Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

193results about How to "Guaranteed conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion secondary battery using lithium iron phosphate as anode material with overall consideration of high and low temperature performance

InactiveCN101394008AExtended operating temperature rangeWide temperature rangeSecondary cellsPhosphateEthyl butyrate

The invention discloses an aqueous electrolyte solution of a secondary lithium ion battery with ferric phosphate considering as the positive material and with both the high temperature performance and the low temperature performance. The aqueous electrolyte solution comprises LiPF6 lithium salt, an organic solvent and a film-forming additive, and is characterized in that the electrolyte solution further comprises high temperature additive; the organic solvent is composed of one or a plurality of carbonic esters and one or more carboxylic esters with low melting point and high boiling point. The carboxylic esters with low melting point and high boiling point are selected from one or a combination of methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate. The high temperature additive is 1, 3- propane sultone and 1, 4- butane sultone. The electrolyte solution is used for maintaining both the circulation performance in a high temperature state and the low temperature laying performance of the secondary lithium ion battery with the ferric phosphate lithium as the positive material.

Owner:GUANGZHOU TINCI MATERIALS TECH

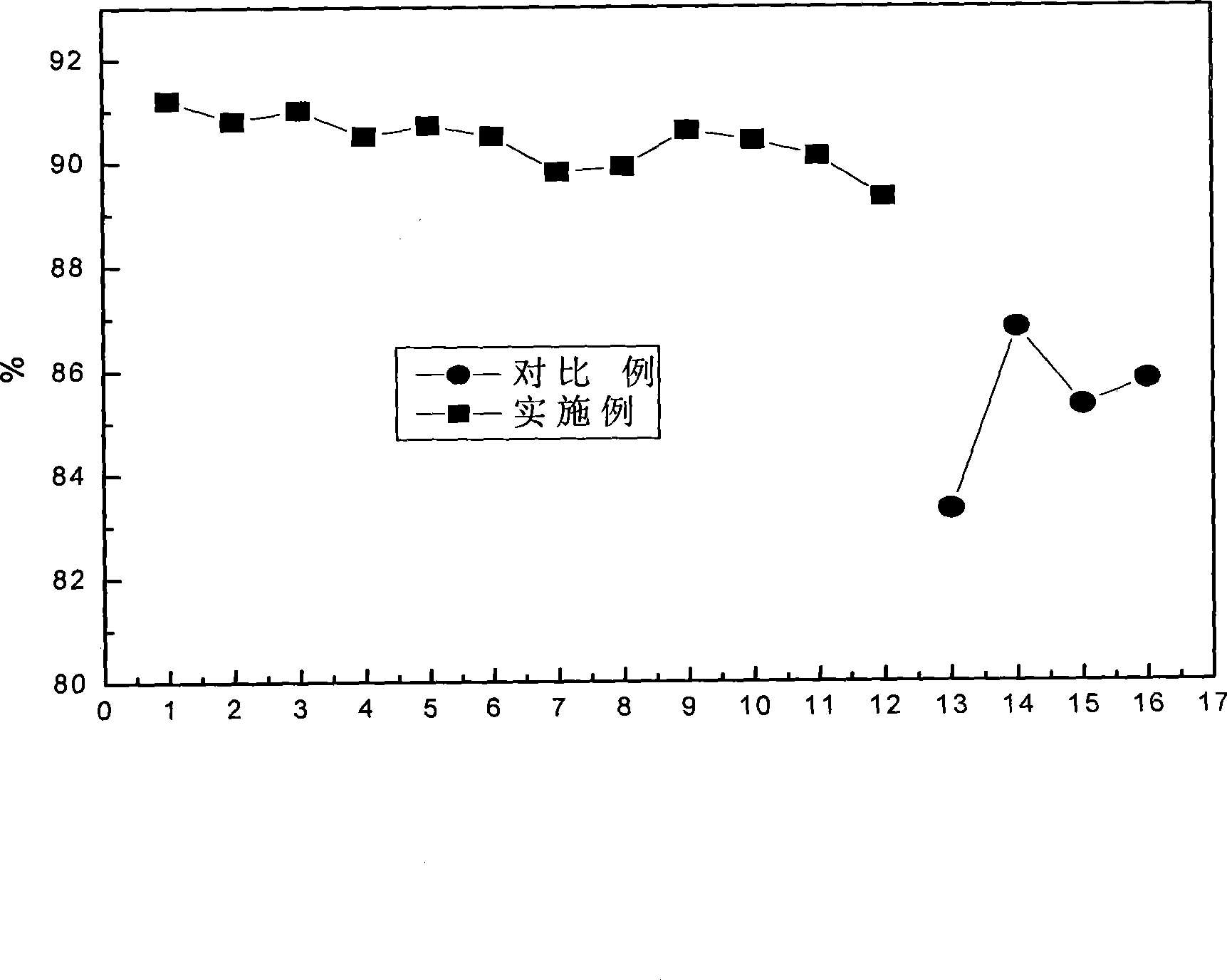

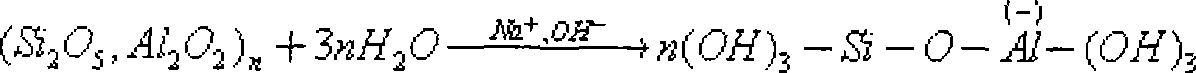

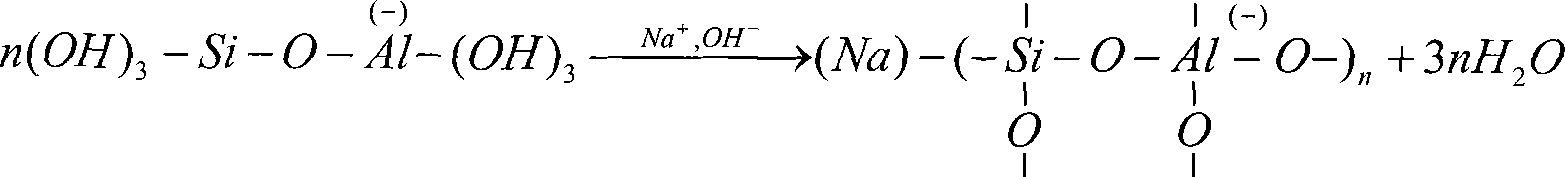

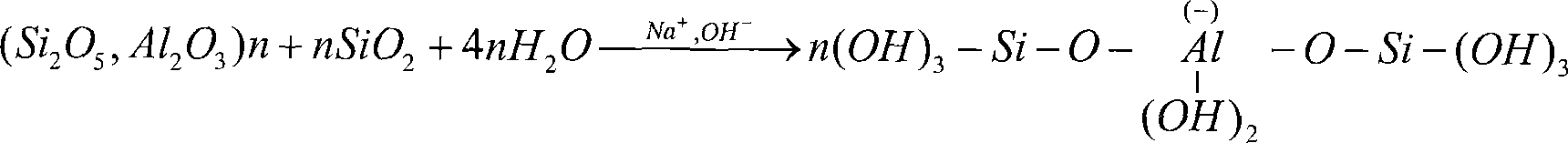

Geo polymer base composite material double pole plate and its preparing method

InactiveCN101051691AImprove volume stabilityReduce manufacturing costCell electrodesFuel cell detailsFiberCarbon fibers

