Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

213 results about "Neutral proteinase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Neutral Protease (Dispase) Neutral protease is an extremely stable Zn-metalloendopeptidase that is produced by Paenibacillus polymyxa. It is involved in the generation of beta- and alpha-amylases from the large amylase precursor.

Micromolecule walnut peptide and preparation method thereof

InactiveCN105002247AHigh egg contentLow costPeptide preparation methodsFermentationAlkaline proteaseProtein structure

The invention relates to a micromolecule walnut peptide and a preparation method thereof. The preparation method sequentially comprises the following steps of protein extraction, twice enzymolysis, filtering, purification, concentration and drying. In the twice enzymolysis process, alkaline protease with the mass being 1-3% that of the walnut protein is added into a walnut protein extracting solution for once enzymolysis; enzyme deactivation is performed on a once enzymolysis solution after the once enzymolysis is finished; one or more kinds of proteinase including the flavored proteinase, the neutral proteinase and the papain with the mass being 1-3% that of the walnut protein are added after the once enzymolysis solution obtained after enzyme deactivation is performed is cooled for secondary enzymolysis. According to the preparation method, the twice enzymolysis method is adopted, due to the specificity of the structure of the walnut protein structure, sufficient enzymolysis cannot be performed on the walnut protein through enzymolysis of one proteinase, and the twice enzymolysis method is adopted for ensuring that the enzymolysis is brought into play on the most suitable condition of each proteinase, and therefore the obtained walnut peptide content is high.

Owner:BEIJING TIANTAI BIOTECH

Pre-treatment of cotton fabrics by rolling and piling up of enzyme

The invention provided a fore treatment process of the enzyme rolling pile for the fabric which belongs to the fore treatment process of the dyeing and finishing field. The process is: first to impregnate the fabric into the mixture of the alkali pectinase liquid, neutral proteinase liquid and xylanase liquid, then to keep the temperature, next to wash with the hot water (killing the enzyme) and the cool water last to blanch with the H2O2. The pectinase is produced by the Bacillus subtilis WSHB04-03. The process has many merits such as high efficiency, low work output and the energy conservation and so on.

Owner:JIANGNAN UNIV

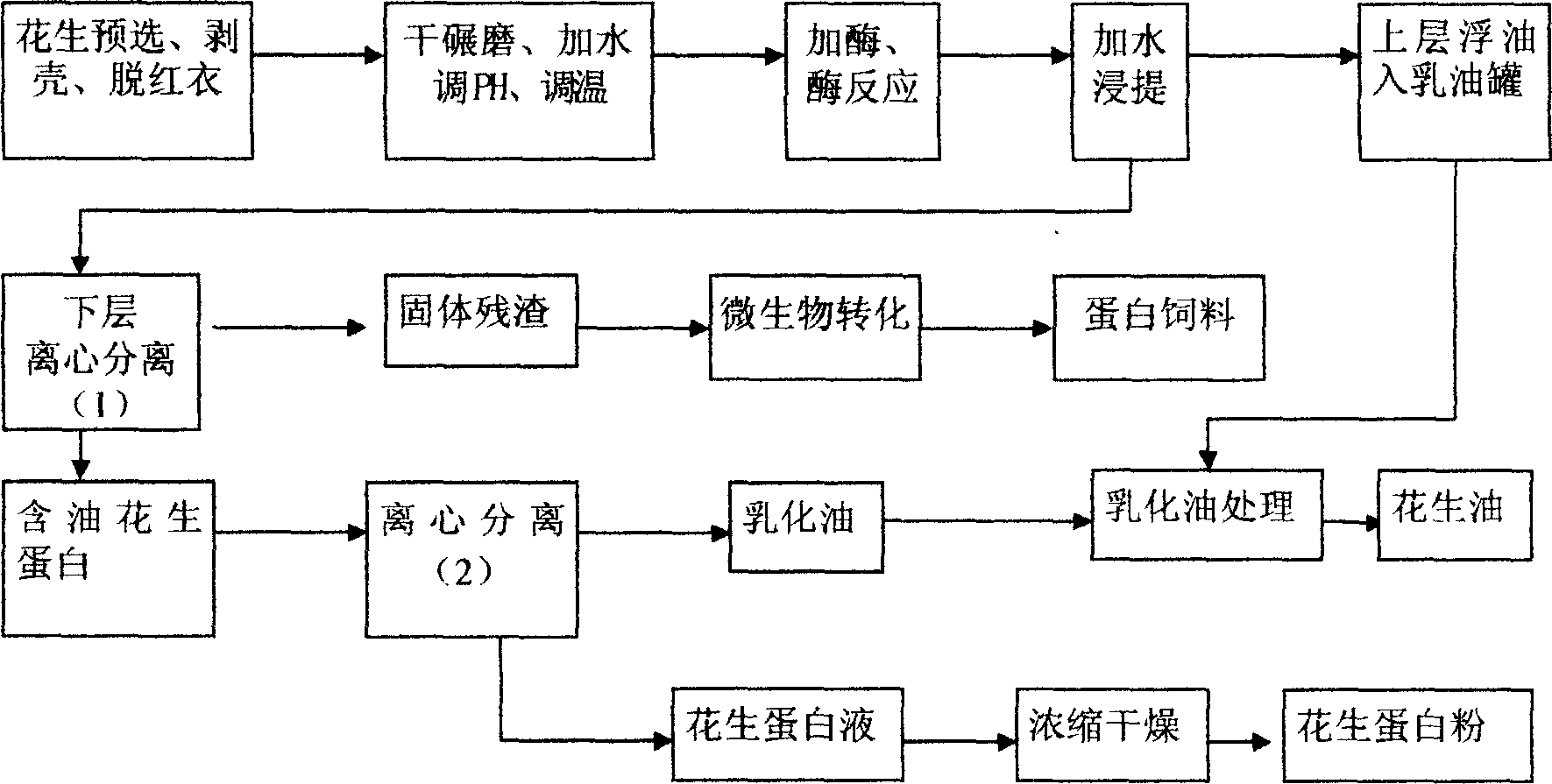

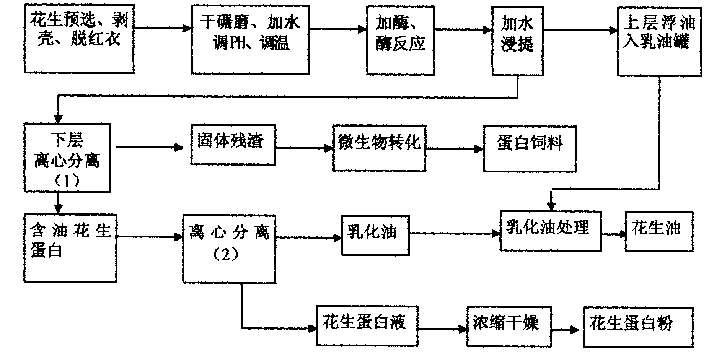

Peanut protein and fat enzyme extracting process

InactiveCN1419837AReduce adsorptionEasy to separateProtein composition from vegetable seedsFatty-oils/fats productionPectinaseNeutral proteinase

A process for extracting protein and oil from peanut by enzyme method includes pre-treating raw material, removing shell, peeling, grinding, enzymolizing with cellulase, pectinase, or neutral proteinase, leaching in water, and separating protein and oil. Its advantages are high yield, and low content of oil in protein powder.

Owner:厦门中盛粮油集团有限公司

Method for extracting dietary fiber from potato residues

InactiveCN101715946AReduce pollutionSolve processing problemsFood preparationNeutral proteinaseSolanum tuberosum

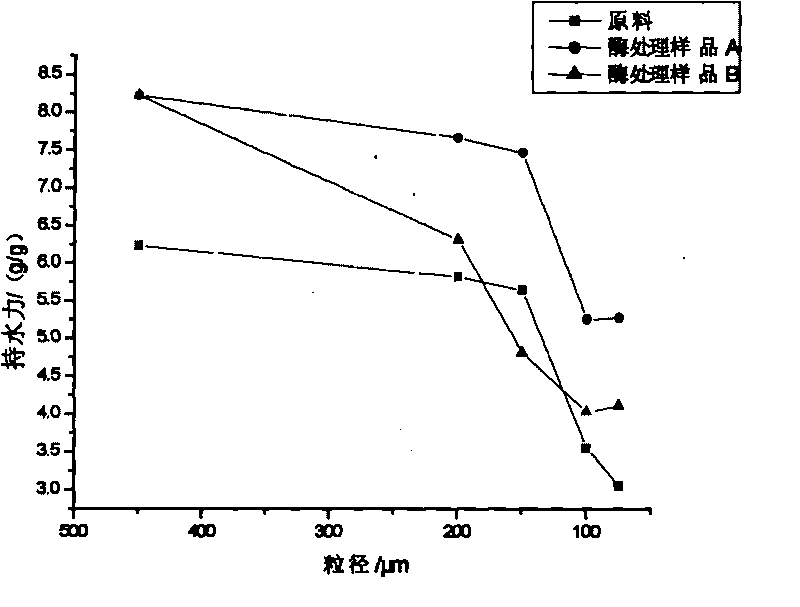

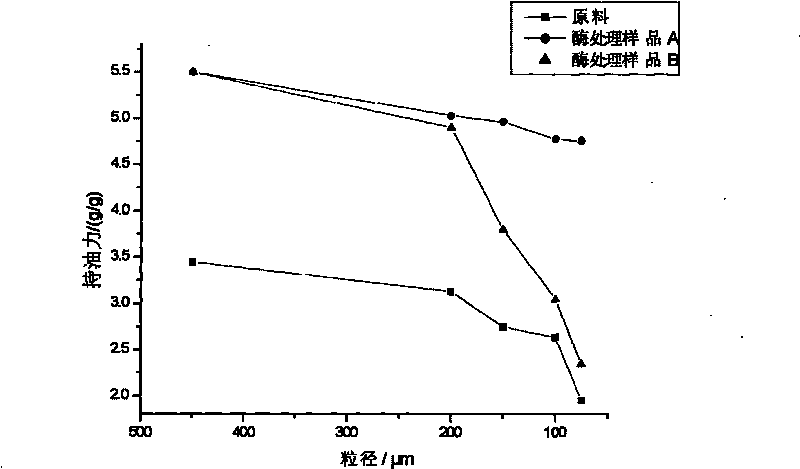

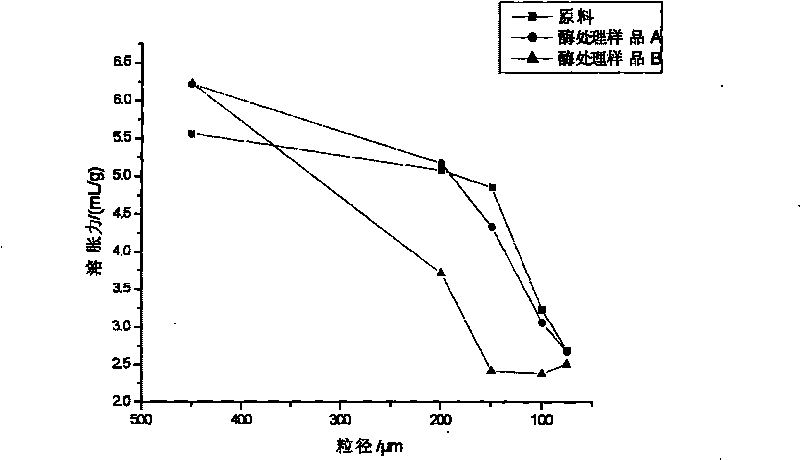

The invention discloses a method for extracting a dietary fiber from potato residues, which comprises the following steps of: drying potato residues, pulverizing and screening to prepare potato residue powder; adding water into the potato residue powder, uniformly mixing to form a potato residue pulp, carrying out enzymolysis processing by using mixed enzyme, boiling and cooling; adding neutral proteinase to carry out enzymolysis processing, boiling and cooling, wherein the activity of the neutral proteinase is 1,600AU; filtering to form filter liquid and filter residues; and drying, pulverizing and screening the filter residues to obtain the dietary fiber. The invention improves the water-holding capacity and the oil-holding capacity of the potato dietary fiber by bio-enzyme processing and obtains a production process of the dietary fiber with optimal grain diameter simultaneously.

