Microgel with nanometer grade sensitivity of temperature and PH value and preparation method thereof

A microgel and sensitive technology, which is applied in the field of nanoscale microgel with temperature and pH sensitivity and its preparation, can solve the problems of increasing total cost and time, and large particle size of colloidal particles, and achieve total saving The effect of cost and time, wide application range and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

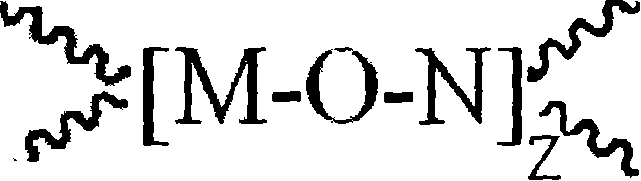

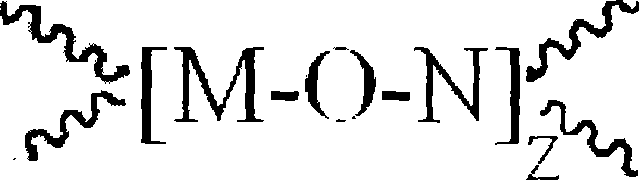

Method used

Image

Examples

Embodiment 1

[0046] Put 1.5g of isopropylacrylamide, 0.05g of acrylic acid, and 0.1g of methylenebisacrylamide into 50g of deionized water at the same time, and stir to form a uniform and transparent reactant aqueous solution. The process conditions: the stirring speed is 300 rev / min, the time is 30 minutes.

[0047] The ammonium persulfate initiator of 0.1g is added into 50g deionized water, and at room temperature, it is made into an initiator aqueous solution with a concentration of 0.2% by weight, and first adjusted to pH=3 ± 0.5 with acetic acid, and then feeds nitrogen gas, and the stirring speed is 200 rev / min, gradually raise the temperature to 75°C, equilibrate for 30 minutes before use.

[0048] Under nitrogen conditions, the prepared 51.65g reactant aqueous solution was added dropwise in the aforementioned initiator aqueous solution, and the system changed from transparent to light blue after 10 minutes of reaction, and finally a milky white nano-scale microgel dispersion was ob...

Embodiment 2

[0053] Put 1.4g of isopropylacrylamide, 0.4g of acrylic acid, and 0.1g of methylenebisacrylamide into 50g of deionized water at the same time, and stir to form a uniform and transparent aqueous solution of reactants. The process conditions: the stirring speed is 300 rev / min, the time is 30 minutes.

[0054] Add 0.1 g of potassium persulfate initiator into 50 g of deionized water, and make an aqueous initiator solution with a concentration of 0.2% by weight at room temperature, adjust the pH to 3 ± 0.5 with acetic acid, and then pass in N 2 , the stirring speed is 200 rev / min, the temperature is gradually raised to 70°C, and it is ready to use after equilibrating for 30 minutes.

[0055] Under nitrogen conditions, the prepared 51.9g reactant aqueous solution was added dropwise in the aforementioned initiator aqueous solution, and the system changed from transparent to light blue after 10 minutes of reaction, and finally a milky white nano-scale microgel dispersion was obtained....

Embodiment 3

[0060] Dissolve 1.4g of vinyl acrylamide, 0.2g of acrylic acid, and 0.1g of methylenebisacrylamide in 50g of deionized water at the same time, and make a uniform and transparent reactant aqueous solution after stirring. The process conditions: the stirring speed is 300 rpm / minute, the time is 40 minutes.

[0061] Add 0.1 g of ammonium persulfate initiator to 50 g of deionized water, and make an aqueous initiator solution with a concentration of 0.2% by weight at room temperature, first adjust the pH to 3 ± 0.5 with acetic acid, and then pass in N 2 , the stirring speed is 200 rev / min, the temperature is gradually raised to 75°C, and it is ready to use after equilibrating for 30 minutes.

[0062] Under the nitrogen condition, the prepared 51.7g reactant aqueous solution was added dropwise in the aforementioned initiator aqueous solution, and the system changed from transparent to light blue after 10 minutes from the start of the reaction, and finally a milky white nano-scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com