Isolation material, cell back field back electrode and production method thereof, solar cell and production method thereof

A technology of solar cells and isolation materials, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of insufficient battery quality or reliability, lowering the resistivity of the electrode area, and inability to weld, and achieve performance such as component welding and reliability. Improvement, improved sintered compactness and thermal expansion coefficient, reduced effect of current collection voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

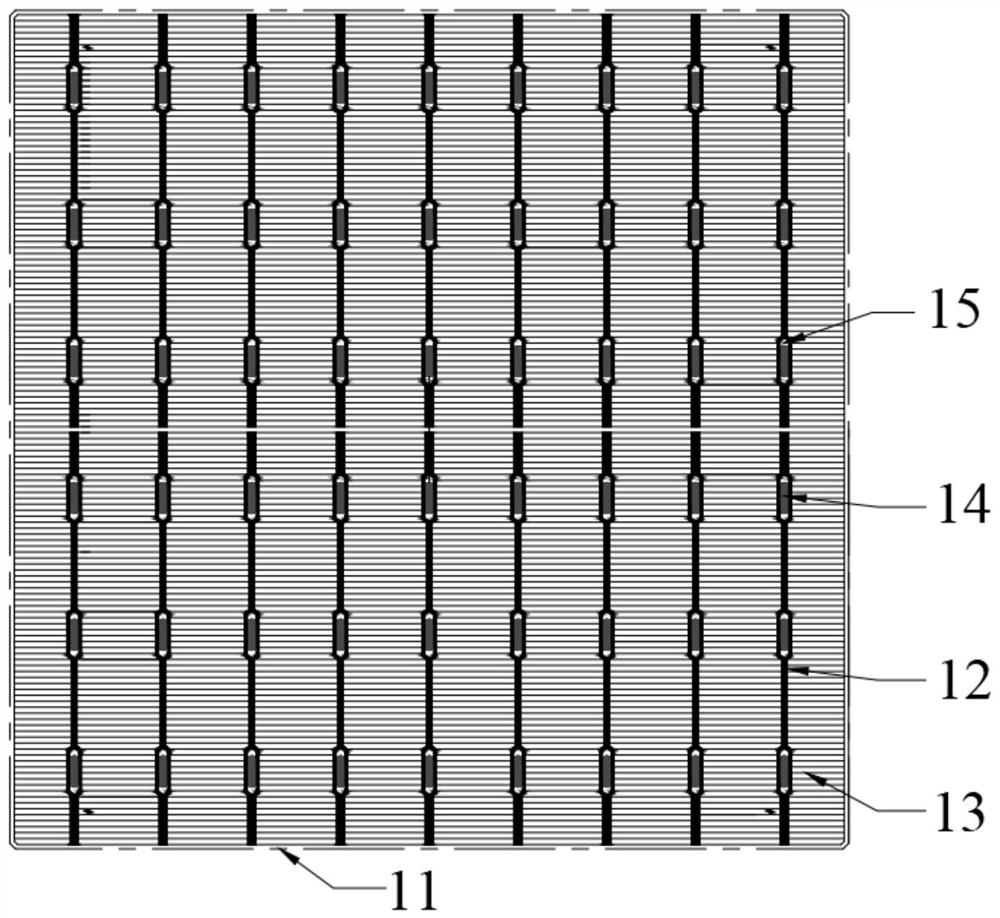

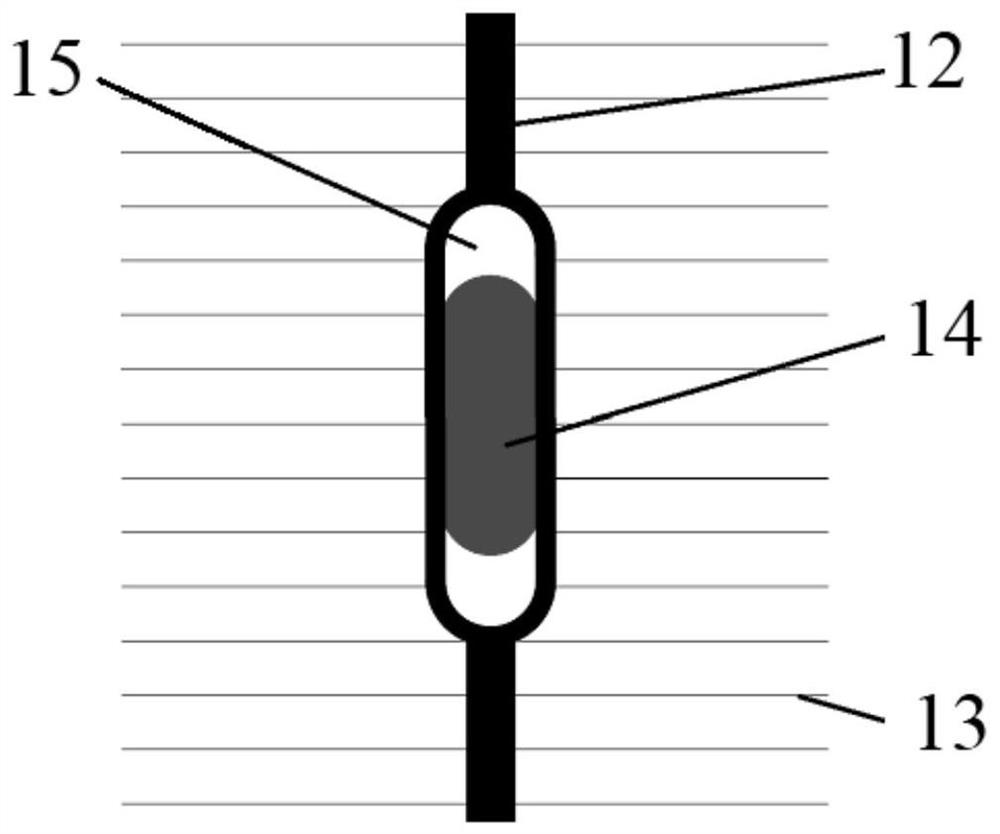

[0053] combine Figure 4-Figure 9 , the back pole of a kind of solar cell back field of present embodiment, comprises silicon back substrate 21, aluminum electrode 22 and silver electrode 24, and the aluminum electrode 22 of all-aluminum back field is set on the silicon back substrate 21, for single-sided cell, all aluminum The aluminum electrode 22 of the back field is that the aluminum back field covers the entire surface of the silicon back substrate 21. For a double-sided battery, the aluminum electrode 22 of the all-aluminum back field is also covered with an aluminum electrode on the back surface of the silicon wafer in the silver electrode area. The aluminum electrode 22 includes an aluminum electrode main grid 221 and an aluminum electrode sub grid 222, the aluminum electrode sub grid 222 is consistent with the design of a conventional double-sided battery, a laser grooved area 27 is arranged on the silicon back substrate 21, and the aluminum electrode sub grid 222 area...

Embodiment 2

[0057] The solar cell back field back pole structure of the present embodiment is as embodiment 1, and the preparation process of this back field back pole is as follows:

