO LTD

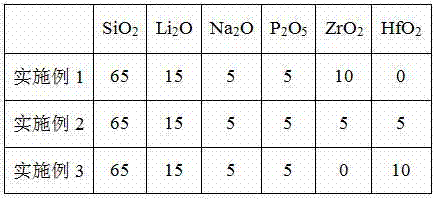

ZrO2 (zirconium oxide) and HfO2 (hafnium oxide)-codoped microcrystalline glass of dentistry

InactiveCN107056071AHigh strengthPromote crystallizationImpression capsDentistry preparationsLithium oxideSilicon dioxide

The invention discloses a ZrO2 (zirconium oxide) and HfO2 (hafnium oxide)-codoped microcrystalline glass of dentistry and a preparation and a use method thereof. The ZrO2 and HfO2-codoped microcrystalline glass is prepared from the following components in parts by mass: 60 to 75% of SiO2 (silicon dioxide), 10 to 25% of Li2O (lithium oxide), 2 to 8% of Na2O (sodium oxide), 2 to 8% of P2O5 (phosphorus pentoxide), 0 to 15% of ZrO2 and 0 to 15% of HfO2, wherein the sum of mass fractions of the components is 100%. The preparation method comprises the following steps of using a smelting and casting method to obtain a glass block; crystallizing and treating, so as to obtain a glass intermediate R2SiO3 (R=Li and Na) which can be easily processed by machines; performing secondary heat treatment, so as to obtain the finished product of the microcrystalline glass using R2Si2O5 (R=Li and Na) as the main crystal phase. The microcrystalline glass has the excellent mechanical properties of bending strength and the like, and can be applied to the full-ceramic restoration materials of dentistry.

Owner:FUZHOU UNIV

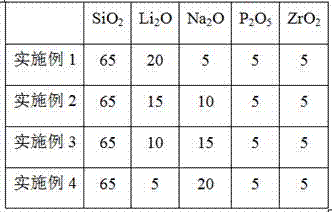

Lithium sodium codoping dental nucleated glass, and preparation and application thereof

InactiveCN107082568AHigh strengthPromote crystallizationImpression capsDentistry preparationsLithiumAdditive ingredient

The invention discloses lithium sodium codoping dental nucleated glass, and a preparation and application thereof. The dental nucleated glass is prepared from the following ingredients in percentage by mass: 65 to 75 percent of SiO2, 5 to 20 percent of Li2O, 5 to 20 percent of Na2O, 4 to 6 percent of P2O5 and 4 to 6 percent of ZrO2, wherein the mass percent sum of the raw materials is 100 percent. The raw materials are treated by a molten casting method to obtain a glass block body; through crystallization treatment, a glass intermediate R2SiO3(R=Li and Na) capable of realizing mechanical processing is obtained; then, through secondary heating treatment, the nucleated glass finished product using R2Si2O5(R=Li and Na) as major crystalline phases is obtained. The nucleated glass finished product has excellent mechanical properties such as excellent bending strength, and can be used as a dental all-ceramic restorative material.

Owner:FUZHOU UNIV

Lightweight aluminum alloy composite material, compressor roller and preparation method of compressor roller

PendingCN114045417AReduce weightReduce operating energy consumptionTransportation and packagingMetal-working apparatusCarbide siliconCorrosion

The invention discloses a lightweight aluminum alloy composite material which comprises 0.5-2% of a lubricating phase, 0.5-15% of a ceramic phase and the balance of a matrix alloy, wherein the matrix comprises the following elements in percentage by mass: 20-30% of silicon, 2-4% of copper, 2-4% of magnesium, 0.1-0.5% of zirconium, 0.1-2% of iron, 0.1-2% of nickel and the balance of aluminum; the lubricating phase is molybdenum disulfide, and the ceramic phase is one or a combination of two of zirconium oxide and silicon carbide powder. The invention further discloses a compressor roller prepared from the lightweight aluminum alloy composite material and a preparation method of the compressor roller. The lightweight aluminum alloy composite material provided by the invention has good wear-resistant and high-strength properties, is light in weight, is used for manufacturing parts, such as rollers, and is small in specific gravity and low in noise, the wear-resistant and corrosion-resistant properties are improved, and the maintenance caused by wear is greatly reduced.

