Raw material selection of straw board and producing technique thereof

A technology for straw board and production process, which is applied in the direction of wood processing utensils, pretreatment and application of molding materials, etc., to achieve the effects of reducing raw material cost, low raw material cost, and simplifying process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

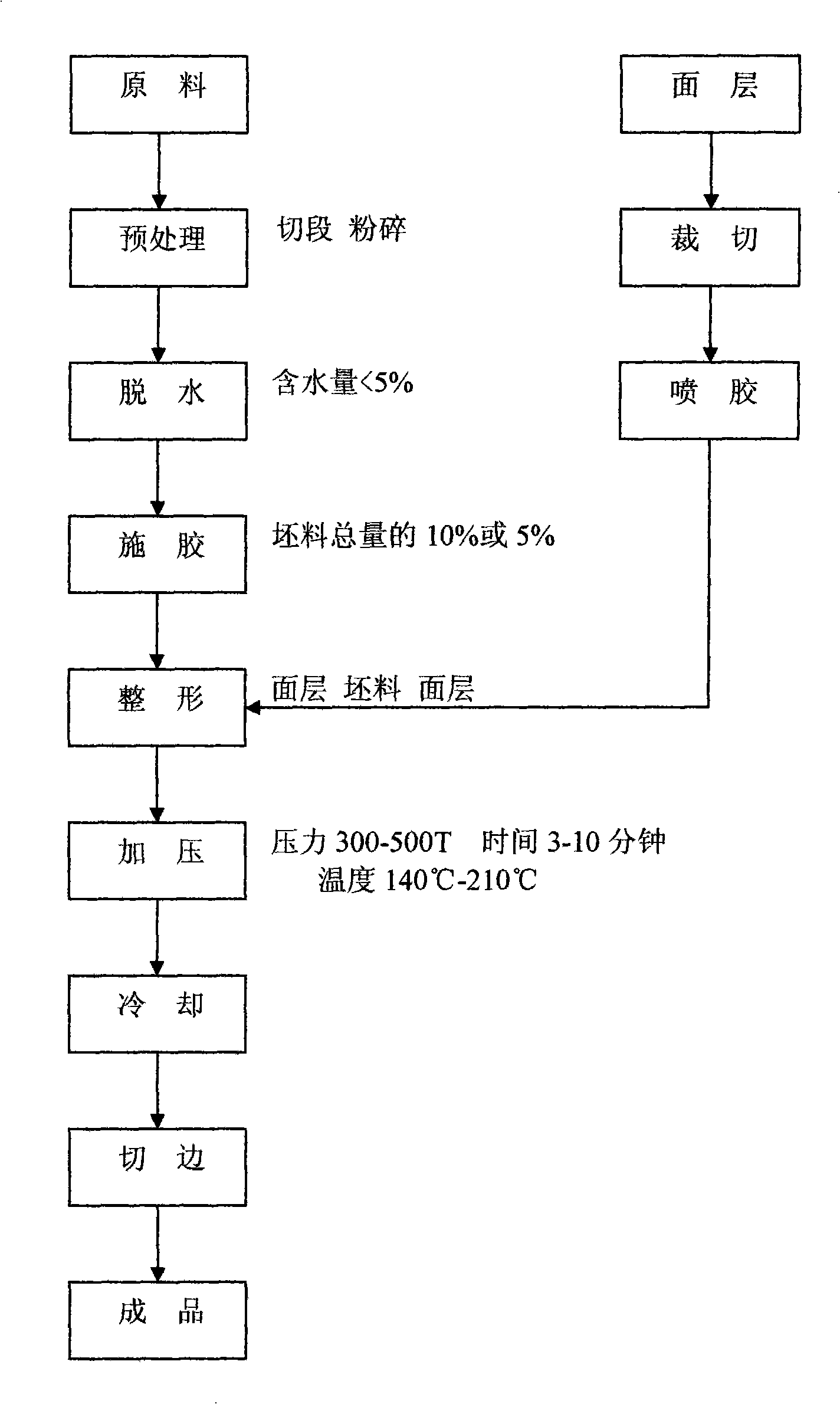

Method used

Image

Examples

Embodiment 1

[0016] Firstly, the rice straw, wheat straw and reed are machine-rolled into strips and sheets. Next, cut 40% of them into 30mm-80mm long pieces, and crush the remaining 60%. Then enter the dehydration process. Straw, rice husk and sawdust must be dehydrated. Make the water content <5%. Next, the ratio of raw materials is carried out. Mix with 40% of 30mm-80mm long straw segments and 60% of crushed straw, or mix with 40% of straw segments and 60% of sawdust or rice husk. Sizing while mixing. The amount of glue used can be determined according to the type of glue used. If urea-formaldehyde resin glue is used, it can be applied according to 10% of the total weight of the blank. If isocyanate glue is used, it can be applied at 5% of the total weight of the blank. The surface layer is made of 120g corrugated paper or 0.8mm thick veneer single piece. The top layer is to be trimmed. On the basis of the national standard 2440mm×1220mm (length×width), a margin of 50mm is rese...

Embodiment 2

[0018] In the pretreatment process, the reeds are machine-rolled into strips and slices, and then cut into 30mm-80mm long pieces, and the rice straw or wheat straw is crushed with a grinder. All raw materials are then dehydrated. Make the water content <5%. Then enter the proportioning and mixing process. First cut the small reeds with a length of 30mm-80mm, and apply 5% isocyanate glue to the crushed straw material according to the ratio of 4:6 and stir together for 3-5 minutes. The surface layer is made of 220g corrugated paper. First cut the corrugated paper (without spraying glue) and lay it on the aluminum formwork. Enter the shaping process. Lay the stirred blank on the surface layer with a thickness of 40mm. Then lay the surface layer and upper formwork. Go to the heating and pressing process. Straw boards with a thickness of 10mm can be produced. It can press 20 sheets each time. The pressure is 400T. The temperature was 160°C. The time is 8 minutes. After ...

Embodiment 3

[0020] Use 40% of 30mm-80mm long straw segments, match with 60% crushed material, apply 10% urea-formaldehyde resin glue, and stir for 5 minutes. Enter the shaping process. The surface layer is made of 120g corrugated paper. After the surface layer is cut, it needs to be sprayed with glue. Then lay the glued face paper on the template. Lay the sizing and mixing blank on the surface layer with a thickness of 30mm. Then lay the surface layer and formwork, and send it to the press. The pressure is 400T, the temperature is 210°C, and the time is 8 minutes. A straw plate of 2440mm×1220mm×8mm is pressed. Cut the periphery after cooling, that is, the production is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com