3D printing device used for preparing aluminum matrix composite and printing method thereof

An aluminum-based composite material and 3D printing technology, applied in the field of 3D printing, can solve the problems of increasing the difficulty of laser 3D printing technology, enhancing the uneven distribution of particles, and increasing the cost of 3D printing, so as to reduce material costs, improve mechanical properties, and improve uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

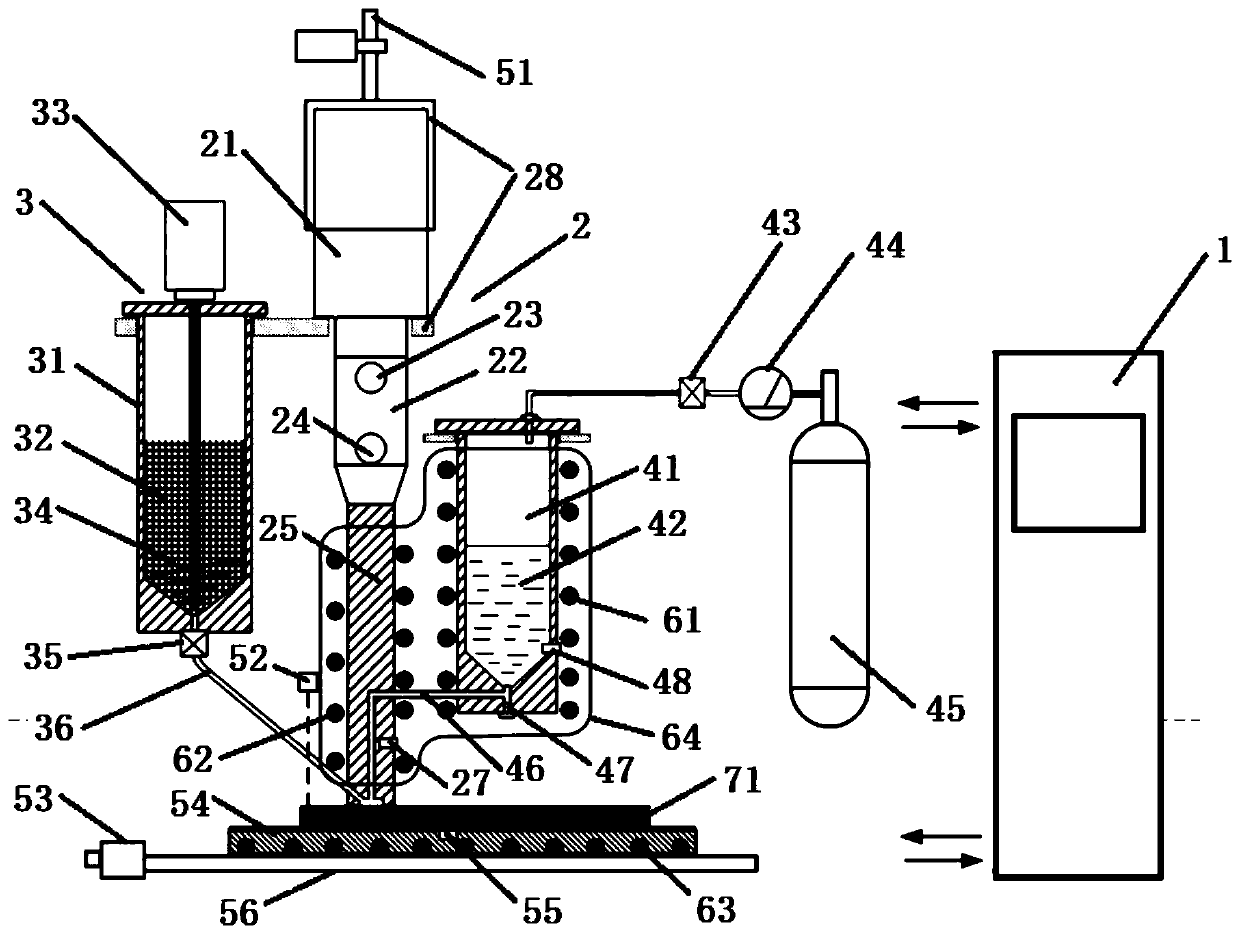

[0051] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment, a 3D printing device for preparing aluminum-based composite materials in this embodiment, which includes: an industrial control cabinet 1, an ultrasonic-assisted printing module 2, a material storage module 3 and a three-dimensional mobile module, the industrial control cabinet 1 Including the control of total power, heating power, temperature, argon switch and three-dimensional movement.