Owner:YULIN NORMAL UNIVERSITY

Frit composition, frit paste composition, sealing method and electric device

The invention relates to frit composition, frit paste composition comprising the frit composition, a sealing method adopting the glass frit paste composition and an electric device for sealing with the sealing method. According to the frit composition, a manganese-nitrogen compound which has a specific molecular formula and adopts an anti-perovskite crystal structure is taken as filler and has a negative thermal expansion characteristic in a certain temperature range, the overall thermal expansion coefficient of the frit composition can be well adjusted, accordingly, the overall thermal expansion coefficient of the cured glass frit can approach that of a glass substrate, and the frit composition can be better matched with the glass substrate.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

Palladium/ceramic composite film

InactiveCN109957772AAdjust the coefficient of thermal expansionImprove high temperature structural stabilityVacuum evaporation coatingSputtering coatingSputteringCeramic composite

The invention discloses a palladium / ceramic composite film. The composite film is loaded on a porous carrier. The composite film is formed by combining metal palladium or a palladium alloy and ceramics, wherein the volume of the palladium or the palladium alloy accounts for 30%-99%. The composite film is prepared through a physical vapor deposition method. A magnetron sputtering method is preferably adopted for preparing, and the composite film is obtained through sputtering of a palladium or palladium alloy target and a ceramic target at the same time. Through combining of a palladium film and the ceramics, on one hand, ceramic particles are dispersed and distributed in the continuous palladium or palladium alloy, the function of pinning is achieved for the palladium grain boundary, and palladium grain high-temperature grain growth and roughening difficulty is increased; and on the other hand, through introduction of the ceramics, the function of adjusting the palladium film heat expansion coefficient can be achieved, palladium film and ceramics or glass heat expansion mismatching is reduced, and the high-temperature structure stability of the palladium film is improved.

