Anode carbon block with centre joint groove

An anode carbon block and slot groove technology is applied in the field of prebaked anode carbon block structure and preparation for aluminum electrolytic cells, and can solve the problem of easy cracking, affecting the quality of aluminum liquid and electrolyte, and large damage to the carbon block force system structure. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

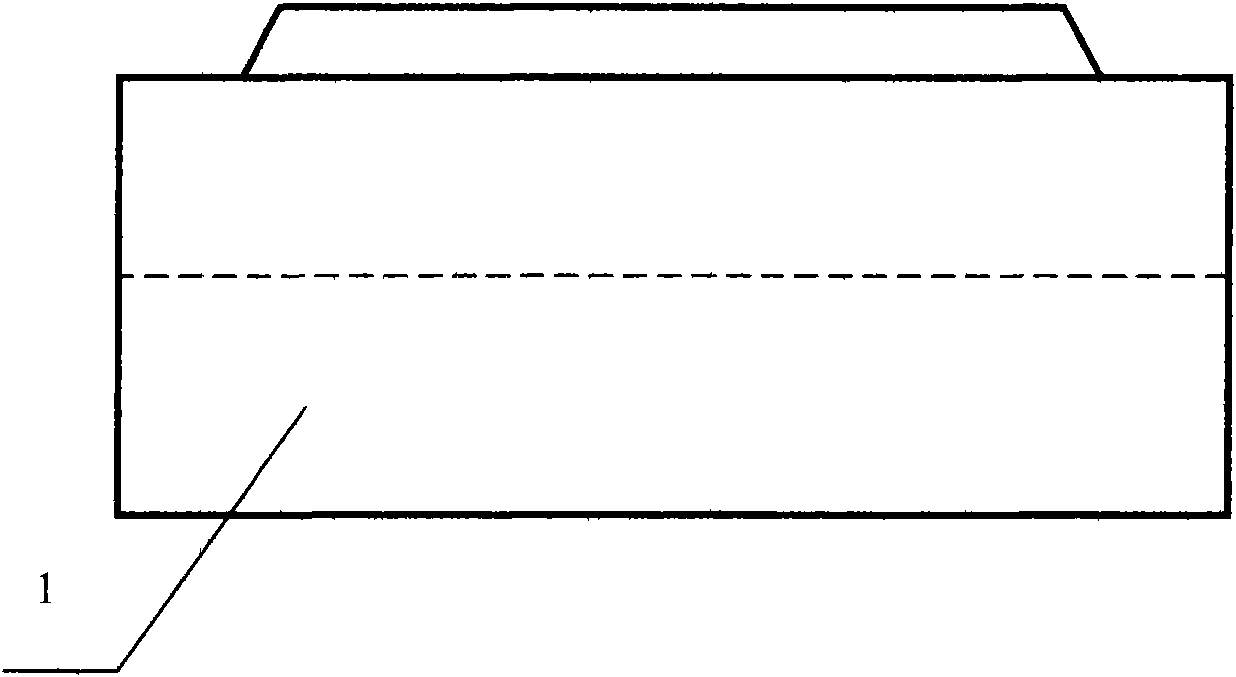

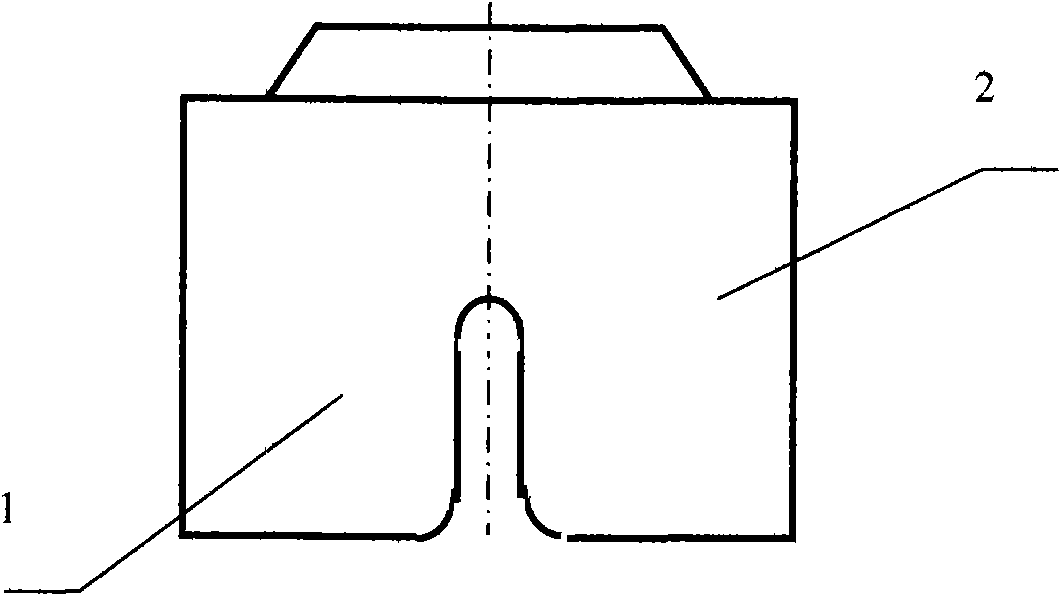

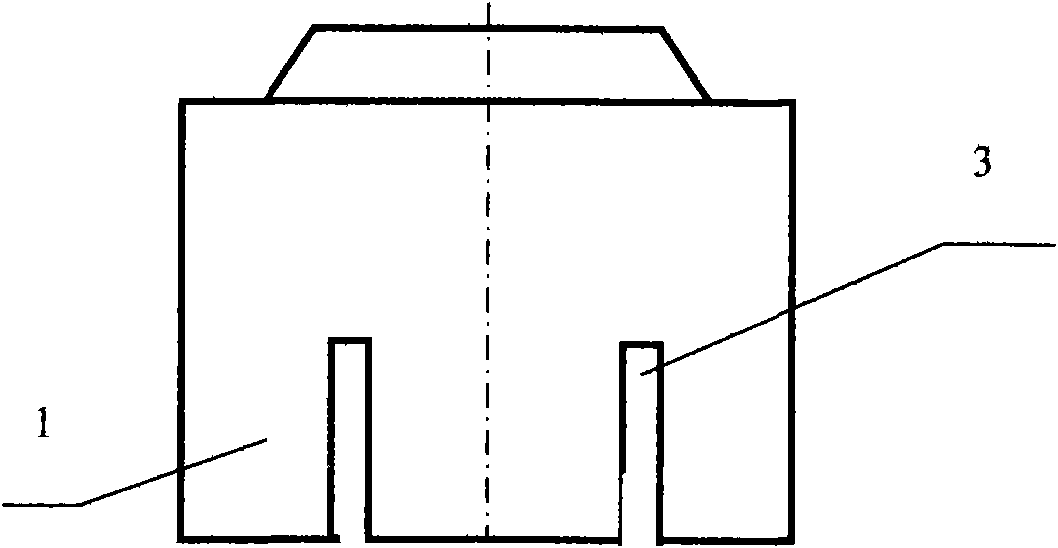

[0015] The present invention is an anode carbon block with a central slit groove. Its manufacturing process is basically the same as that of the current general solid anode carbon block and the anode carbon block with two debt grooves. The difference is It is: at the bottom of the original solid anode carbon block (1), open a middle slot groove (2) with a width of more than 20mm, a width of about 35mm, and a height of about 250mm along the length direction of the carbon block (1). figure 1 , figure 2 shown. , to overcome the current common slotted carbon block to open two narrow grooves (3) with a width less than 18mm, in order to overcome the difficulty of cleaning the coke particles in the narrow groove, and to open two grooves to cause the carbon block to be easily damaged, and the yield is low shortcoming,

[0016] After the anode carbon block with the middle slot groove is applied to the production of the aluminum electrolytic cell, the middle slot groove (2) is condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com