Method of preparing corrosive thermal insulation anti-ablation composite coating on light alloy surface

A composite coating and light alloy technology, which is applied to the device for coating liquid on the surface, anti-corrosion coating, coating, etc., can solve the problems of poor bonding force, poor heat resistance performance, difficult control of coating quality and thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

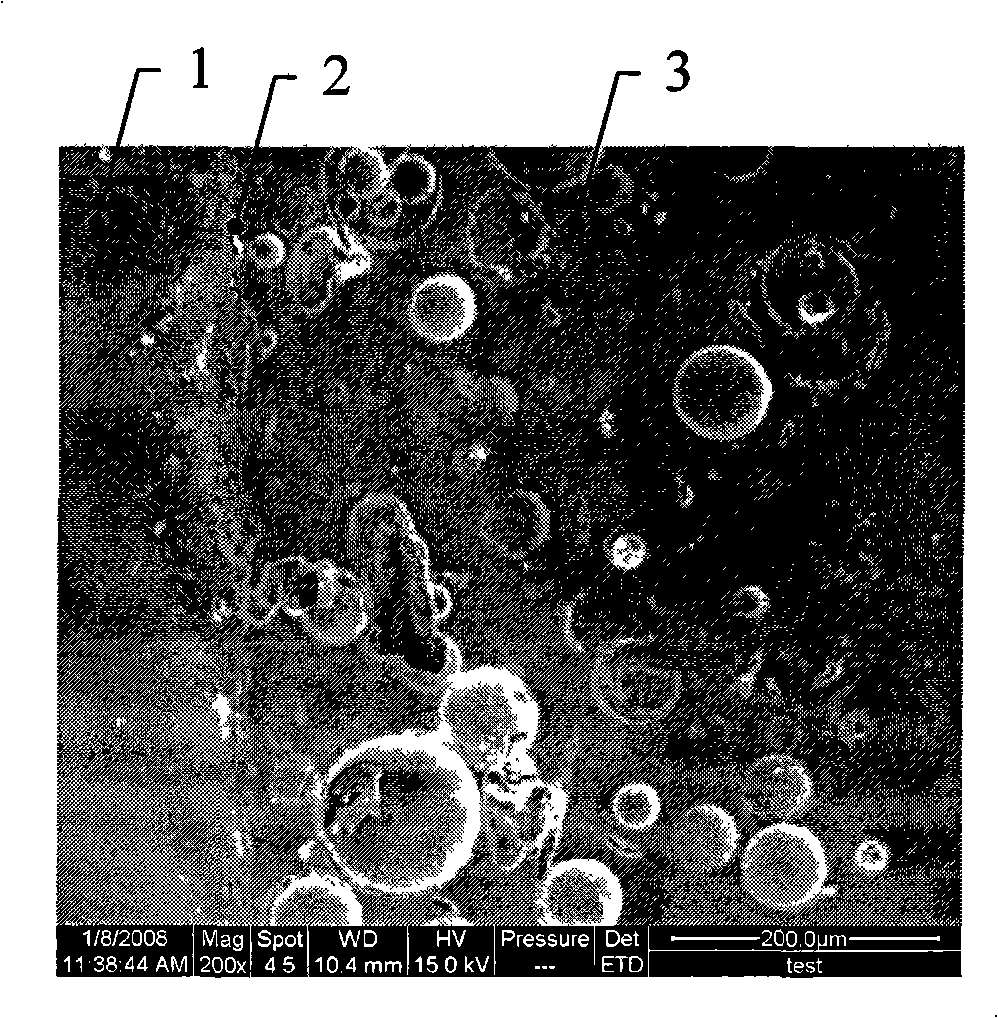

Image

Examples

specific Embodiment approach 1

[0009] Specific Embodiment 1: In this embodiment, the method for preparing an anti-corrosion, heat-insulating and anti-ablation composite coating on the surface of a light alloy is carried out as follows: 1. After degreasing the surface of the light alloy, connect the positive output end of the pulse power supply to the light alloy 1. Connect the negative output terminal of the pulse power supply to the stainless steel, then put the light alloy and stainless steel into the electrolytic tank, and make the alkaline electrolyte in the electrolytic tank submerge the light alloy and stainless steel to ensure that the light alloy and stainless steel are not in the electrolytic tank Contact; 2. Turn on the power supply, control the output voltage of the pulse power supply to 400-650V, the frequency is 400-800Hz, the duty cycle is 4%-20%, the output time is 30-100min, and the temperature of the electrolyte is controlled during the power-on process Below 50°C, the surface micro-arc oxid...

specific Embodiment approach 2

[0012] Specific embodiment two: the differences between this embodiment and specific embodiment one are: in step two, the output voltage of the control pulse power supply is 450-550V, the frequency is 500-700Hz, the duty cycle is 8%-16%, the output time 50-80 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: The differences between this embodiment and Embodiment 1 are: in step 2, the output voltage of the control pulse power supply is 500V, the frequency is 600Hz, the duty cycle is 12%, and the output time is 65min. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire ablation rate | aaaaa | aaaaa |

| Mass ablation rate | aaaaa | aaaaa |

| Wire ablation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com