Resource-saving boron-containing high-speed steel composite roll and preparation method thereof

A composite roll, resource-saving technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of reduced probability of broken rolls, complicated manufacturing process, reduced peeling rate, etc., to achieve reduced burning loss, less inclusions, Effect of improving hardenability and hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

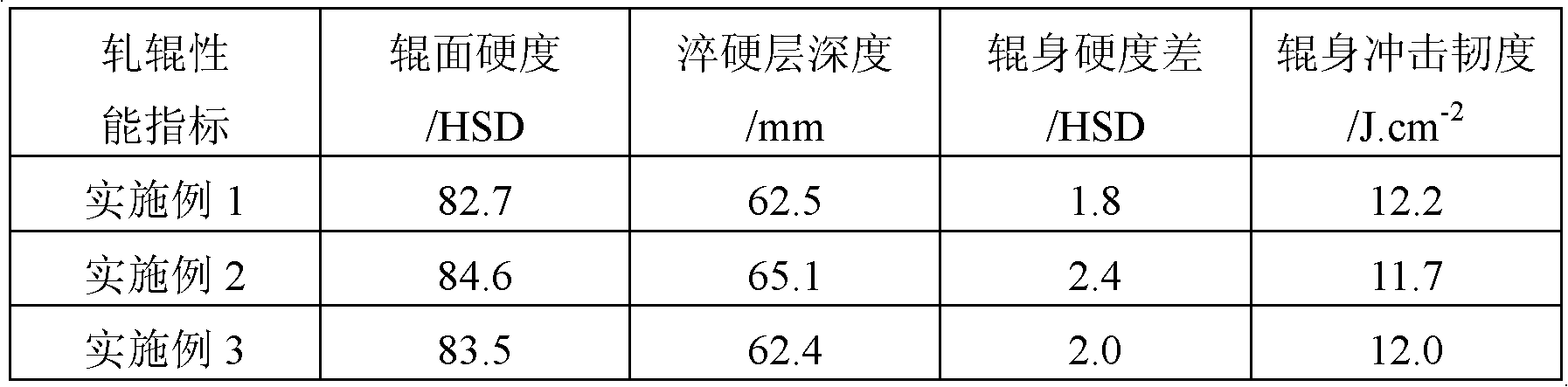

Embodiment 1

[0041] The boron-containing high-speed steel composite roll of the present embodiment is Tropical continuous rolling work rolls. The outer layer (that is, the roller body) and the roller core are smelted in a 750kg and 3000kg medium frequency induction furnace respectively, and the manufacturing process steps are:

[0042] The first step: Melting of the outer boron-containing high-speed steel material

[0043] ① First mix the high-speed steel rolls, high-chromium cast iron rolls and high-nickel-chromium infinite chilled cast iron rolls with alloy iron filings, tungsten slag iron alloys, and low-carbon scrap steel sheets, and compact them on a press to form a size (150-250 )mm×(150~250)mm×(150~250)mm squares, and then put the compacted squares into the induction furnace for heating and melting.

[0044] ② After the molten steel is melted, when the temperature of the molten steel reaches 1552°C, first add low-carbon ferromanganese for pre-deoxidation, then use magnesium-alumi...

Embodiment 2

[0057] The boron-containing high-speed steel composite roll of the present embodiment is Tropical continuous rolling work rolls. The outer layer (that is, the roll body) and the roll core are melted in a 1500kg medium frequency induction furnace and a 10 ton hot air cupola respectively. The manufacturing process steps are:

[0058] The first step: Melting of the outer boron-containing high-speed steel material

[0059] ① First mix the high-speed steel rolls, high-chromium cast iron rolls and high-nickel-chromium infinite chilled cast iron rolls with alloy iron filings, tungsten slag iron alloys, and low-carbon scrap steel sheets, and compact them on a press to form a size (150-250 )mm×(150~250)mm×(150~250)mm squares, and then put the compacted squares into the induction furnace for heating and melting.

[0060] ② After the molten steel is melted, when the temperature of the molten steel reaches 1579°C, first add low-carbon ferromanganese for pre-deoxidation, then use magnes...

Embodiment 3

[0073] The boron-containing high-speed steel composite roll of the present embodiment is Bar mill work rolls. The outer layer (that is, the roller body) and the roller core are melted in a 500kg intermediate frequency induction furnace and a 1000kg intermediate frequency induction furnace respectively. The manufacturing process steps are:

[0074] The first step: Melting of boron-containing high-speed steel material in the outer layer

[0075]① First mix the high-speed steel rolls, high-chromium cast iron rolls and high-nickel-chromium infinite chilled cast iron rolls with alloy iron filings, tungsten slag iron alloys, and low-carbon scrap steel sheets, and compact them on a press to form a size (150-250 )mm×(150~250)mm×(150~250)mm squares, and then put the compacted squares into the induction furnace for heating and melting.

[0076] ②After the molten steel is melted, when the temperature of the molten steel reaches 1568°C, first add low-carbon ferromanganese for pre-deoxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com