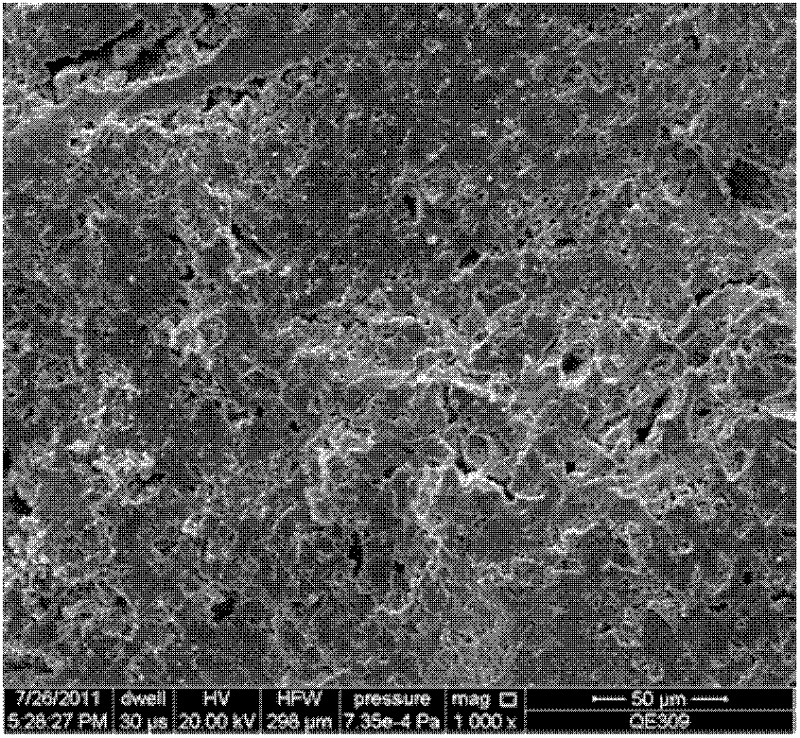

Characters of bipolar plate of polymer based composite material are that it is produced from materials of Meta kaolin, conductance material, and solution of water glass. The conductance material is composed of graphite and carbon fiber. Doping quantity of graphite is 20-40% of mass of meta kaolin, and doping quantity of carbon fiber is 10-20%. Mass ratio between solution of water glass, meta kaolin, and conductance material 0.4-0.8:1. The said Meta kaolin is obtained by calcinating kaolin in coal series sold on market or pure kaolin at 600-850 deg.C. Modulus m of solution of water glass is equal to 2.8-3.5, and Baume degree is equal to 35-45. Features of the bipolar plate are: low cost, good corrosion resistance, high mechanical strength, light weight, good conductivity, no poison and pollution on fuel cell of proton exchange membrane.

Owner:WUHAN UNIV OF TECH

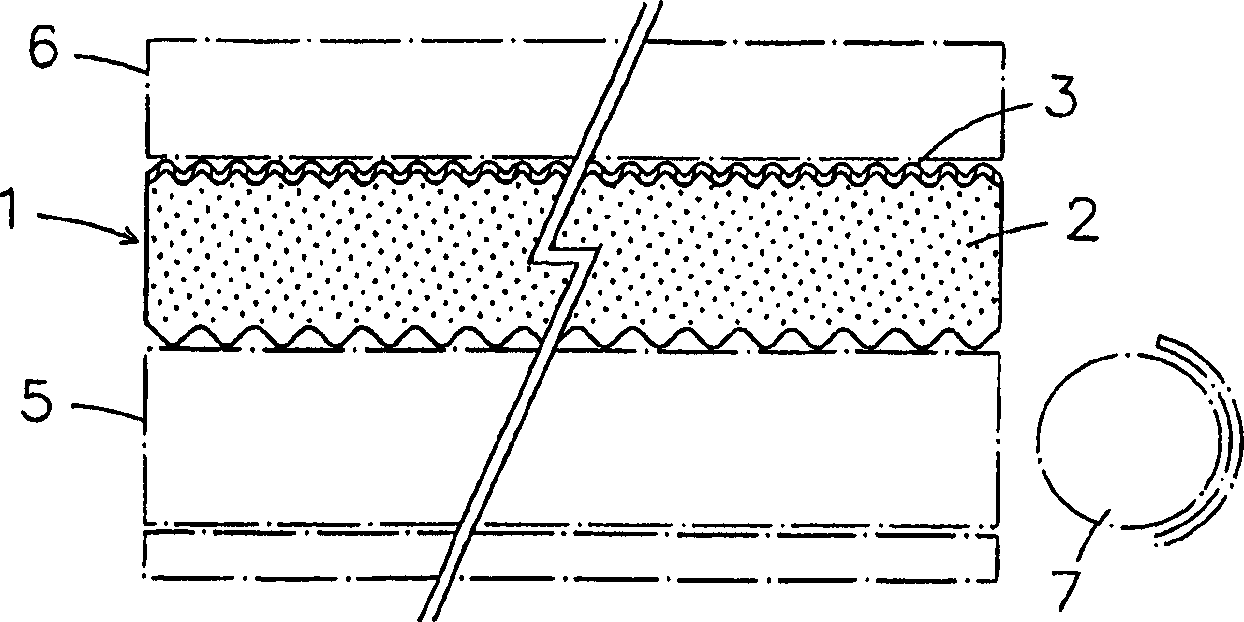

Electromagnetic-shielding light diffusion sheet

InactiveCN1781034ASatisfactory conductivityGuaranteed conductivityLayered productsDiffusing elementsDiffusionSurface resistivity

An electromagnetic-shielding light-diffusing plate having good electromagnetic-shielding performance and high light transmittance is disclosed. Light diffused from the electromagnetic-shielding light-diffusing plate is uniform and has little variation in brightness. The electromagnetic-shielding light-diffusing plate is characterized in that a light-transmitting conductive layer with a surface resistivity not exceeding 105Ω / □ is formed on at least one surface of the main body of the light-diffusing plate.

Owner:多喜兰株式会社

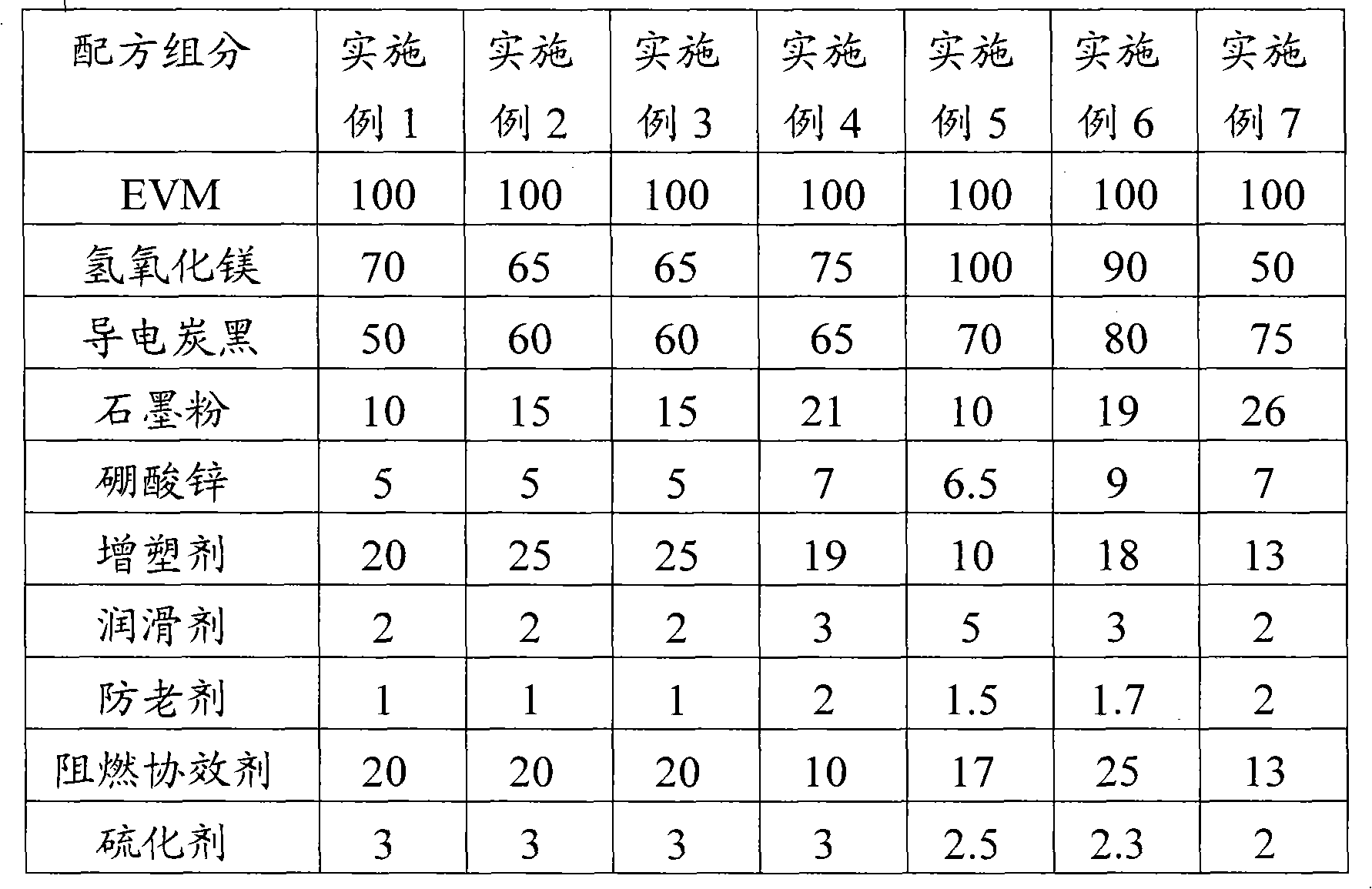

Conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and preparation method thereof