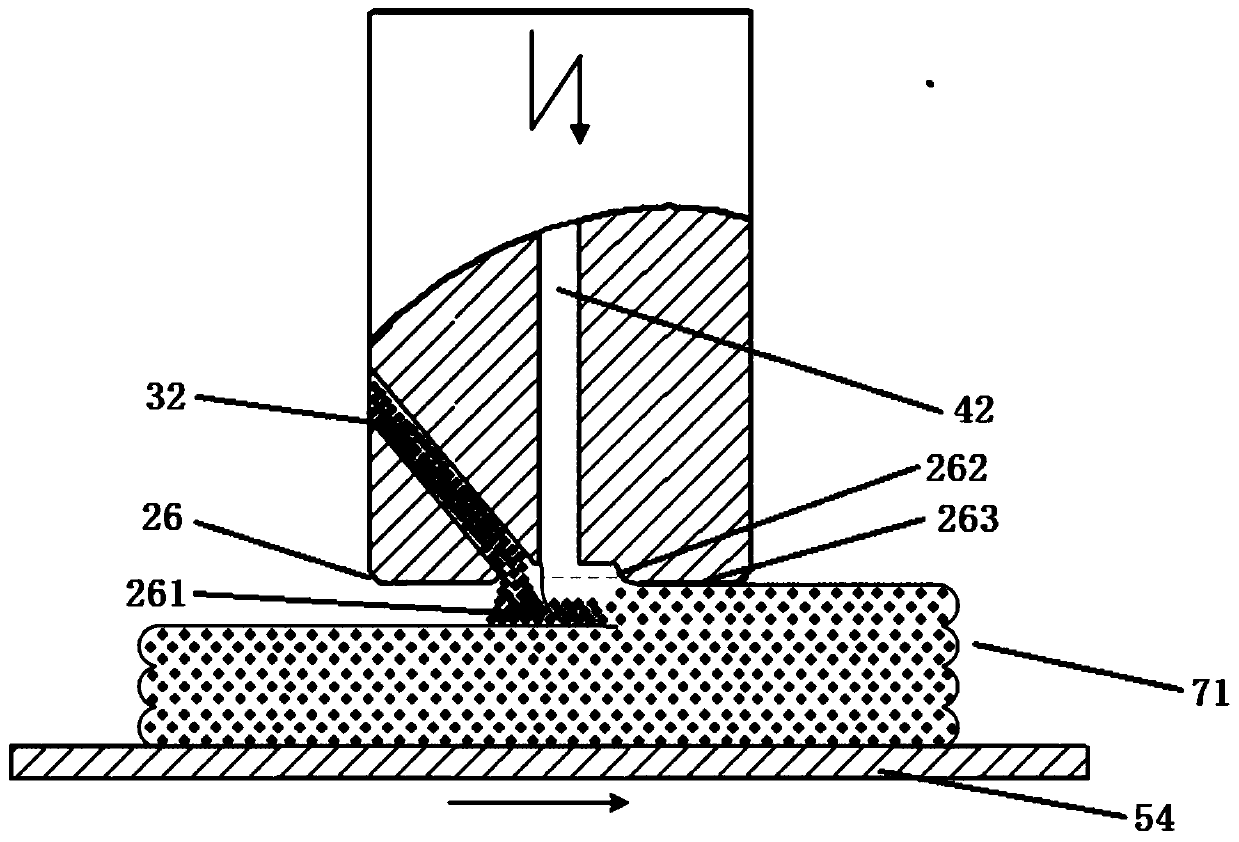

[0052] The ultrasonic auxiliary printing module 2 includes an ultrasonic transducer 21, a horn 22, a cooling water outlet 23, a cooling water inlet 24, an ultrasonic tool head 25, a printing nozzle 26, a second temperature sensor 27, and a Z-axis support 28 , the substrate 54 , the third temperature sensor 55 , the second heating module 62 and the third heating module 63 . The three-dimensional moving module includes a Z-axis synchronous motor 51 , a laser rangefinder 52 , an XY-axis synchronou...

specific Embodiment approach 2

[0055] Specific implementation mode two: combination figure 1 and figure 2 Describe this embodiment, the circular groove of the printing nozzle 26 of this embodiment is a spherical pit, the diameter of the spherical pit is 1 / 4-1 / 2 of the diameter of the ultrasonic tool head, and the spherical center of the spherical pit should be located below the plane of the printing nozzle 26, The distance is about 100-400μm, which is the ultrasonic gathering point, where high acoustic energy can be obtained, thereby obtaining a higher density cavitation bubble distribution, which is conducive to the rapid breaking of the oxide film and the separation of ceramic particles and metal liquid. Moisture bond. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0056] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment. This embodiment provides an ultrasonic-assisted 3D printing method for aluminum-based composite materials. The method selects a temperature 20-100°C higher than the melting point of the metal material to be printed as the printing temperature, and the preheating temperature of the substrate It is 50-200°C lower than the melting point of metal materials, and the printing speed is 5-20cm / min. It can realize the printing of base aluminum alloy raw materials without size limitation. By adjusting the flow rate of ceramic powder and aluminum alloy melt, different areas of aluminum matrix composite materials have different reinforcement phase content and aluminum matrix composite material with different reinforcement phase content. Adjustable printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com