Rail trolley for industrial tool conveyance and rail

A rail trolley and rail car technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inconvenient assembly and disassembly, insufficient flexibility, cumbersome operation, etc., and achieve the effect of precise and stable mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

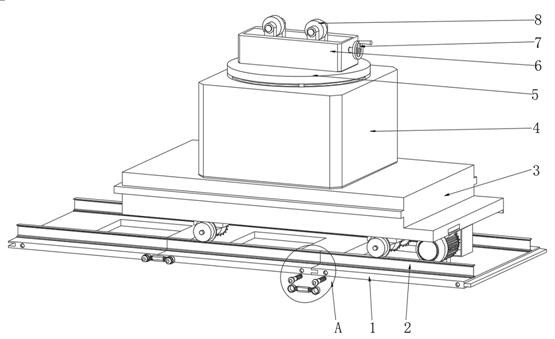

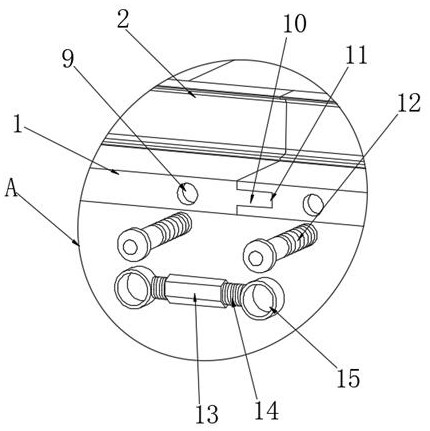

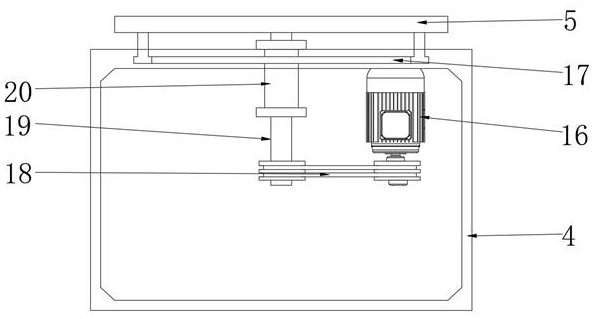

[0024] see Figure 1~5 , in an embodiment of the present invention, a rail trolley and a track for industrial tool transmission, including a guide rail frame 1, the guide rail frame 1 is connected by a locking mechanism, and an I-shaped guide rail 2 is symmetrically fixed above the guide rail frame 1, The locking mechanism includes positioning screw holes 9 symmetrically opened at the edge positions of the front and rear ends of the guide rail frame 1, the inside of the positioning screw hole 9 is screwed with a positioning bolt 12, and the outer side of the positioning bolt 12 is sleeved with a fastening collar 15, The inner side of the fastening collar 15 is symmetrically fixed with a telescopic screw 14, and the outer side of the telescopic screw 14 is sleeved with an adjusting screw sleeve 13, and one end of the guide rail frame 1 is provided with a packaging slot 11, and the other end of the guide rail frame 1 is provided with a Package block 10, the inner diameter of pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com