ActiveCN101942144AGood oil resistanceLow crystallization plasticizing temperatureInsulated cablesNon-conductive material with dispersed conductive materialVulcanizationHazardous substance

The invention relates to a conductive screening material, in particular to a conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and a preparation method thereof. The conductive screening material comprises the following basic components: 100 parts of ethylene-vinyl acetate rubber, 50-100 parts of magnesium hydroxide, 50-80 parts of conductive black, 10-30 parts of graphite powder, 5-10 parts of zinc borate, 10-25 parts of plasticizer, 2-5 parts of lubricant, 1-2 parts of antiager, 10-30 parts of flame retarding synergist, 2-3 parts of vulcanizer and 1-2 parts of vulcanization assistant. The preparation method comprises the four steps of material preparation, mixing, extrusion and tabletting. The conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material has the advantages of high conductivity, good oil resistivity, excellent flame retarding effect, no peculiar smell, easy stripping and high heat resistance level, and can pass the environment protection authentication of RoHS (Restriction of the use of certain Hazardous Substances Registration), REACH (Evaluation, Authorization and Restriction of Chemicals) and the like.

Owner:中广核三角洲(江苏)塑化有限公司

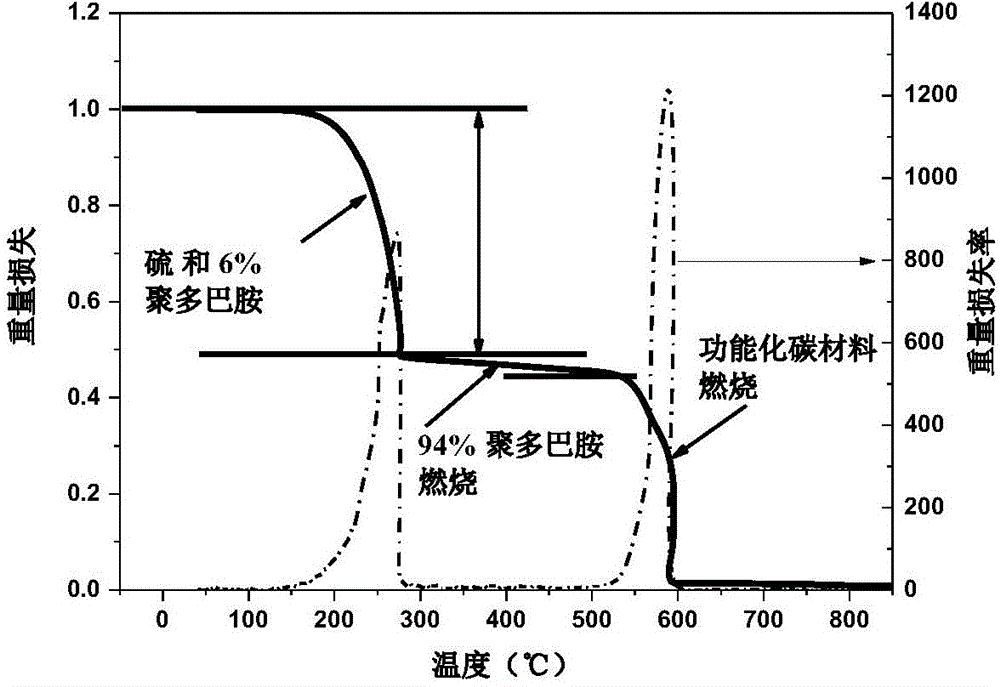

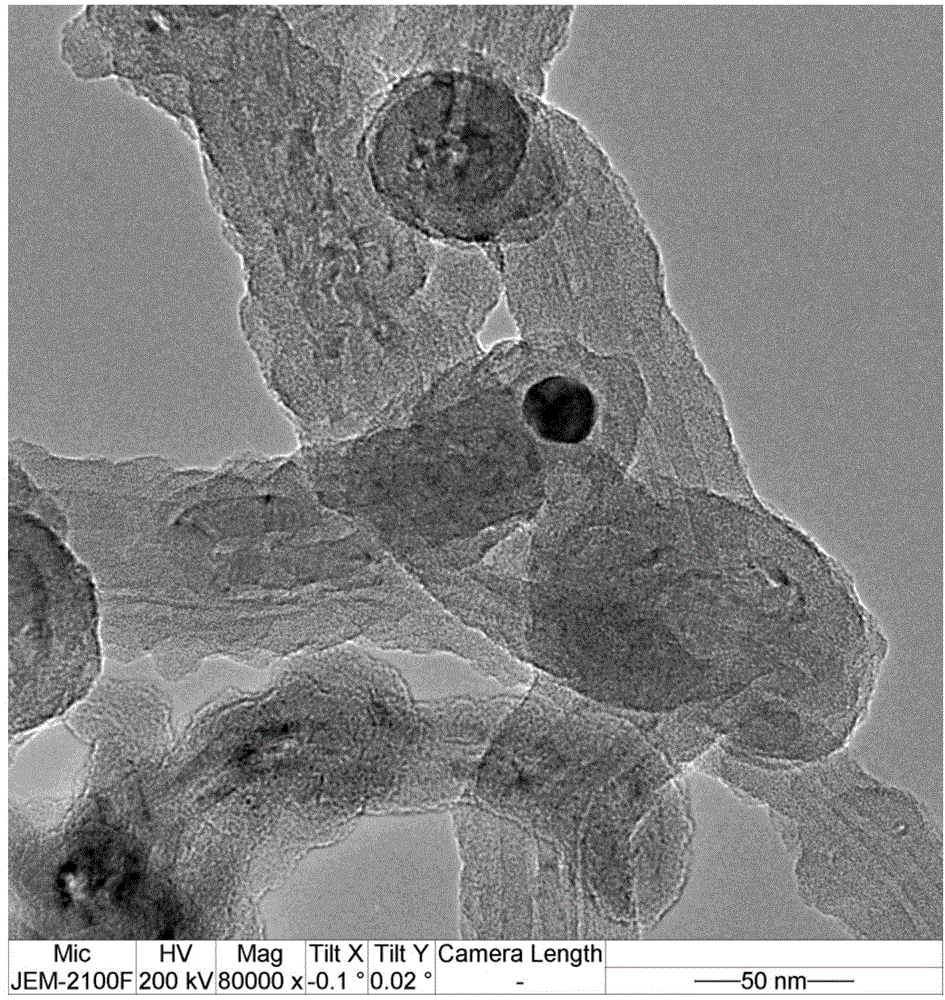

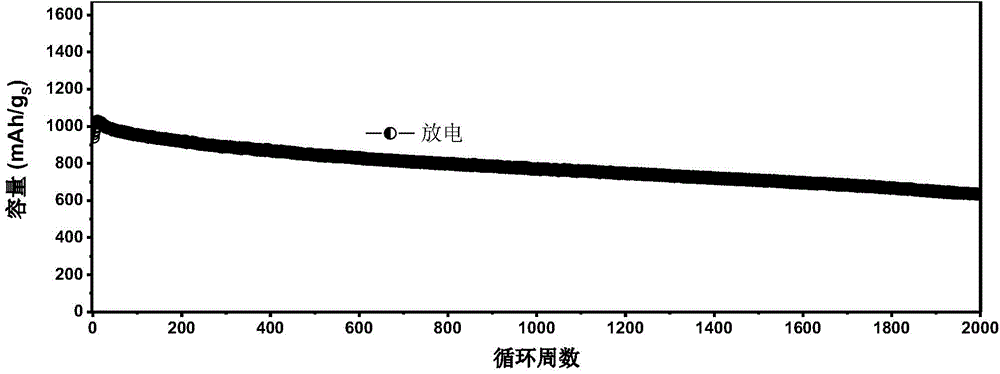

Anode material of lithium-sulfur battery, lithium-sulfur battery and method for preparing anode material