Owner:SOUTH CHINA UNIV OF TECH

Processing method of waste tobacco

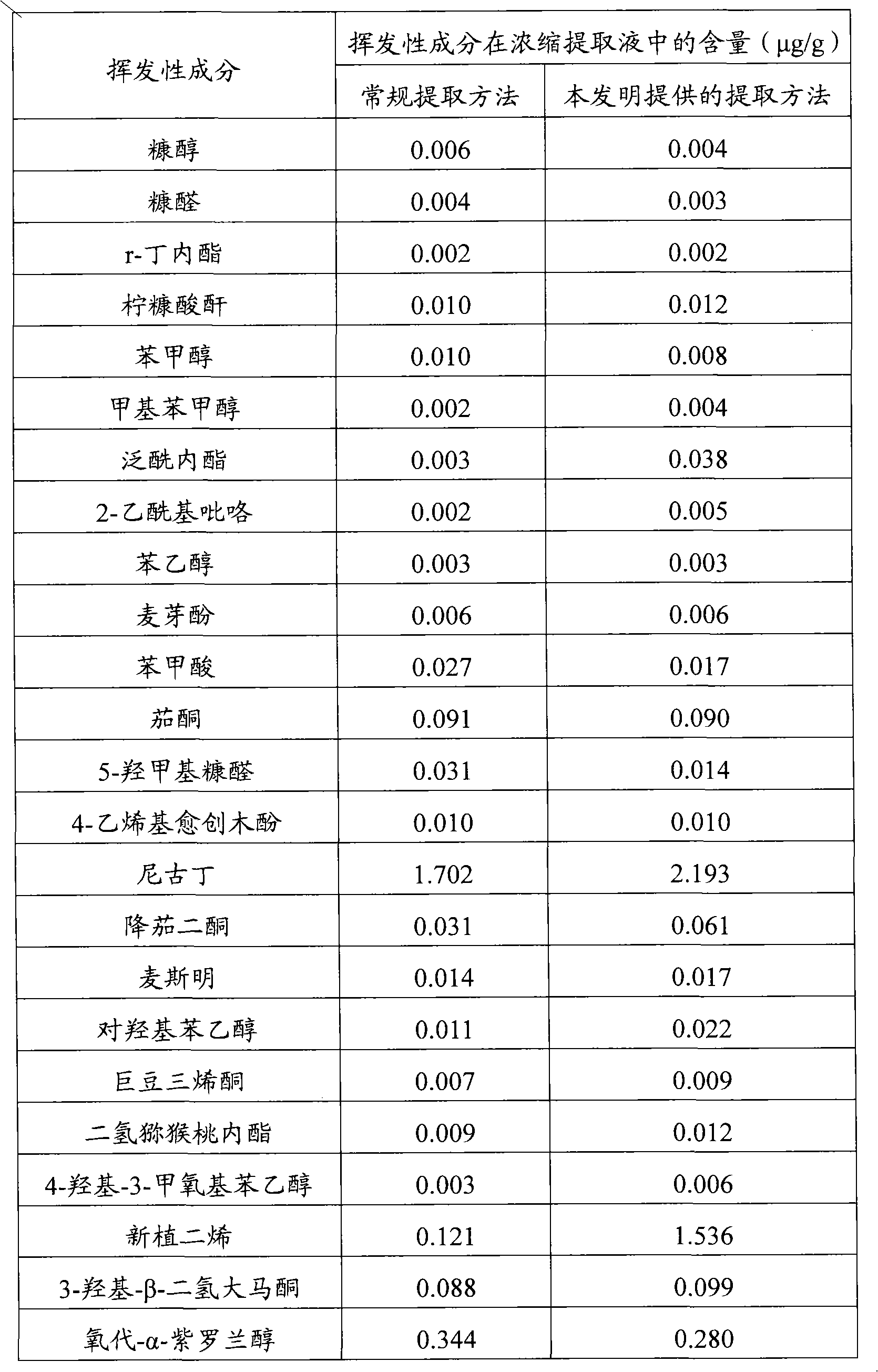

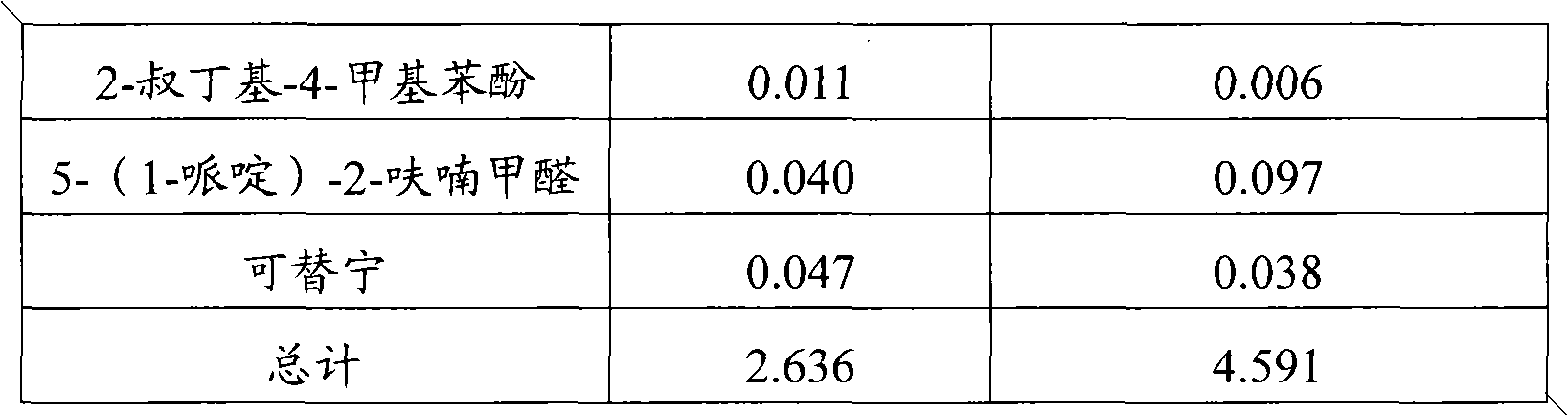

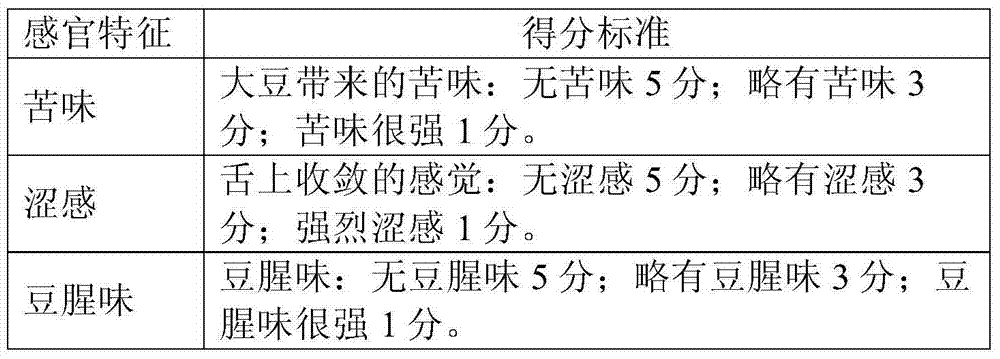

ActiveCN101940361ARich in active ingredientsIncrease pleasureTobacco preparationMass ratioReaction temperature

The invention relates to the field of processing of tobacco, and discloses a processing method of waste tobacco. The method comprises the following steps: reacting the waste tobacco, composite plant hydrolase accounting for 0.05-3 wt% of waste tobacco, 0.05-3 wt% of cellulase and 0.05-3 wt% of neutral proteinase in a buffer solution with the pH value of 4.5-6.0 for 4-8 hours, wherein the volume-to-mass ratio by mL / g of buffer solution to waste tobacco is 5-10:1; filtering after the reaction, taking the filter residues, and adding water for reextraction, wherein the volume-to-mass ratio by mL / g of water to waste tobacco is 2-4:1; and mixing the extracts. When the extraction yield and extract purity in the method and prior extraction method are measured, the result indicates that the method enhances the extraction efficiency by 25.2%, increases the content of volatile components by 74.2% as compared with the conventional method, and increases the content of main fragrance component neophytadiene by 6 times. The method has the advantages of low water consumption, low reaction temperature and simple operation, and lowers the production cost.