Owner:GRIMAT ENG INST CO LTD

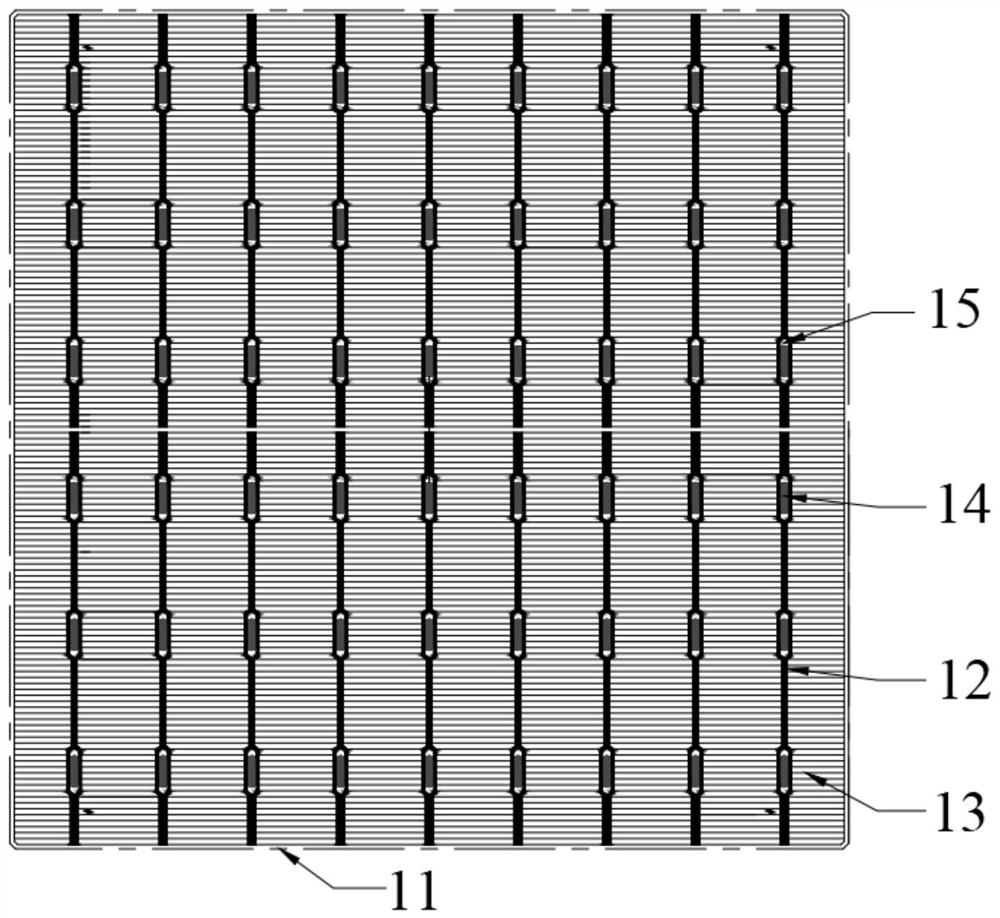

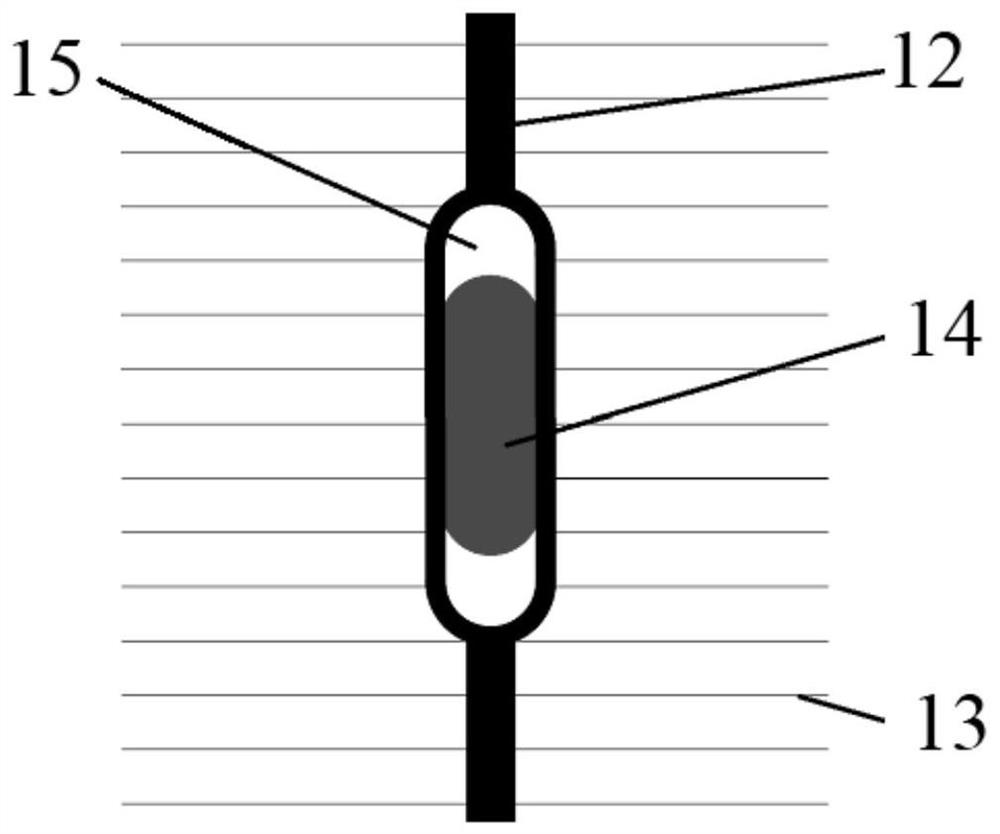

Isolation material, cell back field back electrode and production method thereof, solar cell and production method thereof

PendingCN112909103ASolve Welding ProblemsImproved coefficient of thermal expansionFinal product manufacturePhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses an isolation material, a cell back field back electrode and a production method thereof, a solar cell and a production method thereof, and belongs to the technical field of crystalline silicon solar cell production. The back field back electrode comprises a silicon back substrate, an aluminum electrode and a silver electrode, the aluminum electrode is arranged on the silicon back substrate, the silver electrode is arranged on the aluminum electrode, an isolation layer is arranged between the silver electrode and the aluminum electrode, and the isolation layer is composed of a glass powder, an auxiliary powder, an organic carrier and auxiliaries. The weight percentage of the glass powder is 35-80%, the weight percentage of the auxiliary powder is 0.5-25%, and the weight percentage of the organic carrier and the auxiliaries is 15-45%. The isolation layer is inserted between the silver electrode and the aluminum electrode to block direct contact between the silver electrode and the aluminum electrode so that mutual permeation of a silver paste and an aluminum paste in a sintering process is effectively isolated, and the improvement or solution of the all-aluminum back field battery on performances such as battery quality, assembly welding, reliability and the like is realized.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