ActiveCN104617327AGuaranteed conductivityGood structural stabilityCell electrodesLi-accumulatorsCarboxylationDopamine hcl

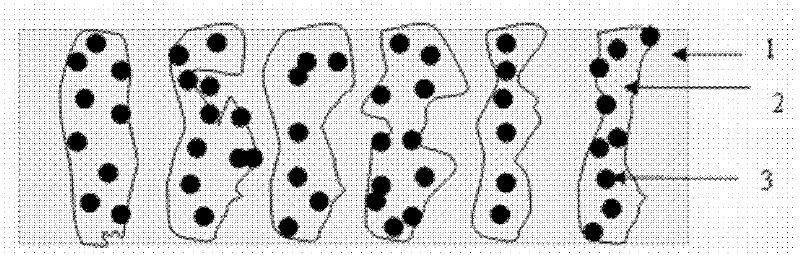

The invention relates to an anode material of a lithium-sulfur battery, the lithium-sulfur battery and a method for preparing the anode material, and belongs to the field of battery materials. The center of the anode material is made of a functionalized carbon nano-material, the middle interlayer is made from sulfur, and the outer layer adopts a polydopamine film, wherein the functionalization method is hydroxylation or carboxylation. The preparation method comprises the following steps: dissolving the carbon nano-material in an alkaline or acid liquid to obtain the functionalized carbon nano-material; adding the functionalized carbon nano-material in a sulfur water solution, stirring, dropwise adding diluted acid to the solution, and obtaining the functionalized carbon nano-material coated with sulfur on the outer side; adding the functionalized carbon nano-material coated with sulfur on the outer side in a tris(hydroxymethyl) methane buffer solution, and performing a polymerization reaction to a dopamine hydrochloride solution, so as to obtain the anode material. The invention further relates to the lithium-sulfur battery using the anode material. The battery can further comprise a polyethylene diaphragm modified by polydopamine. The anode material can inhibit the shuttle flying effect and the structural damage caused by volume expansion; and the lithium-sulfur battery is good in cycle performance and capacity retention ratio.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

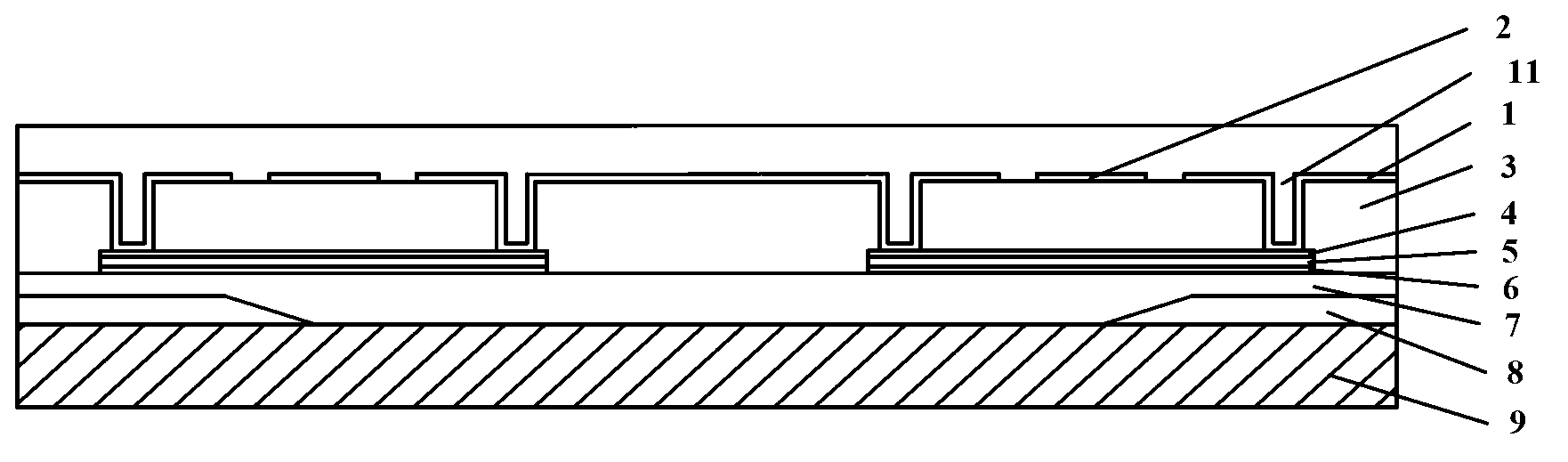

Touch screen, electronic equipment including same and method for manufacturing same

InactiveCN102799311AGuaranteed conductivityAvoid Oxide ResistanceElectronic switchingInput/output processes for data processingOrganic matterMetal

The invention relates to the technical field of touch screens, and in particular relates to a touch screen, electronic equipment including the same and a method for manufacturing the same. The touch screen comprises driving electrode layers, a transparent polymerization organic matter layer and a metal bridge, wherein the metal bridge is used for conducting two adjacent driving electrode layers; and a protective layer for covering the metal bridge and preventing oxidization of the metal bridge is arranged between the driving electrode layers and the metal bridge. According to the touch screen provided in the invention, as the protective layer covers the metal bridge, the metal bridge is not subjected to an oxidation reaction due to the contact of the metal bridge and a transparent polymerization organic matter, thus the conductivity of the metal bridge is effectively guaranteed, the impedance of an oxidation layer is avoided from increasing, and the yield of the touch screen is improved.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Capacitive touch control panel

ActiveCN105183246AImprove touch sensitivityReduce light transmissionInput/output processes for data processingElectrical and Electronics engineeringElectrode

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Preparation process for high-strength high-conductivity micro copper wire

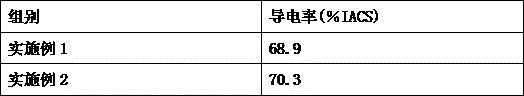

The invention discloses a preparation process for a high-strength high-conductivity micro copper wire. The preparation process comprises the following steps: S1, adding electrolytic copper into a smelting furnace, preserving heat and melting the electrolytic copper completely to obtain molten copper, introducing an inert gas, adding a composite refining agent, standing and slagging; S2, detecting that the molten copper comprises the following components in percentage by weight: 0.45 to 0.55 percent of Ti, 0.25 to 0.35 percent of Zr, 0.07 to 0.09 percent of Te, 0.07 to 0.09 percent of La, 0.03 to 0.05 percent of Y, 0.15 to 0.25 percent of Sn, less than or equal to 0.05 percent of Mg, and the balance of Cu; S3, enabling a crystallizer of a continuous casting machine to extend into the molten copper, and drawing upwards through a drawing roller mechanism to form an oxygen-free copper rod; S4, extruding the oxygen-free copper rod continuously and drawing repeatedly to obtain the high-strength high-conductivity micro copper wire. According to the copper wire which is prepared by the preparation process, the electric conductivity reaches over 95 percent IACS, and moreover, the tensile strength is also over 480 MPa.