Owner:CHINA TOBACCO GUANGDONG IND

Method for preparing soybean peptides through enzymolysis of soy protein

ActiveCN104719611AReduce bitternessHigh yieldVegetable proteins working-upAlkaline proteaseNeutral proteinase

The present invention relates to a method for preparing soybean peptides through enzymolysis of soy protein, wherein the obtained soybean peptides have characteristics of low bitter taste and high yield, and the contents of free amino acids and the peptides having a molecular weight of less than 150 Da or greater than 2000 Da are low. The method comprises: adding water to soybean protein to prepare a 4-12 wt% soybean separation protein liquid, adjusting the temperature and the pH value, sequentially adding a proper amount of alkaline proteinase adopted as the endopeptidase, neutral proteinase and flavourzyme adopted as the exopeptidase, carrying out an enzymolysis reaction, adjusting the pH value of the enzymolysis liquid, carrying out enzyme inactivation, centrifugating, taking the supernatant, sterilizing, and carrying out spray drying to obtain the soybean peptide.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Method for preparing nano natural silk protein powder

ActiveCN101168763AStrong enzyme cutting functionUniform DigestionFermentationFreeze-dryingCentrifugation

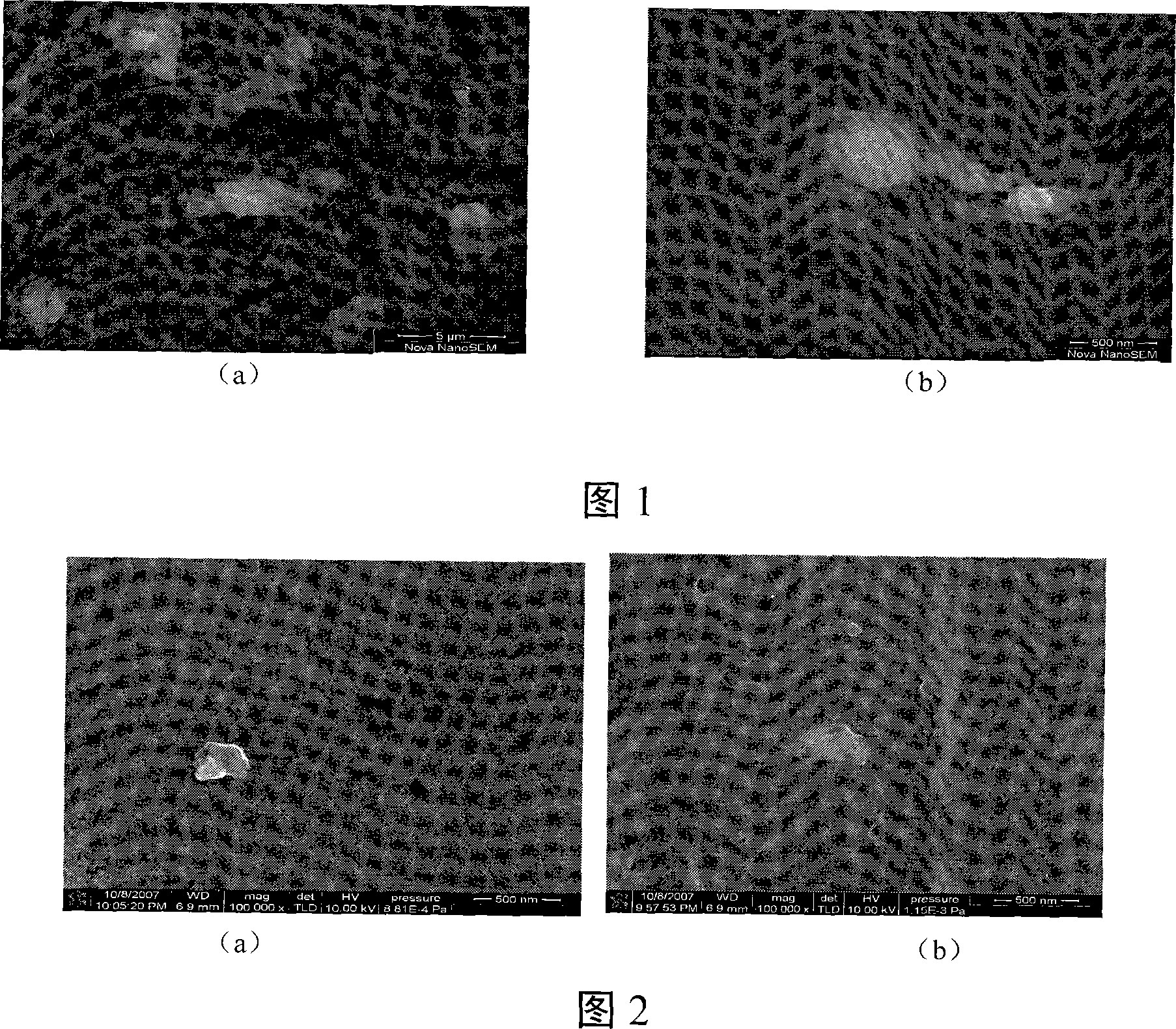

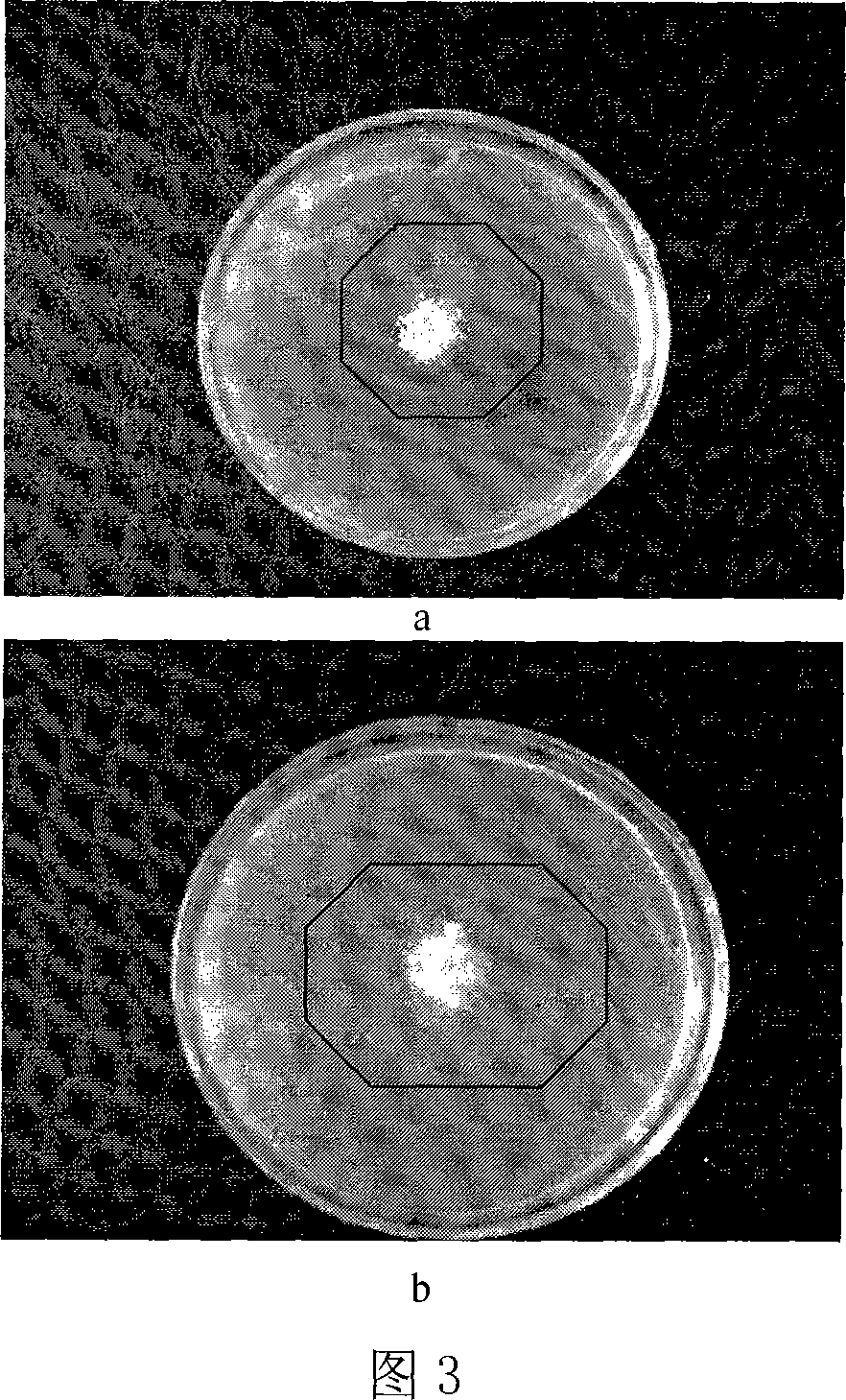

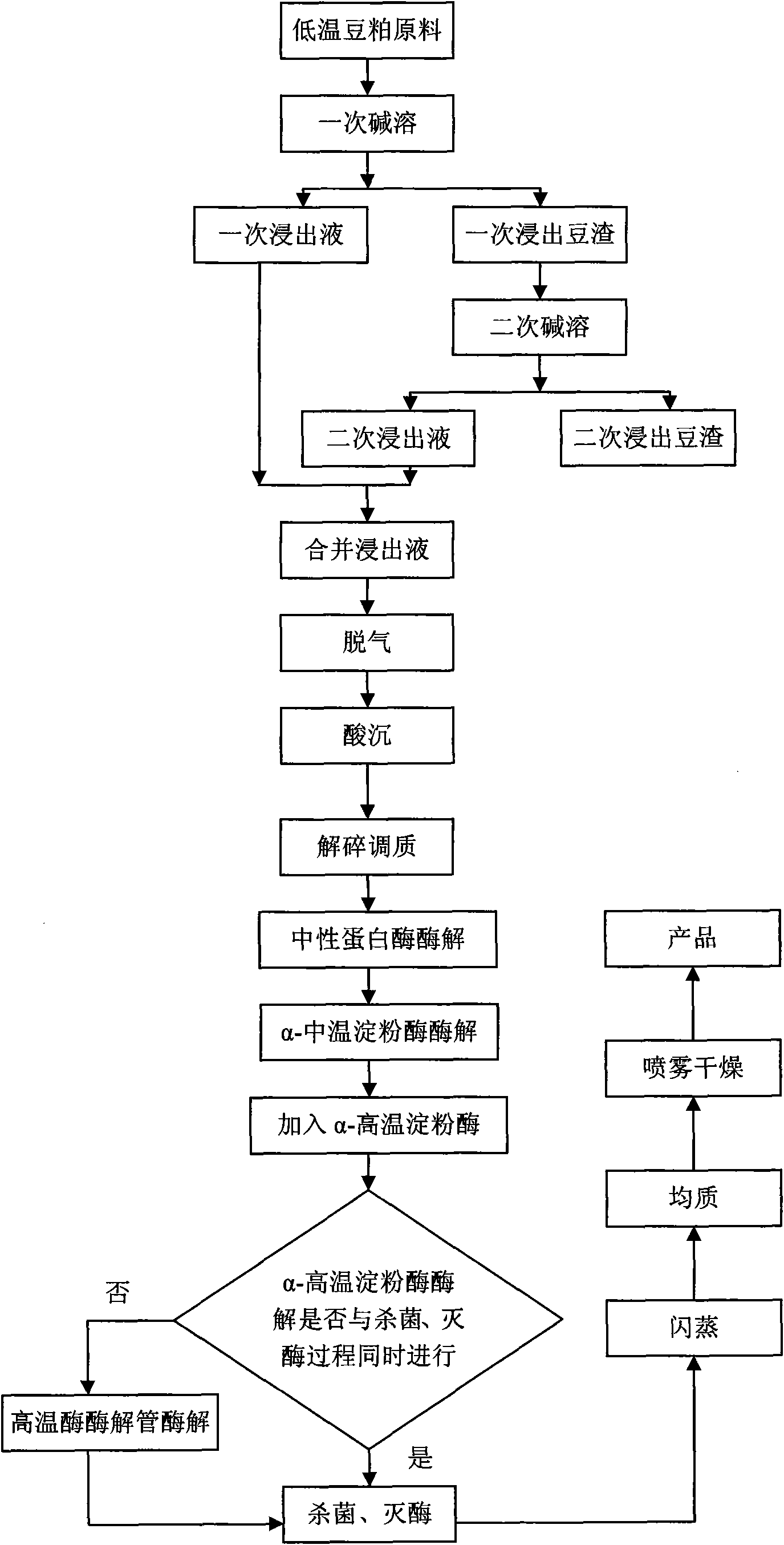

The invention discloses a method for preparing nanometer natural silk fibroin albumen powder. Silk fibroin albumen is dissolved in mixed solvent of 50 to 60 wt percent of NaSCN or LiBr: CH3OH: H2O (the weight ratio is 40 to 60: 22 to 42: 10 to 30), dialyzed and concentrated by water, enzymatically hydrolyzed by Alpha chymotrypsin or neutral proteinase, and finally evaporated, dried and collected through a freeze drying method or centrifugation. The size of the nano-particles obtained in the method is 80 to 500 nm. The method has the advantages that the preparation process is simple, the mass and industrialized production can be performed, and simultaneously the obtained nanometer natural silk fibroin albumen powder particles are uniform, have appropriate sizes, and are favorable for application.

