Technique of preparing novel grain reinforced aluminum base composite material and special equipment thereof

A technology for particle-reinforced aluminum and composite materials, which is applied in the field of preparation technology and equipment of metal matrix composite materials, can solve problems such as affecting the mechanical properties of composite materials, uneven distribution of SiC particles, and inability to achieve industrialized production, and achieves simplified melting pool and Mixing pool system, simple structure, convenient control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

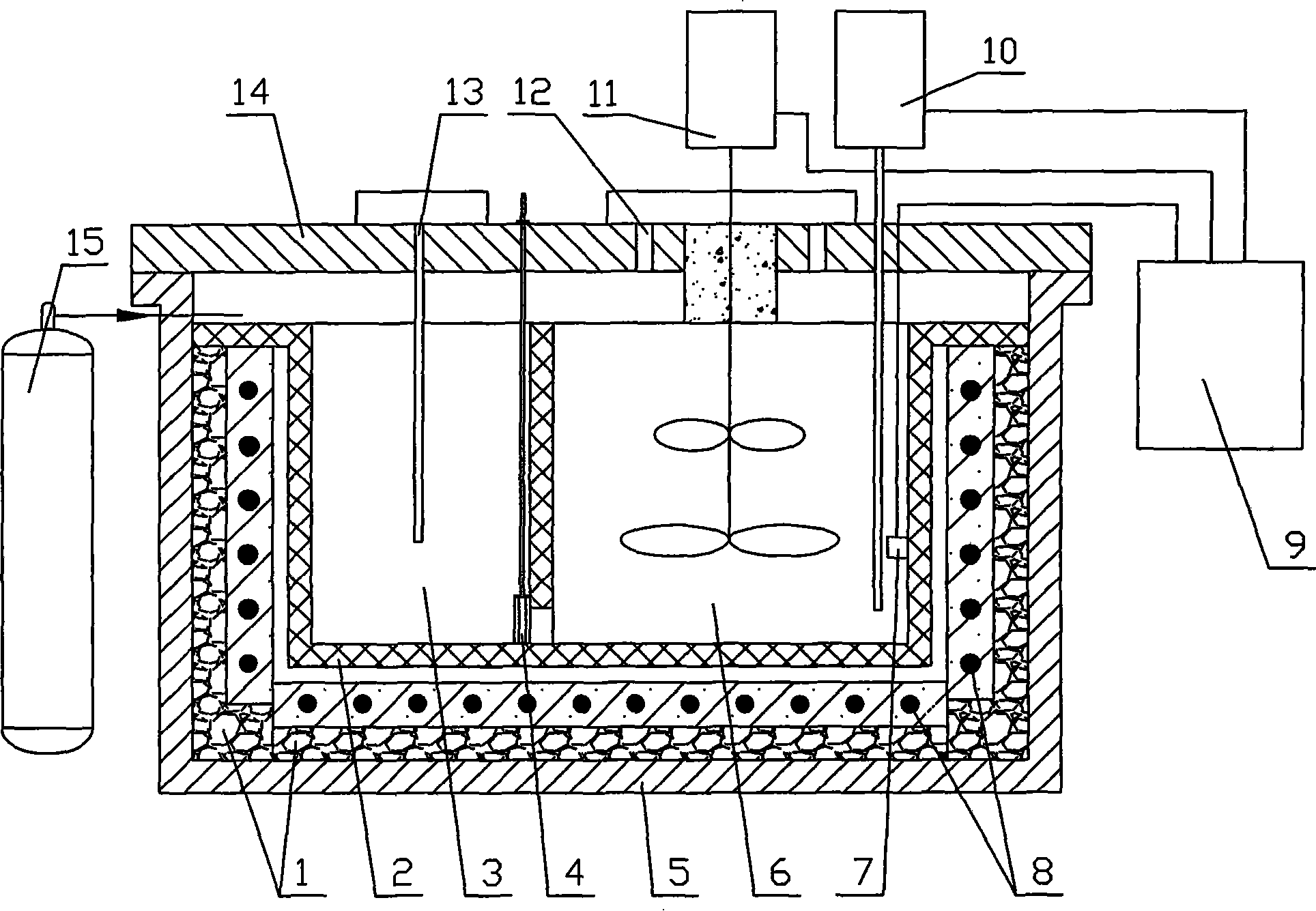

[0029] Embodiment one, see figure 1 , in the figure, the melting pool 3 and the mixing pool 6 of the special equipment used in the preparation method of the new particle-reinforced aluminum-matrix composite material are conjoined structures, which are separated longitudinally by a cavity 2 with an upper end open, between the two The lower end of the body wall is provided with a communication hole, the communication hole is provided with an opening and closing valve 4, the cavity 2 is arranged in an open casing 5, and a heating device 8 is arranged between the cavity 2 and the open casing 5 And the heat preservation device 1, the upper end of the open shell 5 is provided with an end cover 14, the end cover 14 above the melting pool 3 is provided with a matrix alloy feeding hole 13 and a sealing cover, and the end cover 14 above the mixing pool 6 is provided with a silicon carbide Feeding hole 12 and sealing cover, mixing tank 6 are respectively provided with stirring device 11,...

Embodiment 2

[0039] Embodiment two, basically the same as embodiment one, the difference is:

[0040] The aluminum matrix alloy is 6061, the volume of the aluminum matrix alloy accounts for 90% of the total volume of the raw materials, the average particle size of SiC is 12 μm, and the surface oxidation treatment of SiC is carried out under the condition of 900°C×0.8h, and the volume of SiC accounts for 10% of the total volume of the raw materials. %; the stirring time is 1h, the stirring speed is 600r / min, and finally the product is cast directly through the mold. All the other contents are the same as in Embodiment 1.

Embodiment 3

[0041] Embodiment three, is basically the same as embodiment one, the difference is:

[0042] The aluminum matrix alloy is 6061, the volume of the aluminum matrix alloy accounts for 80% of the total volume of the raw materials, the volume of SiC accounts for 20% of the total volume of the raw materials, the stirring time is 0.8h, and the stirring speed is 800r / min. All the other contents are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com