Plasma in situ reaction composite treating process of tube inner wall

InactiveCN1570209AAdjust the coefficient of thermal expansionImprove performanceMetallic material coating processesPlasma generatorBottle

A pipe inner wall plasma in-situ reaction composite processing technology is characterized in that: the processing technology comprises the following steps: (1) preparing thermal reaction powder; (2) preparing the workpieces for processing; (3) starting the workbench, opening the gas and cooling water switch of the plasma equipment, opening the power supply and starting arc by high frequency, adjusting the technological parameter range of the plasma beam, adjusting the rotation speed of the workpiece, and adjusting the feeding speed of the plasma generator; (4) closing the plasma power supply and the switches of the air bottle and powder feeder, and closing the cooling water switch; (5) arranging the processed workpieces in order for use later. The tapered composite coating with high strength can be obtained by the technology.

Owner:崔洪芝 +1

Preparation method of carbon nanotube composite metal paste

InactiveCN110890169AImprove thermal conductivityImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureNano copperMetal powder

The invention discloses a preparation method of carbon nanotube composite metal paste. The preparation method comprises the following steps: S1, preparing a carbon nanotube subjected to first metal surface modification; S2, mixing the first metal surface modified carbon nano tube with metal powder and an organic carrier to form carbon nano metal paste; wherein the mass mixing ratio of the carbon nano tube to the metal powder ranges from 1: 59 to 1: 19, and the mass mixing ratio of the first metal surface modified carbon nano tube and the metal powder to the organic carrier ranges from 1: 3 to1: 5.7. According to the invention, the technical problems of low thermal conductivity, low electric conductivity and poor shear strength after the existing nano copper paste is sintered are solved, and the electric conductivity, the thermal conductivity, the shear strength and the connection strength of a sintered layer are improved.

Owner:SHENZHEN INST OF WIDE BANDGAP SEMICON

Leadless low-melting glass production method

The invention discloses a lead-free low melting point glass and a method for producing the same. The melting temperature of the glass is between 400 and 680 DEG C and the thermal expansion coefficient thereof is between 75 and 130*10<-7> per degree centigrade. The method comprises the following steps: adopting a material with certain chemical activity to prepare a phosphate system powder material with a wide process range and strong adaptability; dissolving the phosphate system powder material in a hydrochloric acid environment so as to synthesize chloride containing Sn4P2O7, Ba<2+>, Al<3+>, Zn<2+>, Sr<2+>, Cu<+> and Ca<2+> so as to form a glass pre-matrix; and melting the glass pre-matrix and then compounding the glass pre-matrix with low expansion stuffing so as to generate a lead-free inorganic sealing material. The lead-free low melting point glass is suitable to adjust the thermal expansion coefficient and has lower softening temperature and good chemical stability.

Owner:贵州威顿晶磷电子材料股份有限公司

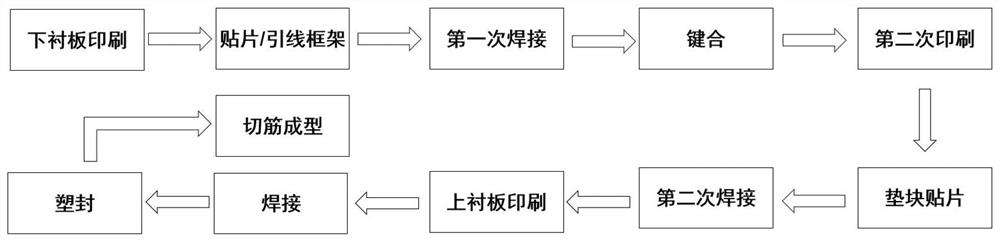

Manufacturing method of power module and power module

ActiveCN112164675ASimple production processReduce inductanceAdditive manufacturing apparatusSemiconductor/solid-state device detailsProcess engineeringChipset

The invention provides a manufacturing method of a power module and the power module. The problems that a traditional power module is complex in manufacturing process and low in production efficiencyare solved. The embodiment of the invention provides a manufacturing method of a power module and the power module, the manufacturing method comprises the steps that an integrated lining plate is prepared, the integrated lining plate is prepared by adopting an additive manufacturing method, and the integrated lining plate comprises the steps that a first integrated lining plate and / or a second integrated lining plate are / is prepared; and a chip is assembled between the first integrated lining plate and the second integrated lining plate to form the power module.