Owner:重庆惠森驰恒医疗器械有限公司

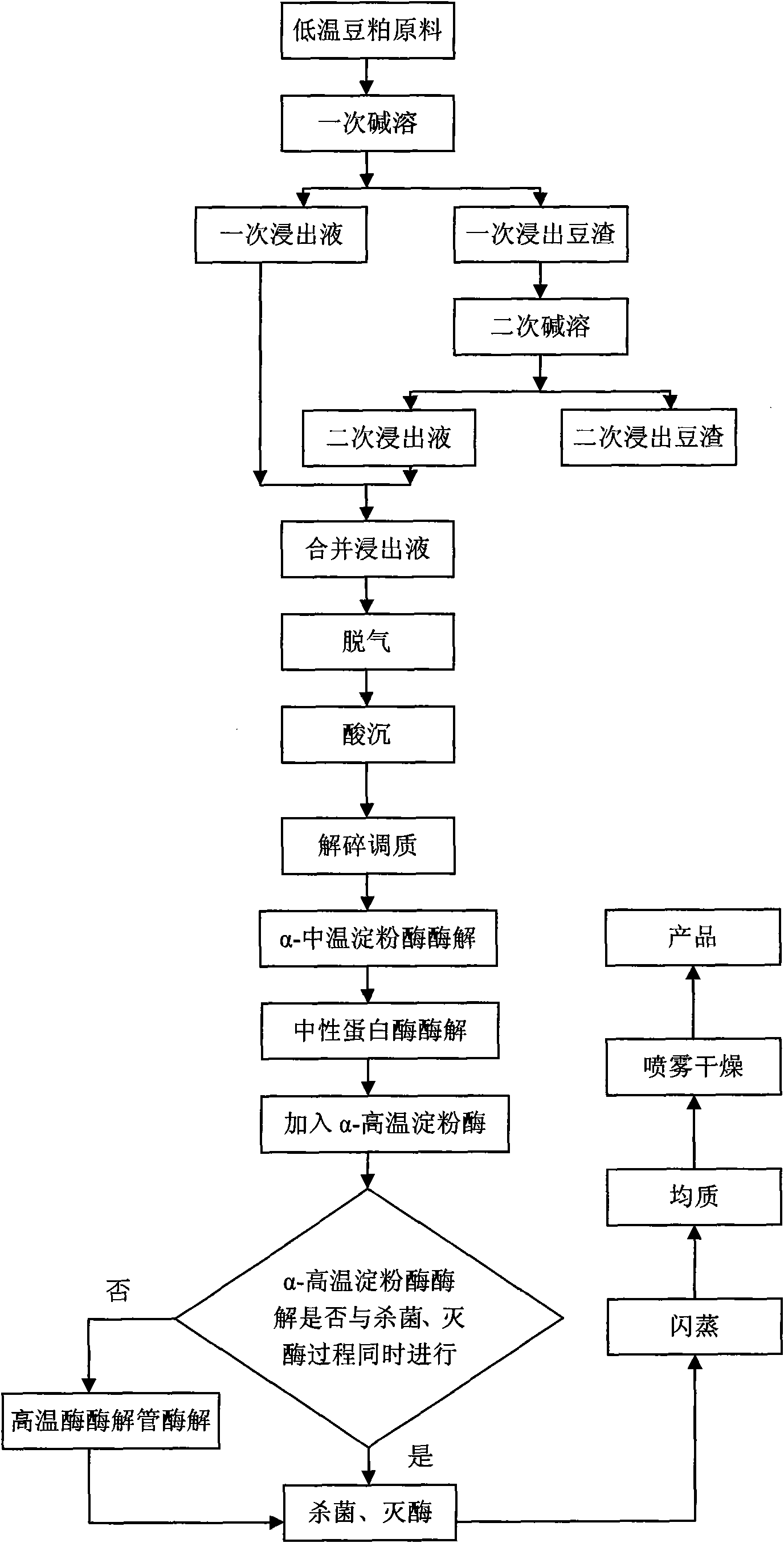

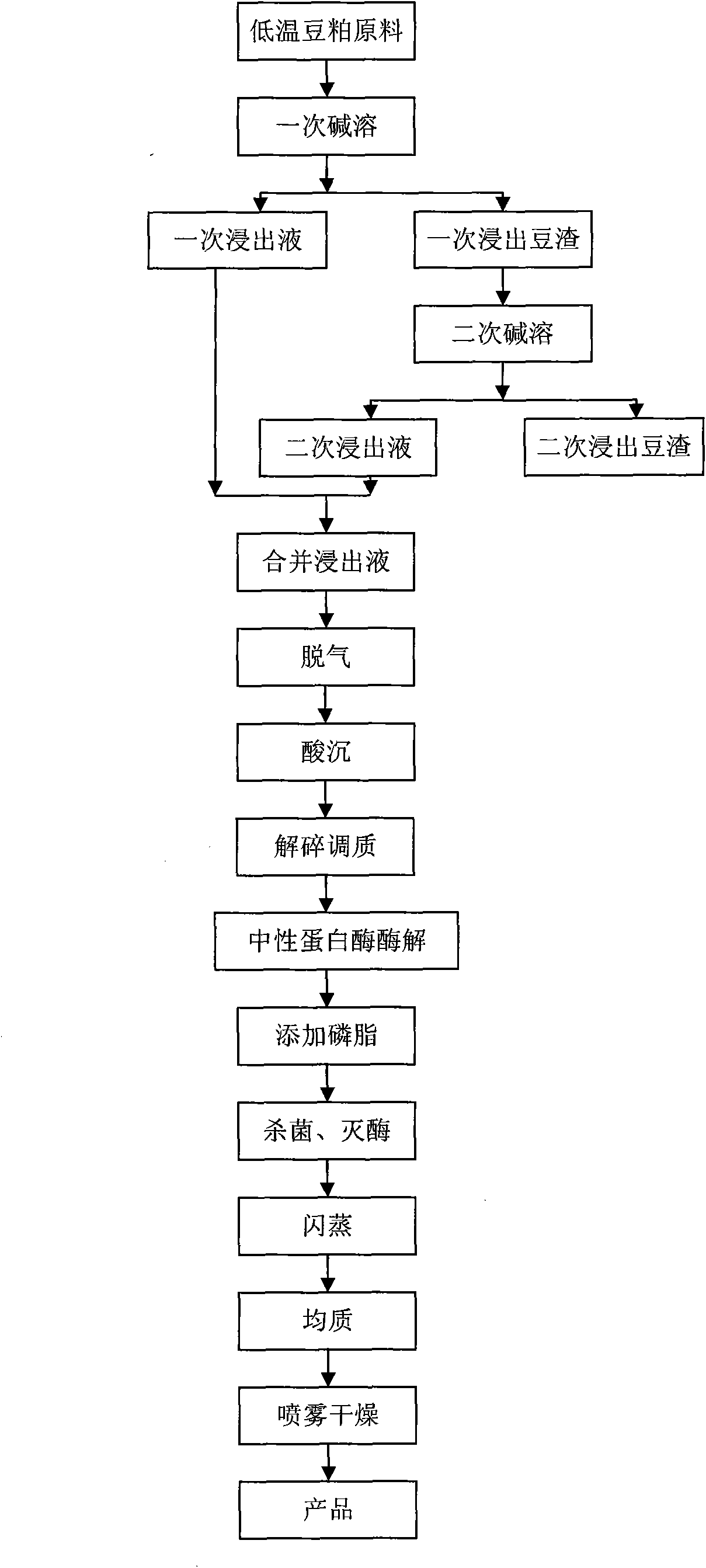

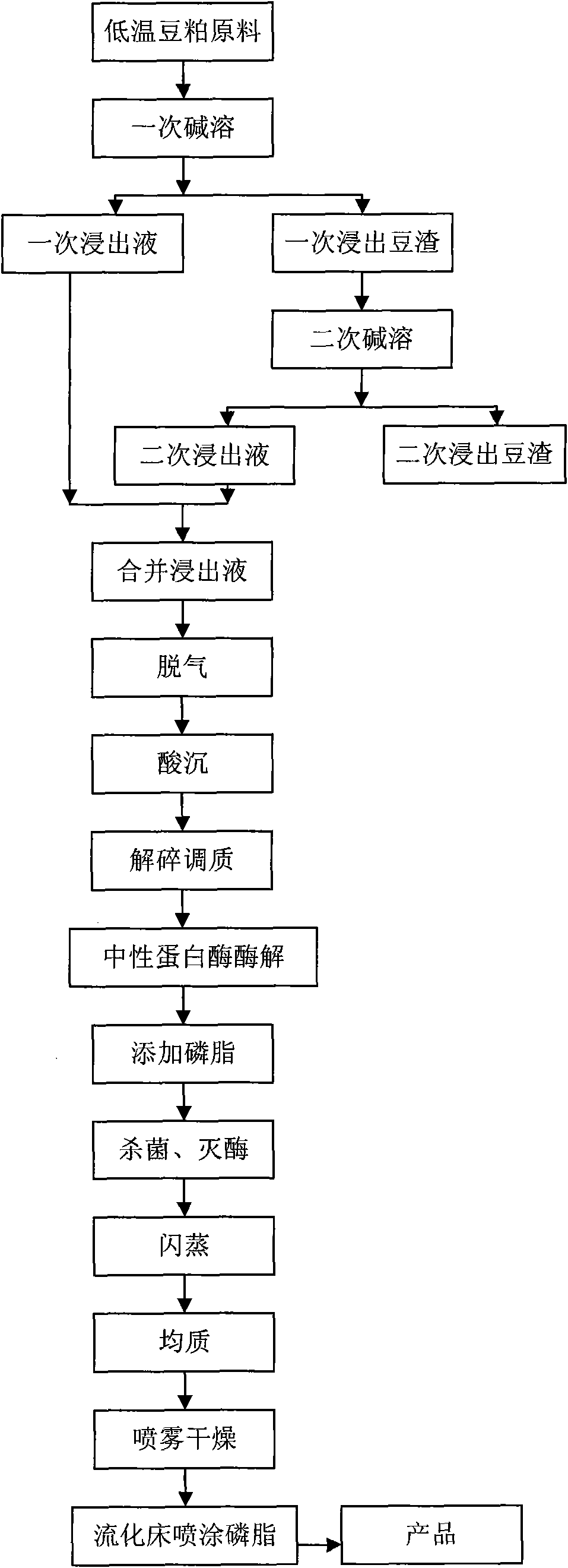

High-dispersibility isolated soybean protein and preparation method thereof

ActiveCN101569344AImprove pass rateFast dispersionProtein composition from vegetable seedsVegetable proteins working-upNeutral proteinaseIce cream

The invention discloses a high-dispersibility isolated soybean protein obtained by an enzymatic modification method and a preparation method thereof. The method comprises the following steps: taking low temperature bean pulp as a raw material, preparing isolated protein curd by alkali extraction, degasification and acid precipitation, and then enzymolyzing the isolated protein curd with neutral proteinase, alpha-moderate temperature amylase and alpha-high temperature amylase, and heating to inactivate enzyme, sterilizing, flash vaporizing, homogenizing, and spray drying after the reaction to obtain the soybean protein with low bitterness, high dispersibility, poor gelatination capacity and good suspension stability. The isolated soybean protein can be applied as a protein additive to milk powder, milk beverage, yoghurt, soy milk, ice cream, nutrition food, athletic food and health products.