Owner:安徽晋源铜业有限公司

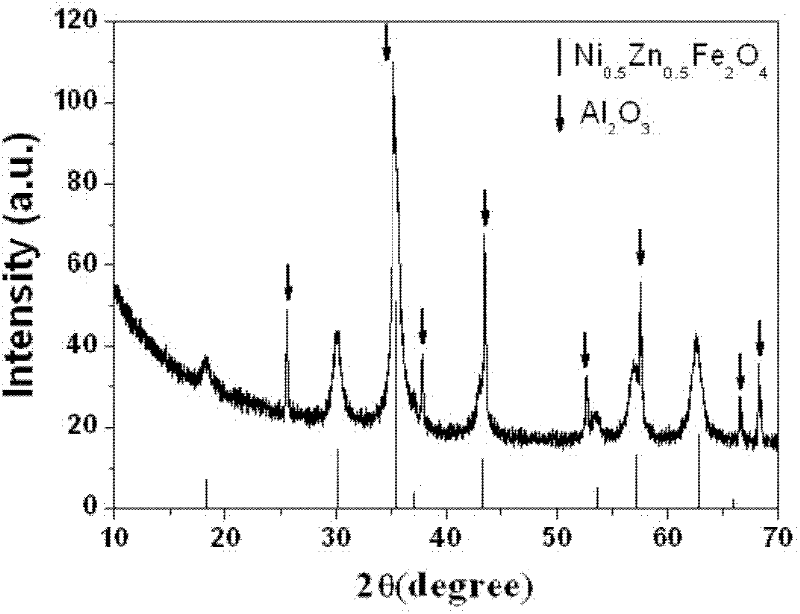

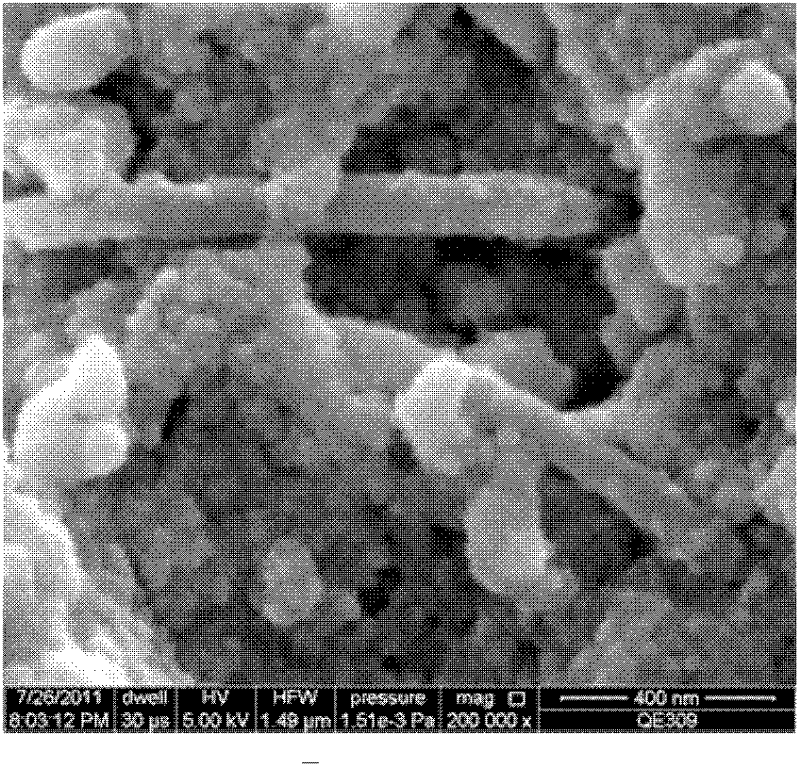

Ferrite-based ceramic composite material as well as preparation method and application thereof

ActiveCN102390989AMeet low temperature requirementsRealize the structureCeramic compositeStructure and function

The invention discloses a ferrite-based ceramic composite material as well as a preparation method and application thereof. The composite material is composed of ferrite, a carbon nanotube and a ceramic material, wherein the ferrite and the ceramic material are cladded on the tube wall of the carbon nanotube, and the ceramic material is one or several kinds of aluminum oxide, aluminum nitride, and silicon nitride. The three phases of materials, namely, the ferrite, the carbon nanotube and the ceramic, are compounded to make the advantages and disadvantages of all phases of materials complementary, so that the electrical conductance of the composite material is increased, the impedance matching performance of the composite material is improved, the wave absorption performance of the composite material is made adjustable, the structure and function integration of the ferrite-based ceramic material is realized, and thus, the application range of the composite material in the high-tech field is expanded. In addition, the powder of the composite material is prepared by adopting a coprecipitation hydrothermal method and is further prepared into a block material by adopting a microwave sintering method, and the ferrite-based ceramic composite material has the advantages that all phases are dispersed uniformly, the densification degree of the sintered material is high, the production cost is low, and the large-scale industrialization is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-conductivity thermal-treatment type medium-strength aluminum alloy conducting filament

ActiveCN104975211AHigh strengthGuaranteed conductivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsThermal treatmentHigh conductivity

The invention provides a high-conductivity thermal-treatment type medium-strength aluminum alloy conducting filament, and belongs to the technical field of electric transmission line overhead conductors of the electric power industry. The high-conductivity thermal-treatment type medium-strength aluminum alloy conducting filament solves the technical problems that in the prior art, conductivity is low, and electric transmission line loss is high. The microstructure of alloy is adjusted by controlling the content of B, Mg, Si, Cu and other microalloying elements and adopting the thermal treatment process, and therefore the medium-strength aluminum alloy filament is developed, wherein the conductivity of the filament is not smaller than 59.2% IACS (20 DEG C), the tensile strength of the filament is not smaller than 240 MPa, and the ductility of the filament is not smaller than 4.0%.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +6

Method for preparing anode of solid oxide fuel cell by using immersion method

InactiveCN102332588AWide variety of sourcesImprove conductivityCell electrodesAir atmospherePorosity

The invention discloses a method for preparing an anode of a solid oxide fuel cell by using an immersion method, belongs to the method for preparing the anode of a fuel cell, and solves the problem of easiness in performance weakening caused by low stability and easiness in aging of the conventional anode, which is prepared by using the immersion method, of the solid oxide fuel cell. The method comprises the following steps of: 1, preparing immersion liquid; 2, adding the immersion liquid into a porous anode supporting body, and roasting; 3, repeating the step 2, and sintering in an air atmosphere; and 4, restoring, and thus obtaining the anode of the solid oxide fuel cell. The method has the advantages that: selectable raw material sources are wide; a preparation process is simple; expensive experimental instruments are not required; large-scale application can be realized; the stability of the anode, which is prepared by using the immersion method with a dispersing agent, of the solid oxide fuel cell is improved; the electric conductivity and catalytic performance of the anode can be improved; porosity can be guaranteed by immersion of the porous anode supporting body; and fuel gas can smoothly reach the anode and an electrolyte interface for reaction, and generated water is drained.

Owner:HARBIN INST OF TECH

Conductance compound material and preparing process

InactiveCN101252029AGuaranteed conductivityGuaranteed corrosion resistanceAldehyde/ketone condensation polymer adhesivesNon-conductive material with dispersed conductive materialEpoxyMass ratio

The present invention relates to a conductive composite material and a manufacture art thereof, in particular to a mixed epoxy resin and phenolic resin / graphite matrix conductive composite material and a manufacture art thereof. The mass ratio of the material formula is as follows: graphite material of 70 to 90 percent; epoxy resin of 0 to 24 percent; phenolic resin of 30 to 2 percent. The manufacture art is as follows: (1) preparing the epoxy resin, the phenolic resin and the graphite according to the mass percent; (2) mixing and grinding the epoxy resin, the phenolic resin and the graphite to obtain refined and even mixed powder, the granularity is between 100 meshes and 180 meshes; (3) packing the mixed powder into a pressing molding mold; heat-pressing and sintering to mold; the molding temperature is from 180 to 310 DEG C; the molding pressure is from 10 to 40 MPa; and the temperature pressure keeping time is from 30 to 120 min. The material is mainly used for producing bipolar plates of proton exchange membrane fuel cells and other electrodes. In the condition that the conductivity rate and corrosion resistant capacity are ensured, the conductive composite material has comparatively high strength and density. The manufacture art of the conductive composite material is simple, energy-saving, environmentally friendly, low in cost and wide in application range.

