Treatment method of acrolein production residual liquid

A treatment method and technology of acrolein, applied in carboxylate preparation, organic chemistry, etc., can solve the problem of high treatment cost and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 1000ml three-necked flask, add 800ml of acrolein-producing tail liquid (containing 5% acrylic acid), and under the condition of slow stirring, dropwise add 40g of 40% sodium hydroxide aqueous solution, and keep the temperature of the system ≤40℃ during the dropwise addition, After the dropwise addition, the temperature of the system was lowered to 30°C, 14g of 15% sodium hydroxide aqueous solution was added dropwise, then the temperature was raised to 60°C and kept for 1 hour. Dry in a vacuum oven at 70°C for 12h to obtain a white solid of sodium acrylate.

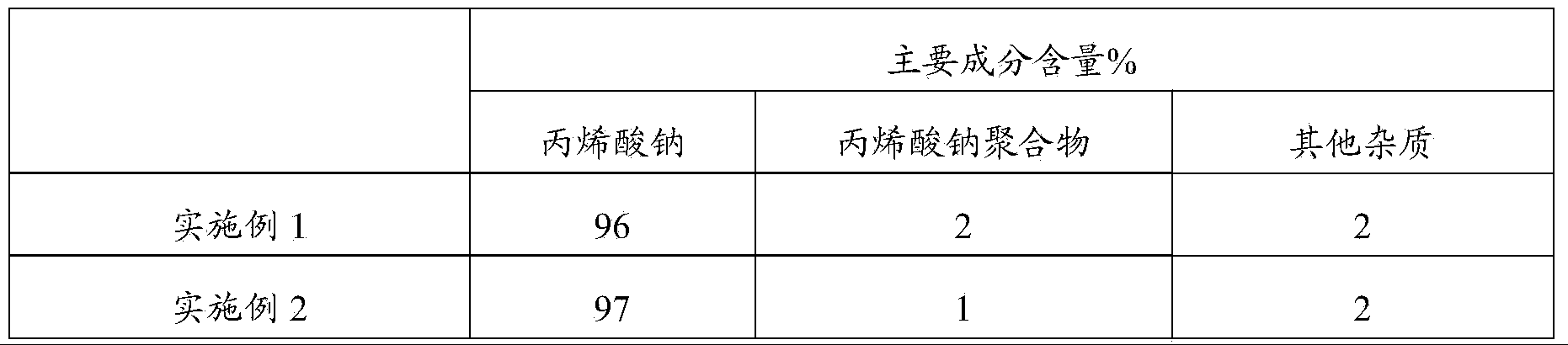

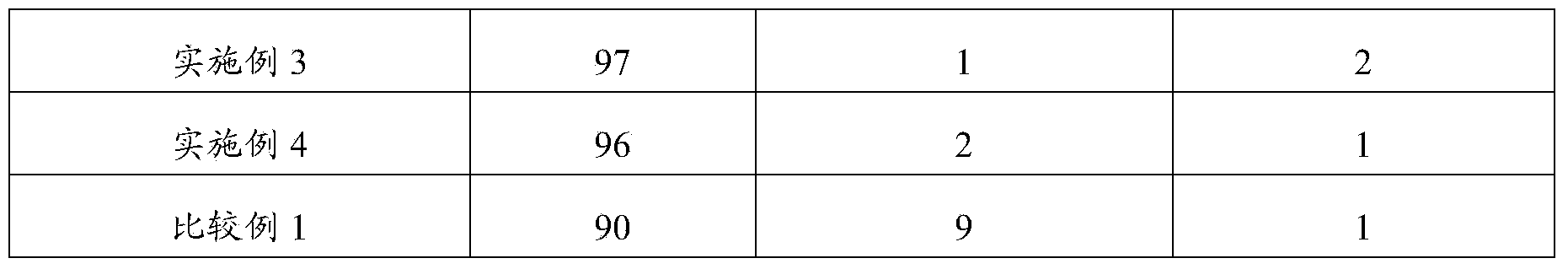

[0037] The sodium acrylate solid obtained in Example 1 was tested by gel permeation chromatography, and the obtained results are shown in Table 1.

Embodiment 2

[0039] In a 1000ml three-necked flask, add 800ml of the tail liquid of acrolein production (containing 5% acrylic acid), and under the condition of slow stirring, add 65g of 30% sodium hydroxide aqueous solution dropwise, and keep the temperature of the system ≤ 40 ℃ during the dropwise addition, After the dropwise addition, the temperature of the system was lowered to 30°C, 20g of 10% sodium hydroxide aqueous solution was added dropwise, then the temperature was raised to 60°C and kept for 1 hour. Dry in a vacuum oven at 70°C for 12h to obtain a white solid of sodium acrylate.

[0040] The sodium acrylate solid obtained in Example 2 was tested using gel permeation chromatography, and the obtained results are shown in Table 1.

Embodiment 3

[0042] In a 1000ml three-necked flask, add 800ml of the tail liquid of acrolein production (containing 7% acrylic acid), and under the condition of slow stirring, add 60g of 50% sodium hydroxide aqueous solution dropwise, keep the temperature of the system ≤ 40 ℃ during the dropwise addition, After the dropwise addition, the temperature of the system was lowered to 30°C, 12g of 10% sodium hydroxide aqueous solution was added dropwise, then the temperature was raised to 60°C and kept for 1 hour. Dry in a vacuum oven at 70°C for 12h to obtain a white solid of sodium acrylate.

[0043]The sodium acrylate solid obtained in Example 3 was tested by gel permeation chromatography, and the obtained results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com