Owner:黑龙江省哈高科营养食品有限公司

Soya protein oligopeptides production

InactiveCN1439720AReduce manufacturing costSimplify downstream processingFermentationAlkaline proteinaseNeutral proteinase

A process for preparing soybean protein oligopeptide from concentrated soybean protein, separated soybean protein, defatted soybean powder, soybean dregs, or soybean cake features the cooperative hydrolysis with alkaline proteinase, acidic proteinase and / or neutral proteinase at 30-70 deg.C for 2-24 hr. Its advantages are simple downstream steps and low cost.

Owner:DALIAN UNIV OF TECH

All-soybean peptide nourishment and preparation method thereof

ActiveCN101731443AOvercoming Nutritional MonotonySolve the degradabilityProtein composition from vegetable seedsVegetable proteins working-upNeutral proteinaseBifidus factor

The invention relates to an all-soybean peptide nourishment comprising oligopeptide, small peptide, polypeptide, a linoleic acid, a linolenic acid, an oleic acid, an eicosapentaenoic acid, a bifidus factor, phosphorus, saponin, vitamins and trace elements and a preparation method thereof, solving the problem of thorough beany flavor elimination and low percent conversion from protein into peptides. The preparation method of the all-soybean peptide nourishment comprises the following steps of: freezing soybeans, and then grinding into soybean milk; sequentially grinding the soybean milk 2 to 3 times through a colloid grinder and a high-pressure homogenizing grinder with the pressure of 600-700 Kg and the fineness of 500-600 meshes, and then stirring at the pressure of 0.7-0.8 MPa and the temperature of 130-132 DEG C; after the temperature is reduced, adding a lipase for biochemical degradation; after an enzyme is inactivated, knocking into a nano-grade high-pressure homogenizing grinder with the pressure not lower than 1000 Kg and the fineness not higher than 0.3-0.5 mu for grinding; then adding a neutral proteinase for biochemical reaction; filtering through vacuum micropores of 10-20 micrometers so as to obtain an all-soybean peptide stock solution; and finally preparing the all-soybean peptide nourishments of various types.

Owner:黑龙江万物生生物科技有限公司

Method for high efficiency extracting momordica polysaccharide from balsam pear

The present invention discloses a method for extracting balsam pear polysaccharide from balsam pear. Said method includes the following steps: slicing fresh balsam pear raw material, vacuum drying, grinding the dried balsame pear slices to obtain balsam pear powder, using ethyl alcohol to make extraction, filtering and drying so as to obtain the balsam pear powder which can be used as raw material for subsequent process; adding distilled water into said balsame pear powder, using cellulase whose mass percentage concentration is 0.2-0.6% to make treatment for 10-12 min, filtering to obtain residue, then adding distilled water according to the mass ratio of 1:25-30, using wicrowave with 700W-1000W to make treatment for 3-5 min, heating for 3.5-4h in water bath with 55-60deg.C, filtering to obtain filtrate; finally, using neutral proteinase to treat said filtrate, using dialysis bag to make dialysis, making rotary evaporation, utilizing absolute ethyl alcohol to make precipitation and vacuum drying at 40-45deg.C so as to obtain the invented product-light-yellow balsame pear polysaccharide.

Owner:GUANGZHOU JINYANG COSMETICS

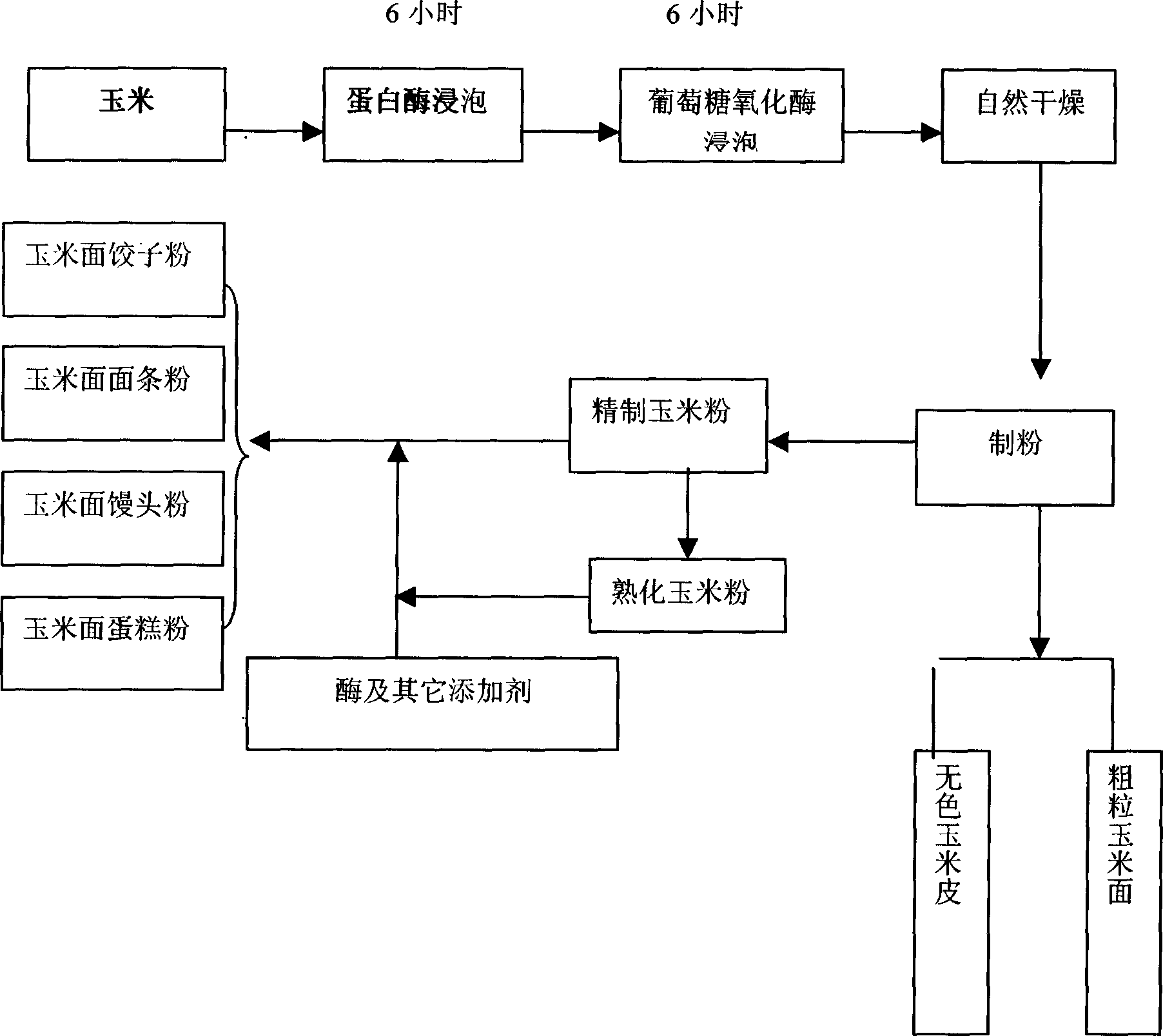

Special-purpose maize flour

The present invention discloses one kind of special corn powder superior to available corn powder, which has poor processing performance, coarse mouth feeling, unbalanced nutrients and other merits. The special corn powder is produced based on the different effects of neutral proteinase, glucose oxidase, alpha-mylase and cellulase on corn or corn powder, and by means of glutelin powder, soybean powder, sodium alginate and guar gum to raise the stiffness and water preserving capability of corn powder and cooking to raise the viscosity of corn powder. The special corn powder is treated with enzyme preparation and natural flour additive while its nutritive components are maintained. The special corn powder may be special dumpling corn powder, special steamed bread corn powder, special self-fermenting steamed bread corn powder, special noodles corn powder, special cake corn powder, etc.

Owner:HEBEI AGRICULTURAL UNIV.

Preparation of depressor peptide by silkworm chrysalis

InactiveCN1896267AInhibit ACE activityWith antihypertensive effectFermentationCardiovascular disorderHydrolysateNeutral proteinase

The present invention discloses a method of preparing antihypertensive peptide from silkworm pupa which includes the following steps: the defatted dry powder of silkworm pupa or silkworm pupa protein powder is mixed with water at the mass ratio of 1:6-7, the pH value is adjusted to 6.0-6.5, then neutral proteinase is added for hydrolysis at 50-55DEG C for 120-200 minutes, the result hydrolysate is antihypertensive peptide. The weight of the said neutral proteinase is 0.9-1.1% of the defatted dry powder of silkworm pupa or silkworm pupa protein powder. The method in the present invention that utilizes silkworm pupa to prepare antihypertensive peptide has lower cost and better effect.

