Synthetic method of superhigh temperature resistant zirconium carbide ceramic precursor

A technology of ceramic precursors and synthesis methods, applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of poor compatibility between materials, toxicity of raw materials, poor stability, etc., to improve product performance and solvent toxicity. Small, low synthesis temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

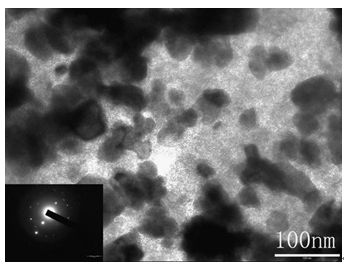

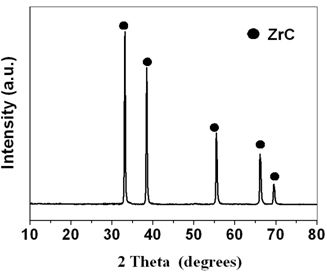

[0017] Example 1: 6.44 g of zirconium oxychloride was dissolved in 50 mL of anhydrous methanol, stirred at room temperature to dissolve, then cooled in an ice bath, 2.48 g of salicyl alcohol was added dropwise, and finally 4.24 g of triethylamine was added dropwise at a rate of 1 Drops / second, magnetic stirring is performed during the dropwise addition. After the dropwise addition, the ice bath was removed, and the reaction was carried out at room temperature for 4 h. The solvent was evaporated by rotary evaporation for 10 min, 50 mL of tetrahydrofuran was added, stirred at room temperature for 2 h, filtered with suction, and the precipitate of triethylamine hydrochloride was filtered off. The solvent was evaporated from the filtrate by rotary evaporation for 15 min, and 100 mL of n-hexane was added, stirred at room temperature for 12-48 h, filtered to obtain a light yellow precipitate, and vacuum-dried at 50 °C for 3 h to obtain the zirconium carbide precursor. The precursor...

Embodiment 2

[0019] Example 2: 6.44 g of zirconium oxychloride was dissolved in 50 mL of anhydrous methanol, stirred at room temperature to dissolve, then cooled in an ice bath, 3.47 g of salicyl alcohol was added dropwise, and finally 4.24 g of triethylamine was added dropwise at a rate of 1 Drops / second, magnetic stirring is performed during the dropwise addition. After the dropwise addition, the ice bath was removed, and the reaction was carried out at room temperature for 4 h. Rotary steam for 10 min to remove the solvent, add 50 mL of tetrahydrofuran, stir at room temperature for 2 h, and filter with suction to remove the precipitate of triethylamine hydrochloride. The solvent was evaporated from the filtrate by rotary evaporation for 15 min, and 100 mL of n-hexane was added, stirred at room temperature for 12-48 h, filtered to obtain a light yellow precipitate, and vacuum-dried at 50 °C for 3 h to obtain the zirconium carbide precursor. The precursor is easily soluble in organic sol...

Embodiment 3

[0020] Example 3: 6.44 g of zirconium oxychloride was dissolved in 50 mL of anhydrous methanol, stirred at room temperature to dissolve, then cooled in an ice bath, 3.22 g of salicyl alcohol was added dropwise, and finally 4.24 g of triethylamine was added dropwise at a rate of 1 Drops / second, magnetic stirring is performed during the dropwise addition. After the dropwise addition, the ice bath was removed, and the reaction was carried out at room temperature for 4 h. Rotary steam for 10 min to remove the solvent, add 50 mL of tetrahydrofuran, stir at room temperature for 2 h, and filter with suction to remove the precipitate of triethylamine hydrochloride. The solvent was evaporated from the filtrate by rotary evaporation for 15 min, and 100 mL of n-hexane was added, stirred at room temperature for 12-48 h, filtered to obtain a light yellow precipitate, and vacuum-dried at 50 °C for 3 h to obtain the zirconium carbide precursor. The precursor is easily soluble in organic sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com