Preparation method of aluminum-boron alloy powder and aluminum-boron slurry of crystalline silicon cell

A technology for solar cells, aluminum boron alloys, used in metal/alloy conductors, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

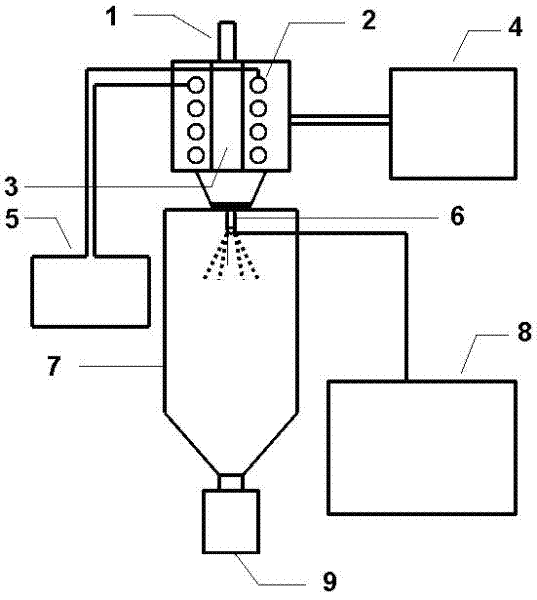

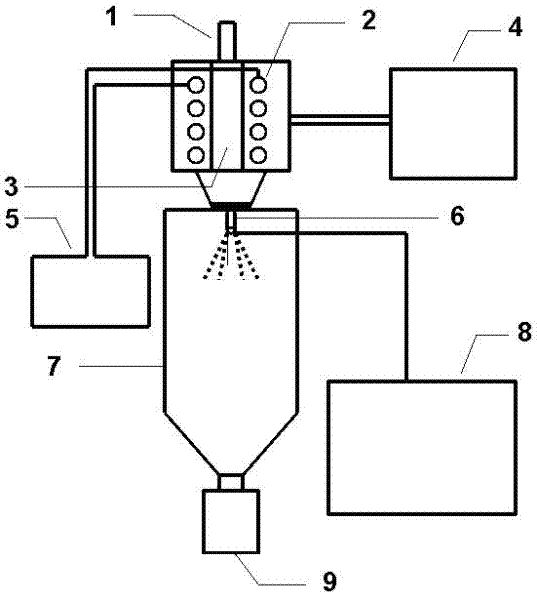

Image

Examples

example 1

[0029] 2) Mix the four substances of aluminum-boron alloy powder, inorganic glass binder, organic binder and additives with mass percentages of 72-82%, 0.1-10%, 15-25%, and 1-5%, respectively, and mix Finally, a conductive aluminum-boron slurry with a particle size of ≤15 μm and a viscosity of 30,000-40,000 mPa·s is rolled with a three-roll rolling mill;

[0030] 3) Silicon wafer cleaning, acid removal of damaged layer, pn junction fabrication, edge etching, silicon nitride film deposition, printing and sintering of the back surface field and front and back electrodes, wherein the preparation method of the back surface field is to adopt the method of the present invention The obtained aluminum-boron paste and conventional aluminum paste (Flue AL840 conductive aluminum paste) were uniformly coated on the back surface of the crystalline silicon battery by screen printing, and after drying, they were respectively sintered at 800°C for no more than 3min.

[0031] Various perform...

example 2

[0036] 2) Mix the four substances of aluminum-boron alloy powder, inorganic glass binder, organic binder and additives with mass percentages of 72-82%, 0.1-10%, 15-25%, and 1-5%, respectively, and mix Finally, a conductive aluminum-boron slurry with a particle size of ≤15 μm and a viscosity of 30,000-40,000 mPa·s is rolled with a three-roll rolling mill;

[0037] 3) Silicon wafer cleaning, acid removal of damaged layer, pn junction fabrication, edge etching, silicon nitride film deposition, printing and sintering of back field and positive and negative electrodes, wherein the preparation method of back surface field is obtained by the present invention The aluminum-boron paste and the conventional aluminum paste (Flue AL840 conductive aluminum paste) are evenly coated on the back surface of the crystalline silicon battery by screen printing, and after drying, they are respectively sintered at 800 ° C for no more than 3 minutes. .

[0038] Various performance parameters of the...

example 3

[0043] 2) Mix the four substances of aluminum-boron alloy powder, inorganic glass binder, organic binder and additives with mass percentages of 72-82%, 0.1-10%, 15-25%, and 1-5%, respectively, and mix Finally, a conductive aluminum-boron slurry with a particle size of ≤15 μm and a viscosity of 30,000-40,000 mPa·s is rolled with a three-roll rolling mill;

[0044] 3) Silicon wafer cleaning, acid removal of damaged layer, pn junction fabrication, edge etching, silicon nitride film deposition, printing and sintering of back field and positive and negative electrodes, wherein the preparation method of back surface field is obtained by the present invention The aluminum-boron paste and the conventional aluminum paste (Flue AL840 conductive aluminum paste) are evenly coated on the back surface of the crystalline silicon battery by screen printing, and after drying, they are respectively sintered at 800 ° C for no more than 3 minutes. .

[0045] Various performance parameters of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com