Owner:ZHEJIANG UNIV

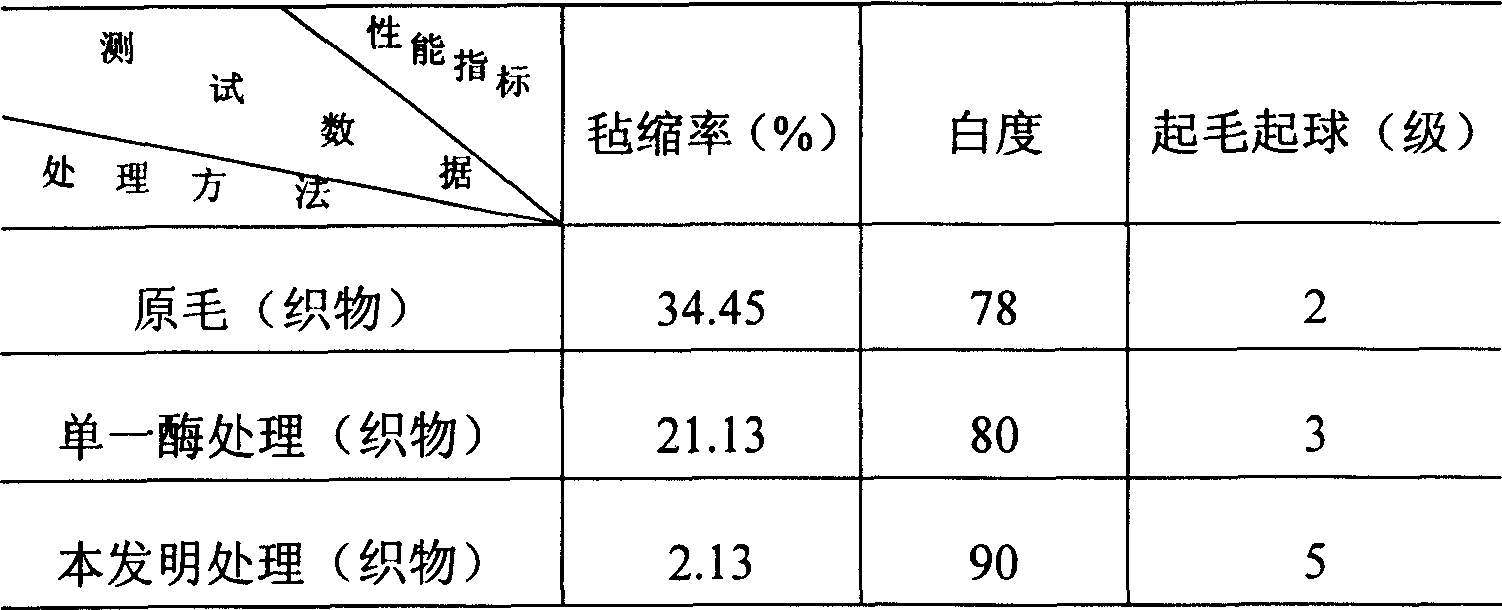

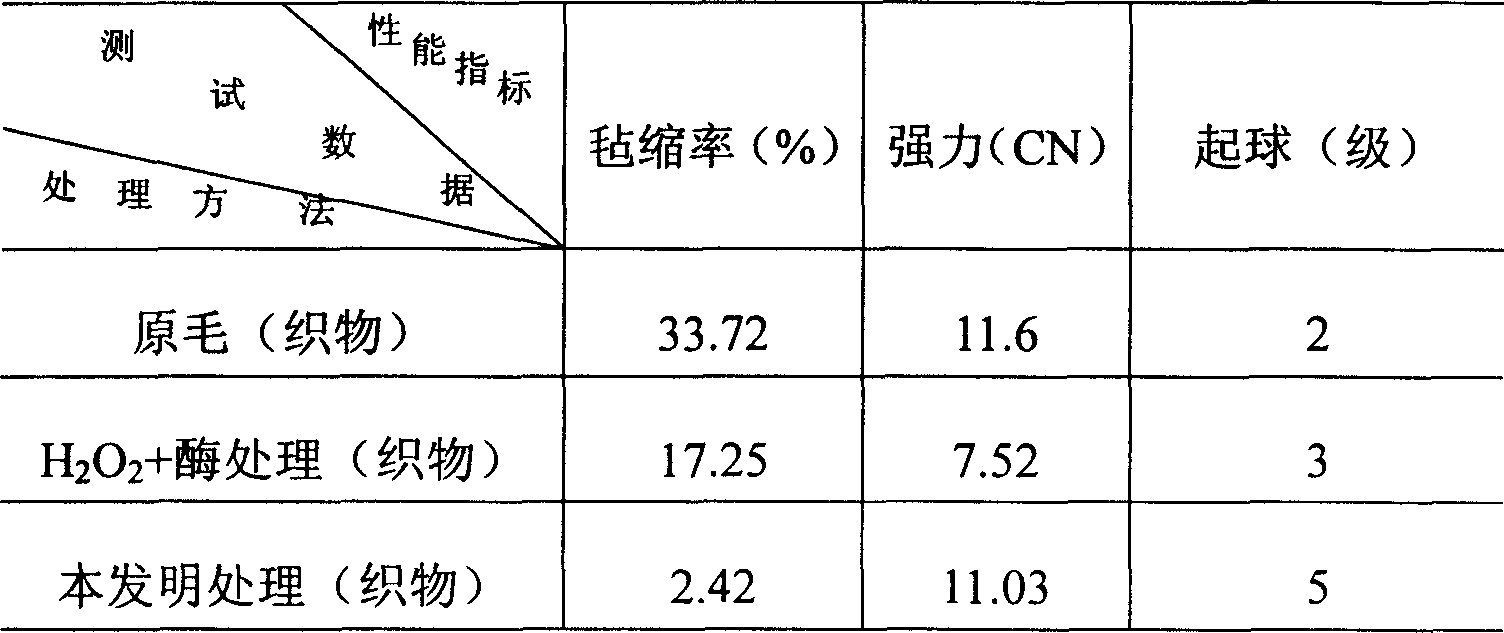

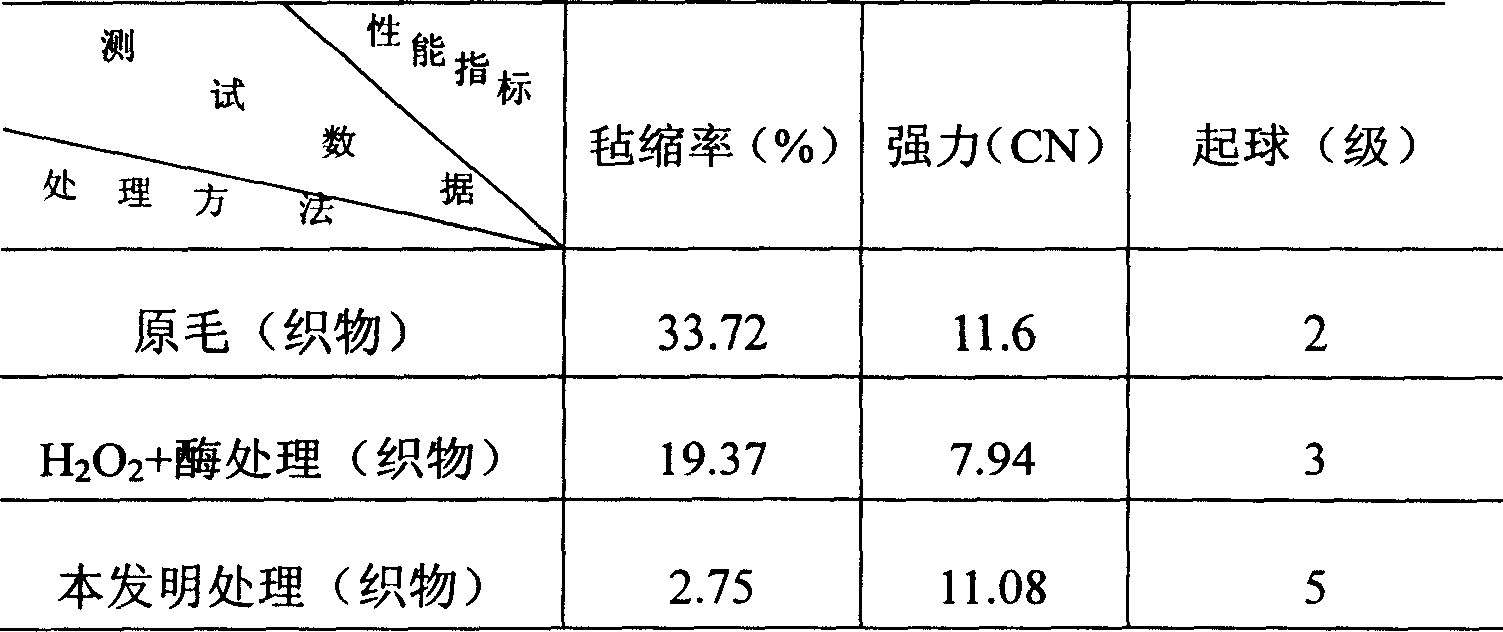

Finishing method for preventing felting and shrinking of wood fabric

InactiveCN1693575AQuality is not affectedAvoid damageBiochemical fibre treatmentHazardous substanceNeutral proteinase

The invention is a wool anti-felting finishing method, and its character: the preprocessing adopts chitosan water solution for soaking and adopts neutral proteinase and neutral fatty to make enzyme degradation treatment, thus making the felting ratio of the processed wool fabric less than 3%, and strong damage within 5% and raising balling resistance of wool fiber by 2-3 grades, and also the whiteness, able to completely meet the machine washing requirement. The invention simplifies the processing course and shortens the process flow and has a shorter cycle so as to strengthen the feasibility in industrialized operation and has no residual harmful matters and can not cause environmental pollution.

Owner:ENZYME ENG INST SHAANXI PROVINCE ACAD OF SCI

Process for producing yeast from waste beer yeast liquid

The technological process of preparing zymogen with waste beer yeast liquid includes the following steps: heating waste beer yeast liquid to 50-55 deg.c and maintaining at the temperature for certain period while controlling pH 5.5-6.5; adding salt, potassium dihydrogen phosphate and magnesium chloride to promote cell wall breaking and autolysis while maintaining the temperature and stirring; adding enzyme preparation before maintaining for 25-30 hr to dissolve cell completely and to make amino acid, nucleotide and other nutrients dissolved into solution; and further centrifugation, concentration and disinfection to obtain zymogen. Owing to the addition of helicase and neutral proteinase as enzyme preparation and the strict control in reaction temperature and pH value, the zymogen prepared is delicious and mellow and may be used as seasoning. In addition, the production process is short and high in yield.

Owner:TANGSHAN LUCHU IND & TRADING

Preparation method of high-purity silk fibroin peptide

InactiveCN103243145AMeet the use requirementsSolve puzzlesPeptide preparation methodsFermentationPolymer scienceNeutral proteinase

The invention discloses a preparation method of high-purity silk fibroin peptide. The preparation method comprises the following steps of: (1) degumming and refining damaged cocoon or bavella silk serving as a raw material by using an Na2CO3 solution, and then washing and drying to obtain silk fibroin; (2) dissolving the silk fibroin by using a CaCl2-H2O-C2H5OH ternary system; (3) diluting, and then carrying out enzymolysis by using neutral proteinase; (4) filtering by adopting electrodialysis; (5) filtering by adopting dislysis; and (6) concentrating, carrying out spray drying, and sterilizing to obtain the high-purity silk fibroin peptide. According to the preparation method, tests prove that the desalinization ratio is 99.5%, and the content of peptide in a finally obtained silk fibroin peptide product is more than 94% and meets the use requirements of pharmaceuticals, cosmetics, medical materials, and the like, so that the problem of the field is solved, and the creativity is achieved.

