Tungsten-copper composite material and preparation method thereof

A composite material, tungsten-copper technology, applied in the field of tungsten-copper composite materials and its preparation, can solve the problems of insufficient continuous and uniform material structure, poor ablation resistance, etc., to achieve enhanced ablation resistance, enhanced strength, and improved uniformity of structure The effect of sex and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

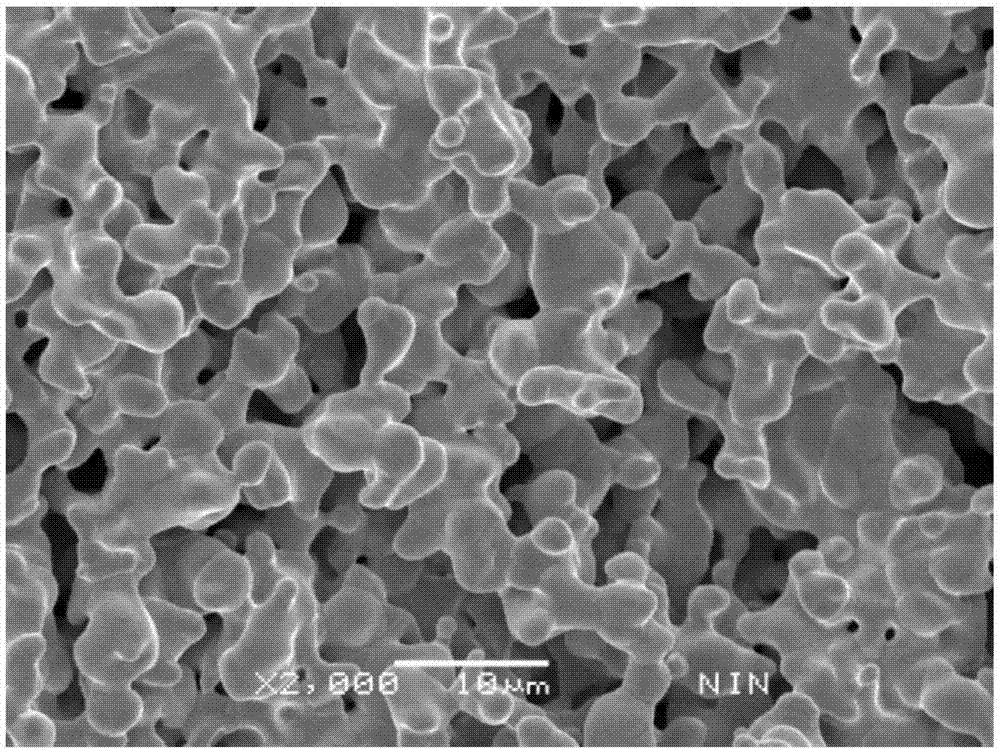

[0040] This embodiment includes the following steps:

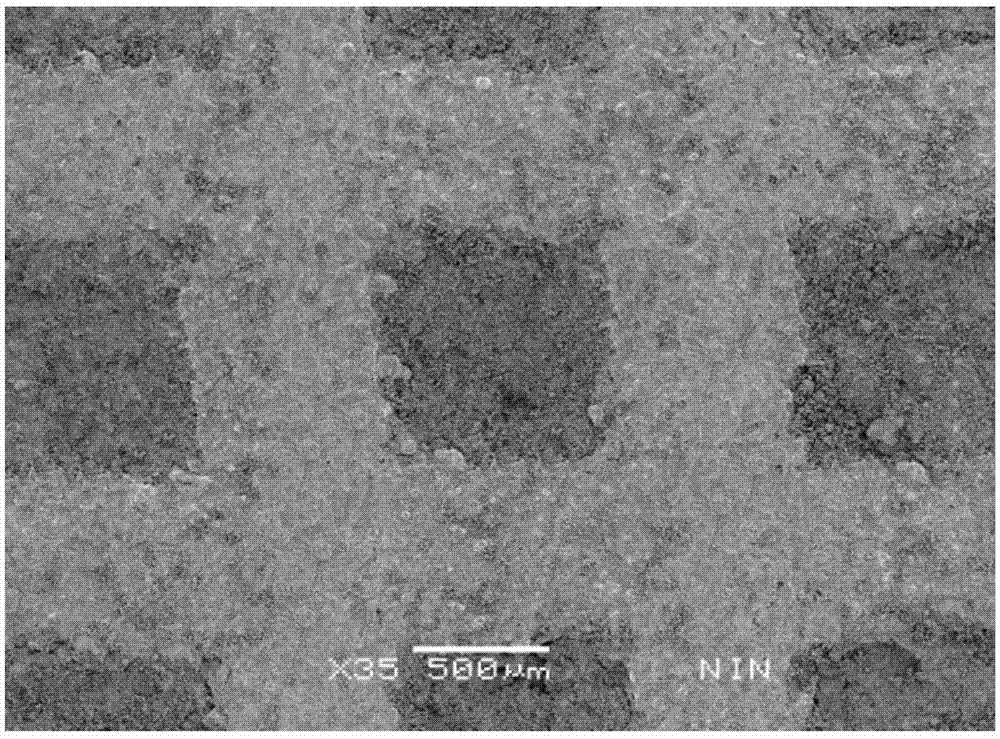

[0041] Step 1. The tungsten skeleton 1 is prepared by electron beam selective melting and forming, and the specific process is as follows:

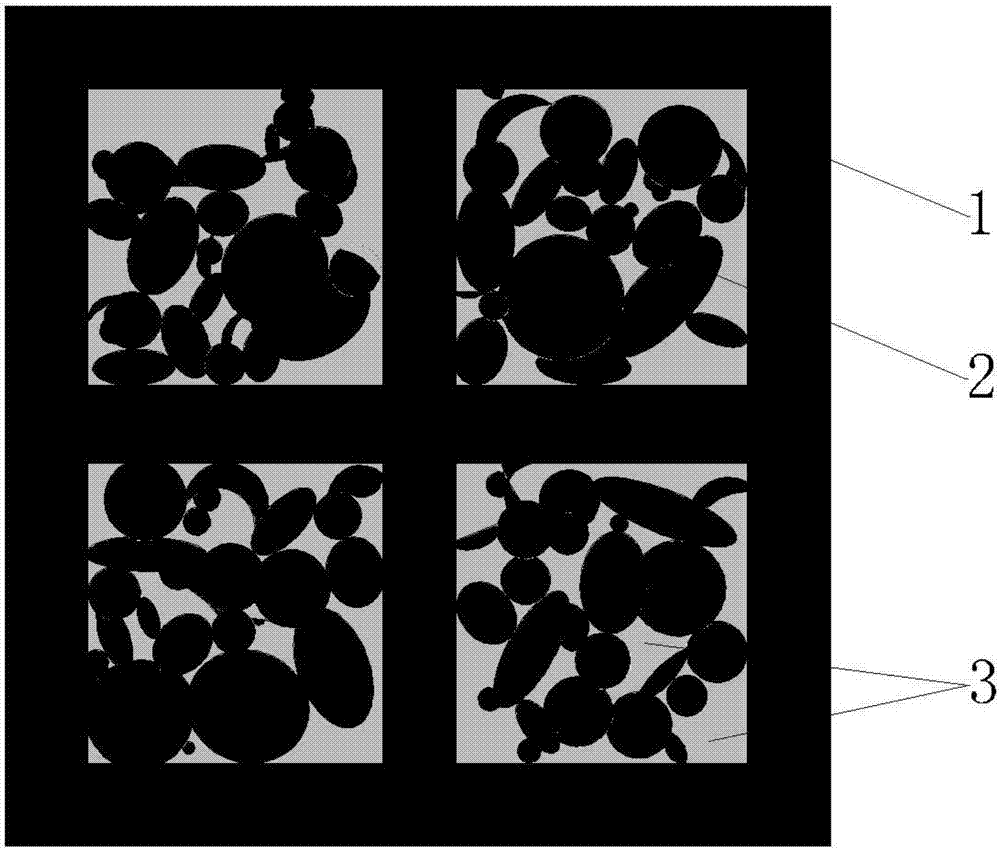

[0042] Step 101, using three-dimensional modeling software to establish a three-dimensional model of the tungsten skeleton 1, the size of the tungsten skeleton 1 is 20mm×20mm×20mm, and the porosity is 40%;

[0043] Step 102, slice the three-dimensional model of the tungsten skeleton 1 established in step 101 by slice software, the thickness of each slice is 50 μm, obtain the slice data, and then import the slice data into the electron beam selective melting forming equipment;

[0044]Step 103: Spread the tungsten powder on the bottom plate of the electron beam selective melting forming equipment according to the slice data in the electron beam selective melting forming equipment, and use the electron beam to perform selective melting of the tungsten powder to form a single-layer solid...

Embodiment 2

[0055] This embodiment includes the following steps:

[0056] Step 1. The tungsten skeleton 1 is prepared by electron beam selective melting and forming method, and the specific process is as follows:

[0057] Step 101, using three-dimensional modeling software to establish a three-dimensional model of the tungsten skeleton 1, the size of the tungsten skeleton 1 is 20mm×20mm×20mm, and the porosity is 45%;

[0058] Step 102, slice the three-dimensional model of the tungsten skeleton 1 established in step 101 by using layer-slicing software, the thickness of each slice is 100 μm, and obtain layer-slicing data, and then import the layer-slicing data into the electron beam selective melting forming equipment;

[0059] Step 103: Spread the tungsten powder on the bottom plate of the electron beam selective melting forming equipment according to the slice data in the electron beam selective melting forming equipment, and use the electron beam to perform selective melting of the tungs...

Embodiment 3

[0067] This embodiment includes the following steps:

[0068] Step 1. The tungsten skeleton 1 is prepared by electron beam selective melting and forming method, and the specific process is as follows:

[0069] Step 101, using three-dimensional modeling software to establish a three-dimensional model of the tungsten skeleton 1, the size of the tungsten skeleton 1 is 20mm×20mm×20mm, and the porosity is 50%;

[0070] Step 102, slice the three-dimensional model of the tungsten skeleton 1 established in step 101 by slice software, the thickness of each slice is 70 μm, obtain the slice data, and then import the slice data into the electron beam selective melting forming equipment;

[0071] Step 103: Spread the tungsten powder on the bottom plate of the electron beam selective melting forming equipment according to the slice data in the electron beam selective melting forming equipment, and use the electron beam to perform selective melting of the tungsten powder to form a single-lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com