Owner:SHANDONG UNIV

High voltage electrolyte for lithium ion batteries

ActiveCN104282939AImprove solubilityAvoid structural changesSecondary cellsSolubilityHydrofluoroether

The invention discloses a high voltage electrolyte for lithium ion batteries, the high voltage electrolyte is composed of an organic solvent, electrolyte lithium salt and a cathode film-forming additive, wherein the organic solvent is a mixed solvent of fluorinated ethylene carbonate, trifluorinated propylene carbonate and hydrofluoroether, the electrolyte lithium salt mixed is lithium salt of lithium hexafluorophosphate and lithium bis(oxalate)borate. The high voltage electrolyte effectively solves the problems that fluorinated solvents are high in viscosity and the electrolyte lithium salt is poor in solubility in fluorinated organic solvents, so that the fluorinated organic solvents can be directly used as the organic solvents in lithium ion battery electrolyte, the high voltage electrolyte has wide electrochemical window and good oxidation resistance and high voltage resistant characteristics, has high electric conductivity, can guarantee the high magnification and power characteristics of a power battery, is high in safety, and can greatly improve the safety performance of the power battery.

Owner:WANXIANG 123 CO LTD

Electro-conductive filament

InactiveCN105803276ASimple preparation processEasy to operateMetal/alloy conductorsElectro conductivityDuctility

The invention provides an electro-conductive filament which is characterized in that trace amounts of B and Sc are added into a Al-Mg-Si alloy and heat treatment is carried out after wiredrawing at room temperature. The invention aims to solve the technical problems of low electro-conductivity and high transmission line loss. As the contents of microalloying elements of B, Mg, Si and Sc and the technology for heat treatment are controlled to adjust the microstructure of an alloy, the moderately strong electro-conductive filament being 59.5% IACS (20 DEG C) or higher in electro-conductivity, 250 MPa or higher in tensile strength and 4.5% or higher in ductility is obtained.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +6

Method for preparing graphene conductive polymer conductive adhesive and graphene conductive polymer conductive adhesive

ActiveCN104178074AGuaranteed conductivityEvenly dispersedAldehyde/ketone condensation polymer adhesivesNon-conductive material with dispersed conductive materialPolymer scienceConductive polymer

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Preparation method of proton exchange membrane and polyimide perfluorosulfonic acid resin proton exchange membrane obtained thereby

InactiveCN102477162AEvenly distributedThe content is easy to controlCell component detailsFuel cell detailsAcetic anhydridePolyamide

The present invention provides a preparation method of a proton exchange membrane. The method comprises dispersing perfluorosulfonic acid resin in an organic solvent with a high boiling point of 140-205 DEG C to obtain a perfluorosulfonic acid resin solution; adding an organic thermal stabilizer and aromatic diamine into the perfluorosulfonic acid resin solution, and adding aromatic dianhydride to obtain a polyamic acid perfluorosulfonic acid resin solution; coating the polyamic acid perfluorosulfonic acid resin solution on a glass plate, and drying to obtain a polyamic acid perfluorosulfonic acid resin composite membrane; and soaking the composite membrane in a mixed solvent containing acetic anhydride and pyridine, and allowing cyclodehydration reaction at a room temperature to obtain a polyimide perfluorosulfonic acid resin proton exchange membrane. The prepared proton exchange membrane has high electrical conductivity and good high-temperature resistance, and it is free of through holes, to thereby improve safety of batteries.

Owner:BYD CO LTD

Polyaniline-sulfonated graphene composite electrode material and preparation method thereof

ActiveCN104681300AEasy to prepareLow cost of preparationHybrid capacitor electrodesHybrid/EDL manufacturePolyvinylidene fluorideCurrent collector

The invention discloses a polyaniline-sulfonated graphene composite electrode material and a preparation method thereof. The preparation method comprises the following steps: fully mixing an aniline monomer with sulfonated graphene uniformly; performing in-situ polymerization to synthesize a polyaniline-sulfonated graphene composite material; doping with sulfuric acid; mixing the composite material, acetylene black and polyvinylidene fluoride; preparing N-methyl pyrrolidone as a solvent; coating slurry on a current collector stainless steel sheet for drying to obtain the composite electrode material. The preparation method is simple, rapid and environmentally-friendly in process. The prepared composite electrode material has the advantages of excellent rate performance, high circulation stability, high specific capacitance and the like, and is suitable for a super capacitor electrode material.

Owner:TIANJIN UNIV

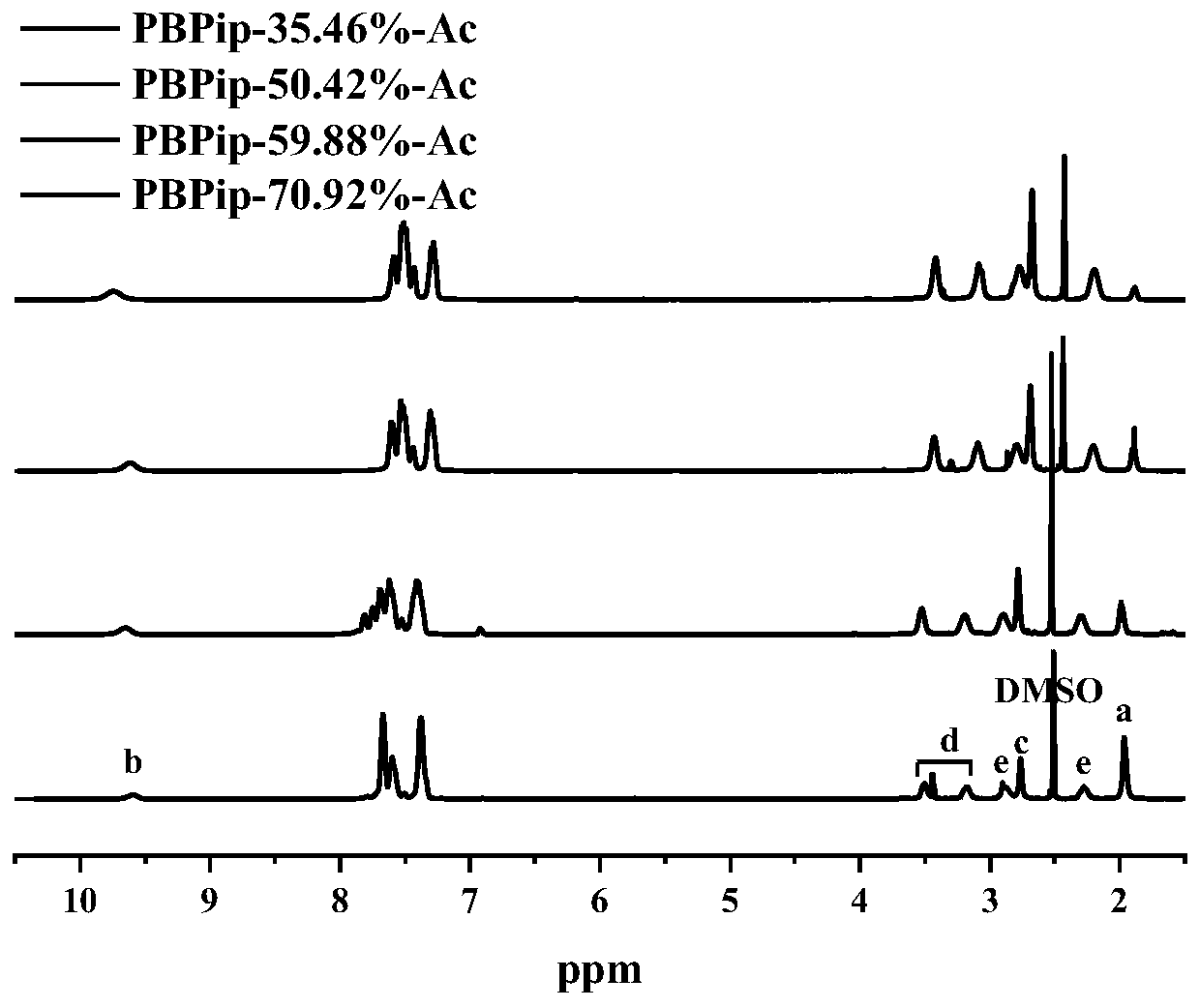

Novel block anion exchange membrane and preparation method thereof

InactiveCN105906812AHigh conductivity free volume increaseIncreased free volumeFuel cellsPolymer scienceFuel cells