[0058] (1) The aluminum electrode 22 of the all-aluminum back field method is first prepared on the silicon back substrate 21. For a single-sided battery, the aluminum electrode 22 of the all-aluminum back field covers the entire back surface of the silicon wafer for the aluminum back field. For the double-sided battery, the aluminum electrode 22 of the all-aluminum back field is to cover the back surface of the silicon wafer with an aluminum electrode in the silver electrode area. The aluminum electrode sub-gate 222 is consistent with the design of the conventional double-sided battery. This area corresponds to the laser grooved area 27 one-to-one to realize the contact between the aluminum electrode 22 and the silicon back substrate 21, and realize the collection and derivation of the carriers on the back....

Embodiment 3

[0063] The structure and preparation process of the back field and back electrode of the solar cell in this embodiment are basically the same as in Embodiment 1 and Embodiment 2, and the isolation layer 26 inserted between the silver electrode 24 and the aluminum electrode 22 to block the direct contact between the silver electrode and the aluminum electrode The characteristics are as follows:

[0064] The isolation layer 26 is composed of the following ingredients in weight percentage: 35-80% of glass powder; 15-45% of organic vehicle and additives; 0.5-25% of auxiliary powder.

[0065] It is worth noting that the present invention solves the reliability problem of the all-aluminum back field route through the barrier material. The barrier material is mainly composed of glass powder. On the one hand, the glass powder physically separates the silver paste and the aluminum paste to avoid welding problems caused by mutual penetration during co-sintering. In addition, through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com