Lightweight aluminum alloy composite material, compressor roller and preparation method of compressor roller

A composite material and aluminum alloy technology, which is applied in the field of aluminum alloy materials and its preparation, can solve problems affecting energy efficiency, noise maintenance, poor corrosion resistance, high specific weight, etc., and achieve improved self-lubricating performance, improved wear resistance, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

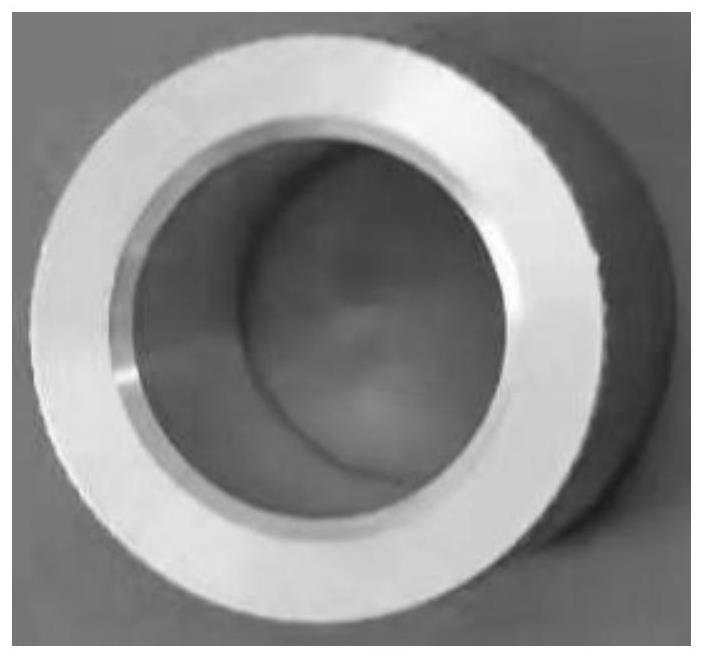

Image

Examples

Embodiment 1

[0025] Composition characteristics of aluminum alloy ceramic composite material: aluminum 67.613%, silicon 18.2%, copper 2.275%, magnesium 1.82%, zirconium 0.182%, iron 0.455%, nickel 0.455%, molybdenum disulfide 1%, zirconia 2%, silicon carbide powder 6%. Among them, the base aluminum alloy content is 91%. The ingredient ratio of the base aluminum alloy is: 74.3% of aluminum, 20% of silicon, 2.5% of copper, 2.0% of magnesium, 0.2% of zirconium, 0.5% of iron and 0.5% of nickel.

[0026] Lubricating phase: molybdenum disulfide 1%.

[0027] Ceramic phase: zirconia 2%, silicon carbide powder 6%.

[0028] Roller preparation:

[0029] (1) Proportion of matrix alloy Raw materials are taken from raw materials, melted and atomized by rapid solidification gas atomization to make matrix alloy powder, and the powder is sieved through 100 mesh. Wherein, in the method of rapid solidification gas atomization, the atomizing gas is nitrogen or air, and the temperature of the atomizing mel...

Embodiment 2

[0042] The difference with embodiment 1 is:

[0043] Composition characteristics of aluminum alloy ceramic composite material: aluminum 63.063%, silicon 22.75%, copper 2.3%, magnesium 1.84%, zirconium 0.184%, iron 0.46%, nickel 0.46%, molybdenum disulfide 1%, zirconia 2%, silicon carbide powder 6%. Among them, the base aluminum alloy content is 91%. The ingredient ratio of the base aluminum alloy is: 69.3% of aluminum, 25% of silicon, 2.5% of copper, 2.0% of magnesium, 0.2% of zirconium, 0.5% of iron and 0.5% of nickel.

Embodiment 3

[0045] The difference with embodiment 1 is:

[0046] Composition characteristics of aluminum alloy ceramic composite material: aluminum 63.063%, silicon 22.75%, copper 2.3%, magnesium 1.84%, zirconium 0.184%, iron 0.46%, nickel 0.46%, molybdenum disulfide 1%; silicon carbide 8%. Among them, the base aluminum alloy content is 91%. The ingredient ratio of the base aluminum alloy is: 69.3% of aluminum, 25% of silicon, 2.5% of copper, 2.0% of magnesium, 0.2% of zirconium, 0.5% of iron and 0.5% of nickel.

[0047] Lubricating phase: molybdenum disulfide 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com