The invention discloses a novel block anion exchange membrane. A block main chain of the anion exchange membrane contains a bending unit (biphenyl fluorene) and a twisting unit (phthalazinone); according to the structure, a non-coplanar effect can be enhanced. A preparation method of the anion exchange membrane comprises the following steps of performing polycondensation on decafluorobiphenyl (slightly excessive) and bisphenol fluorine to prepare an oligomer 1; using the decafluorobiphenyl and 4-(4-hydroxyphenyl)-2,3-phthalazine-1-one to prepare an oligomer 2; polymerizing the oligomer 1 with the oligomer 2 to obtain a polymer main chain, and performing ionization treatment, membrane casting and alkali treatment on a chloromethylation main chain to obtain the anion exchange membrane. The anion exchange membrane has better chemical stability, and higher electric conductivity and resistance to swelling, and is suitable for being applied in the aspect of alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

Method for preparing fuel cell polar plate through 3D printing

InactiveCN109378497AHigh glass transition temperatureGuaranteed conductivityAdditive manufacturing apparatus3D object support structuresVitrificationGlass fiber

The invention discloses a method for preparing a fuel cell polar plate through 3D printing. The fuel cell polar plate is prepared by the following steps: (a) sequentially adding nano-alloy powder, polylactic acid, glass fibers and an emulsifying agent into a dichloromethane solvent, so as to prepare solid jelly; (b) carrying out low-temperature thermal treatment on the solid jelly under a vacuum condition, and carrying out ball milling, granulation and wiredrawing, so as to obtain a 3D printing raw material; and (c) printing the 3D printing raw material, carrying out plasma thermal treatment,so as to obtain a core-shell structure fuel cell polar plate material in which an alloy phase is packaged with modified polylactic acid. The method has the beneficial effects that the prepared fuel cell polar plate has good surface hydrophobicity, high glass transition temperature and softening temperature and good conductivity and can adequately meet the demands of fuel cells; and meanwhile, theprocess is simple, the yield and the cost are superior, and the method has potential in large-scale application.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Gas sensor

ActiveCN1963486AGuaranteed conductivitySimple structureMaterial resistanceElectricityElectrical connection

A gas sensor is disclosed having an element holder body with which a senor element is fixedly supported, and an atmosphere-side insulator covering a base portion of the sensor element and providing electrical connection between lead wires and terminal electrodes of the sensor element. The element holder body includes a housing and an element-side insulator fixedly mounted in the housing. The atmosphere-side insulator incorporates therein a plurality of spring terminals held in electrical contact with the electrode terminals of the sensor element. At least one of the element holder body and the atmosphere-side insulator carries thereon convexed portions with which the atmosphere-side insulator can tilt with respect to the element holder body.

Owner:DENSO CORP

Processing method of rolled copper foil mother material

ActiveCN104057260AGood electrical conductivityHigh dimensional accuracyMetal rolling arrangementsCopper foilSurface layer

The invention discloses a processing method of a rolled copper foil mother material, and belongs to a high-precision soft-state red copper belt. According to the method, the conventional flow process for the red copper belt processing is changed from the production flow process, firstly, from cast ingots, high-quality raw materials are adopted for producing the cast ingots with compact tissues and qualified ingredients through semi-continuous casting; after hot rolling cogging, four-side milling is carried out for milling out surface layer scales; then, a rolling machine is adopted for rolling finished products through adopting short-rolling-process and large-processing-rate processing; in addition, the belt material plate type is improved through a stretch bender; next, the annealing is carried out through a gas pad type continuous annealing furnace; and finally, the shearing and trimming is carried out, and the operation turns to a copper foil workshop. The processing method provided by the invention has the characteristics that the conductivity is good, the dimension precision is good, the surface quality is good, the internal tissue is good, the performance is uniform, the plate shape is flat and straight, no burr exists at the edges, and the like. Therefore good popularization and application values are achieved.

Owner:CNMC ALBETTER ALBRONZE

Method for preparing cross-linked alkaline anion exchange membrane based on flexible long side chain polycation structure

InactiveCN110690486AGood alkali resistanceReduce offenseFinal product manufactureFuel cellsPhysical chemistryBackbone chain

The invention provides a method for preparing a cross-linked alkaline anion exchange membrane based on a flexible long side chain polycation structure, and belongs to the field of fuel cell anion exchange membrane materials. The alkaline anion exchange membrane is prepared by subjecting a halogenated polycation cross-linking agent and a biphenyl polymer to a menshutkin reaction, including four steps composed of synthesis of a polymer main chain, ionization of a polymer membrane main chain, film casting, and alkali treatment. The method of the invention is simple. The polycation structure promotes the formation of a hydrophilic and hydrophobic microphase separation structure. The flexible long side chain cross-linked structure inhibits the water absorption and swelling of the membrane, improves the mechanical properties of the membrane on the basis of ensuring electrical conductivity, thereby mitigating the contradiction between the electrical conductivity and the mechanical strength, and improving the alkali stability of the ion exchange membrane.

Owner:DALIAN UNIV OF TECH

Clamping holder for hollow silicon core

The invention discloses a clamping holder for a hollow silicon core, and belongs to clamping mechanisms in lap-joint for silicon cores. The clamping holder comprises a connecting seat (5), and a fixing mechanism for a vertical silicon core tube (3), wherein the fixing mechanism for a vertical silicon core tube (3) is arranged on the upper-part surface of the connecting seat (5); and the fixing mechanism for a vertical silicon core tube (3) is used for fixing the inner hole of the lower end of the vertical silicon core tube (3), or fixing the outside of the lower end of the vertical silicon core tube (3), or fixing the inner hole of the lower end of the vertical silicon core tube (3) and the outer edge surface of the vertical silicon core tube (3) simultaneously. The clamping holder disclosed by the invention is used for fixing the hollow silicon core via an insertion rod on the connecting seat, or fixing the hollow silicon core via a sleeve on the connecting seat, or fixing the lower end of the hollow silicon core via the combination of the insertion rod and the sleeve. The clamping holder disclosed by the invention is simple in structure, and especially suitable for fixing a hollow silicon core structure.

Owner:LUOYANG JINNUO MECHANICAL ENG

Preparation method for graphite film as well as product and application of graphite film

The invention relates to a preparation method for a graphite film. The method comprises the following steps: heating a PI film to temperature of 650-750 DEG C, keeping the temperature for 100-150 min,continuing to raise the temperature to 850-950 DEG C, keeping the temperature for 100-150 min, continuing to raise the temperature to 1250-1350 DEG C, keeping the temperature for 80-130 min, and performing cooling to obtain a carbonized film; and (2) performing graphitization: performing graphitization on the carbonized film obtained in the step (1) by adopting the following gradient heating procedure: heating the carbonized film to temperature of 1550-1650 DEG C, keeping the temperature for 20-60 min, continuing to raise the temperature to 1750-1850 DEG C, keeping the temperature for 20-90 min, continuing to raise the temperature to 2300-2400 DEG C, keeping the temperature for 20-90 min, performing heating to temperature of 2750-2900 DEG C, and performing cooling to obtain the graphite film with high orientation, high crystallinity and high conductivity.

Owner:SHUZHOU GU CARBON NEW MATERIAL

Socket joint type silicon core lapping structure and method capable of increasing contact area and reducing electric resistance

ActiveCN102344141AImprove qualityPrevent lodgingSilicon compoundsElectrical resistance and conductanceHydrogen

The invention belongs to a silicon core lapping method in a polysilicon production process by a Siemens method, and particularly relates to a socket joint type silicon core lapping structure and method capable of increasing contact area and reducing electric resistance. Both sides of a horizontal silicon core (2) are respectively provided with a lapping surface (6) formed by a bifacial trough (5), or provided with an end U bayonet (7); and the upper ends of two vertical silicon cores (3) are respectively provided with a lapping surface (6) formed by a bifacial trough (5), or provided with an end U bayonet (7). The lapping method comprises the following steps: preprocessing the horizontal silicon core and vertical silicon cores; and after lapping the silicon cores, putting the silicon cores in a reducing furnace, and introducing hydrogen and trichlorosilane to carry out reducing reaction, so that required polysilicon forms the silicon core on the silicon core surface, thereby implementing multiple reduction processes of polysilicon. By using the invention, the lap joint of the silicon cores has large contact surface, and the step of drawing silicon core spherosome in all existing techniques is not needed, thereby ensuring the increase of yield.

