Method of producing aluminium polychloride using aluminium hydroxide mud

A technology of polyaluminum chloride and aluminum hydroxide, applied in aluminum chloride, aluminum halide, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, waste of land resources, etc. Waste of land resources, beneficial to environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

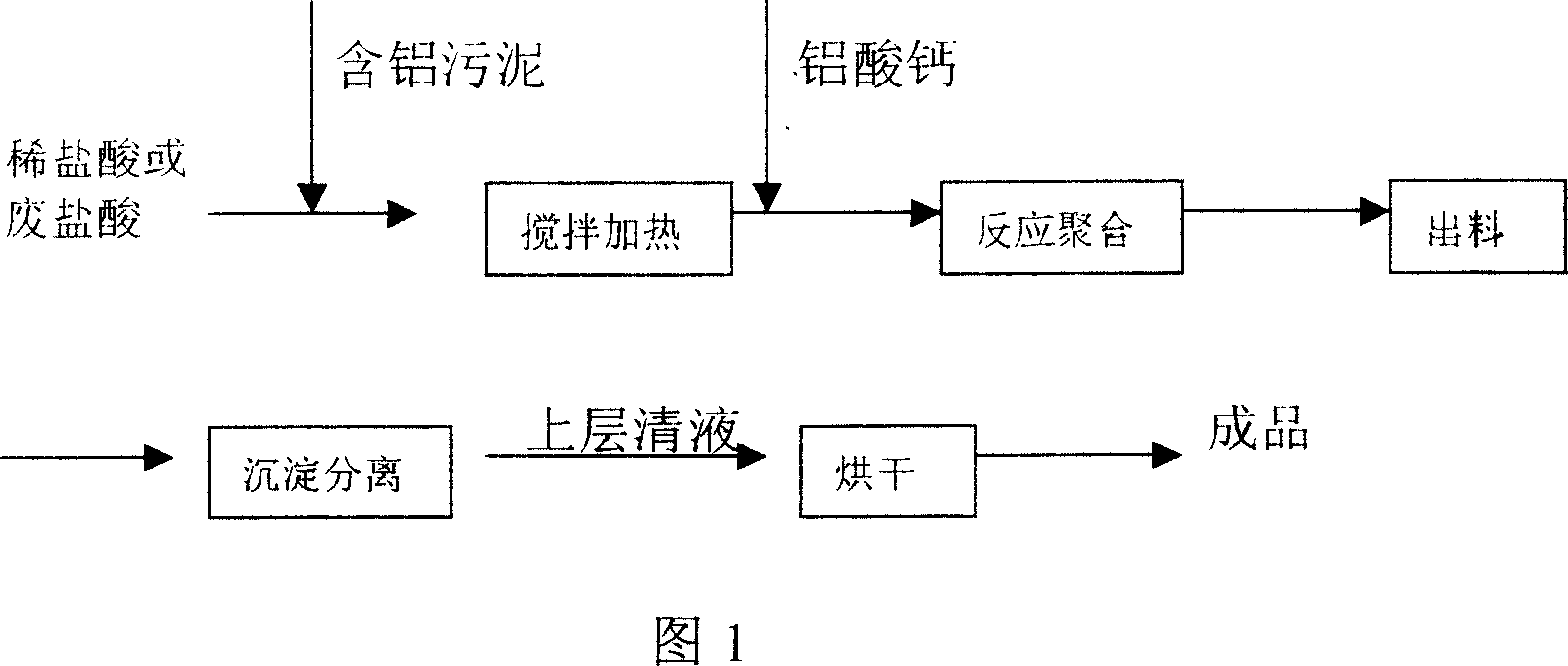

[0017] The present invention uses the aluminum hydroxide sludge produced in the production of aluminum materials to produce polyaluminum chloride using the following process steps:

[0018] In the present invention, 45% by weight of dilute hydrochloric acid (20% acid content) is added to the reaction tank, 45% by weight of aluminum hydroxide sludge is gradually added, and the reaction is stirred to completely react and dissolve the aluminum hydroxide sludge to gradually generate liquid aluminum trichloride. , Stop heating when the heating temperature reaches 75°C; gradually add 19% by weight of calcium aluminate powder and 1% by weight of defoamer, continue the reaction and dissolve, and gradually increase the temperature to 100°C (boiling); add calcium aluminate powder Then use a precision pH test paper of 0 to 5 to detect the pH value, so that the pH value is controlled at 4.5. If the pH value is less than 4.5, you can continue to add calcium aluminate powder, if it is higher th...

Embodiment 2

[0021] The present invention uses the aluminum hydroxide sludge produced in the production of aluminum materials to produce polyaluminum chloride using the following process steps:

[0022] In the present invention, 50% by weight of waste hydrochloric acid (20% acid content) is added to the reaction tank, 39% by weight of aluminum hydroxide sludge is gradually added, and the reaction is stirred to completely react and dissolve the aluminum hydroxide sludge to gradually generate liquid aluminum trichloride. ; Stop heating when the heating temperature reaches 80°C; gradually add 10% by weight of calcium aluminate powder and 1% by weight of defoamer, continue the reaction to dissolve, and gradually increase the temperature to 105°C (boiling); add calcium aluminate powder Then use a precision pH test paper of 0 to 5 to detect the pH value, so that the pH value is controlled at 4. If the pH value is less than 4, you can continue to add calcium aluminate powder, if it is higher than 4, ...

Embodiment 3

[0025] The present invention uses the aluminum hydroxide sludge produced in the production of aluminum materials to produce polyaluminum chloride using the following process steps:

[0026] In the present invention, 42% by weight of dilute hydrochloric acid (20% acid content) is added to the reaction tank, and 40% by weight of aluminum hydroxide sludge is gradually added, and the reaction is stirred to completely react and dissolve the aluminum hydroxide sludge to gradually generate liquid aluminum trichloride. , Stop heating when the heating temperature reaches 80°C; gradually add 17% by weight of calcium aluminate powder and 1% by weight of defoamer, continue the reaction and dissolve, and gradually increase the temperature to 110°C (boiling); add calcium aluminate powder Then use a precision pH test paper of 0 to 5 to detect the pH value, so that the pH value is controlled at 4.2; then the material is discharged after the heat preservation reaction for 2 hours. After natural pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com