Lithium sodium codoping dental nucleated glass, and preparation and application thereof

A glass-ceramic and dental technology, applied in the direction of dental preparations, dentistry, dental prosthesis, etc., to achieve the effect of easy-to-obtain raw materials, increase strength, and promote the crystallization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

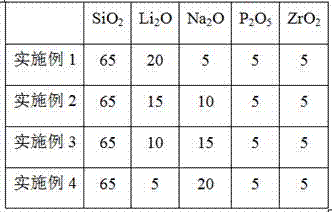

Embodiment 1

[0043] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、Na 2 CO 3 , NH 4 h 2 PO 4 and ZrO 2 ), use a ball mill to mix evenly for 8 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 4°C / min to 330°C and 850°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500°C and keep it warm for 1 hour; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, and the powder is directly heated to 1500°C / 1 hour for remelting ;Cast the remelted molten glass into a mold preheated at 550°C, quickly put it into a resistance furnace, heat it at 500°C for 10 minutes, then immediately rise to 550°C and hold it for 30 minutes, then cool with the furnace. The cast glass block is first subjected to nucleation at 625°C / 1 hour and crystalliz...

Embodiment 2

[0045] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、Na 2 CO 3 , NH 4 h 2 PO 4 and ZrO 2 ), use a ball mill to mix evenly for 8 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 4°C / min to 330°C and 850°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500°C and keep it warm for 1 hour; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, and the powder is directly heated to 1500°C / 1 hour for remelting ;Cast the remelted molten glass into a mold preheated at 550°C, quickly put it into a resistance furnace, heat it at 500°C for 10 minutes, then immediately rise to 550°C and hold it for 30 minutes, then cool with the furnace. The cast glass block is first subjected to nucleation at 610°C / 1 hour and crystalliz...

Embodiment 3

[0047] According to the ratio of each component in Table 1, a certain amount of analytically pure raw material (SiO 2 , Li 2 CO 3 、Na 2 CO 3 , NH 4 h 2 PO 4 and ZrO 2 ), use a ball mill to mix evenly for 8 hours; then put the powder into a platinum crucible, place it in the air atmosphere of a box-type resistance furnace, and heat it at 4°C / min to 330°C and 850°C for 1 hour each to remove nitrogen and carbon , continue to heat up to 1500°C and keep it warm for 1 hour; then, take out the crucible, pour the melt into deionized water to quench, and dry to obtain fragments of glass melt; ball mill again, and the powder is directly heated to 1500°C / 1 hour for remelting ;Cast the remelted molten glass into a mold preheated at 550°C, quickly put it into a resistance furnace, heat it at 500°C for 10 minutes, then immediately rise to 550°C and hold it for 30 minutes, then cool with the furnace. The cast glass block is first subjected to nucleation at 605°C / 1 hour and crystalliz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com