Complete set of titanium ceramic powder for dental department and preparation method thereof

A technology of porcelain powder and porcelain powder, which is applied in dental preparations, dentistry, dental prosthesis, etc., can solve the problems of porcelain layer fracture and poor bonding strength, and achieve the effect of reducing the temperature of porcelain and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

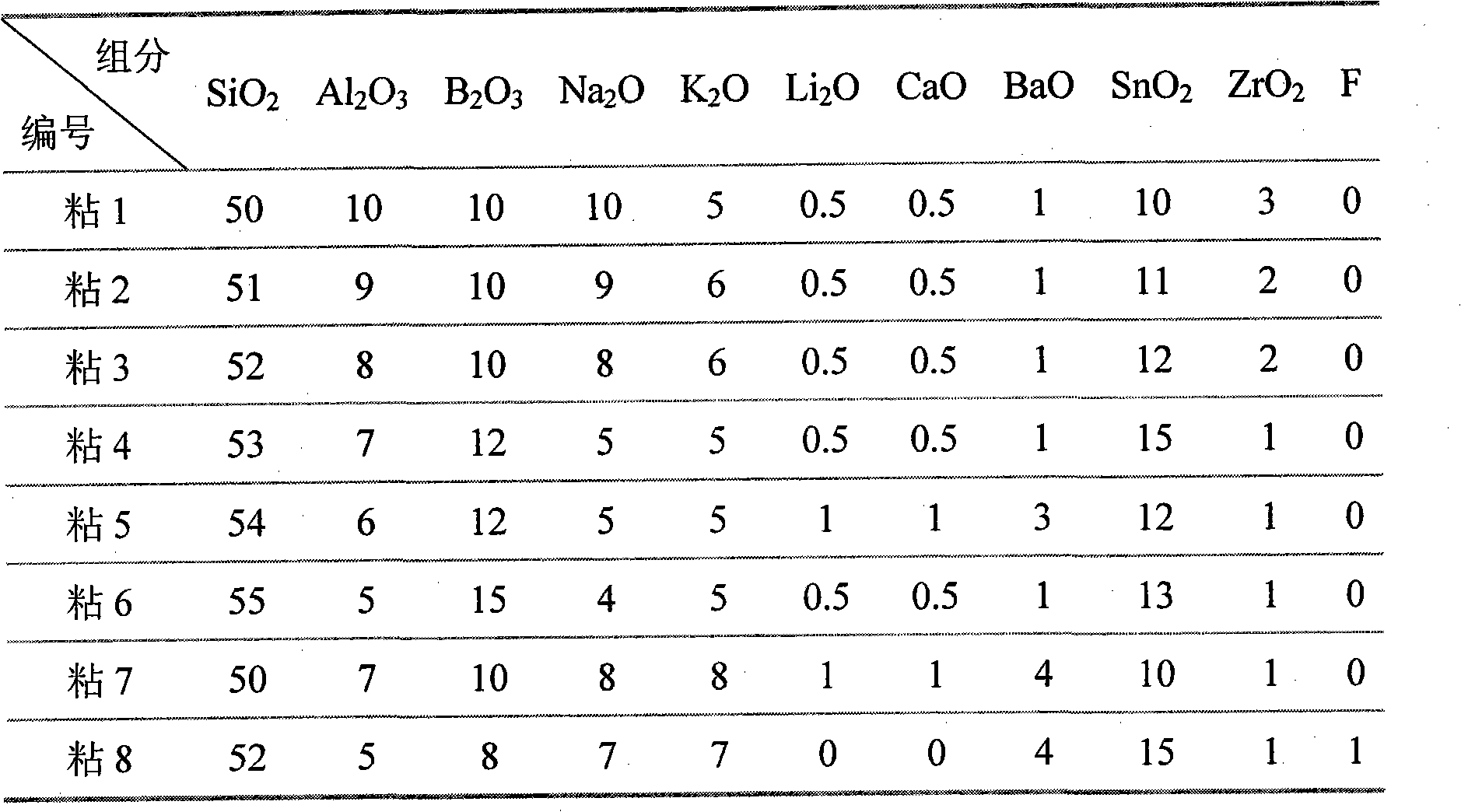

