Ferrite-based ceramic composite material as well as preparation method and application thereof

A technology of ceramic composite materials and ferrite materials, applied in the field of magnetic composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

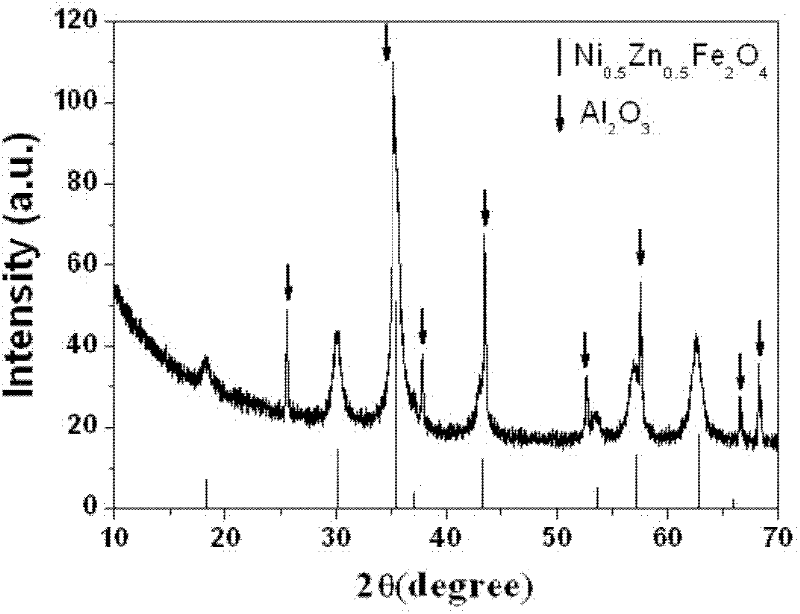

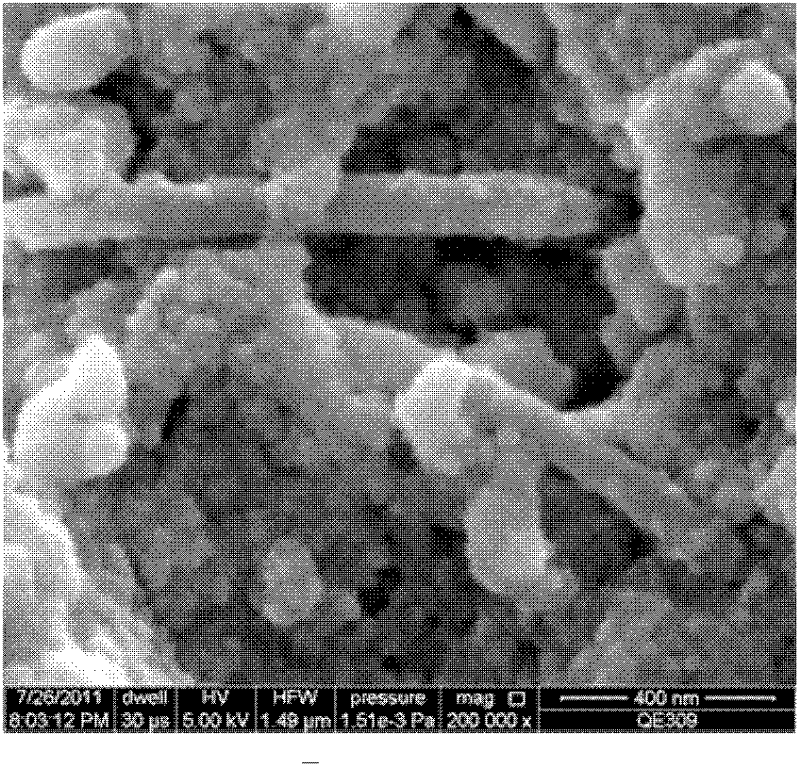

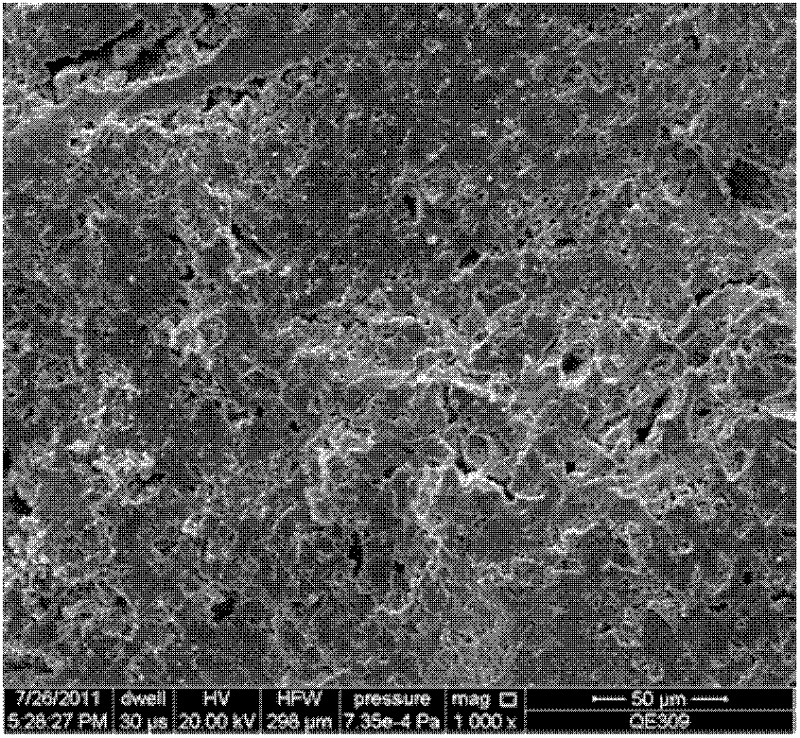

Embodiment 1

[0059] In this embodiment, the ferrite-based ceramic composite material is composed of ferrite, carbon nanotubes and alumina, and the ferrite and alumina are coated on the tube wall of the carbon nanotubes, and its chemical expression is: 1% CNTs -Ni 0.5 Zn 0.5 Fe 2 o 4 -10%Al 2 o 3 , where 1% represents the mass percentage of CNTs in the total mass of ferrite-based ceramic composites, and 10% represents Al 2 o 3 The mass percentage of the total mass of the ferrite-based ceramic composite material.

[0060] The 1%CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 -10%Al 2 o 3 The concrete preparation method of composite material is as follows:

[0061] (1) Weigh 0.5g of carbon nanotubes and 200ml of concentrated nitric acid and mix them, reflux for 5h in an oil bath at 150°C to prepare modified carbon nanotubes, and then dissolve the modified carbon nanotubes in sodium lignosulfonate In the supersaturated solution, ultrasonic crushing for 45 minutes to obtain a uniformly dispersed carb...

Embodiment 2

[0077] In this embodiment, the ferrite-based ceramic composite material is composed of ferrite, carbon nanotubes and aluminum nitride (AlN), and the ferrite and aluminum nitride are coated on the tube wall of the carbon nanotubes. The chemical expression is : 5% CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 -20% AlN,

