Cross-linkable quantum dot and preparation method thereof, array substrate and preparation method of array substrate

An array substrate and quantum dot technology, which is applied in the field of cross-linkable quantum dots and its preparation, can solve problems such as difficult to meet, and achieve the effect of improving utilization rate and process yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] This example relates to a method for preparing cross-linkable quantum dots of various colors.

[0109] Preparation of cross-linkable green quantum dots using green quantum dot raw materials:

[0110] The green quantum dot raw material (its trade name is green quantum dot, purchased from Guangdong Pujiafu Photoelectric Technology Co., Ltd. The quantum dot raw material is synthesized according to the traditional heat injection method, and the ligands it has include trioctylphosphine, trioctyl Ligands such as phosphine oxide, oleylamine, oleic acid) and pyridine were contacted with stirring under ambient conditions for 2 hours at a weight ratio of 1:5, thereby replacing the ligand of the quantum dot raw material with pyridine; then by centrifugation method to separate quantum dots with pyridine. Then, the quantum dots with pyridine react with the cross-linking ligand raw materials (mercaptoacetic acid and 1-cyclohexene-1-acetic acid, purchased from Aladdin reagent network...

Embodiment 2

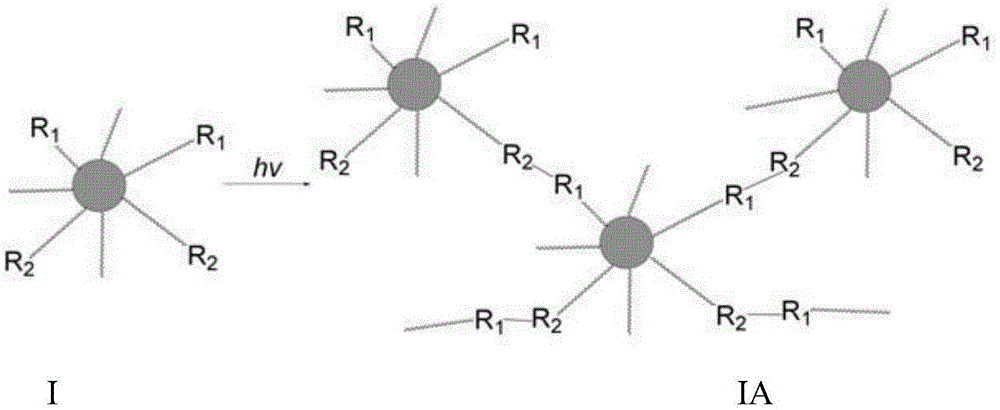

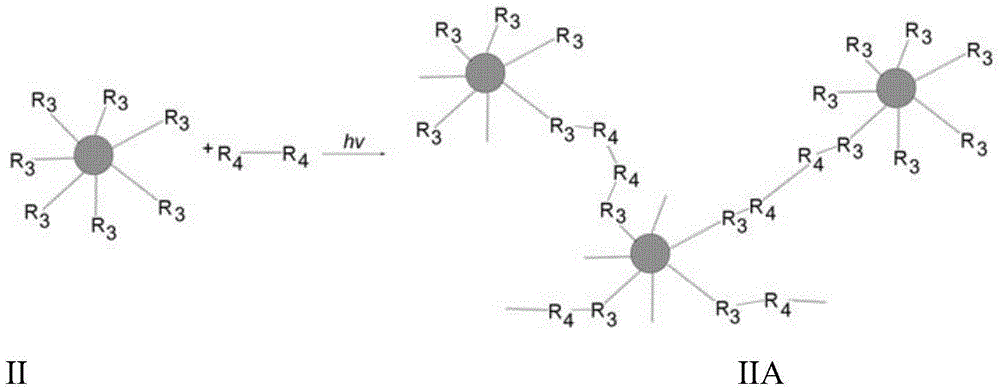

[0118] This example discloses a method for preparing monofunctional cross-linkable quantum dots of various colors. This method is similar to embodiment 1, the difference is:

[0119]The quantum dot feedstock (such as the quantum dot feedstock used in Example 1, such as the green quantum dot feedstock, blue quantum dot feedstock, and red quantum dot feedstock) was contacted with pyridine in a weight ratio of 1:5 under ambient conditions under stirring 2 hours, thereby replacing the ligand of the quantum dot raw material with pyridine; and then separating the quantum dots with pyridine by centrifugation and other methods. Then, react the quantum dots with pyridine with the cross-linking ligand raw material (thioglycolic acid, purchased from Aladdin Reagent Network Co., Ltd.) with monofunctional groups, so that pyridine is replaced with ligands with monofunctional groups, thereby obtaining monofunctional Functional group cross-linkable quantum dots. The monofunctional cross-lin...

Embodiment 3

[0123] This embodiment relates to a method for preparing green cross-linkable quantum dots sensitive to I line.

[0124] The green quantum dot raw material (its trade name is green quantum dot, purchased from Guangdong Pujiafu Optoelectronics Technology Co., Ltd. The green quantum dot raw material is synthesized according to the traditional heat injection method, and the ligands it carries include trioctylphosphine, three Ligands such as octylphosphine oxide, oleylamine, oleic acid) and pyridine were contacted under ambient conditions with stirring for 2 hours with a weight ratio of 1:5, thereby replacing the ligand of the green quantum dot raw material into pyridine; The quantum dots with pyridine are separated by methods such as centrifugation. Then, the quantum dots with pyridine were combined with the cross-linking ligand raw materials with two functional groups (which can be tert-butoxycarbonyl protected-C-methylcalixarene[4] with carboxyl group and diphenyl Iodine (9,10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com