Owner:SUZHOU UNIV

Polypeptide production method for enhancing utilization ratio of protein

ActiveCN104073540ANo need for desalinationSimple processFermentationProteinase activityAlkaline proteinase

The invention relates to a polypeptide production method which sequentially comprises the following steps: (1) taking a protein-containing raw material, adding water, and immersing to obtain a first solution; (2) stirring and homogenizing the first solution; (3) carrying out enzymolysis on the first solution with alkaline proteinase; (4) inactivating and centrifugating the enzymolysis solution obtained in the step (3) to obtain a supernate A and a precipitate A; (5) adding water to the precipitate A to obtain a second solution; carrying out enzymolysis on the second solution with neutral proteinase; (6) inactivating and centrifugating the enzymolysis solution obtained in the step (5) to obtain a supernate B and a precipitate B; (7) adding water to the precipitate B to obtain a third solution; carrying out enzymolysis on the third solution with acidic protease; (8) inactivating the enzymolysis solution obtained in the step (7), and centrifugating to obtain a supernate C; (9) mixing the supernate A, supernate B and supernate C to obtain a polypeptide mixed solution; and (10) removing water in the polypeptide mixed solution to obtain the polypeptide. The method can enhance the protein utilization ratio of the raw material and obtain the high-quality polypeptide product.

Owner:RUNKE BIOENG FUJIAN

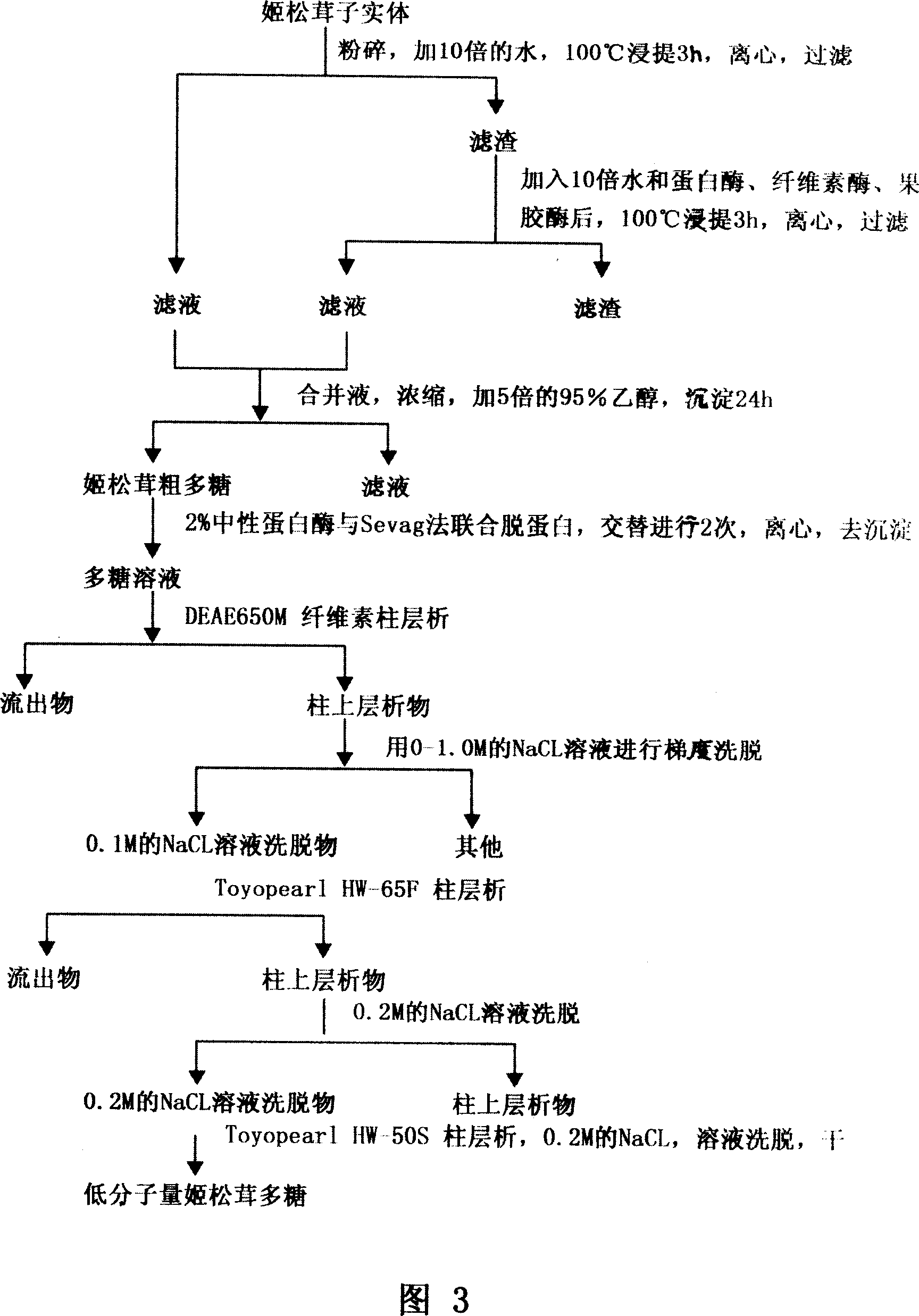

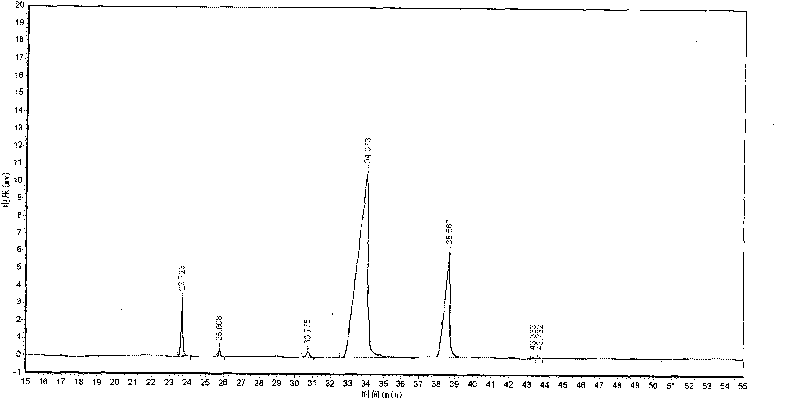

Low molecular Brazil mushroom polysaccharide and its prepn process and application in antagonizing tumor metastasis

InactiveCN101067006AHigh purityImprove performanceOrganic active ingredientsFungi medical ingredientsChromatographic separationCellulose

The present invention discloses one kind of low molecular Brazil mushroom polysaccharide and its preparation process and application in antagonizing tumor metastasis. The low molecular Brazil mushroom polysaccharide extracted from the sporophore of edible fungus Brazil mushroom has homogeneous glucosan in molecular weight of 48,000 as the main component. It is prepared with sporophore of Brazil mushroom, and through crushing, leaching in distilled water, precipitating in alcohol to obtain coarse Brazil mushroom polysaccharide product, deproteinizing, chromatographic separation in DEAE650M cellulose column, gradient eluting with NaCl solution, chromatographic separation of eluted liquid in Toyopearl HW-65F column, eluting with NaCl solution, chromatographic separation of eluted matter in Toyopearl HW-50S column, eluting with NaCl solution, and drying.

Owner:QIQIHAR MEDICAL UNIVERSITY

Process for hydrolyzing fish processing leftover using emzyme preparation

InactiveCN1943365AIncrease added valueMeat/fish preservation using chemicalsFresh fishNeutral proteinase

A process for treating tailings of processing fish with the enzymes, such as one of or the combination of two more of the neutral proteinase,alkali protease,papainase,flavor protease and trypsinase. The hydrolysis process includes 7 steps as following, adjusting the substance concentration, high temperature denaturalization, cooling down and adjusting the pH to 8.0-9.5, heat preservation at 35-6deg.C for 30-50min, enzymolysis for 2-6hr, enzyme destroyed at 85-100deg.C for 10-30min, then it will be separated to get the hydrolysis product. Such product can be used in the food industry with fresh fish flavor. The added value of the fish processing tailings will be greatly improved and it will make sense to the aquaculture and the environment.

Owner:天津市诺奥科技发展股份有限公司

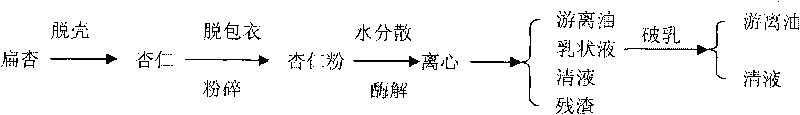

Biological method for extracting grease from flat almond

InactiveCN101736046APrevent oxidationAvoid residueFatty-oils/fats productionFermentationEmulsionAlkaline proteinase

The invention relates to a biological method for extracting grease from flat almonds. The method comprises the following steps of: crushing the flat almonds in a dry way, mixing the crushed flat almond powder and water, regulating pH to 6.5-7.5 and the temperature to 50 DEG C, adding neutral proteinase accounting for 0.1-1.0% of the flat almond powder to carry out enzymolysis for 2-6 hours, reducing the temperature to 40 DEG C and regulating the pH 7.5-8.5, adding alkaline proteinase accounting for 0.1-1.0% of the raw materials to carry out enzymolysis for 2-6 hours to obtain enzymolysis liquid; directly centrifuging the enzymolysis liquid to respectively obtain free oil, emulsion, hydrolytic liquid and almond dregs from top to bottom, adding biological lipopeptid demulsifying agents accounting for 0.1-0.5% of the volume of emulsion into the emulsion, demulsifying and centrifuging again for separation to obtain free oil, and merging the free oil to obtain flat almond oil. The invention can avoid the formation of stable emulsion by adopting a dry method, the demulsifying agents are saved, and the cost is reduced; the flat almond oil prepared by the biological method can avoid problems of fat oxygenation caused by squeezing grease, and solvent remain caused by extracting oil in a lixiviation method.

Owner:BOHAI UNIV

Method for treating defatted bean-dregs and product therefrom

InactiveCN1860906AImprove utilization efficiencyHigh extraction rateVegetable proteins working-upPectinaseSoluble fiber

A method for processing the defatted soybean dregs as the by-product generated by extracting soybean isoflavone from defatted soybean cake features that said fatted soybean dregs are hydrolyzed by use of neutral proteinase, pectinase and cellulase to obtain soybean fiber product with high content of soluble fiber.

Owner:哈尔滨美佳娜生物工程有限责任公司

Nano edible fiber products and preparation method and application thereof

The invention relates to a nanometer dietary fiber product, takes the wheat bran or malt or rice bran as raw materials and comprises biological enzymatical hydrolysis, concentration, spraying or freeze-drying. According to the weight percentages, the product contains non-aqueous dietary fiber 55%-65%, water-soluble dietary fiber of fiber peptide 30%-40%, and balancing water, wherein, the fiber peptide accounts for 10%-20% of the total amount of water-soluble dietary fiber. The invention carries out the biological enzymatical hydrolysis to raw materials through neutral proteinase, which can carry on hydrolysis to macromolecular proteins in the raw materials to be further divided into micro-molecule peptide and effectively convert the utilization of proteins, and facilitates digestion and absorption of bodies. The original minerals such as B clan vitamin, selenium, and magnesium and the like in the raw materials lead the spillage of extremely rich micronutrients such as vitamin E and B clan vitamin to be substantially enhanced, and the absorbed rate is achieved to correspondingly increase.