[0078] Wherein 5% means that CNTs accounts for the mass percentage of the total mass of the ferrite-based ceramic composite material, and 20% means that AlN accounts for the mass percentage of the total mass of the ferrite-based ceramic composite material.

[0079] The 5%CNTs-Ni 0.5 Zn 0.5 Fe 2 o 4 The specific preparation method of -20% AlN composite material is as follows:

[0080] (1) Weigh 0.5g of carbon nanotubes and 200ml of concentrated nitric acid and mix them, reflux for 5h in an oil bath at 150°C to prepare modified carbon nanotubes, and then dissolve the modified carbon nanotubes in sodium lignosulfonate In the supersaturated solution, ultrasonic crushing for ...

Embodiment 3~9

[0094] Same as Example 1, in Examples 3-9, the ferrite-based ceramic composite material is also composed of ferrite, carbon nanotubes and alumina, and the ferrite and alumina are coated on the tube wall of the carbon nanotubes, The chemical expressions thereof are shown in Table 1 below, respectively.

[0095] The preparation methods of the ferrite-based ceramic composite materials in Examples 3-9 are basically the same as in Example 1, except that the sintering temperature and holding time are different values, as shown in Table 1 below.

[0096] Chemical expression and preparation conditions of ferrite-based ceramic composite material in table 1 embodiment 3~9

[0097] Example

chemical expression

Sintering temperature

3

5%CNTs-NiFe 2 o 4 -5%Al 2 o 3

800

1

4

2%CNTs-ZnFe 2 o 4 -10%Al 2 o 3

1000

1

5

10%CNTs-Ni 0.25 Zn 0.5 Cu 0.25 Fe 2 o 4 -15%Al 2 o 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com