Owner:湖南国芯半导体科技有限公司

A kind of low-melting-point glass powder for vacuum glass sealing and anodic bonding enhanced packaging method thereof

ActiveCN108298822BLower working temperatureThe range of thermal expansion coefficient is adjustableThermal dilatationAnodic bonding

The invention relates to the technical field of vacuum glass manufacturing, in particular to a vacuum glass sealing material and an anodic bonding enhanced sealing method thereof. An adopted edge sealing material is lead-free low-melting-point glass powder, and the glass powder is characterized by being low in sealing temperature and adjustable in thermal expansion coefficient, the requirements for low temperature sealing can be met, and the anodic bonding is used to enhance the vacuum glass sealing to achieve a low temperature sealing process. The lead-free low-melting-point glass powder is fully melted and does not crack during the sintering process at 300-450 DEG C, and forms a good infiltration with substrate; and at the same time, an anodic bonding sealing technology is used to further lower the sealing temperature and improve the sealing strength and quality. A new technical scheme is provided for vacuum glass edge sealing, a vacuum glass sealing process is improved, and a new solution is provided for preparing the vacuum glass excellent in performance.

Owner:WUHAN UNIV OF TECH

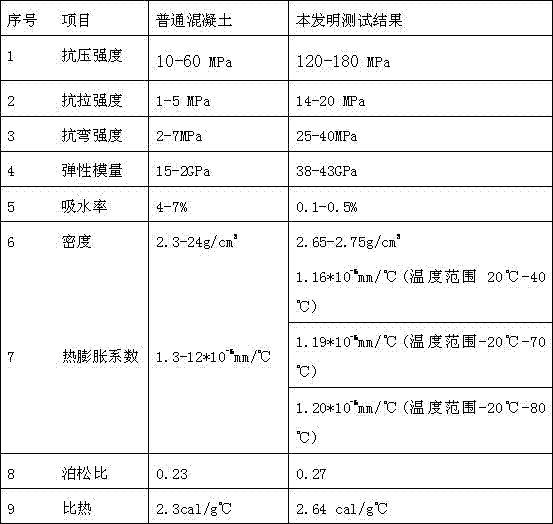

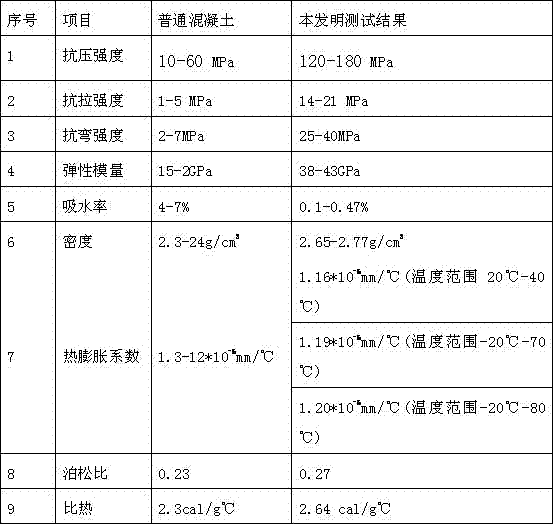

Machine tool bed cast from waste ceramic

The invention discloses a machine tool bed cast from waste ceramics. The machine tool bed has the advantages of being high in stability, low in thermal expansion coefficient, good in pressure and tension resistance, and the like, and in addition, as waste ceramics are adopted as a raw material, the problem that waste ceramics are randomly disbanded, hard to recycle, and the like, is solved, and the purpose of turning wastes into wealth is achieved. The machine tool bed cast from waste ceramics is mainly prepared from the following raw materials in parts by weight: 70-75 parts of waste ceramicpieces or waste ceramic granules, 8-15 parts of waste ceramic powder, 7-10 parts of an epoxy resin, 1.75-2.5 parts of a curing agent, 1 part of a carbon fiber, 1 part of a basalt fiber, 0-1 part of bismuth, Bi, 0-1 part of antimony, 8-10 parts of silicon powder and 0-10 parts of alumina powder.

Owner:福建振丰矿物新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com