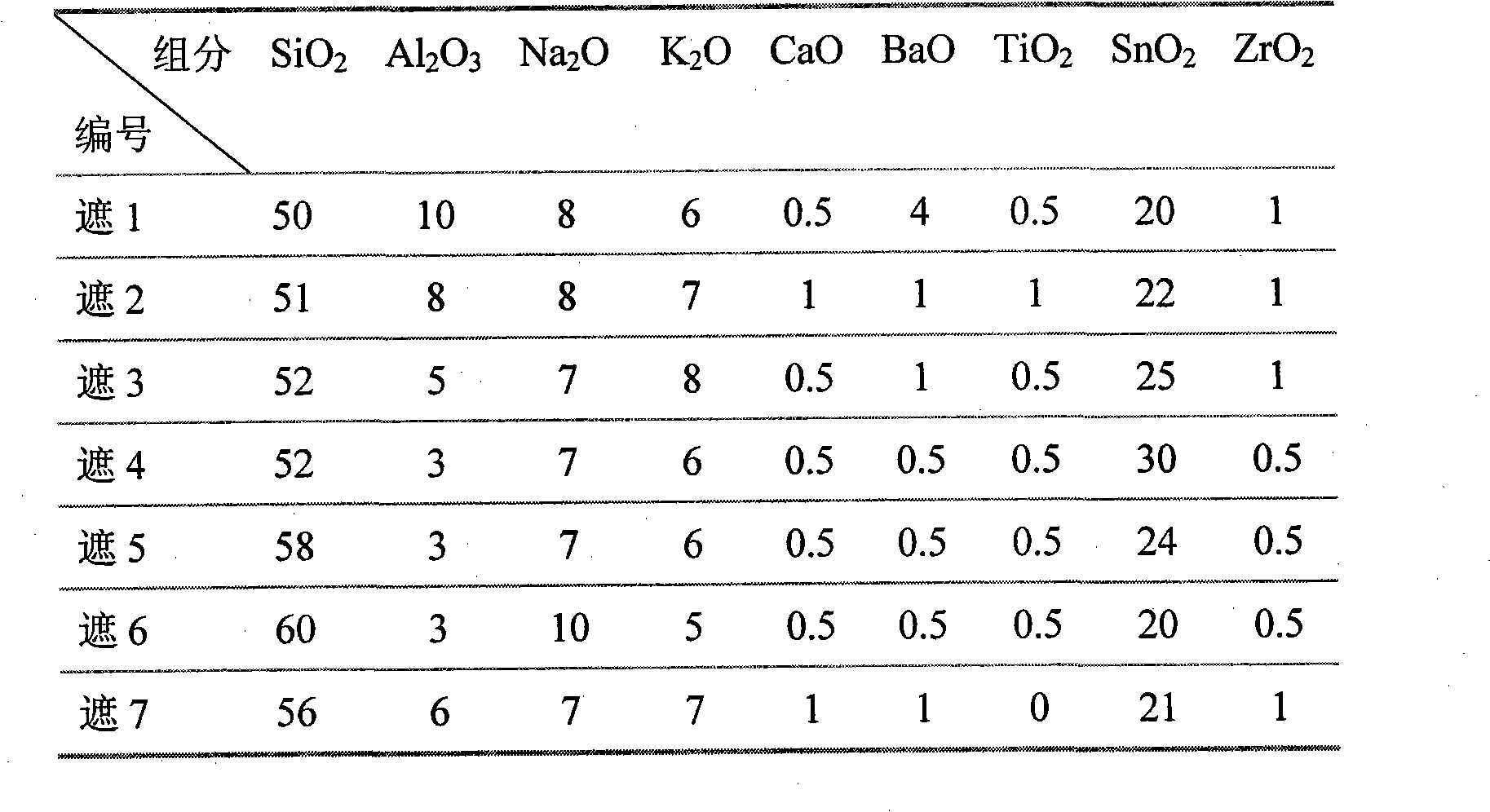

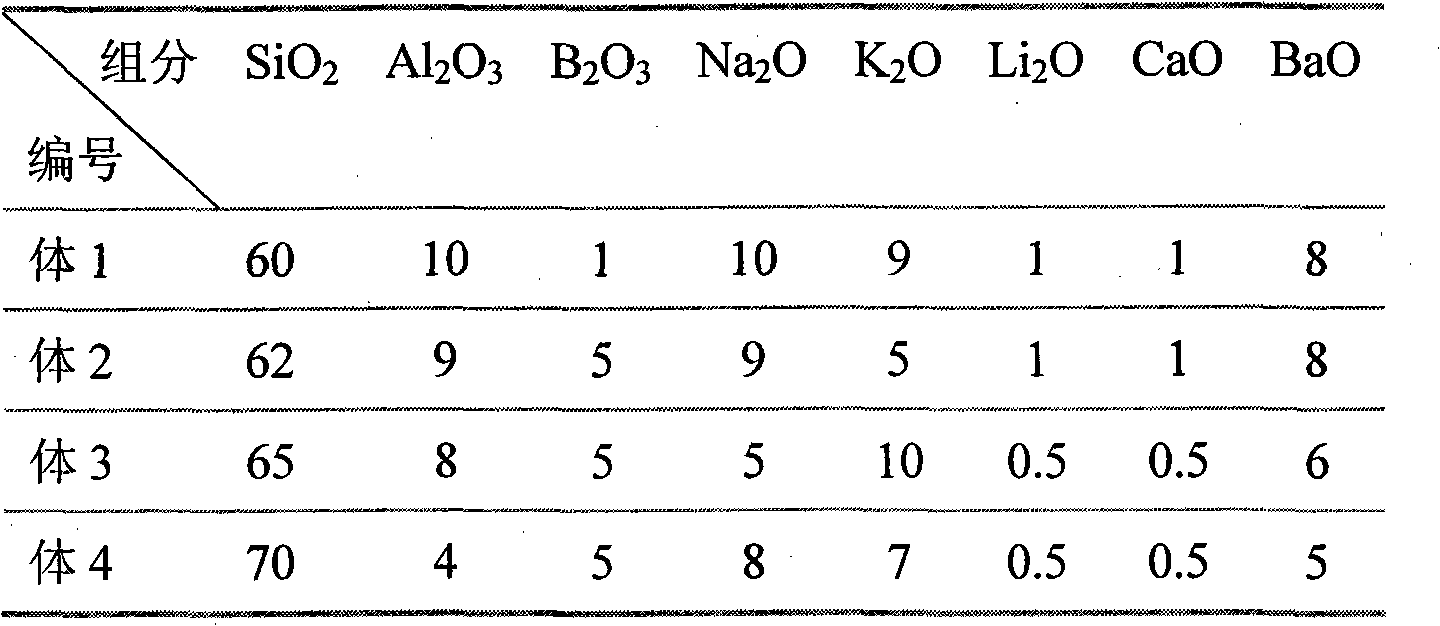

[0025] A set of titanium porcelain powders for dentistry, including bonded porcelain powders, opaque porcelain powders and body porcelain powders. Among them: the composition of the bonding porcelain powder is shown in Table 1. A total of 8 trials with specific formulations were carried out.

[0026] When calculating the actual formula, SiO 2 、Al 2 o 3 , CaO, SnO 2 , ZrO 2 Introduced directly with oxides, B 2 o 3 Introduced with boric acid, Na 2 O, K 2 O. Li 2 O and BaO are introduced with the corresponding carbonates, and F is introduced with the corresponding fluorides. The other elements introduced in the fluorides are considered in the calculation and the corresponding elements are deducted. According to the composition, calculate the corresponding addition amount of various raw materials.

[0027] Table 1

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com