Silicon carbide fiber reinforced aluminium phosphate ceramic-based composite and preparation method thereof

A silicon carbide fiber and composite material technology, applied in the field of composite ceramic materials, can solve problems such as the decline of mechanical properties at room temperature and high temperature, weak oxidation resistance of carbon fibers, corrosion of quartz fibers, etc., and achieve excellent mechanical properties, good bonding effect, and low temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment is a silicon carbide fiber-reinforced aluminum phosphate ceramic-based composite material. The aluminum phosphate ceramic-based composite material uses silicon carbide fiber as a reinforcement and aluminum phosphate as a matrix.

[0026] Step 1. Put the silicon carbide fiber cloth cut to a suitable size into acetone and wash it in ultrasonic for 1 hour, and then put it in an oven for drying; the drying temperature is 80°C; the ultrasonic power is 100W.

[0027] Step 2. Preparation of silicon carbide fiber cloth anti-oxidation coating. Put the silicon carbide fiber cloth in step 1 into the polyamic acid solution with a concentration of 20wt% for 10 minutes for dipping treatment, then take it out and perform heat treatment at high temperature to obtain a silicon carbide fiber cloth with an anti-oxidation coating. Repeat this process to obtain multiple pieces of silicon carbide fiber cloth with anti-oxidation coating.

[0028] Step 3. Preparation of alumin...

Embodiment 2-9

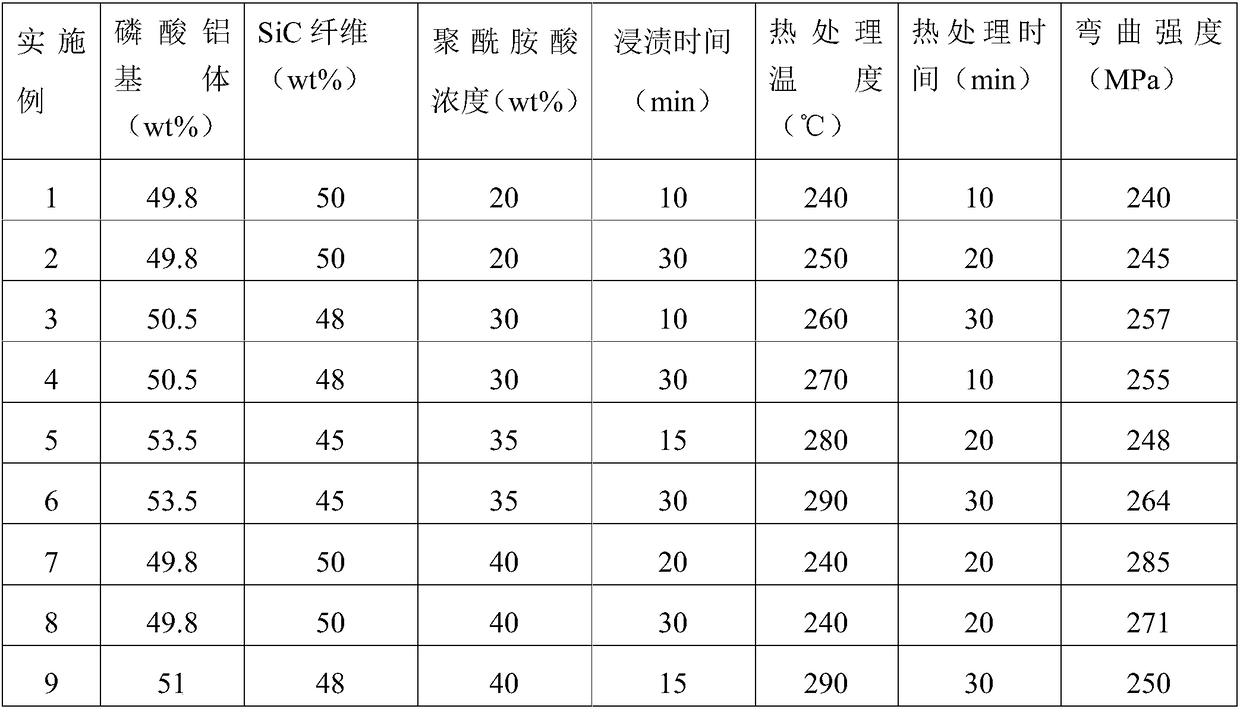

[0031] Using the same steps as in Example 1 to prepare silicon carbide fiber reinforced aluminum phosphate ceramic matrix composites, the mass fraction of fiber cloth, polyamic acid concentration, dipping time, high temperature treatment temperature, treatment time and bending strength after preparation during the preparation process Specifically as shown in Table 1:

[0032] Table 1 Example 1-9 preparation conditions and test results

[0033]

Embodiment 10

[0035] Step 1. Put the silicon carbide fiber cloth cut to a suitable size into acetone and wash it in ultrasonic for 1 hour, and then put it in an oven for drying; the drying temperature is 80°C; the ultrasonic power is 100W.

[0036] Step 2. Preparation of silicon carbide fiber cloth anti-oxidation coating. Put the silicon carbide fiber cloth in step 1 into the polyamic acid solution with a concentration of 30wt% and soak it for 20 minutes, carry out the dipping treatment, then take it out, and perform heat treatment at 290°C for 20 minutes to obtain the silicon carbide fiber with an anti-oxidation coating cloth. Repeat this process to obtain multiple pieces of silicon carbide fiber cloth with anti-oxidation coating.

[0037] Step 3. Preparation of aluminum phosphate slurry. Phosphoric acid (H 3 PO 4 ), aluminum hydroxide (Al(OH) 3) and alumina to prepare aluminum phosphate slurry. Put a certain amount of phosphoric acid into a beaker, then put the beaker into a 90°C wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com