Steel plate for automobile axle housing and production method thereof

A production method and technology for steel plates, which are applied to steel plates for automobile axle housings and their production fields, can solve the problems of high production costs and poor cold forming of steel plates, and achieve the effects of reducing yield ratio, improving cold forming properties, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

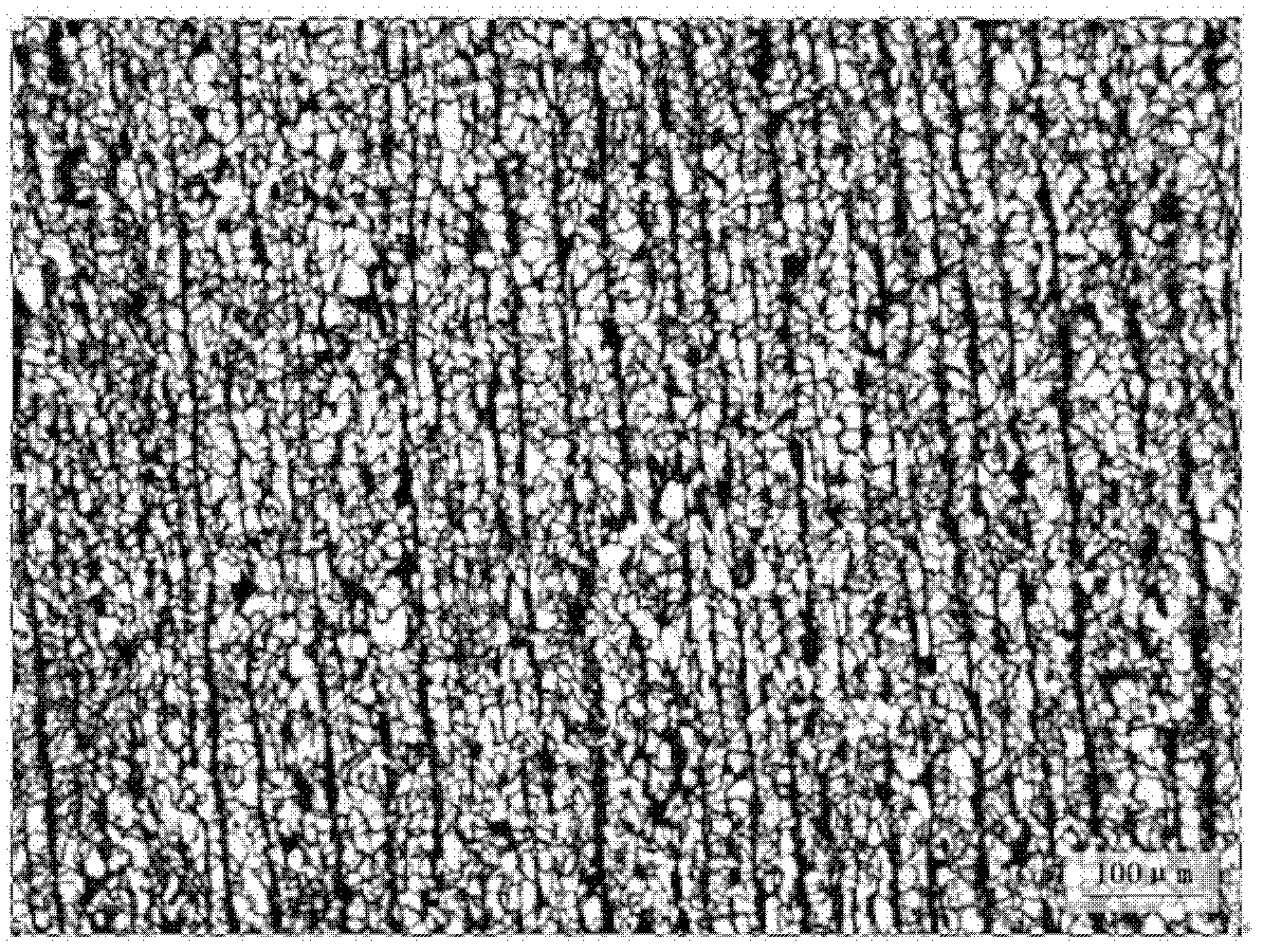

Image

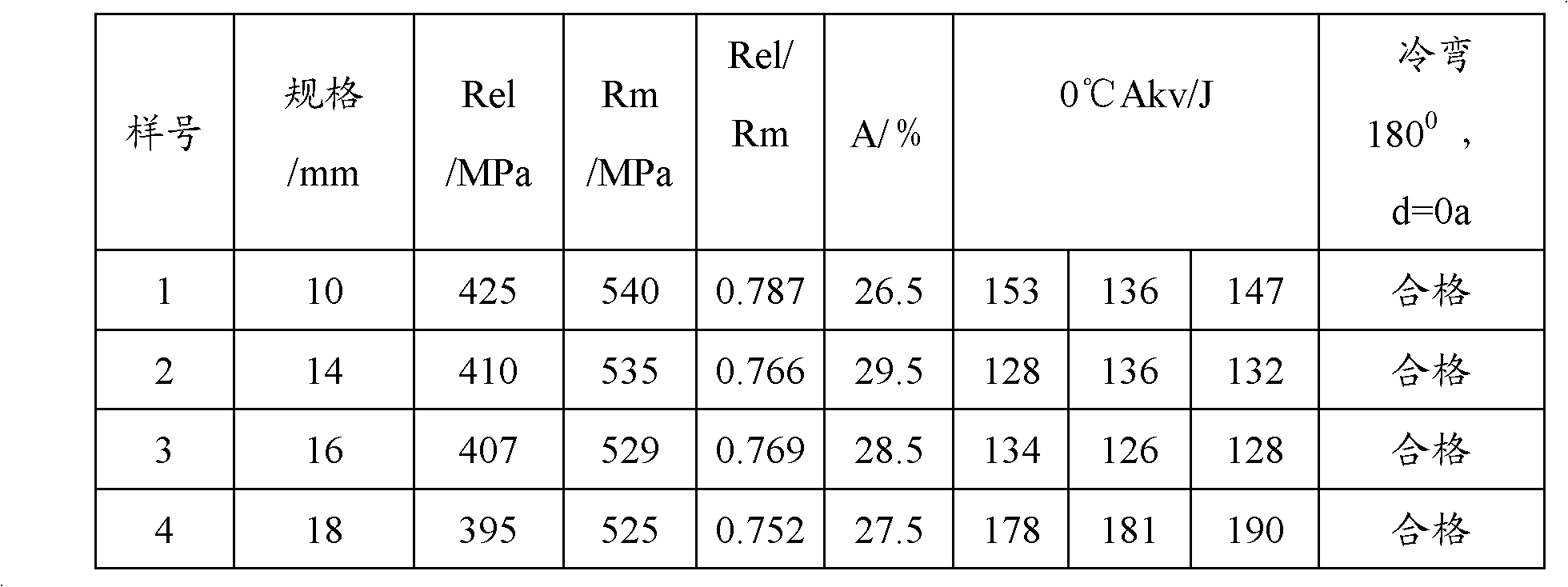

Examples

Embodiment Construction

[0018] The chemical composition design of the automobile axle housing steel plate of the present invention is to consider from the following aspects:

[0019] (1) C: It is the most economical strengthening element in low carbon steel. If the carbon content is too low, the strength cannot meet the requirements. If the content is too high, it can reduce the plasticity and impact toughness of the steel, and deteriorate the cold forming performance and welding performance. Therefore, it is currently used in automobiles. The C content of steel has a tendency to gradually decrease under the premise of ensuring the strength. Therefore, the C content is controlled at 0.10-0.18%.

[0020] (2) Mn: Manganese is a good deoxidizer, and the strength of steel can be improved by using the solid solution strengthening effect of manganese. Mn is very beneficial to improve the low-temperature toughness of steel. With the increase of Mn content, the cold-brittle transition temperature of steel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com