Owner:LUOYANG JINNUO MECHANICAL ENG

Continuous production technology and device for m-aminoacetanilide

ActiveCN109608353AGuaranteed purityGuaranteed conductivityOrganic compound preparationCarboxylic acid amides preparationAcetic acidAfter treatment

The invention discloses a continuous production technology for m-aminoacetanilide. After mother liquor absorbs hydrogen chloride gas, the obtained product, acetic acid and m-phenylenediamine are fed into a primary reaction kettle and subjected to an acylation reaction, and the feeding mas ratio of the fed m-phenylenediamine to the fed hydrogen chloride to the fed acetic acid to the fed mother liquor controlled to be 1:(0.3-0.4):(0.6-0.8):(7-8), one part of materials in the primary reaction kettle is fed into a reaction kettle and cycled, the other part of the materials is fed into a secondaryreaction kettle and reacts, then crystallization and centrifugation are carried out, and a finished product is obtained after treatment. According to the continuous production technology for m-aminoacetanilide, the whole m-aminoacetanilide is produced in a closed system, particularly, non-absorbed hydrogen chloride during the reaction and much acetic-acid waste gas generated when crystallization and centrifugal separation are carried out are absorbed to a final reaction kettle and continue to react, and inorganized gas discharging is reduced; meanwhile comprehensive utilization of resources isachieved, and the yield of the finished product is thus increased.

Owner:ZHEJIANG DIBANG CHEM

Aluminum alloy wire

InactiveCN105695808AImprove conductivityGood mechanical propertiesConductive materialMetal/alloy conductorsFiber structureYttrium

The invention belongs to the field of electric materials, and discloses an aluminum alloy wire. The aluminum alloy wire is prepared from germanium, tantalum, yttrium, rhenium, vanadium, molybdenum, zinc, manganese, chromium, titanium, aluminum, graphite, carbon fibers, nano silica and bisphenol A epoxy resin. The aluminum alloy wire is high in conductivity and excellent in mechanical property, heat resistant property and corrosion resistant property; meanwhile, by means of a modified carbon fiber structure, the mass of the aluminum alloy wire is reduced.

Owner:莒南县美达电力实业有限公司

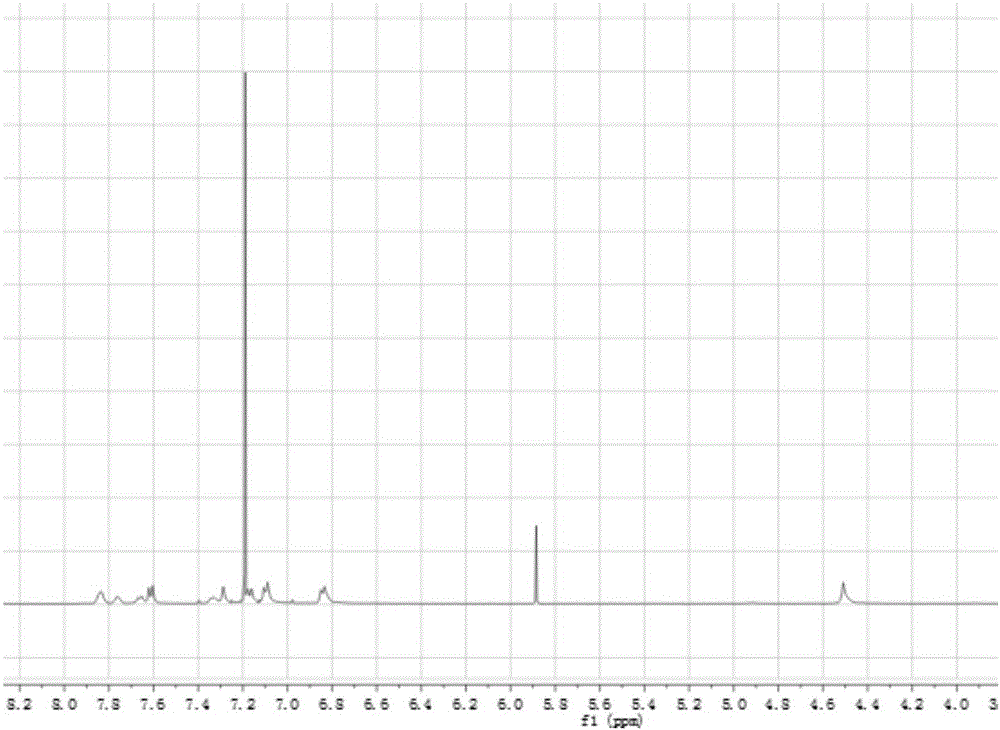

Crosslinked alkaline anion membrane based on piperidine and preparation method thereof

The invention discloses a novel anion exchange membrane and a preparation method thereof. The anion exchange membrane is prepared by initial reaction of a halomethyl group-containing polymer and haloperidine and binary cross-linking with 1,4-dimethylpiperazine or the like, the benzylic position of the membrane adopts piperidine ions with excellent alkaline stability, and the chemical stability isbetter under alkaline conditions; the polycation can effectively improve the ionic conductivity; the cross-linking not only inhibits swelling, but also maintains flexibility and excellent electrical conductivity of the membrane. The anion membrane exhibits excellent chemical stability, high electrical conductivity, low water absorption and swelling resistance, and is suitable for use in the fieldof alkaline fuel cells.

Owner:DALIAN UNIV OF TECH

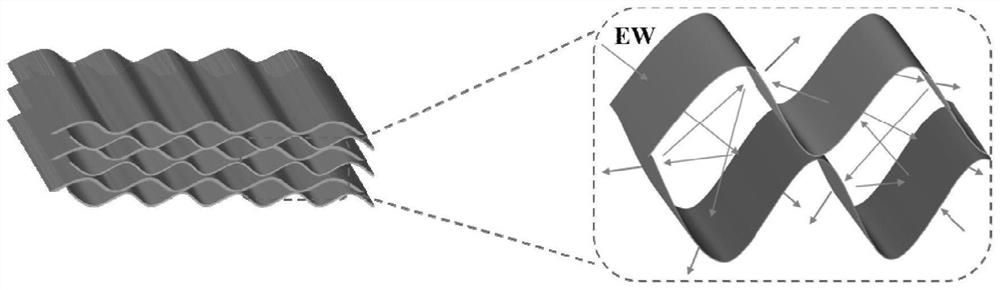

Lightweight porous MXene-based composite film electromagnetic shielding material and preparation method thereof

PendingCN113329603AEasy to operateMultiple scattering/reflection effects increasedMagnetic/electric field screeningClimate change adaptationThin membraneElectric devices

The invention discloses a lightweight porous MXene-based composite film electromagnetic shielding material and a preparation method thereof, and belongs to the technical field of film electromagnetic shielding materials and preparation thereof. Self-assembly of MXene and graphene oxide is realized by taking electrostatic interaction force as driving force on MXene modified by a cationic surface modifier and graphene oxide, and then the lightweight porous MXene-based composite electromagnetic shielding material with ultrahigh specific performance is obtained through film casting and high-temperature annealing. The prepared composite film material has excellent electromagnetic shielding effectiveness and specific effectiveness, and when the thickness is only 15 [mu]m, the porous MXene-based composite film obtained by adding 5 wt% of graphene oxide can keep the electromagnetic shielding effectiveness of 49 dB or above in the whole X wave band. The preparation process is simple and easy to operate, and the material is expected to be applied to the fields of aerospace, military equipment, micro electronic equipment, civil electric appliances and the like.

Owner:JIANGNAN UNIV

High-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire and preparation process thereof

InactiveCN103971781AImprove heat strengthEnhanced interactionMetal/alloy conductorsCable/conductor manufactureRare earthHigh intensity

The invention discloses a high-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire and a preparation process thereof. The high-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire is characterized in that the electromagnetic wire is composed of 1.05-1.10wt% of Ni, 0.55-0.60wt% of Zr, 0.25-0.30wt% of La, 0.25-0.30wt% of Y, smaller than or equal to 0.10wt% of Sc and the rest Cu. The high-strength high-electroconductivity rare-earth and copper alloy electromagnetic wire produced by the preparation process is high in strength and good in tensile performance, and electroconductivity is greatly improved.

Owner:HUNAN LIANDA FENGRONGTONG ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com