Owner:钱康南

Pretreatment of cotton fabrics by composite enzyme rolling and pilling up

The invention provided a fore treatment process of the enzyme rolling pile for the fabric which belongs to the fore treatment process of the dyeing and finishing field. The process is: first to fore treatment of the loom stare using the boiling water, then dipping into the the mixture of the alkali pectinase liquid, neutral proteinase liquid and xylanase liquid, then to wash with the hot water ( killing the enzyme) and the cool water, last to dry in the air. the best pectinase is produced by the Bacillus subtilis WSHB04-03. the process has many merits such as high efficiency, low work output and the energy conservation and so on.

Owner:JIANGNAN UNIV

Injectable soy protein isolate and preparation method thereof

ActiveCN101642184ANo pelletsImprove water retentionVegetable proteins working-upFood preparationHydrolysateProtein isolate

An injectable soy protein isolate and a preparation method thereof belong to the technical field of soy proteins and processing. The preparation method comprises the following steps: using low temperature soy meal as the raw material, preparing milk curds of the protein isolate by carrying out alkali extraction, degasification and acid precipitation on the raw material, then using neutral proteinases to carry out enzymolysis on the milk curds of the protein isolate, adding soy phospholipids for mixing into the enzymatic hydrolysates after enzymolysis, then carrying out thermal enzyme inactivation, sterilization, flash evaporation, homogenization and spray drying to obtain the soy protein with good dispersibility, water absorptivity, water-retaining property, oil absorption property and gelproperty, wherein, the soy phospholipids comprises powdered soy phospholipids, soy lecithin or hydroxylated modified soy phospholipids. The soy protein isolate can be used in such industries as injectable meat products, low temperature meat products, solid beverages, flour products and condiments, etc.

Owner:黑龙江省哈高科营养食品有限公司

Process of producing live microbial composition EM prepn

The live microbial composition EM preparation is produced with rice washing water and through regulating pH value, treating with neutral proteinase, adding certain amount of one of waste molasses, red sugar and starch saccarifying slurry, phosphate, table salt, sulfate and yeast paste, mixing homogeneously, heating at 100 deg.c for 5 min, cooling, inoculating live EM bacterial liquid in 10-20 %, and fermentation to culture. The present invention has simple production process suitable for industrial production and low cost, and can produce high quality live microbial composition EM preparation with high live bacteria content for use in farm production, livestock breeding, food processing, environment protection and other fields.

Owner:中健生物科技(深圳)有限公司

Treatment agent of compound enzyme skin sollagen

InactiveCN1462810AMany mechanisms of actionGood effectPre-tanning chemical treatmentGlue/gelatin preparationPh bufferingAlkaline proteinase

A composite enzyme as the treating agent of leather collegen contains at least two of neutral proteinase, alkaline proteinase and acidic proteinase, pH-buffering agent and additive. It can be used for hydrolysis and softening of leather collegen.

Owner:绵竹市金坤化工有限公司

Method for preparing paeonia suffruticosa pollen protein polypeptide with fermentation process

InactiveCN107523599AHas weight loss effectPromote secretionHydrolasesMetabolism disorderPaeonia suffruticosaEnteropeptidase

The invention discloses a method for preparing paeonia suffruticosa pollen protein polypeptide with a fermentation process. The method comprises steps as follows: pollen wall breaking, extraction of essential oil, fermentation, degreasing and spray drying. Paeonia suffruticosa pollen is frozen, mechanically crushed and subjected to anaerobic fermentation through lactobacillus plantarum and saccharomyces cerevisiae for wall breaking continuously, then, fermentation is performed through bacillus subtilis, neutral protease produced through fermentation by use of the bacillus subtilis is used for enzymolysis of paeonia suffruticosa protein, the paeonia suffruticosa pollen protein polypeptide with active strength is obtained, and then, chitosan immobilized lipase is used for degreasing a fermenting liquid. The method has the benefits as follows: the prepared paeonia suffruticosa pollen protein polypeptide cannot be hydrolyzed by enteropeptidase, directly acts on an in-vivo receptor and has a remarkable effect on reducing blood pressure. Meanwhile, the paeonia suffruticosa pollen protein polypeptide has an unexpected weight losing effect.

Owner:兰溪市沉默生物科技有限公司

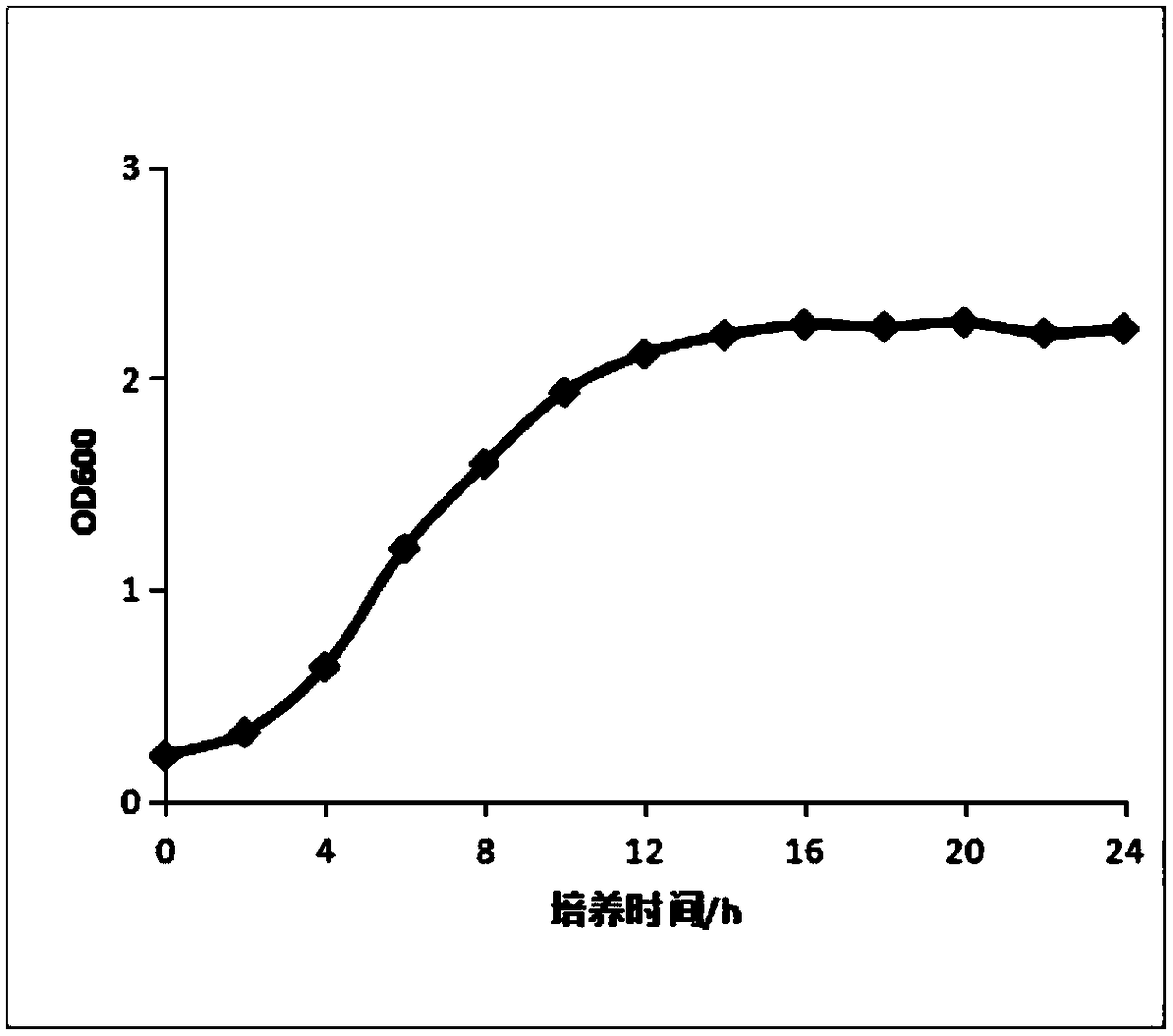

Preparation method of pea peptide with prebiotics effect and application of pea peptide to food

ActiveCN108220371ASuitable for large-scale productionShorten enzymatic hydrolysis process timeProtein composition from vegetable seedsPeptide preparation methodsHydrogenPea protein

The invention discloses a preparation method of a pea peptide with a prebiotics effect. The preparation method comprises the following steps of S1, uniformly agitating pea protein with water accordingto a solid-liquid ratio of (1 to 5) to (1 to 20), so as to obtain a mixed solution, and shifting to S2; S2, in a natural pH (potential of Hydrogen) condition, at a temperature of 45 to 55 DEG C, adding alkali protease into the mixed solution, and carrying out enzymolysis for 0.5h to 1.5h; next, adding neutral proteinase, and carrying out the enzymolysis for 1h to 3h; next, adding papain, carryingout the enzymolysis for 1h to 3h, and shifting to S3; S3, raising the temperature to 90 to 100 DEG C, carrying out enzyme deactivation, and shifting to S4; S4, filtering and collecting filtrate, carrying out vacuum concentration on the filtrate, and then carrying out spray-drying, so as to obtain the pea peptide. The invention also discloses application of the pea peptide with the prebiotics effect, which is prepared and obtained through the method provided by the invention, to food. The pea peptide prepared by the preparation method has the prebiotics effect; the preparation method of the pea peptide does not need to artificially regulate a pH value; the operation is simplified; the preparation time is effectively shortened, and the production cost is decreased.

Owner:武汉天天好生物制品有限公司

Method for making yellow rice wine by plurility of bioenzymes

A process for brewing yellow wine by more kinds of biologic enzyme is characterized by that after the alpha-amylase, cellulase neutral proteinase and saccharifying enzyme are added for treatment, the malt powder, rhizopus powder and active dry yeast are added for fermenting for 30 days, and the "hot coagulation and cold filtering" is performed. Its advantages are low consumption of raw materials, high wine yield increased by 40% or more, low cost and high quality.

Owner:HUNAN SHENGJING SHANHE BIOLOGICAL TECH SHARES

Preparation method of probiotic solid-state fermented complete feed

InactiveCN102742719AImprove digestion and absorption ratePlay a sustained release roleAnimal feeding stuffPichia pastorisNeutral proteinase

The invention discloses a preparation method of probiotic solid-state fermented complete feed. The preparation method is characterized in that lactobacilli, pichia pastoris and bacillus subtilis cultured by a culture medium are mixed with neutral proteinase and water according to a ratio; the mixture in a fog form is sprayed into complete feed according to a certain ratio; and in vacuum, the complete feed with the mixture is subjected to solid state fermentation at a temperature of 30 to 35 DEG C for 3 to 7 days so that the probiotic solid-state fermented complete feed as a product is obtained. The probiotic solid-state fermented complete feed can be directly used for animal feeding without drying. The probiotic solid-state fermented complete feed has the advantages that antibiotics are not adopted; a large amount of live probiotics are used; anti-nutritional factors of crude proteins are destroyed; a large amount of macromolecular nutrients are degraded; product digestibility is high; a feed conversion rate is greatly reduced; and a nitrogen output volume of excrement and urine is reduced.

Owner:SHANGHAI XINNONG FEED

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com